iNO IRXCAM INO160THz User manual

1of 9

IRXCAM INO160THz

160X120 Uncooled THz Bolometric Camera

User Manual

INO

2740, rue Einstein

Sainte-Foy, QC, G1P 4S4 Canada

Tel.: 418-657-7006

Fax: 418-657-7009

July 2010

Proprietary Notice:

Details of design and engineering are the exclusive property of INO and other partners,

and are strictly confidential. The information given herein is subject to change at any

time and without notice.

All rights are reserved. The information included in this document may not be reproduced

or passed on in any manner without prior consent of INO.

2of 9

General Description

The aim of this manual is to present the procedure of installation and associated

precautions to take when using the IRXCAM INO160THz camera module. The technical

specifications and examples of THz imaging are also provided. This document contains

general information about the product, as well as recommendations for its use.

The IRXCAM camera module is based on an uncooled bolometric sensor specially

designed to provide high sensitivity imaging in the terahertz region (optimized at 100 m

wavelength or 3 THz) from a 160X120 focal plane array (FPA) sensor. This module is

designed specifically for developers and integrators. It provides the raw data of the digital

sensor (16-bit, 30 frames per second). The user is then able to select the most appropriate

post-processing treatment method depending on the application. The IRXCAM camera

module provides real-time access to sensor parameters. The user can define the

observation window or adjust the gain and integration time to the dynamic range of the

scene.

The IRXCAM camera module is simple and easy to operate. All functions are controlled

via the IRXCAM software. The starting procedure includes connections between the

camera and the computer via the RJ-45 Ethernet cable, and the +12VDC power supply

and the camera. The user should allow a few minutes for the module warm up before

launching the IRXCAM software. An image is automatically displayed at the startup. It is

obtained from current raw data and last active gain correction, pixel replacements and

offset table.

3of 9

Technical Specifications

Sensor INO160THz

Microbolometer uncooled FPA bolometer

160X120 pixels, 52 m pitch

Optimized metallic FPA package

Silicon float zone FPA window

Optimized for 3 THz (100 m wavelength)

Ceramic Gen II vacuum microbolometer package

Video Output Gigabit Ethernet Link

RJ-45 connector

16 bit raw data

Control Gigabit Ethernet Link

System operation control

Loading of parameters & calibration tables

FPA Operability > 99.9%

Frame Rate 30 Hz

Available Options External trigger input (opto-isolated)

TEC driver

Random access readout

Mechanical support (DEV)

Power Supply +9 to +12 Volts DC

Power Consumption With GigE Link: < 4 Watts

Overall Dimensions 65 mm (H) X 59 mm (W) X 105 mm (L)

Weight ~500 g

Temperature Operating: –30°C to 55°C

Storage: –40°C to 80°C

4of 9

Camera Hardware

The IRXCAM camera module consists of a sensor assembled to an electronic proximity.

The sensor is a sealed box under vacuum containing a microbolometer detector array size

160X120, named INO160THz.The camera assembly is presented in Fig. 1

Fig. 1 IRXCAM Camera Module

5of 9

General Warnings

The IRXCAM camera module is sensitive to electrostatic discharge (ESD). The

following precautions should be taken before handling the camera in order to prevent

possible damage to the equipment.

ESD SENSITIVE

Workstation setup for device utilization:

Choose a place away from the hallway.

Make sure the workstation is in accordance with level ESD Class 1, according to

NASA-8739.7.

Install a ground guard.

Ground all electrical tools and testing equipment.

Wear an ESD smock, nitrile gloves and/or an antistatic bracelet.

6of 9

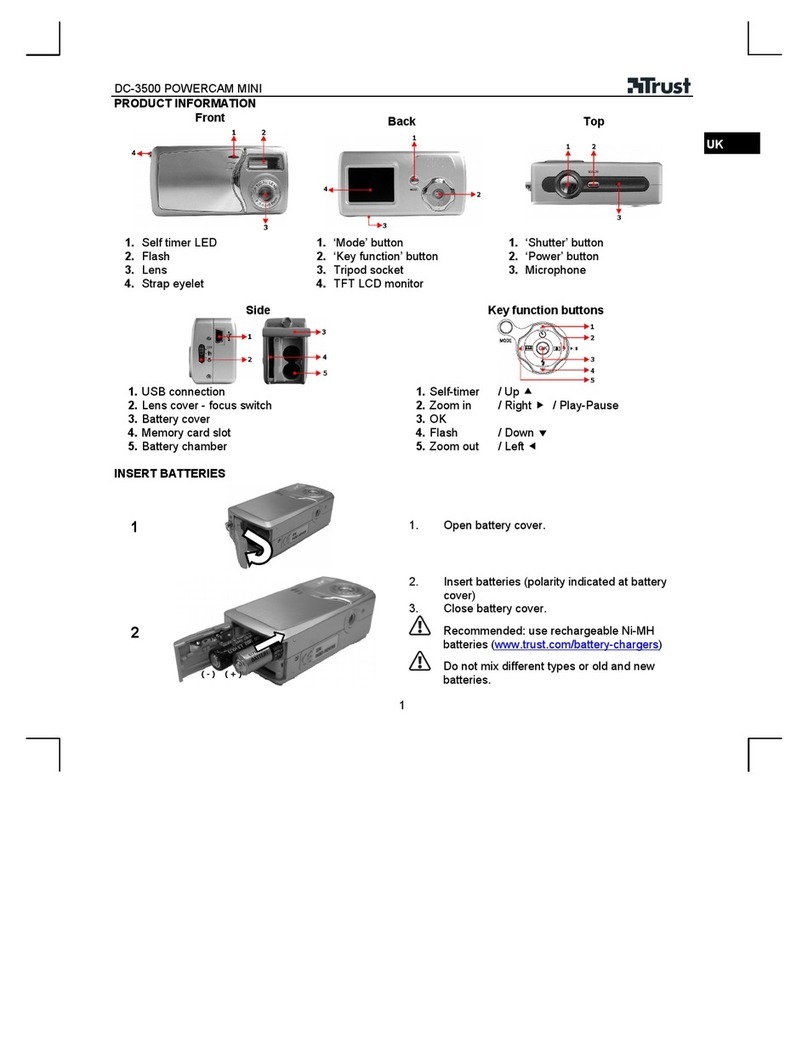

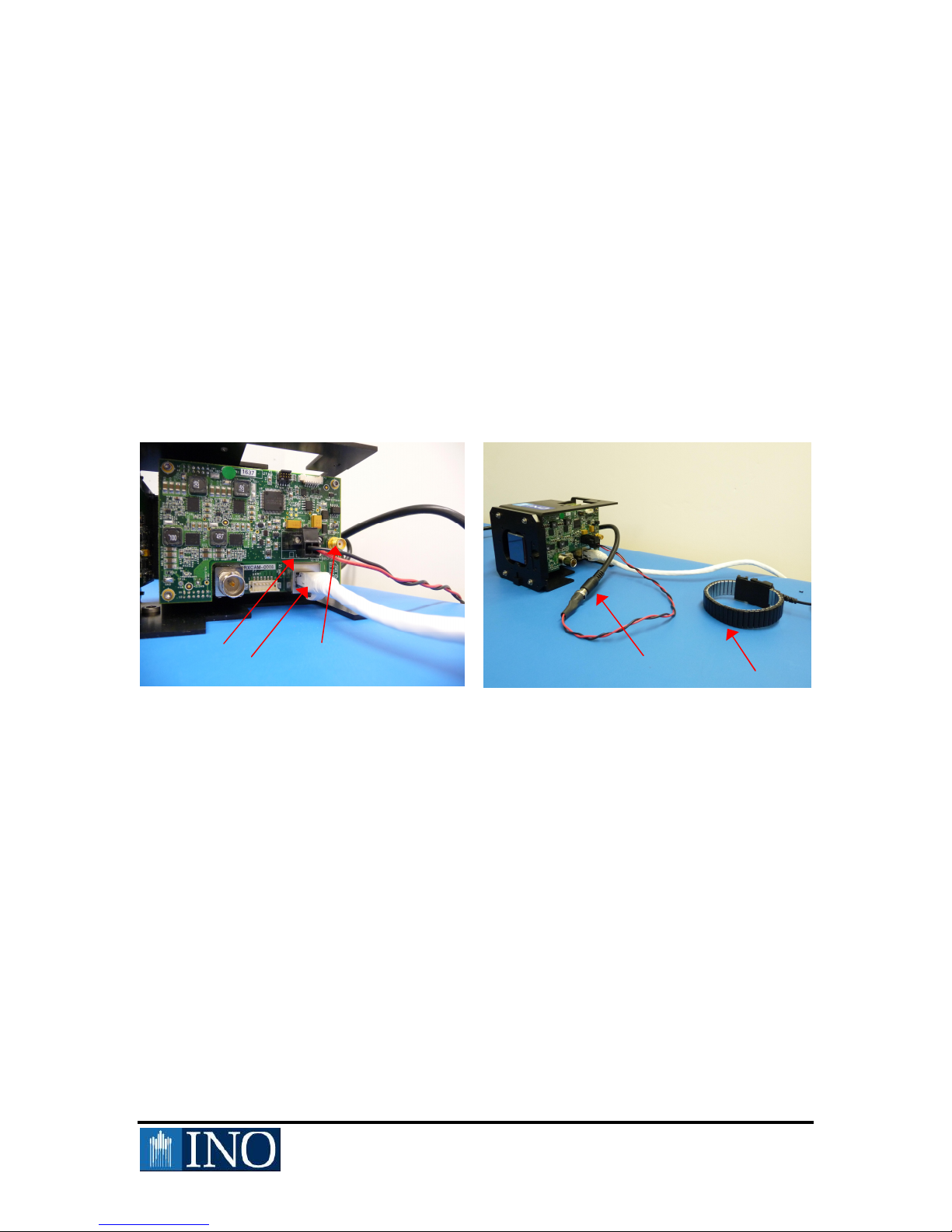

Hardware Installation

The hardware installation can be done once all ESD precautions have been taken. The

electronic module has two outputs and one input connector numbered in Fig. 2.

(1) Power connector

(2) RJ-45 Ethernet data communication connector

(3) SMA input trigger gold-coated connector

The black and red (4) power cable should be connected via a standard power pack. It is

important to remember that an (5) antistatic bracelet should be worn when plugging in

and manipulating camera hardware.

Fig. 2 IRXCAM Interconnections to External Components

All other connectors are not functional with the INO160THz sensor. Note that the

IRXCAM module has been developed to adapt to different INO sensors.

Software Installation

Please refer to the IRXCAM Control Application Software User Manuel.

(1)

(

2

)

(

3

)

(

4

)

(

5

)

7of 9

THz Characterization Setup

The IRXCAM-INO160THz camera module has been tested on a THz characterization

setup (presented in Fig. 3). The THz beam is emitted from a liquid-nitrogen cooled

pulsed quantum cascade laser (QCL) from Laser Components GmbH emitting at a

wavelength of 100 m. The camera module is placed at about 30 cm in front of the THz

QCL source, while a custom silicon float zone THz objective is placed in front of the

QCL for focusing the laser onto the detector. The main characteristics of the custom THz

objective and the THz source are presented in Table 1. The QCL beam has a large

divergence of about 22° involving the use of an optical objective or series of lenses for

collecting and focusing the emitted radiation onto the INO160THz FPA sensor. Note that

the custom objective is usually utilized in front of the camera for imaging applications.

Fig. 3 THz Characterization Setup

8of 9

The nominal peak power of the THz source is about 120 W with 10 sec pulse length.

The duty cycle of the pulsed AVTECH-1011 controller has been set to 10%, yielding an

average power of about 12 W. By considering the transmission value of 65% for the

quartz window and the refractive silicon float zone custom objective in front of the QCL,

the average output power may reach up to 8 W.

Custom THz Objective

Number of lenses 2

Lens material HRFZ-Si

AR coating (thickness) Parylene C (15 m)

Focal length 44 mm

F number 0.95

Aperture stop External, fixed diameter

Object distance 30 cm to infinity

Dimension = 80 mm; length = 60 mm

THz Source

Type Quantum Cascade Laser

Peak power 120 W

Repetition rate 10 kHz

Duty cycle 10%

Average power 12 µW

Pulse duration 10 sec

Central wavelength 100 m

Table 1. Main Characteristics of Custom THz Objective and QCL THz Laser

9of 9

Some images of the QCL beam are presented in Fig. 4. The QCL beam images have been

taken with the IRXCAM-INO160THz camera module. The high level of sensitivity may

be qualitatively seen. The z-scale represents the number of count while the x-y scalesare

the 160X120 pixels number.

Snap_2010-07-07_16-54-50.0891.bmp

Snap_2010-07-07_17-08-05.0280.bmp

Fig. 4Imagesof the QCL Beam Taken with the THz Optimized FPA Mounted on the

IRXCAM Camera Module

Note that the difference between images above is mainly due to the adjusting contrast and

brightness values from the IRXCAM software. The advanced IRXCAM device settings

used for imaging the THz QCL beam are presented in Table 2. Note that all bias voltages

given in Table 2 are given in milliVolts.

Advanced Parameters

VBPIXEL (mV) 1000

VBREF (mV) 1500

VBLINE (mV) 2500

VOUT_CM (mV) 2500

Table 2. IRXCAM Bias Voltage

Table of contents

Popular Digital Camera manuals by other brands

Sony

Sony DSC S650 - Cyber-shot Digital Camera instruction manual

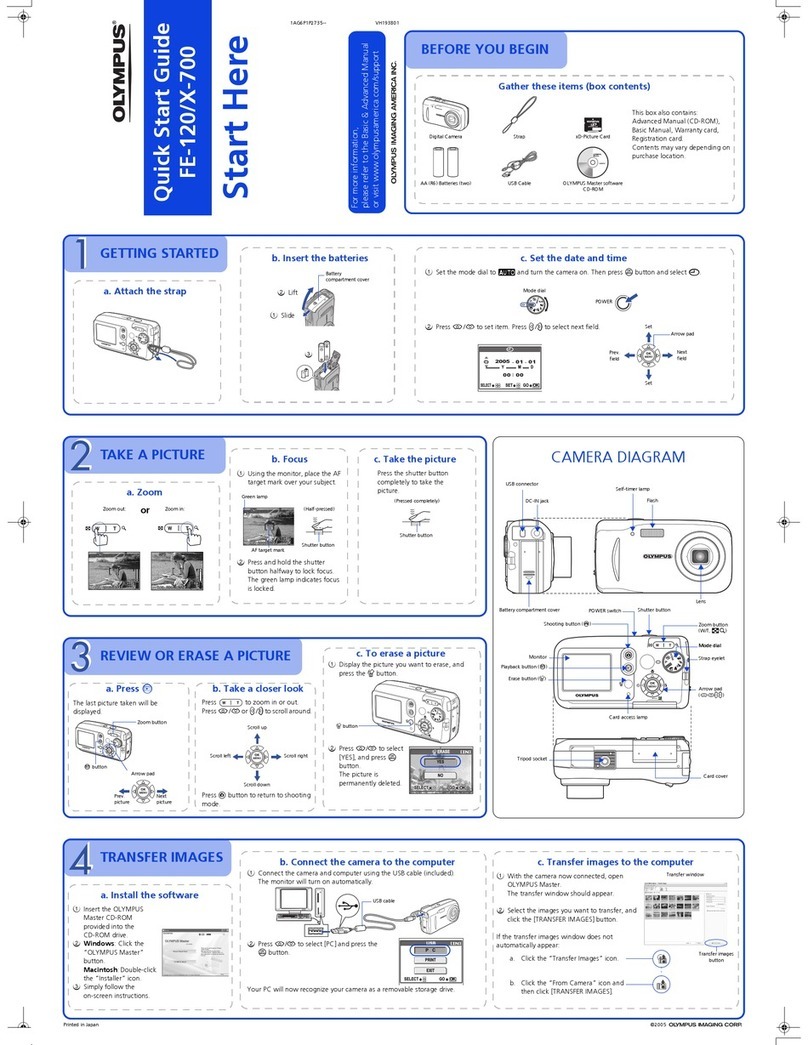

Olympus

Olympus FE 120 - Digital Camera - 6.0 Megapixel quick start guide

Moultrie

Moultrie A-5 user manual

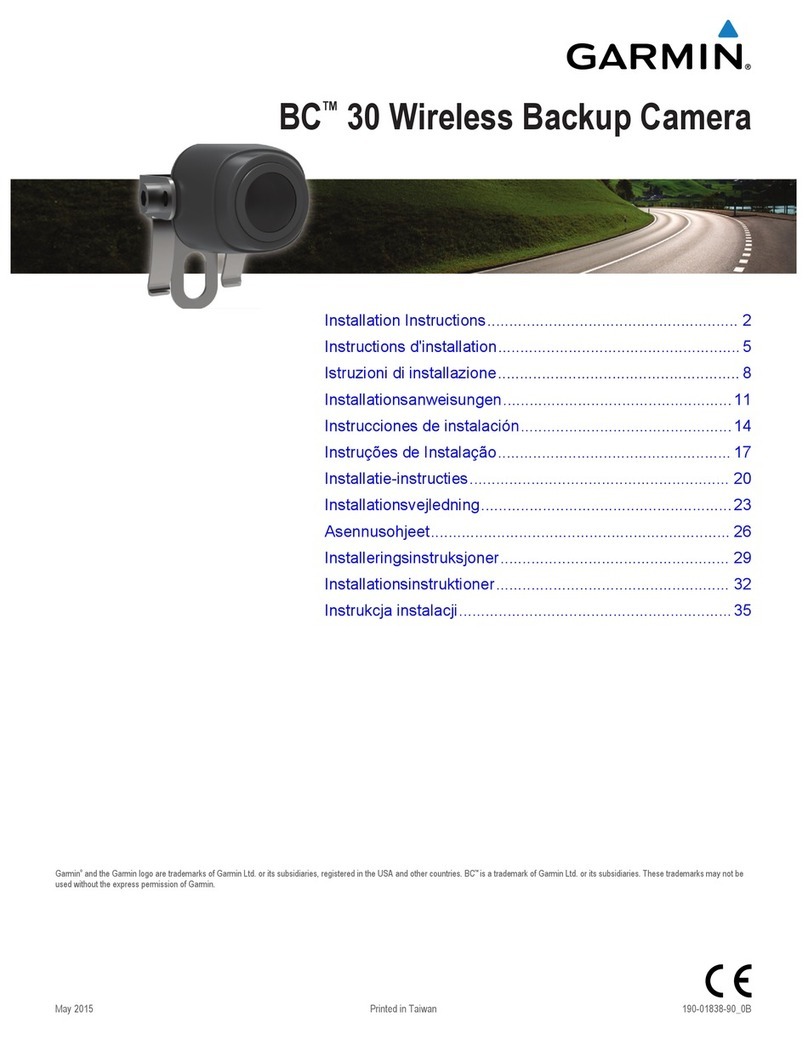

Garmin

Garmin BC installation instructions

JAI

JAI TM-6760 Series Operation manual

Panasonic

Panasonic Lumix DMC-FS5 operating instructions