INTEGRATED PAVING CONCEPTS Rapid Finisher 2 User manual

Updated: Nov 2012

Rapid Finisher 2

Operations Manual

2

Contents

1. Introduction

2. Safety

3. Parts List

4. Specifications & Dimensions

5. Storage Case

6. Preparing for Work

7. Operating Procedure

8. Cleanup

9. Parts List

10. Service

3

The Rapid Finisher 2 is designed for the application of asphalt coatings. This electrically powered

brush will enable the applicator to apply coatings to large projects quickly and efficiently reducing

both time and labor costs.

This fast and easy machine works in a similar manner to a floor polisher, with a multi-brush

Cartridge that effortlessly works the coatings into the asphalt surface at variable speeds up to

70 rpm. Each brush Cartridge has a usable life of 5,000 ft² (500 m²) or more, and the brushes

are easily replaceable.

Introduction

4

Safety

Danger Electric Shock!

∆Never operate machine without the Ground Fault Interrupt (GFI) in line.

Failure to do so could result in death from electric shock

∆Never immerse electrical components in water. Follow the cleaning

instructions in this manual carefully

∆Regularly check to ensure that no electrical wires are worn and exposed.

Replace or repair before use

∆Always unplug the machine when making any repairs or when accessing the

electrical components

Danger! Moving Parts –the Brush Cartridge turns with enough force to cause serious injury.

∆Always unplug the machine before changing the Brush Cartridge

∆Keep fingers, feet and loose clothing away from the brushes when in operation

∆Always keep a firm grip on the handle when operating or it could swing out of your hands and cause

injury or damage

∆Never mechanically hold the throttle open. The throttle is designed to shut off the moment the

operator lets go. If the throttle remains open the machine could cause serious injury and property

damage

Caution Hot! –the motor can become quite hot, even exceeding the temperature of boiling water!

Safety Wear –To avoid injury, always wear safety glasses, ear protection, long pants and steel toed boots

and gloves when operating this equipment.

Ensure that everyone who operates this machine has read and understood this manual.

GFI

5

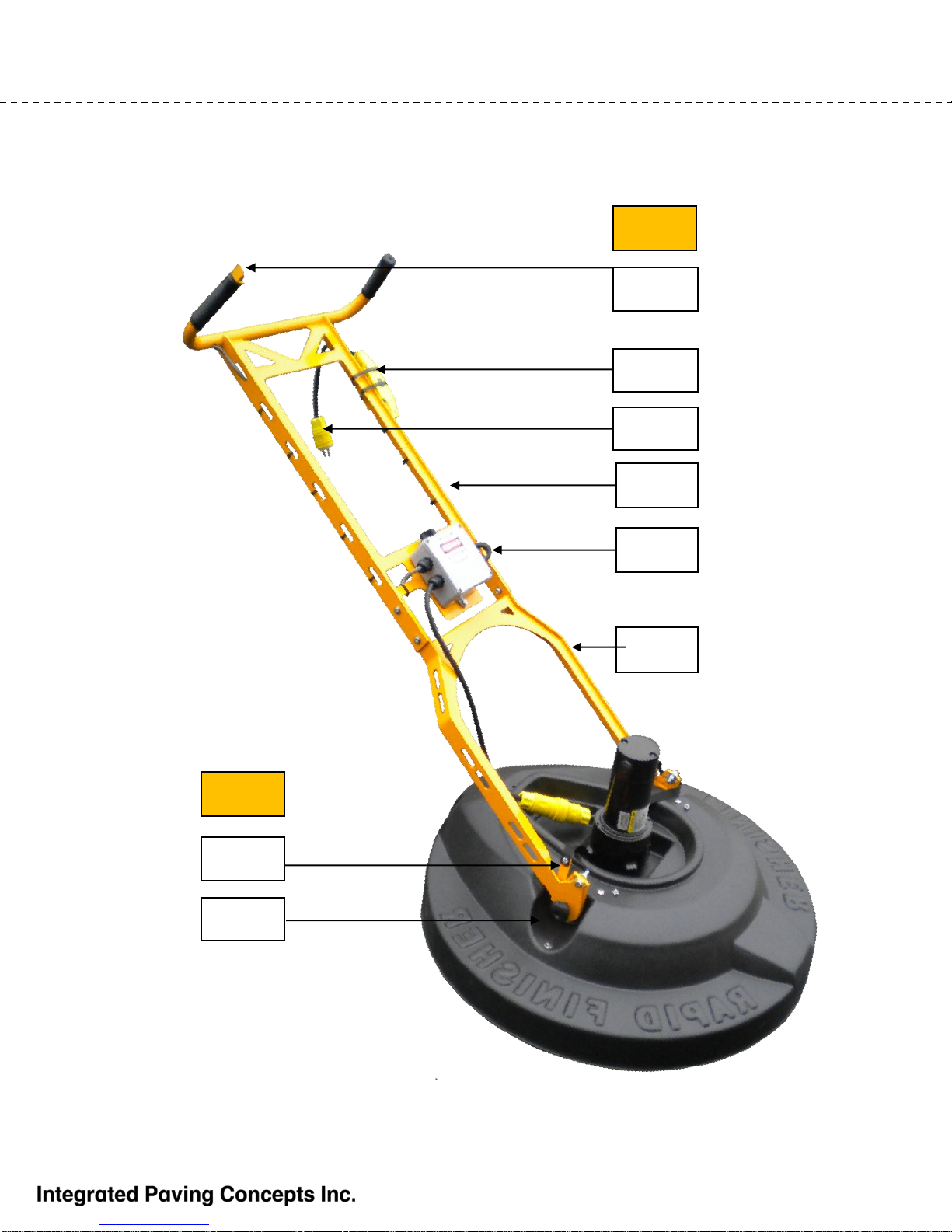

A

B

CD

E

F

G

H

A. Main Body and Motor Assembly with 2 replaceable liners

B. Lower Handle

C. Upper HandleAssembly

D. Brush Cartridge Assembly with brushes

E. Spare Brush Cartridge

F. Spare Brushes (6 pieces)

G. Brush mounting hardware

H. Lower Case Assembly with 2 replaceable liners

Parts List

6

Specifications and Dimensions

Rapid Finisher 2 Specifications

Machine Weight

(Not including Case) lbs

(kg)

Source Electrical

Power 110 or 220 VAC

Electric Gear Motor

¼ HP (186

Watts)

Gear Ratio 40:1

Motor Voltage Up to 110 VDC

Electric Current 2.5 Amps Max.

at 110 VAC

Brush Cartridge

Speed 0 –76 RPM

Handle at 25°

from Horizontal

Handle at 50°

from

Horizontal

32.5”

0.83 m

62”

1.57 m

Locking Handle is adjustable in height from

25°to 50°from horizontal in 5°increments

Generator: Use Honda

inverter type generators only

for the best performance. 3000

watts is recommended to run

the Rapid Finisher 2

7

Preparing for Work

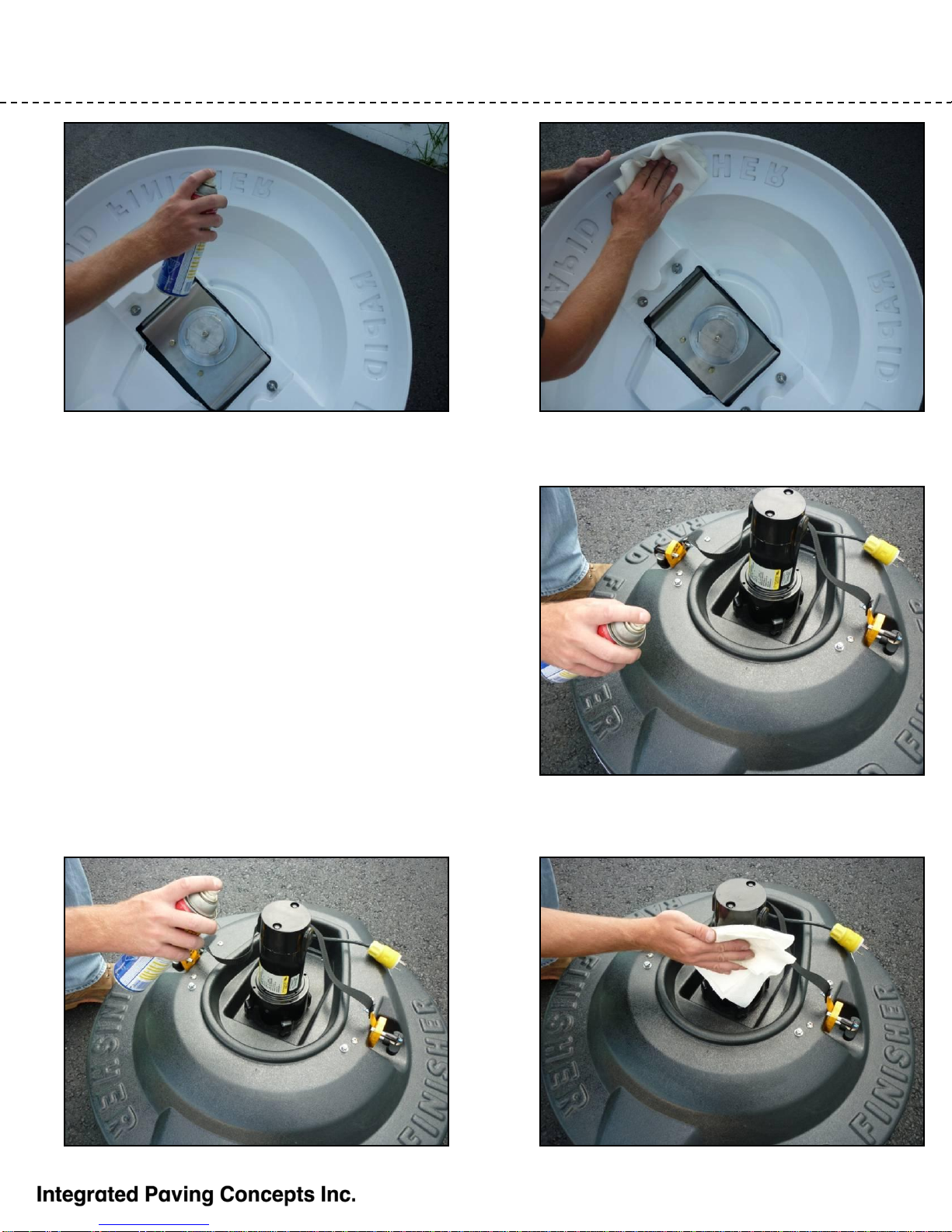

Preventing Coating Buildup

Using a bond breaker on the lower and upper surfaces of

the main body can extend the life of your machine, as

coating buildup on the motor will prevent proper cooling

Use WD40 or cooking oil spray to lightly coat the upper

and lower surfaces. WARNING: don’t use a heavy coat

or allow drips because your coating job may be

compromised if the bond breaker is allowed to mix with

the coatings. Use a cloth to wipe up all excess oil.

Make sure that the motor has a bond breaker applied.

8

Preparing for Work –Cont’d

First, make sure the “legs” on the Cartridge

Lock are aligned with the three protrusions on

the Aluminum Clutch

Attaching and Locking the Brush Cartridge

Place the Brush Cartridge onto the Aluminum

Clutch

Rotate the Cartridge clockwise with a sharp

motion to seat the Cartridge onto the Clutch Rotate the Cartridge Lock counterclockwise to

lock the Cartridge onto the Clutch.

IMPORTANT: to prevent damage to the

Cartridge, always make sure the Cartridge Lock

is properly positioned

9

Preparing for Work –Cont’d

Secure and tighten

the handle with the

Lobed Hand Wheel

fasteners…

use the Ball Lock Pins

to select the desired

handle height

By using both the upper and lower holes for the Ball Lock Pins the handle angle can be adjusted in 5°

increments

Attach Lower Handle

Remove the Lobed Hand Wheel

fasteners and Ball Lock Pins and place

the lower handle in position

10

Operating Procedure

Throttle Control

Make sure you are holding both handles securely

before pushing the throttle button.

To adjust the rotation speed of the brushes

simply adjust the dial on the control box.

11

Operating Procedure –Cont’d

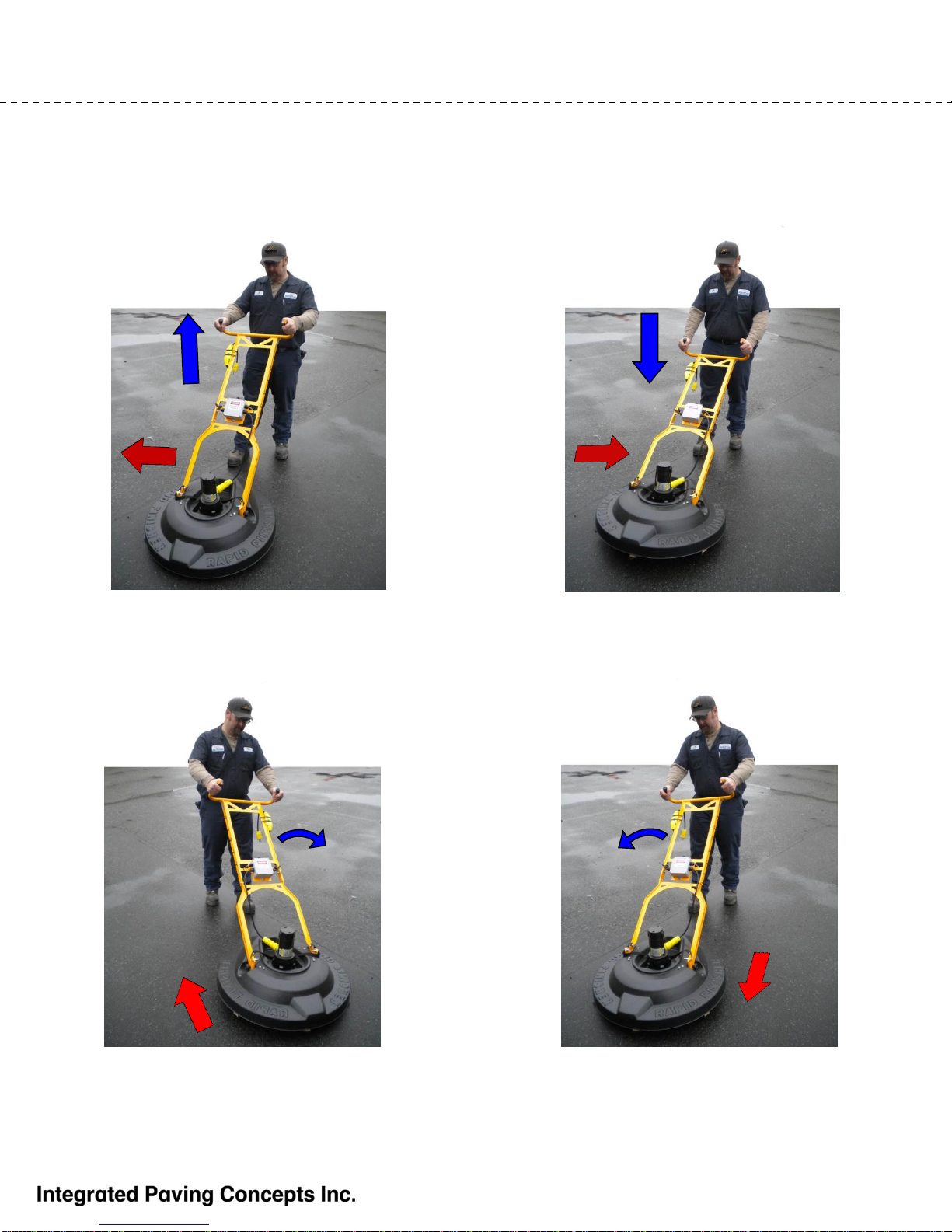

Directional Control

Let the machine do the work for you. Depending on how you manipulate the handle, the machine will

move in different directions

LIFT the handle and the machine will move to

the RIGHT. NOTE: use moderate movements. LOWER the handle and the machine will move

to the LEFT.

TWIST THE HANDLE TO THE LEFT and the

machine will move BACKWARDS. TWIST THE HANDLE TO THE RIGHT and the

machine will move FORWARDS.

12

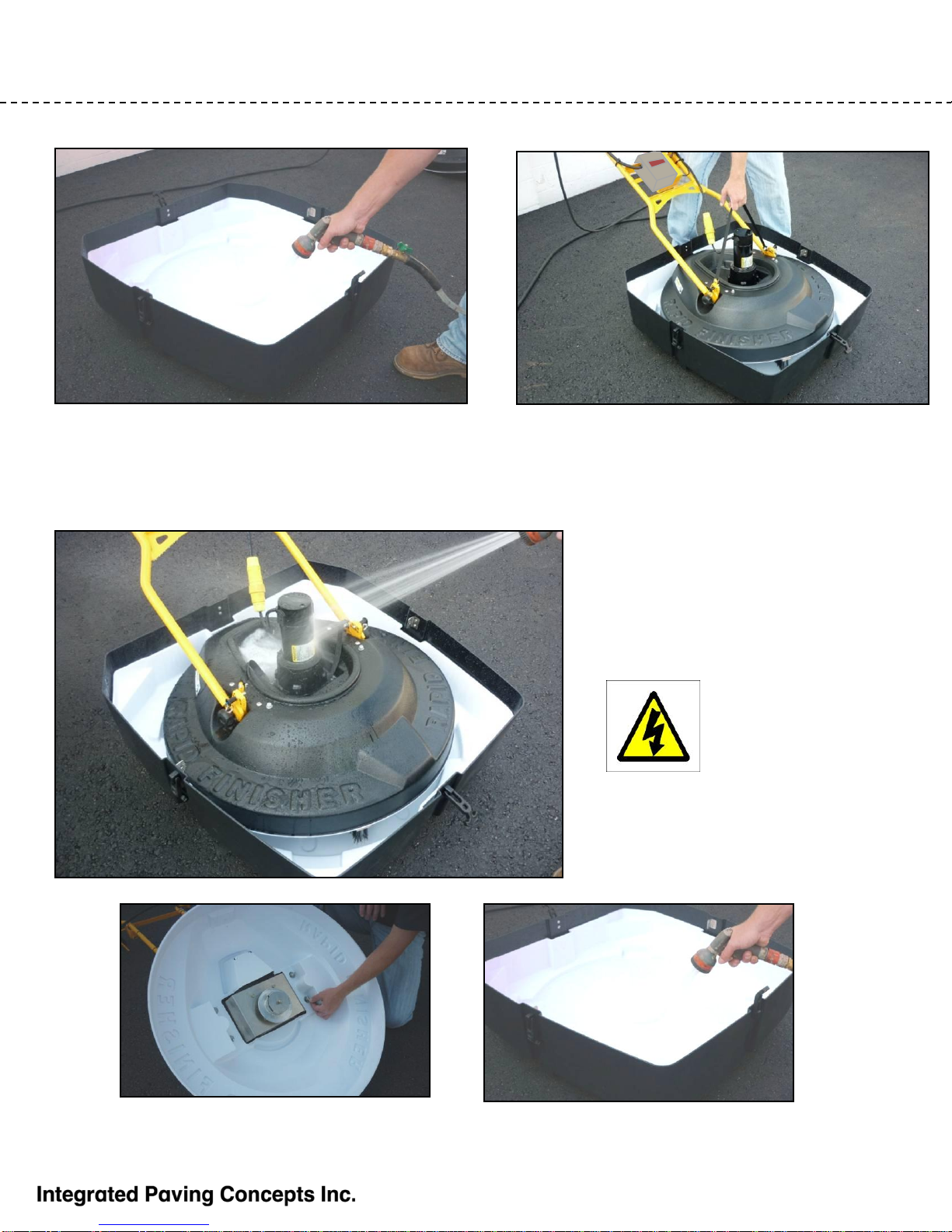

Cleanup

Cleaning the Rapid Finisher 2

Put about 1 –2 inches (25 –50 mm) of water

into the Lower Case that has the Liner/s Lower the machine into the water and run the

brushes at a slow speed until the brushes are

clean

The motor can be washed with

standard hose pressure. CAUTION:

ALWAYS UNPLUG THE MACHINE

FROM THE GENERATOR FIRST.

Never use a pressure washer

CAUTION: NEVER SPRAY OR

IMMERSE THE ELECTRICAL BOX

ON THE HANDLE . USE A DAMP

CLOTH TO WIPE IT DOWN INSTEAD

If the Liners need to be replaced a liner kit (part number 80-0-403A), that contains 2 Base Liners

and 2 Case Liners, is available from Integrated Paving Concepts. The Base Liner is secured by 4

wing nuts and large washers on the underside.

To extend the life of the brushes place the Rapid Finisher 2 in water when it is not being used.

13

REF DESCRIPTION QTY PART NUMBER

1 RF2 Main Body Asbly 1 80-0-400E1

1.1 RF2 Main Body ABS 1 80-0-40002

1.2 DC Gear Motor 1 EC-0-0-034

1.3 RF2 Handle Receiver 2 n/a

1.4 RF2 Bridge Bracket 1 n/a

1.5 RF2 Handle Backing Bracket 2 n/a

1.6 RF2 Aluminum Clutch 1 80-0-40094

1.7 RF2 Brush Cartridge Lock Bracket 1 n/a

1.8 RF2 Brush Cartridge Lock Spring 1 MC-0-0-109

2 RF2 Handle Asbly 1 80-0-400E2

2.1 RF2 Lower Handle 1 n/a

2.1.1 3/8” Lobe Hand Wheel Fastener 2 MC-0-0-280

2.1.2 5/16” Ball Lock Pin 2 MC-0-0-271

2.2 RF2 Upper HandleAsbly 1 n/a

2.2.1 Red Start/Stop Button 1 n/a

2.2.2 RF2 Ground Fault Interrupt ( GFI) 1 80-0-40011

2.2.3 Male power connection 1 n/a

2.2.4 Brush rotation control box n/a

3 RF/RF2 Brush Cartridge Asbly 2 80-0-401

3.1 RF/RF2 Brush Cartridge with Clutch 2 80-0-40061

3.2 RF/RF2 Brushes (come in pack of 24) 12 80-0-410

Parts List

(See the Following Page for Illustrations)

14

Parts List - Illustrations

5

5.3

2.1

2.2.1

2.2

2.2.2

2.1.1

2.1.2

2.2.4

2.2.3

2

2

15

1.2

1.1

1.3

1.4

1.6 1.5

1.7

3.1

3.2

Parts List –Illustrations (cont’d)

3

1

16

Service

Integrated Paving Concepts Inc. is committed to providing the best possible

after-market service. If you require parts, warranty information or service please

visit our website at:

www.streetprint.com

Or call our TechnicalAssistance line:

1-800-688-5652

.

Table of contents