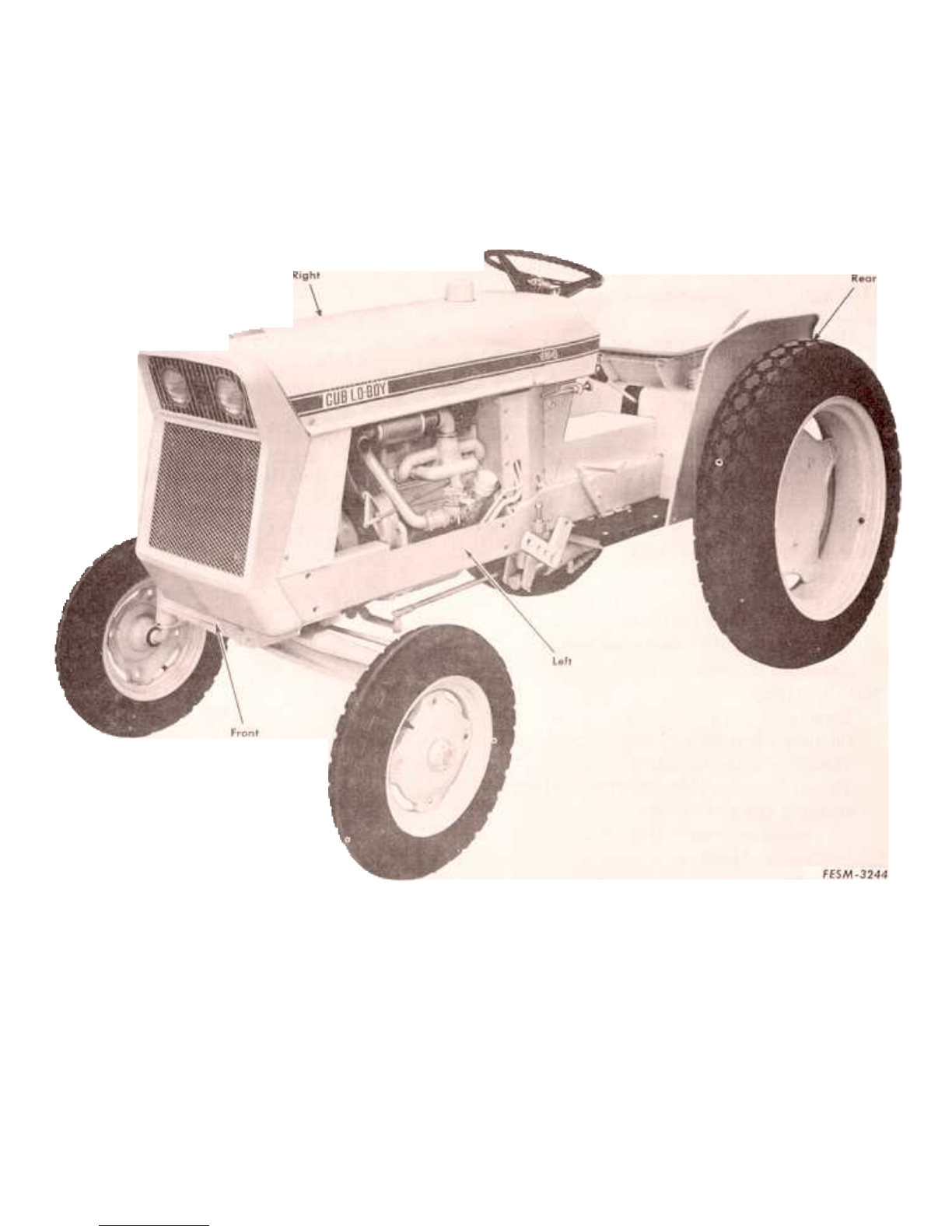

International Harvester Company Cub Lo-Boy C-60 User manual

ENGINE

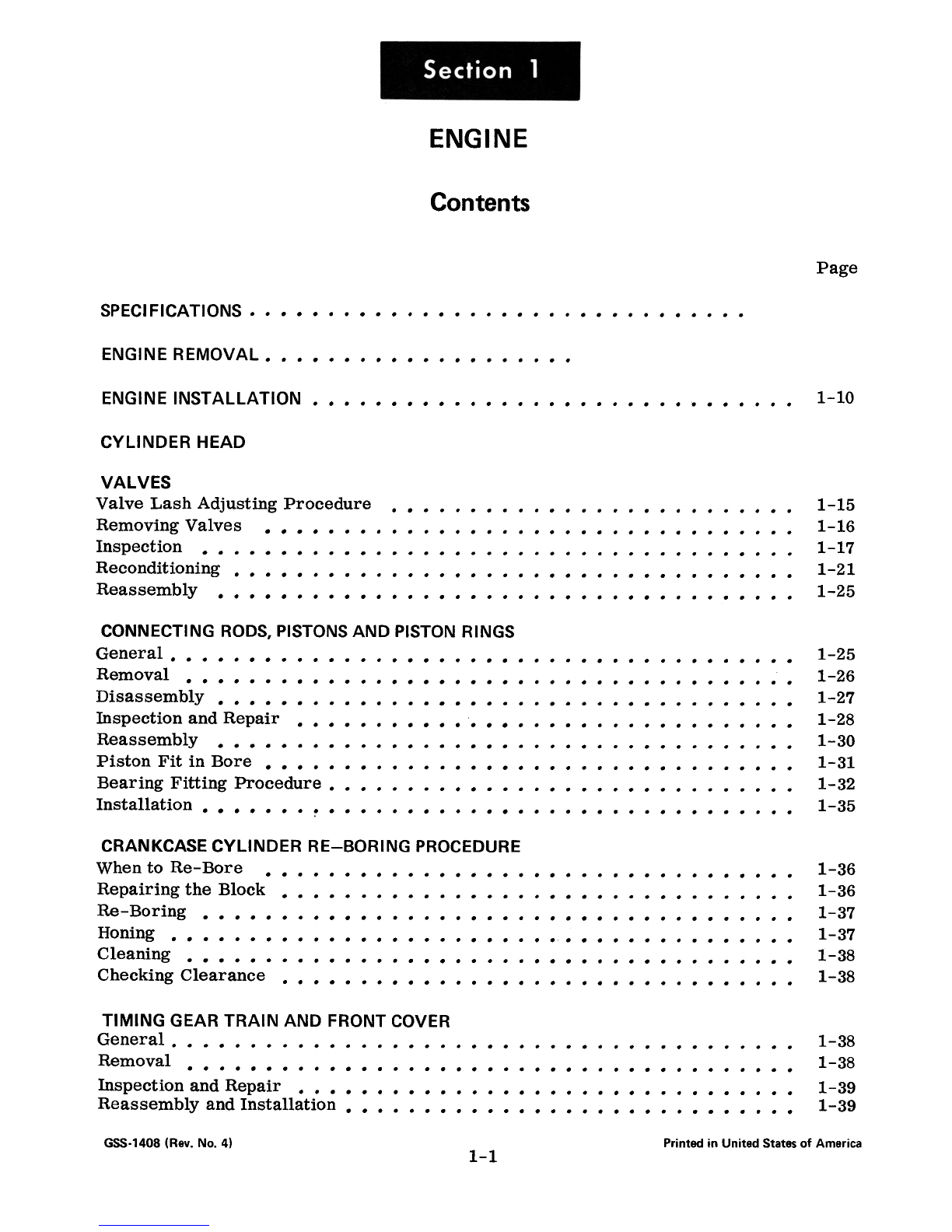

Contents

Page

SPECIFICATIONS.

ENGINEREMOVAL.

1-10

ENGINEINSTAllATION.

CYLINDER HEAD

1-151-161-171-21

1-25

VALVES

Valve Lash Adjusting Procedure.Removing Valves.Inspection.Reconditioning.Reassembly.

CONNECTING RODS, PISTONS AND PISTON RINGSGeneral.

Removal. Disassembly.Inspection and Repair.Reassembly.Piston Fit in Bore.Bearing Fitting Procedure.Installation. ~ 1-251-261-271-281-301-31

1-32

1-35

1-361-36

1-37

1-371-38

1-38

CRANKCASE CYLINDER RE-BORING PROCEDURE

When to Re- Bore.Repairing the Block.Re-BoringHoning.Cleaning.Checking Clearance.

1-38

1-38

1-39

1-39

TIMING GEAR TRAIN AND FRONT COVERGeneral.

Removal.Inspection and Repair.Reassembly and Installation.

GSS-1408(Rev. No.4) Printed in United States of America

1-1

CAMSHAFT

General.Removal. "Inspection and Repair.Installation.

1-42

1-42

1-421-43

CRANKSHAFT AND MAIN BEARINGSGeneral.

Removal.Inspection and Repair.Installation. 1-45

1-45

1-46

1-47

1-501-511-51

1-52

1-52

1-531-54

LUBRICA TI NG 01 L PUMP.GeneralDescription.Oil Pump.Pressure Regulator Valve.Removal and Disassembly.Inspection and Servicing.Reassembly.

COOLING SYSTEM

General Description and Operation.Removal and Disassembly.Inspection and Repair.Fan Service.Reassembly and Installation. 1-55

1-561-571-571-58

TROUBLE SHOOTING

TUNE-UP

GSS-1408(Rev. No.4) Printed in United States of America

1-2

General

Model. C-60

Number of cylinders. ~ 4

Boreandstroke-inches 2-5/8 x 2-3/4

Displacement-cubicinches 59.5

Engine rpm (governed) 154 184 185

Low idle.! 25 475 600

High idle.! 25 2420 2510

Rated load.! 10 2200 2300

Compression ratio. 7.5:1

Compression pressure at cranking speed -psi. 130

Firing order. 1-3-4-2

Ignition timing

Highidle 16oBTDC

400 rpm TDC

Distributor point gap -inch. 020

Spark plug gap-inch 023

NOTE: Proper ig1lition timing at high idle is essential for best ~rformance and engine

life. Therefore, tile distributor should be set to give tile ~ timing at high idle. Any

variance tilat may exist then will occur at the low idle end of the advance curve.

Crankcase

Cylinder bore -inches. 2.625 -2.627

Crankshaft. and Main Bearings

Crankshaft

Type Counterbalanced

Numberofmainjournals 3

Main journal diameter -inches. 1.623 -1.624

Crankpin diameter -inches. 1.498 -1.499

Main Bearings

Type Tri-metal,precision

Runningclearance-inch .002- .003

Thrust bearing location. Center

Thrust bearing side clearance -inch. 004 -.008

Bearing aD and spread

Frontandrear-inches 1.777+.020

Center-inches 1.777 +.002 to .015

Camshaft

Drive. Helical gear

Cam lobe lift (total) -inch. 232.! .002

Journal diameter

Front-inches 1.871-1.872

Center-inches 1.746-1.747

Rear -inch. 872 -.873

Crankcase bearing bore diameters

Front -inches. 1.8740 -1.8755

Center -inches. 1.7490 -1.7505

Rear -inch. 8740 -.8755

GSS-1408 (Rev. No.2) Printed in United States of America

1-4

Camshaft

-Continued

Thrusttakenby Thrustplate

Number of bearings. 3 (bored in crankcase)

Bearing running clearance

Front and center -inch. 002 -.0045

Rear-inch .001-.0035

End clearance -inch. 003 -.012

Connecting Rods

Type. I-Beam

Side clearance -inch. 005 -.012

Bearing running clearance -inch. 002 -.003

Bearing type

Upper end. Bronze bushing

Lower end. Tri-metal, precision

Bearing OD and spread -inches. 1.625 + .025

Piston pin bushing ill -inch (installed) 6879 -.6882

Pistons

Type Camground

Material.. Aluminum alloy

Overall length -inches. 2.875

Diameter -inches. 2.6230 -2.6234

*S1drt clearance, bottom -inch. 0016 -.0024

(measured at 900 from pin hole)

Number of rings per piston. 3

Piston pin hole bore -inch. 6877 -.6880

Width of ring groove -inch

Topcompression. 0955 -.0965

Second compression. 0955 -.0965

Oil control. 1880 -.1890

Ring clearance in groove -inch

Top compression. '. 0020 -.0035

Second compression. 0020 -.0040

Oil control. 0015 -.0030

Full floating

.6875 -.68762.185

-2.195

.010 -.030

.0003 -.0007

.0001- .0005

Piston Pins \

Type. ~Diameter-inchLength -inches.Clearance between end of pin and retainer ring -inch.Clearance in rod bushing-inch .

Clearance in piston -inch.

*See"Piston Fit in Bore", page 1-31.

1-5

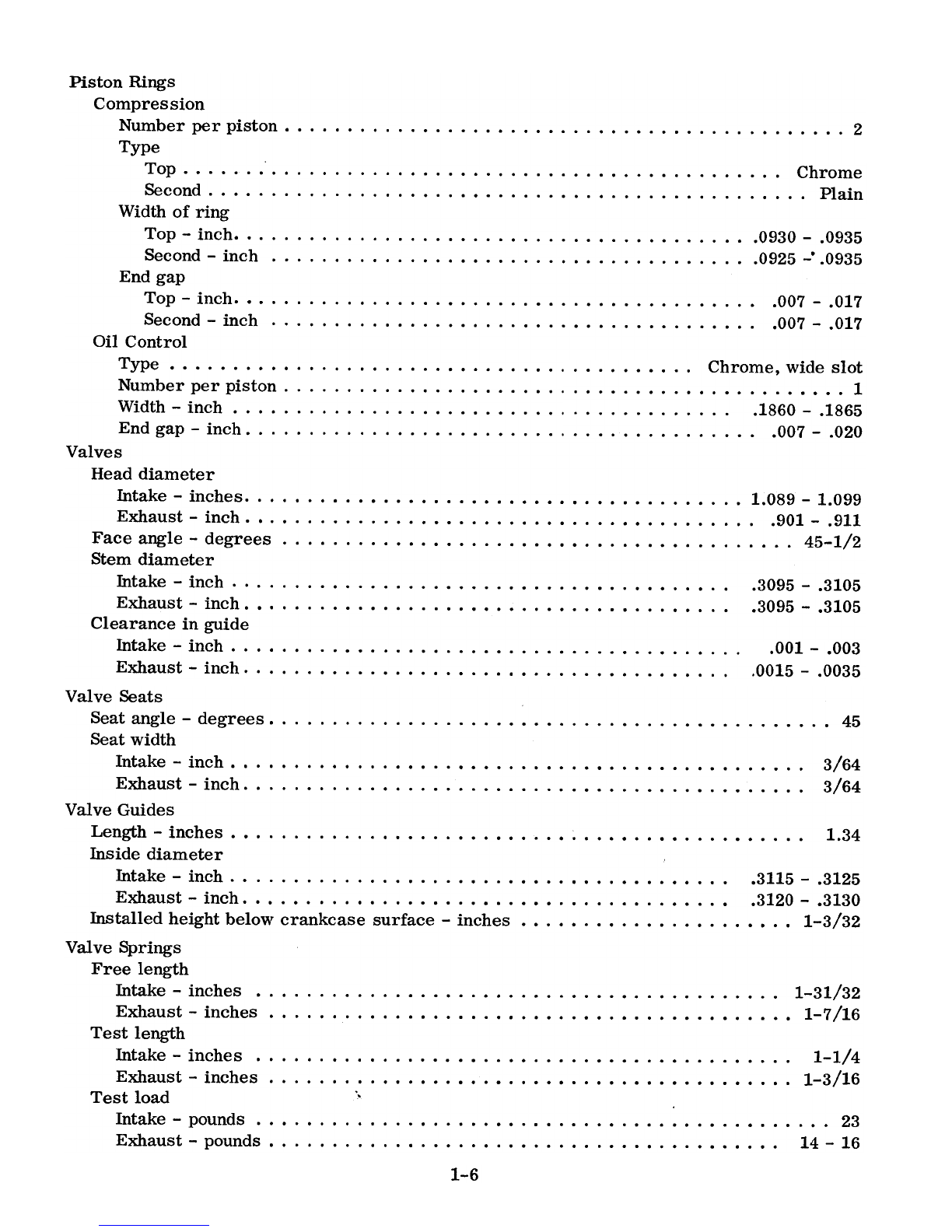

Piston Rings

Compression

Number per piston. 2

Type

Top Chrome

Second Plain

Width of ring

Top -inch. 0930 -.0935

Second-inch 0925-..0935

End gap

Top -inch. 007 -.017

Second-inch. 007 -.017

Oil Control

Type.NumberperpistonWidth -inch.End gap -inch. Valves

Head diameter

Intake -inches. 1.089 -1.099

Exhaust -inch. 901 -.911

Face angle -degrees. 45-1/2

Stem diameter

Intake-inch .3095-.3105

Exhaust-inch .3095-.3105

Clearance in guide

Intake-inchExhaust -inch.

,

Chrome, wide slot,

1,

1860 -.1865,

007 -.020

.001- .003.0015

-.0035

Valve Seats

Seat angle -degrees. 45

Seat width

Intake-inch 3/64

.Exhaust-inch 3/64

Valve Guides

Length-inches 1.34

Inside diameter

Intake -inch. 3115 -.3125

Exhaust-inch .3120- .3130

Installed height below crankcase surface -inches. 1-3/32

Valve Springs

Free length

Intake -inches. 1-31/32

Exhaust-inches 1-7/16

Test length

Intake-inches 1-1/4

Exhaust -inches. 1-3/16

Test load "

Intake-pounds 23

Exhaust-pounds 14-16

1-6

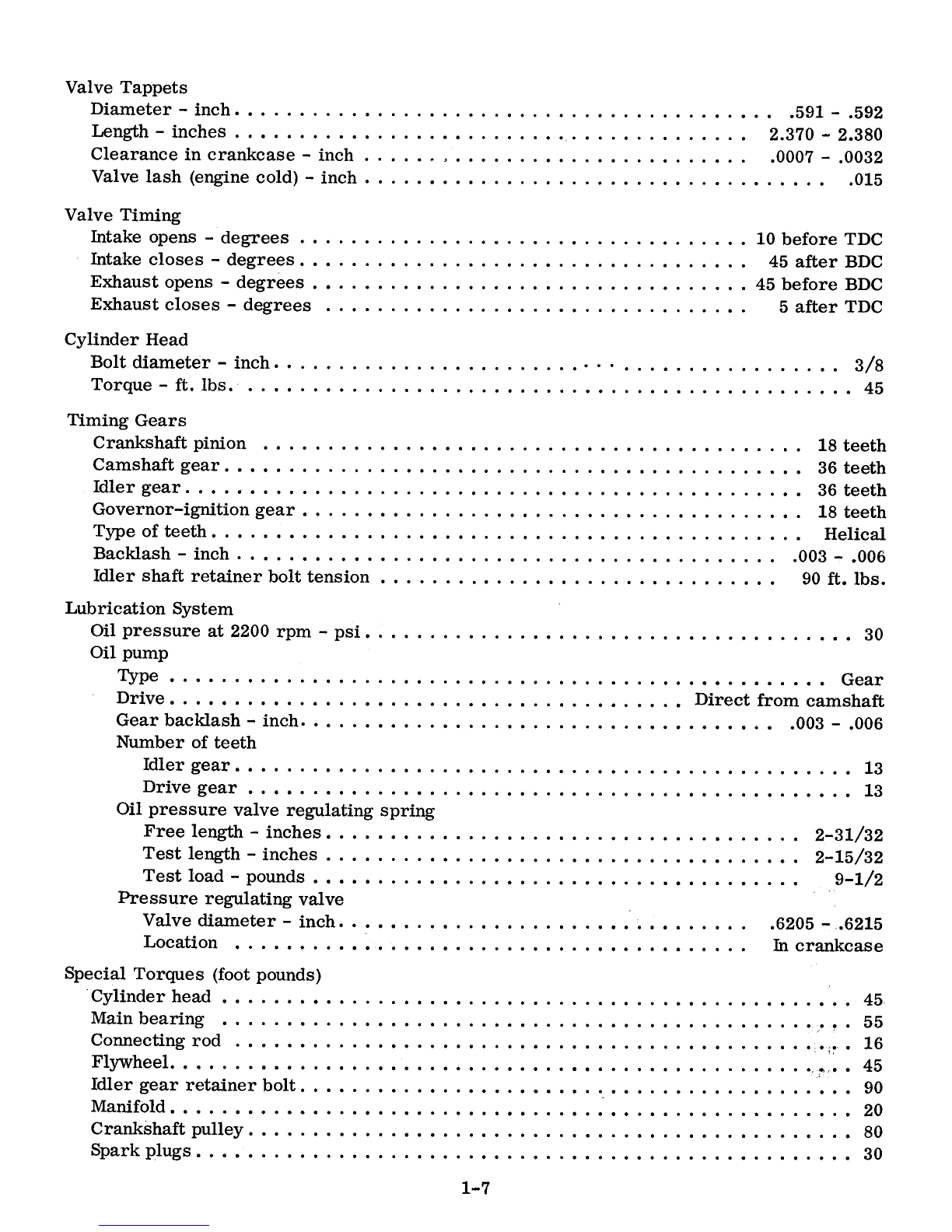

Valve Tappets

Diameter-inch .59.1-.592

Length -inches. 2.370 -2.380

Clearance in crankcase -inch. , 0007 -.0032

Valvelash(enginecold)-inch .0.15

Valve

Timing

Intakeopens-degrees 10beforeTDC

Intakecloses-degrees 45afterBDC

Exhaustopens-degrees 45beforeBDC

Exhaustcloses-degrees 5afterTDC

Cylinder Head

Boltdiameter-inch 3/8

Torque-ft.lbs. 45

Timing Gears

Crankshaft pinion. 18 teeth

Camshaft gear. 36 teeth

Idler gear. 36 teeth

Governor-ignitiongear 18teeth

Type of teeth. Helical

Backlash -inch. 003 -.006

Idler shaft retainer bolt tension. 90ft. lbs.

Lubrication System

Oil pressure at 2200 rpm -psi. 30

Oil pump

Type. Gear

Drive Direct from camshaft

Gear bacldash -inch. 003 -.006

Number of teeth

Idlergear 13

Drive gear. 13

Oil pressure valve regulating spring

Free length -inches. 2-31/32

Testlength-inches 2-15/32

Test load -pounds. 9-1/2

Pressure regulating valve

Valve diameter -inch. 6205 -.6215

Location. In crankcase

Special Torques (foot pounds)

Cylinder head 45

Main bearing. ~ .55

Connectingrod ;~. 16

Flywheel ;0"..45

Idlergearretainerbolt 90

Manifold 20

Crankshaft pulley 80

Sparkplugs 30

1-7

ENGINE REMOVAL

1. Disconnectthe battery ground

cable at the battery.

2. Drain the crankcase oil and re-

move the drain plug in the water inlet

elbow and drain the coolant.

3. Removethe hoodand side sheet

sections.

4. Shut off the fuel at the fuel strainer

(3) and disconnect the fuel line (4) from

the fuel strainer and the carburetor (5).

5. Removethe fuel tank (2).

GSS-1408 (Rev. No. 41 Printed in United States of America

1-8

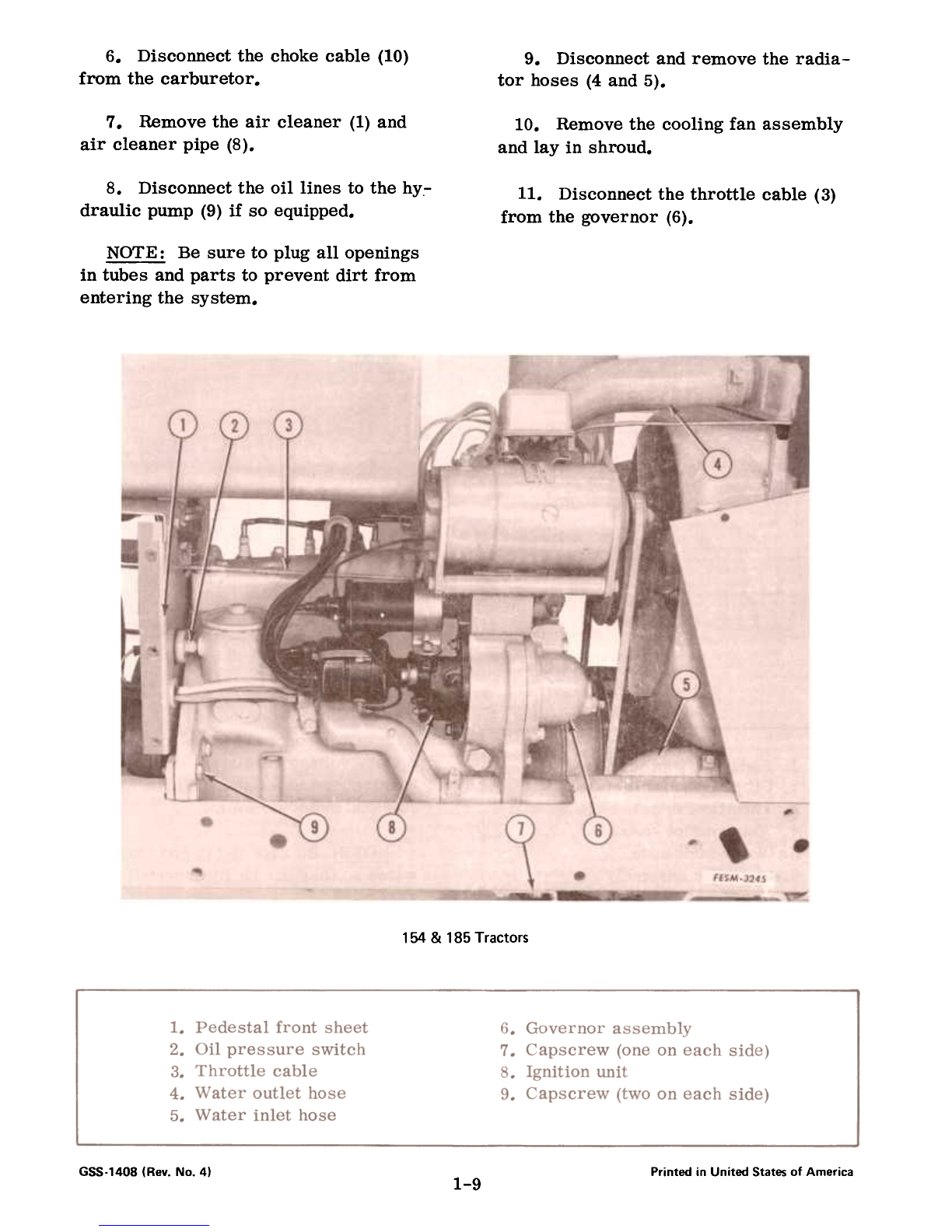

6. Disconnectthe chokecable (10)

from the carburetor. 9. Disconnectandremove the radia-

tor hoses (4and5).

7. Removethe air cleaner (1)and

air cleaner pipe (8). 10. Removethe cooling fan assembly

and lay in shroud.

8. Disconnect the oil lines to the hy.-

draulic pump (9) if so equipped. 11. Disconnect the throttle cable (3)

from the governor (6).

NOTE: Be sure to plug all openings

in tubes and parts to prevent dirt from

entering the system.

154 & 185 Tractors

685-1408 (Rev. No. 41 Printed in United States of America

1-9

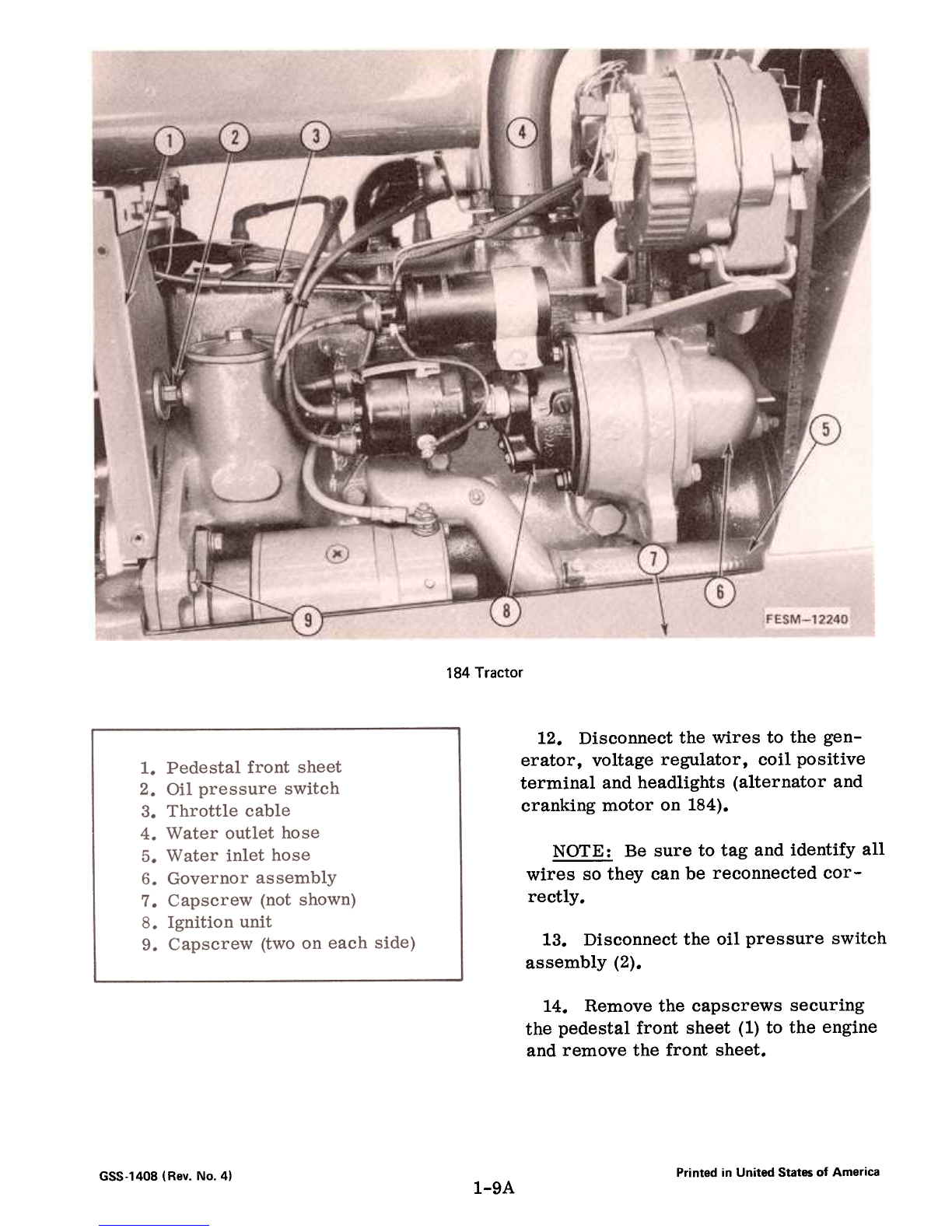

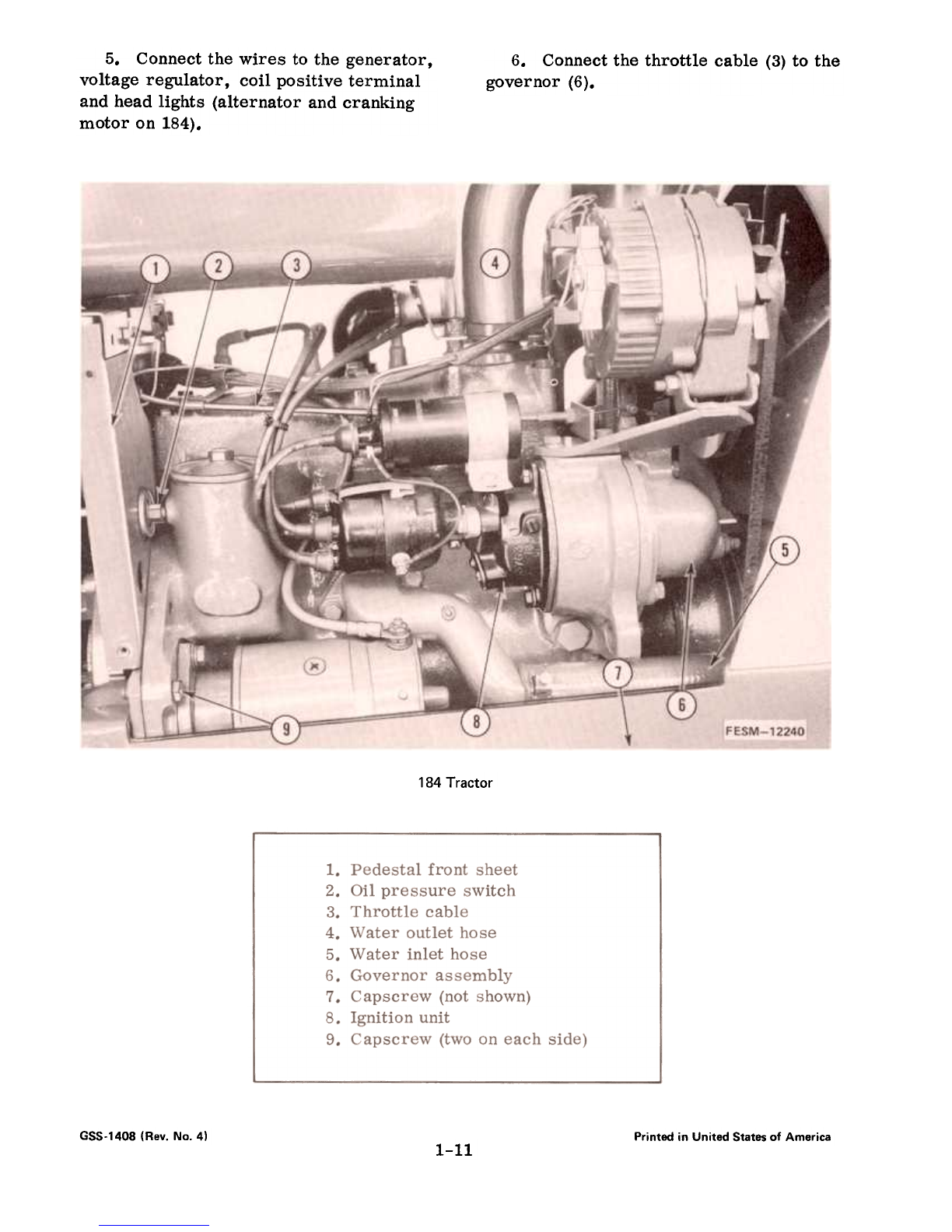

184 Tractor

12. Disconnectthe wires to the gen-

erator, voltage regulator, coil positive

terminal andheadlights (alternator and

cranking motor on 184).

NOTE: Be sure to tag and identify all

wires so they can be reconnected cor-

rectly.

13. Disconnectthe oil pressure switch

assembly (2).

14. Remove the capscrews securing

the pedestal front sheet (1) to the engine

and remove the front sheet.

Printed in United States of America

GSS-140B(Rev. No.4) 1-9A

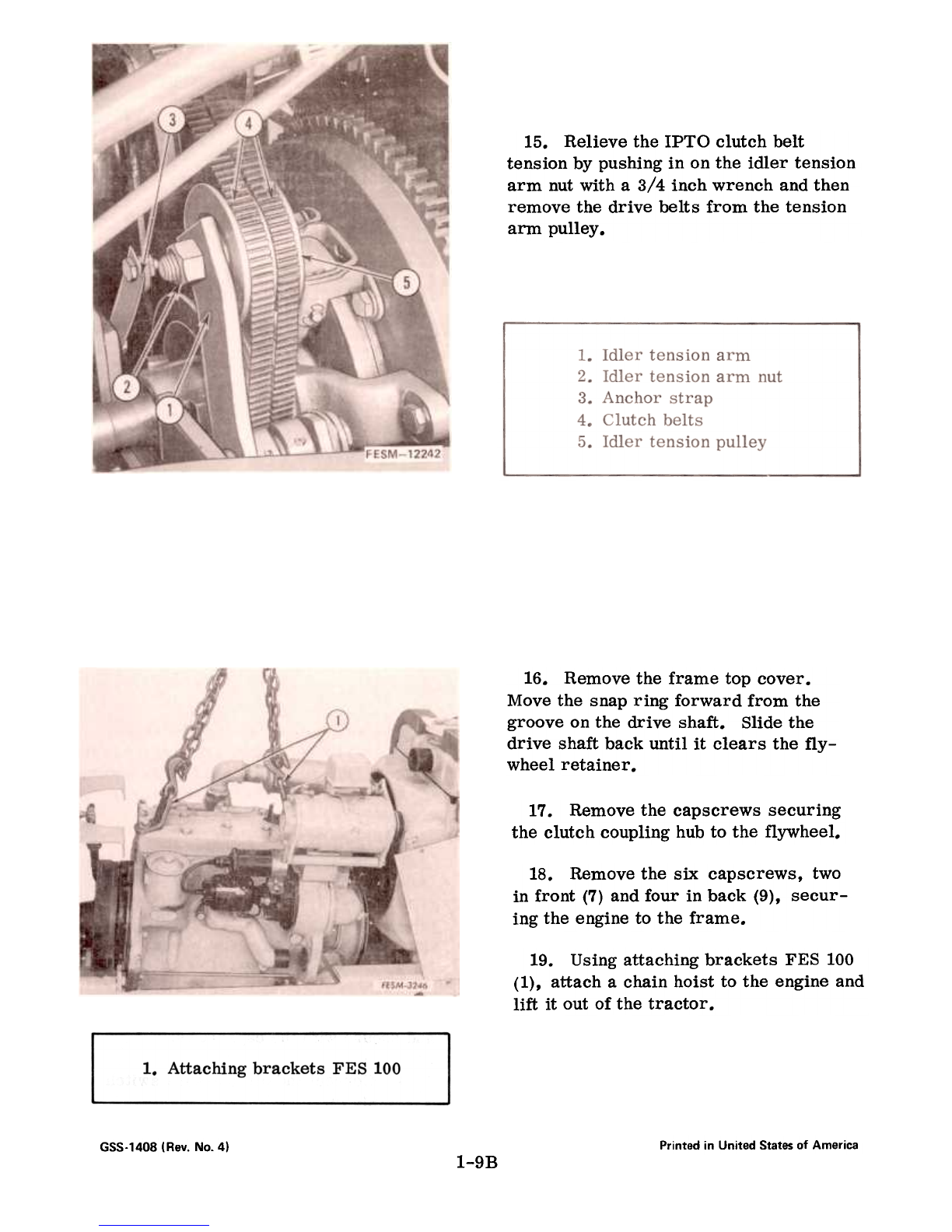

15. Relieve the IPTO clutch belt

tension by pushing in on the idler tension

arm nut with a 3/4 inch wrench and then

remove the drive belts from the tension

arm pulley.

16. Remove the frame top cover.

Move the snap ring forward from the

groove on the drive shaft. Slide the

drive shaft back until it clears the fly-

wheel retainer.

17. Remove the capscrews securing

the clutch coupling hub to the flywheel.

18. Remove the six capscrews, two

in front (7) and four in back (9), secur-

ing the engine to the frame.

19. Using attaching brackets FES 100

(1), attach a chain hoist to the engine and

lift it out of the tractor.

1. Attaching brackets FES 100

Printed in United States of America

GSS-1408 (Rev. No.4) 1-9B

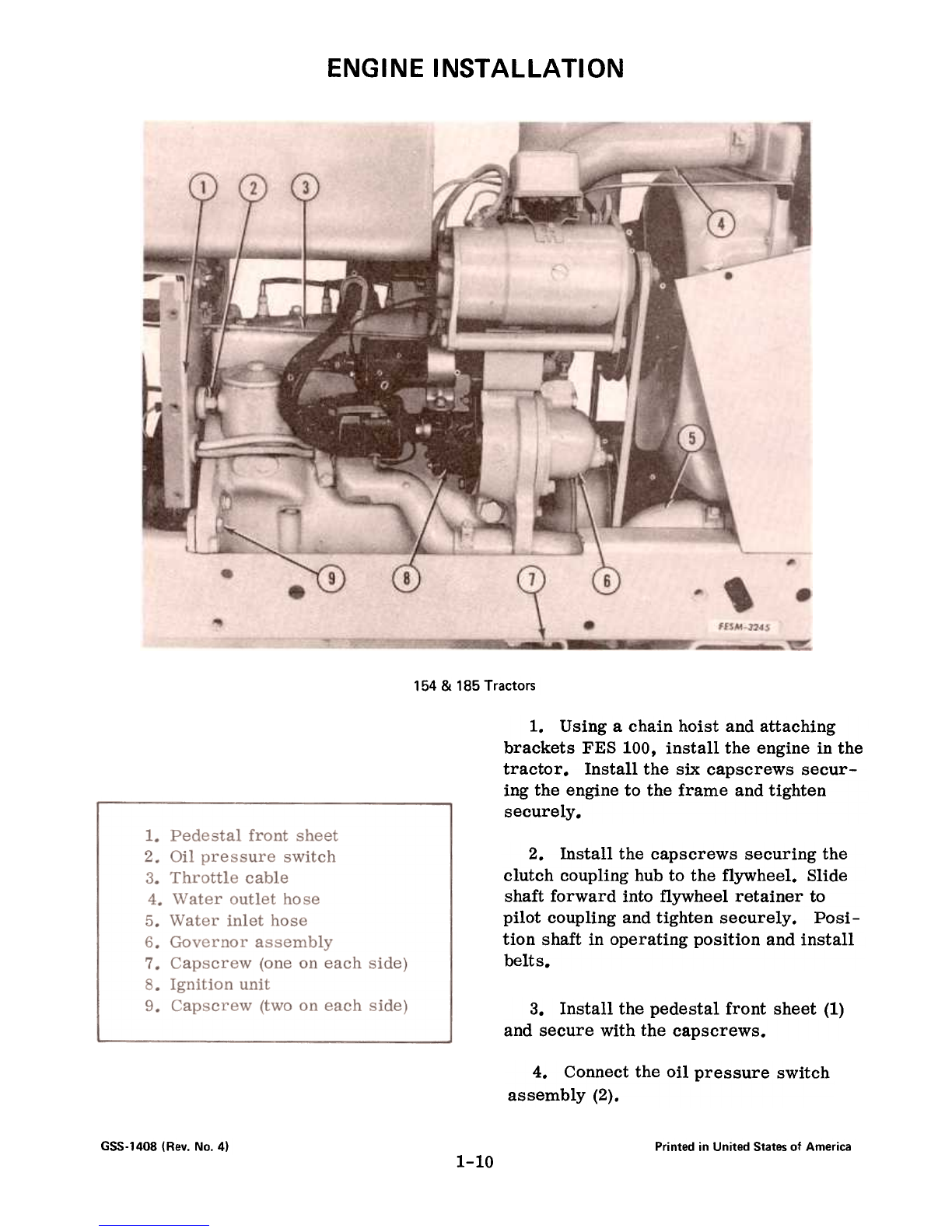

ENGINE INSTALLATION

154 & 185 Tractors

1. Using a chain hoist and attaching

brackets FES 100, install the engine in the

tractor. Install the six capscrews secur-

ing the engine to the frame and tighten

securely.

2. Install the capscrews securing the

clutch coupling hub to the flywheel. Slide

shaft forward into flywheel retainer to

pilot coupling and tighten securely. Posi-

tion shaft in operating position and install

belts.

3. Install the pedestal front sheet (1)

and secure with the capscrews.

4. Connectthe oil pressure switch

assembly (2).

GSS-1408 (Rev. No.4) Printed in United States of America

1-10

5. Connectthe wires to the generator,

voltage reg1l1ator, coil positive terminal

andheadlights (alternator andcranking

motor on184).

6. Connectthe throttle cable (3) to the

governor (6).

184 Tractor

GSS-1408 (Rev. No.4) Printed in United States of America

1-11

6SS-1408 (Rev. No.4) Printed in United States of America

l-llA

7. Install the cooling fan assembly (11).

Be sure the fanblades clear the radiator

shroud. If clearance is not s~ficient, re-

position fan shroud.

8.

Connectthe radiatorhoses.

9. Install the air cleaner (1)and air

cleaner pipe (8). Be sure air cleaner

pipe connectionsare goodto prevent dirt

from entering the engine.

10. Connectthe oil lines to the hydrau-

lic pump(9), (if equipped).

11. Connectthe chokecable (10)to the

carburetor (5).

12. Install the fuel tank (2) and con-

nect the fuel line (4) to the carburetor and

the fuel strainer (3).

13. Install the frame top covert side

sheets andhood.

14. Fill the crankcase with oil andthe

radiator with coolant. Refer to the

Operator's Manual.

Connect the battery ground cable.

15.

GSS-1408 (Rev. No.4) Printed in United States of America

1-liB

THIS PAGE INTENTIONALL V BLANK

Printed in United States of America

GSS-1408 (Rev. No.4) 1-12

CYLINDER

HEAD

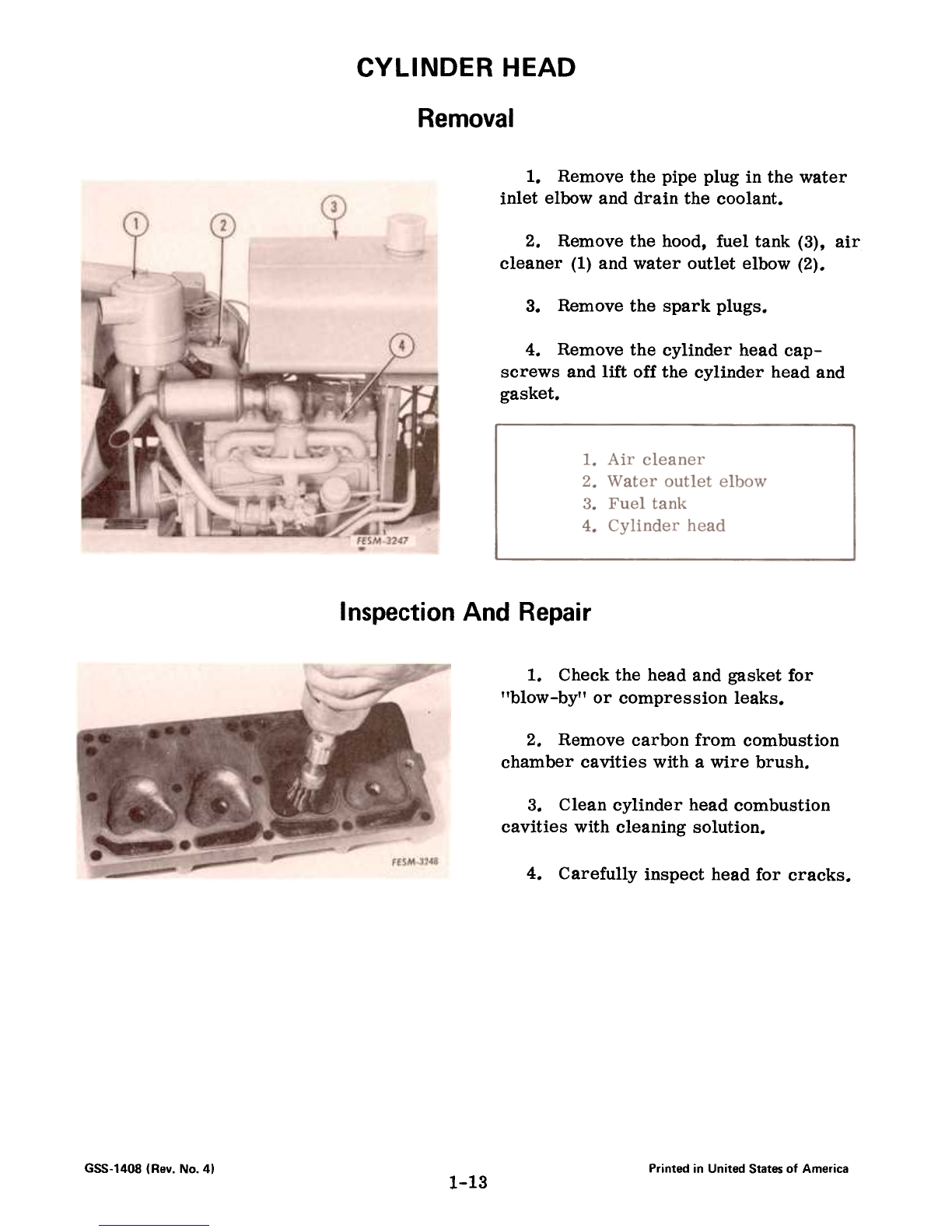

Removal

1. Remove the pipe plug in the water

inlet elbow and drain the coolant.

2. Removethe hood, fuel tank (3), air

cleaner (1)andwater outlet elbow (2).

3.

Removethe sparkplugs.

4. Remove the cylinder head cap-

screws and lift off the cylinder head and

gasket.

Inspection And Repair

1. Checkthe headand gasketfor

"blow-by" or compression leaks.

2. Removecarbon from combustion

chamber cavities with a wire brush.

3. Cleancylinder headcombustion

cavities with cleaning solution.

4.

Carefully inspect headfor cracks.

GSS-1408 (Rev. No. 41 Printed in United States of America

1-13

5. Use a straight edge and inspect for

warped head, particularly in any area

which shows "blow-by."

andcausehot spots. Cleanif necessary

7. Thoroughly clean the gasket surface

to insure proper sealing of the newgasket.

6. Inspect water jacket in head for an

accumulation of rust or lime deposit which

would affect circulation of cooling water

8.

Be sure to use a~ gasket.

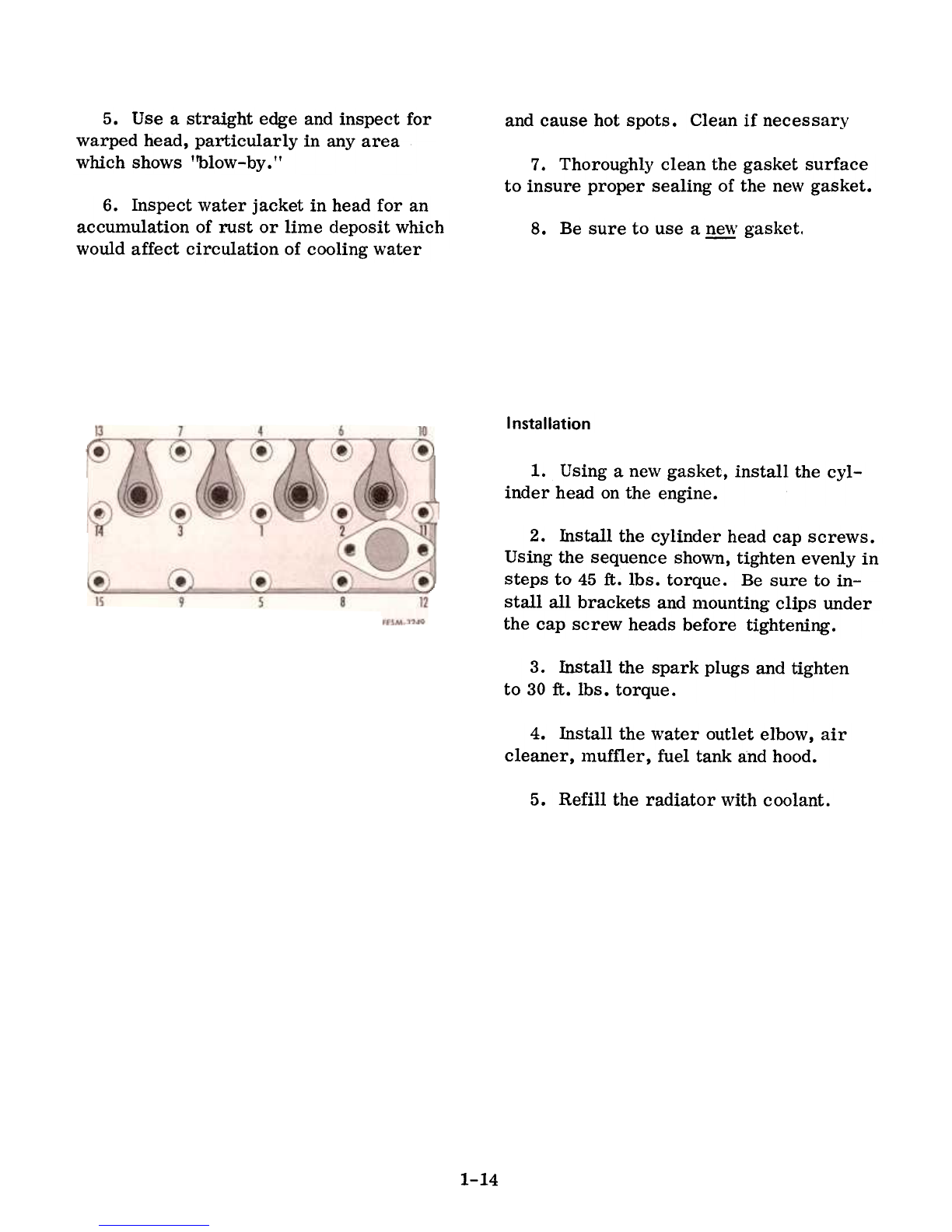

Installation

1. Using a new gasket, install the cyl-

inder head on the engine.

2. Install the cylinder head cap screws.

Using the sequence shoWllt tighten evenly in

steps to 45 ft. lbs. torque. Be sure to in-

stall all brackets and mounting clips under

the cap screw heads before tightening.

3. Install the spark plugs and tighten

to 30ft. lbs. torque.

4. Install the water outlet elbow, air

cleaner, muffler, fuel tank andhood.

5.

Refill the radiator ,vith coolant.

1-14

Valves

valves are adjusted by cranldng the engine

only twice.

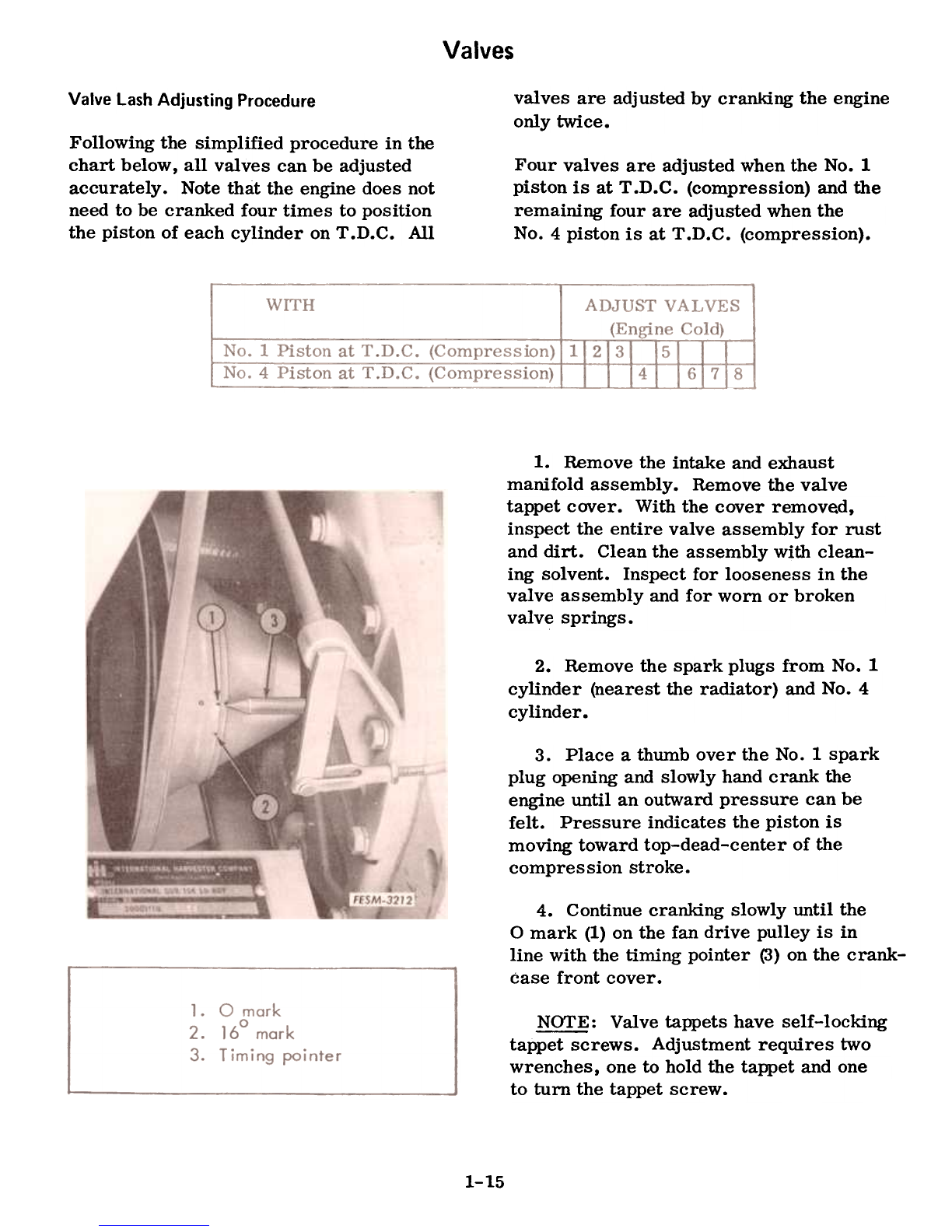

Valve lash Adjusting Procedure

Four valves are adjusted when the No.1

piston is at T.D.C. (compression) and the

remaining four are adjusted when the

No.4 piston is at T.D.C. (compression).

Following the simplified procedure in the

chart below, all valves can be adjusted

accurately. Note that the engine does not

need to be cranked four times to position

the piston of each cylinder on T.D.C. All

1. Remove the intake and exhaust

manifold assembly. Remove the valve

tappet cover. With the cover removed,

inspect the entire valve assembly for rust

and dirt. Clean the assembly with clean-

ing solvent. Inspect for looseness in the

valve assembly and for worn or broken

valve springs.

2. Removethe spark plugs from No.1

cylinder (nearestthe radiator) and No.4cylinder.

3. Place a thwnb over the No.1 spark

plug opening and slowly hand crank the

engjne until an oubward pressure can be

felt. Pressure indicates the piston is

moving toward top-dead-center of the

compression stroke.

4. Continue cranJdng slowly until the

0 mark (1) on the fan drive pulley is in

line with the timing pointer (J) on the crank-

case front cover.

NOTE: Valve tappets have self-locldng

tappet screws. Adjustment requires two

wrenches, one to hold the tappet and one

to turn the tappet screw.

1-15

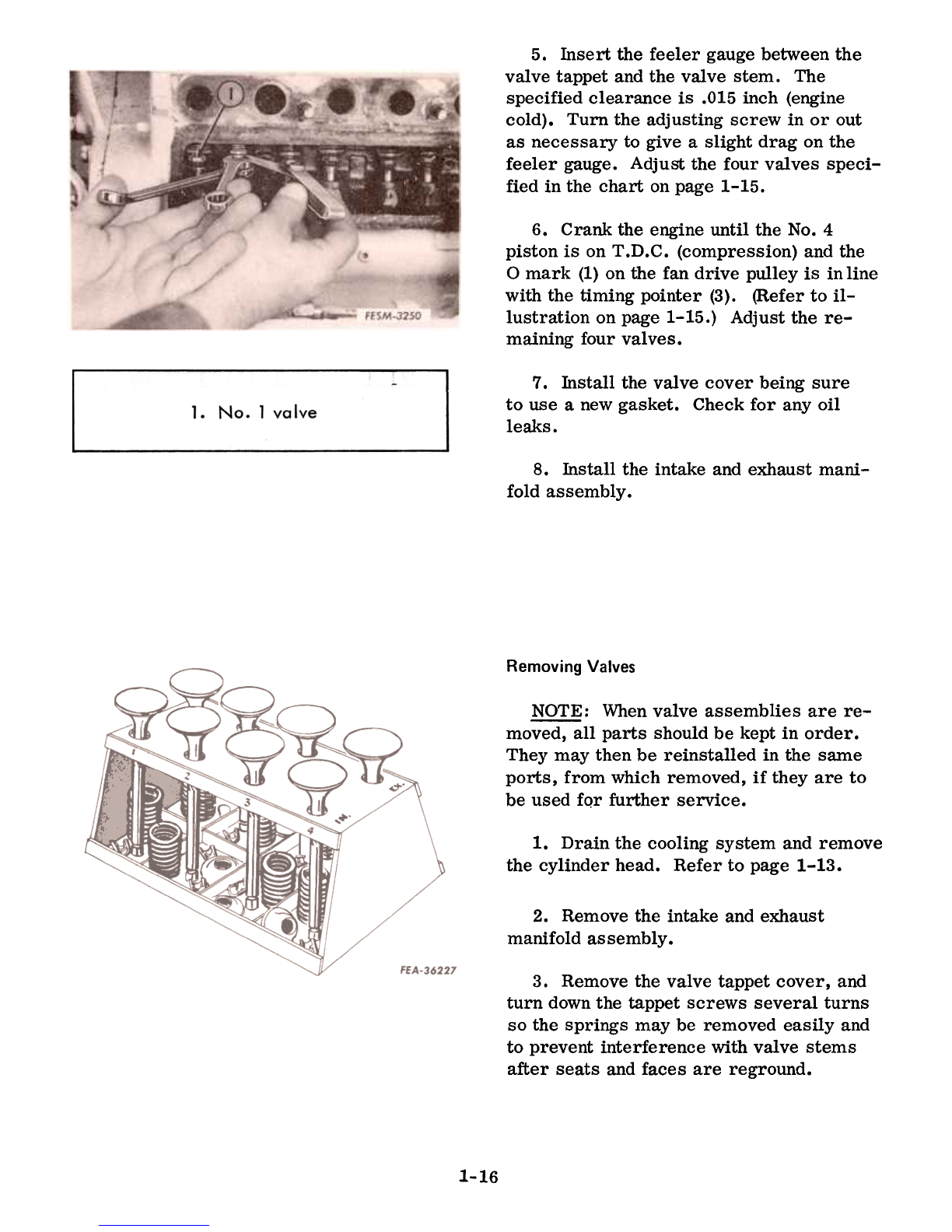

5. Insert the feeler gauge between the

valve tappet and the valve stem. The

specified clearance is .015 inch (engine

cold). Turn the adjusting screw in or out

as necessary to give a slight drag on the

feeler gauge. Adjust the four valves speci-

fied in the chart on page 1-15.

6. Crank the engine until the No.4

piston is on T.D.C. (compression) and the

0 mark (1) on the fan drive pulley is in line

with the timing pointer (3). (Refer to il-

lustration on page 1-15.) Adjust the re-

maining four valves.

7. Install the valve cover being sure

to use a newgasket. Checkfor any oil

leaks.

1. No.1 valve

8. Install the intake and exhaust mani-

fold assembly.

Removing Valves

NOTE: Whenvalve assemblies are re-

moved, all parts should be kept in order.

They may then be reinstalled in the same

ports, from which removed, if they are to

be used fQr further service.

1. Drain the cooling system and remove

the cylinder head. Refer to page 1-13.

2. Removethe intake and exhaust

manifold assembly.

3. Remove the valve tappet cover, and

turn down the tappet screws several turns

so the springs may be removed easily and

to prevent interference with valve stems

after seats and faces are reground.

1-16

Other International Harvester Company Lawn Mower manuals

International Harvester Company

International Harvester Company 105 User manual

International Harvester Company

International Harvester Company 72 User manual

International Harvester Company

International Harvester Company CUB User manual

International Harvester Company

International Harvester Company C-2 User manual

International Harvester Company

International Harvester Company International Cadet 60 User manual

International Harvester Company

International Harvester Company 75 User manual