InPOWER LVD20-100 User manual

© Copyright 2022 InPower LLC

LVD20 Series Owners Manual

Document: OM-230 Version Code: A

Date: May 6, 2019 Date: Mar 31, 2022

Page

1 of 4

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

Introduction

The InPower LVD20 Series is a family of high current, low voltage disconnects. These disconnects are available in

current ratings of 100, 150 and 200 amps, and are packaged in a sealed metal case. As they have extremely low

current draw when in the off state, they are ideally suited for use as battery disconnect switches. A key feature is

the disconnect’s highly efcent, low on-resistance DC power switch. This results in superior performance by pro-

ducing a low voltage drop and generating only a small amount if internal heat.

A status LED indicator is illuminated when the disconnect is on, and ashes to indicate a fault shutdown condition.

Automatic fault shutdown is provided for over current, loss of ground and low battery voltage. Under a fault condi-

tion, the disconnect is latched in the off state. To reset the unit, the fault must be cleared, then the control input

voltage must be removed and then re-applied. Removing the battery cable will also reset the unit.

The control input utilizes a ¼ inch male faston blade terminal. Connections for the high current DC cables utilize

3/8” - 16 stainless steel threaded studs with brass contact pads for low contact resistance. The terminal design

allows the use of an optional rubber terminal protection boot for added protection from the environment, as well as

accidental shorting. Four mounting contact pads allow for the required connection to ground.

System Operation

When positive voltage is applied to the control terminal, the disconnect switch turns ON to pass through battery

power to its load output terminal. When the disconnect switch is on, its controller monitors the battery voltage at its

battery terminal. When the battery voltage drops below 11.5 volts for 60 seconds (factory programmable) the disconnect

switch turns off, removing power from the load terminal, and therefore removes the power draw on the battery.

When the battery is charging and the battery voltage exceeds the shut off preset voltage, the disconnect can be

manually re-actuated by removing the control input voltage and re-applying it (an automatic turn-on may be custom

programmed).

OWNERS MANUAL

Low Voltage Disconnect Models:

LVD20-100 (100 Amps)

LVD20-150 (150 Amps)

LVD20-200 (200 Amps)

InPower Low Voltage Disconnect

Ground

LOAD

Battery

+

+12 Volt Loads

Ground

+12 Volts

Control Switch

Ground

Solid State Contactor

LVD20-200

Lot#

Ground

Status LED

Controller

Control Input

Electronic Switch

LOAD

+BAT

Fuse

© Copyright 2022 InPower LLC

LVD20 Series Owners Manual

Document: OM-230 Version Code: A

Date: May 6, 2019 Date: Mar 31, 2022

Page

2 of 4

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

The Low Voltage Disconnect is controlled by a positive DC voltage on its control terminal. The turnon voltage is >+9.5

Vdc. The must release voltage is <+8.5 Vdc. Note that the input voltage must drop to under +4.0 volts, then

increase to >+9.5 volts to turn on again.

Certain fault conditions will cause the power switch to turn off and remain latched off until the fault is cleared and the

control input voltage is removed, then re-applied. The status LED will ash to indicate a fault. These fault conditions

include:

1. An over-current condition for greater than 500 milliseconds.

2. Loss of ground

3. Low battery voltage

Specications

Current Rating: LVD20-100 LVD20-150 LVD20-200

Maximum current at 43º C (110º F)*

Type A Mounting** 100 Amps 150 Amps 200 Amps

Type B Mounting** 75 Amps 100 Amps 125 Amps

On-resistance at maximum current

and temperature: 2.2 milliohms 1.1 milliohms 0.75 milliohm

* Mounting surface temperature. Note - The maximum current rating will be derated above 43º C (110º F).

** Mounting surface types:

Type A - Mounting surface such as an aluminum plate 0.125 x 16 x 16 inches.

Type B - Mounting surface such as wood, plastic or free air

Mounting Environment: Dry Environment free of water or chemicals on either Type A or Type B surface

Operating Voltage Range: +9.5 to +18.5 volts

Case Maximum Temperature: +185º F (85º C)

Shut Off Voltage: <11.5Vdc for 60 seconds (with ignition ON). When the battery remains below 11.5V

for 60 sec or more the LVD will turn OFF and disconnect the load. To Reset and Acti-

vate the

Disconnect Switch, turn the ignition On (Control Voltage above 9.5V)

Loss of Ground Trip: 250 milliseconds

Over-Current Trip: 100% to 110% of rated amperage for 500 milliseconds

Logic Power Current Draw

With Status LED Off: 80 milliwatts

With Status LED On: 150 milliwatts

Turn-On Delay: 25 milliseconds

Turn-Off Delay: 25 milliseconds

Control Connector Type: 0.25 inch male Faston blade terminal

Control Input Voltage: >+9.5 Vdc to activate, <+8.5 Vdc to deactivate

Control Input Resistance: 120 K Ohm to ground

BAT+ to LOAD Terminal

Leakage Current: 75 microamps maximum

Weight: 0.40 lbs (0.181 kg)

Dimensions: 2.85 (72.29 mm) x 4.35 (110.49) x 1.10 inches (27.94 mm)

Power Terminals: Two (2) 3/8’ - 16 threaded stainless steel studs, with locking nuts.

Optional rubber terminal boots are available.

Power Terminal Torque: 10 Foot Pound Minimum, 15 Foot Pounds Maximum

Case Mounting Screw Torque: 5 Inch Pounds

© Copyright 2022 InPower LLC

LVD20 Series Owners Manual

Document: OM-230 Version Code: A

Date: May 6, 2019 Date: Mar 31, 2022

Page

3 of 4

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

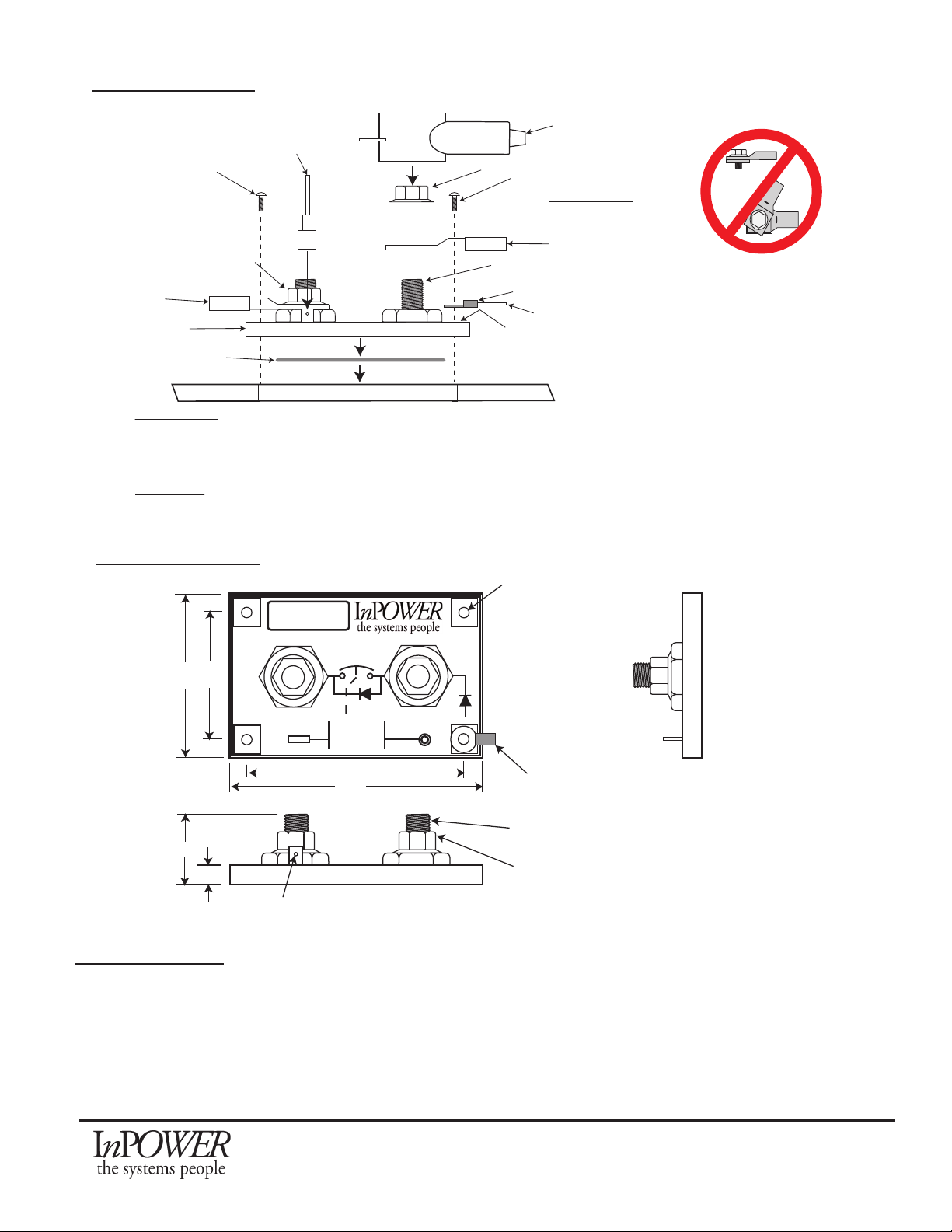

Installation Procedure

WARNING

!

Do not weld on the vehicle with the Low Voltage Disconnect installed as damage to the product may result. If electric

welding is necessary, disconnect the control terminal and the cables attached to the LOAD and BAT+ terminals. Damage

due to electric welding while the unit is installed will void InPower’s warranty.

Introduction

This manual provides instructions for installing InPower LVD20 Series Low Voltage Disconnects. It is important that

you follow these instructions carefully and contact InPower if you need assistance or more information. You can

reach InPower at:

InPower LLC

Customer Support

740-548-0965

www.InPowerLLC.com

Safety Precautions

This product requires the installer to be trained for installation and work on vehicle electrical systems. We recom-

mend that all wiring meet the SAE and applicable vehicle manufacturer’s wiring specications. Inspect the product

and all other components for damage before starting the installation. Do not perform the installation if any problems

exist.

Make sure that the vehicle battery power is disconnected during installation of the Low Voltage Disconnect. Recon-

nect the battery when the installation is complete. Wear appropriate safety equipment such as eyeglasses, face

shield and clothing when installing the equipment and handling the battery. Be careful when working near a battery.

Make sure the area is well ventilated and that there are no ames near the battery. Never lay objects on the battery

that can short the terminals together or to ground. If battery acid gets in your eyes immediately seek rst aid. If acid

gets on your skin immediately wash it off with soap and water.

Mounting Location

First determine where the LVD will be mounted. We recommend mounting it to a at metal surface that can absorb

heat produced by the disconnect (this will provide the best performance). Also take into consideration the maximum

current needed and the maximum mounting surface temperature (See Specication Section). The disconnect

should not be mounted in the engine compartment or any location near the engine’s heat. It is

important that the LVD be mounted in a dry environment where it is not exposed to water or chemi-

cals. For maximum thermal efciency the mounting surface should be a thick metal surface such as an aluminum

plate 1/8 x 16 x 16 inches or larger. To facilitate heat transfer a square piece of thermal transfer material is supplied

with each disconnect. Remove the clear plastic protective coating and insert the heat transfer material between the

disconnect and the mounting surface. Secure the disconnect to the at metal surface using four screws and tighten

to a torque setting of 5 inch pounds. Do not drill out the disconnect’s four mounting pad holes to use a larger

bolt size. If the mounting surface is a good quality ground (low resistance to battery negative terminal) the mount-

ing screws will provide a good ground connection. If the mounting surface is not a good ground, or you are not

sure, you must install a ground wire with a ring terminal under the Ground Terminal Pad.

Connect the Power Cables

First, make sure that the battery is disconnected. Prepare the cable to the battery using a suitable size cable for

the current required and install a crimped lug terminal on the end. Be sure that you have installed a protection

device (fuse, fuse link or circuit breaker) at the battery end of the cable. If the optional rubber terminal boot is

used install the boot over the cable and lug, then install the cable as shown in the diagram on page 4. Torque the

nut to the torque specication shown in the diagram. Slide the boot over the lug and onto the power terminal.

Prepare the cable to the loads and install the cable as you did with the battery cable.

Control Circuit

The control wire must provide a positive DC voltage of at least +9.5 volts to activate the power switch. This could

be the ignition signal or a toggle switch wired to the +12 volt battery. Crimp a female 1/4 inch Faston terminal on the

control wire and attach it to the male control input terminal.

© Copyright 2022 InPower LLC

LVD20 Series Owners Manual

Document: OM-230 Version Code: A

Date: May 6, 2019 Date: Mar 31, 2022

Page

4 of 4

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035 USA

740-548-0965

www.InPowerLLC.com

Installation Diagram

Mechanical Diagram

+BAT

Solid State Contactor

LVD20-200

Lot #

Ground

Status LED

Controller

Control Input

Electronic Switch

LOAD

+BAT

2.85 2.10

3.60

4.35

1.10

0.30

Terminal lug to

ensure a good

ground.

0.187

Stainless steel locking nut

(furnished with product)

3/8 - 16 stainless steel

threaded stud

All dimensions in inches. Not to scale.

Control Input Terminal

3/8 - 16 stainless steel threaded stud

Cable & Lug

Nut

Optional Terminal boot

Mounting screws (4 Required,

8-32) - Not provided

To 12 Volt Loads

Ground wire & lug terminal

To a good quality ground

Ground pad (4 places)

Thermal transfer pad

IMPORTANT!

Torque mounting screws

to 5 Inch Pounds

IMPORTANT!

Torque cable lug nuts to:

Minimum: 10 Foot pounds

Maximum: 15 Foot pounds

Control wire

and 1/4inch

female Faston

terminal

LVD20 Disconnect

To 12 volt battery

(+) and fuse

METAL MOUNTING SURFACE

NOTE - If the mounting screws cannot

provide a good quality ground you must

install a ground lug terminal and ground wire.

IMPORTANT!

The mounting surface provides a means to remove heat that is generated by the LVD.

If this surface is a poor conductor of heat the LVD will have alower currrent rating than

if the surface is a good conductor of heat with a sufficientlylarge area.

LVD20 to be mounted in a dry area, free of water or chemical spray.

NOTE - DO NOT DRILL OUT MOUNTING

HOLES TO ACCOMMODATE LARGER

MOUNTING SCREWS.

WARNING:

1. Do Not Stack terminals on the BAT, LOAD, or GND Pads (the nuts may loosen).

2. Make certain that torque specs are adhered to and that all nuts will not back off or loosen (locking nuts)

Do Not Stack Lugs!

If more power terminations are needed, use a

Power Junction Post or Termination Block

Testing Procedure

Make the following resistance measuremens with a digital multimeter with all wires removed from the LVD.

1. Measure the resistance between the two power terminals (+BAT & LOAD). The resistance should be 200

KOhms.

2. Measure the resistance from the Control Input terminal to one of the ground pads. The resistance should be 120

KOhms.

3. Measure the resistance of each power terminal to a ground pad with the + probe on the power terminal.

4. The resistance should be 120 KOhms.

This manual suits for next models

2