6

TABLE OF CONTENTS

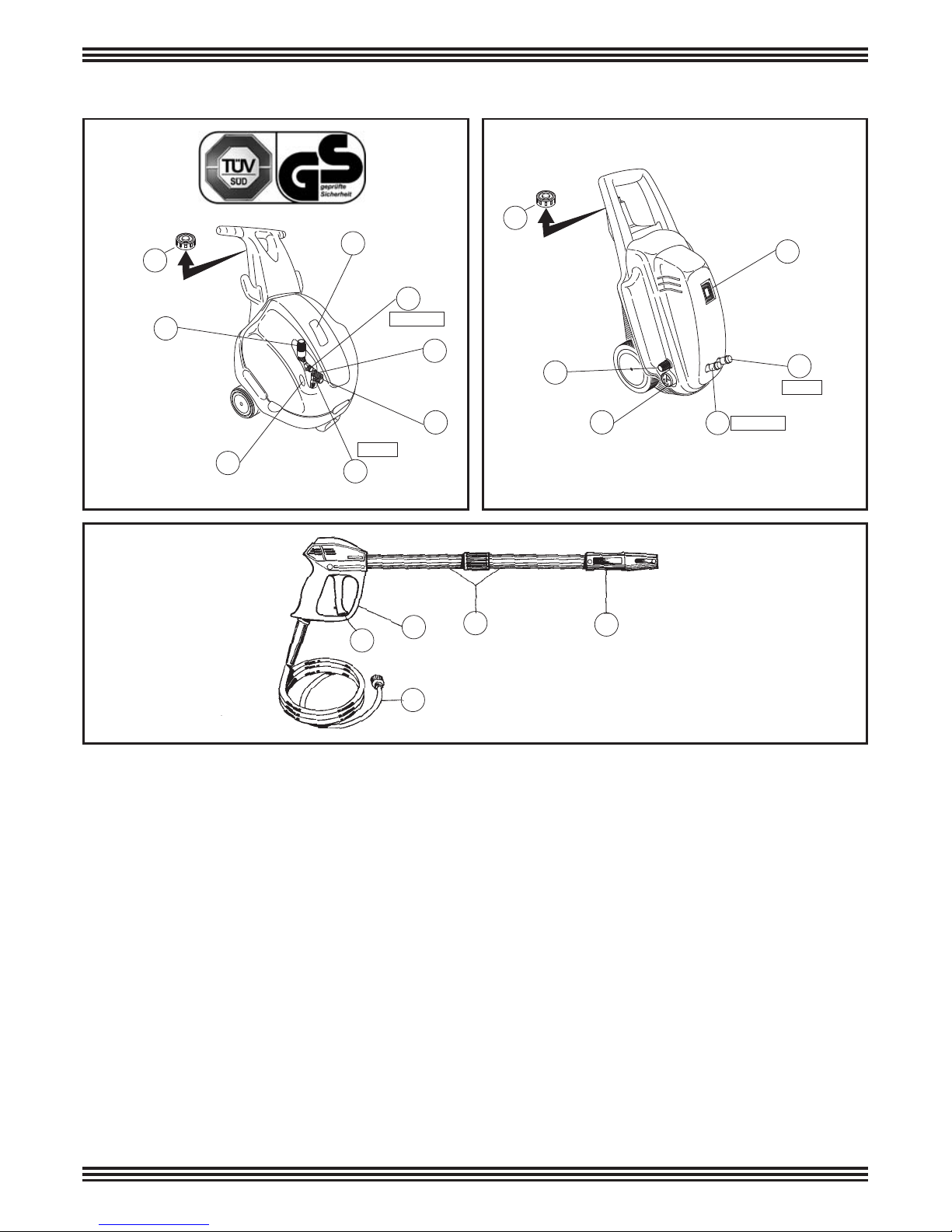

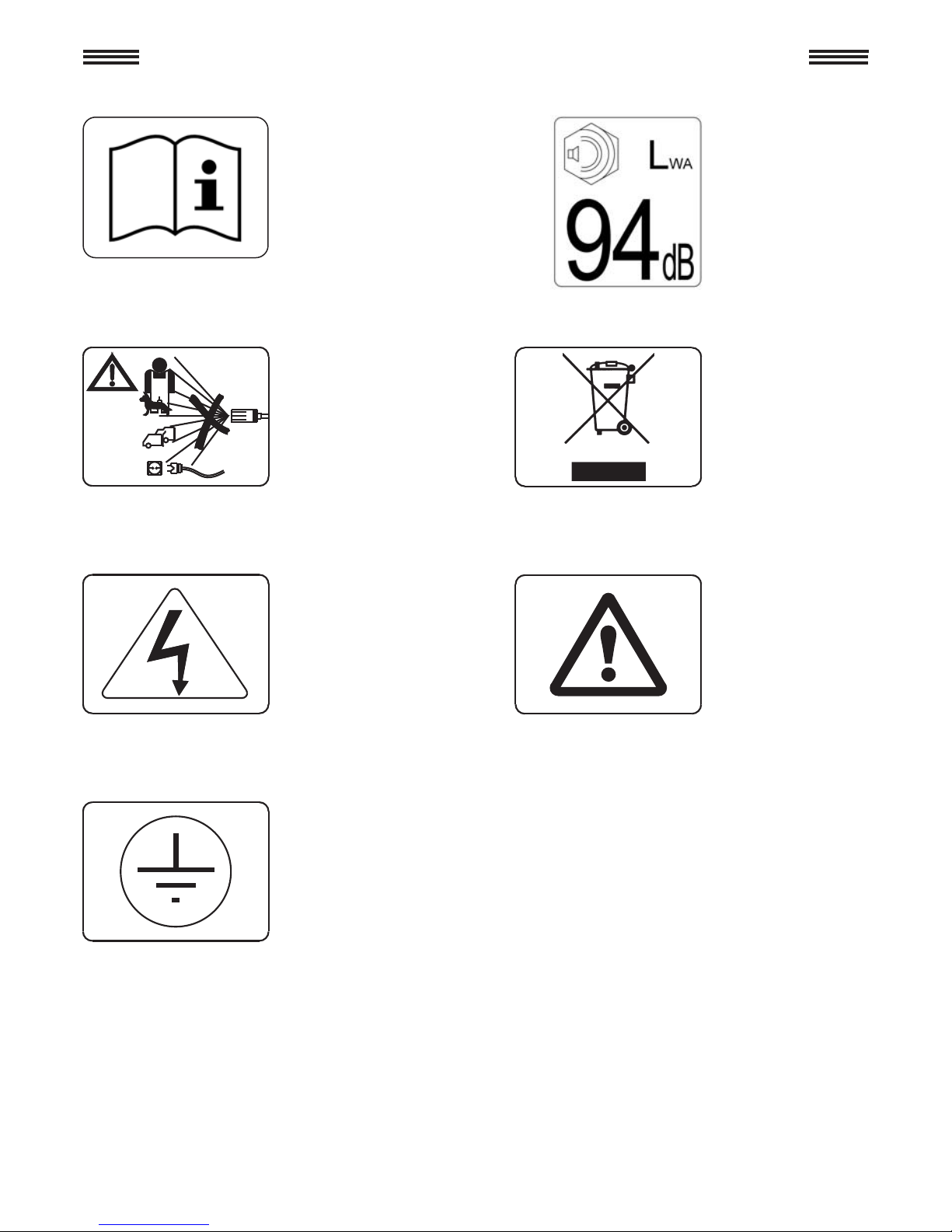

1 - Description of symbols on the high pressure cleaner....................................... 7

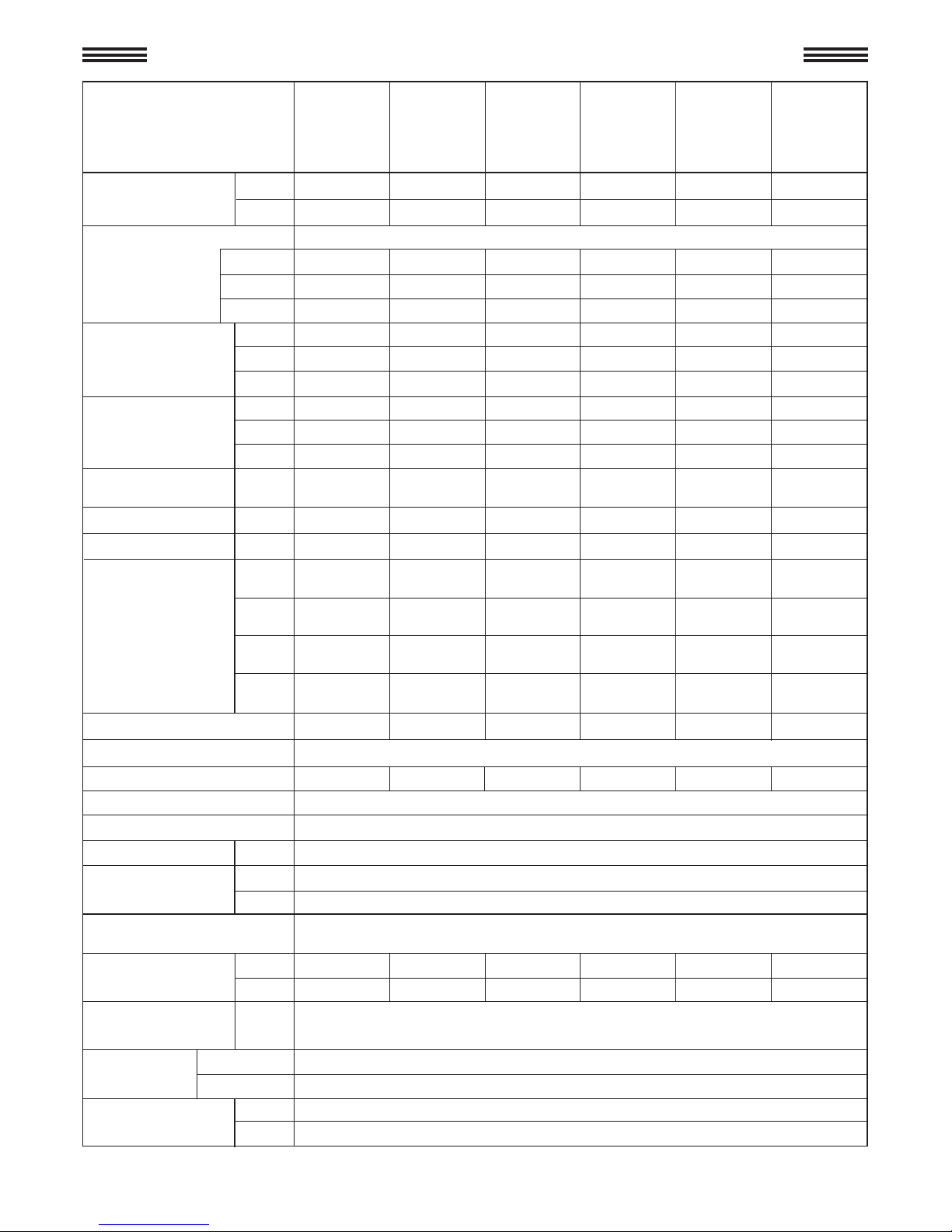

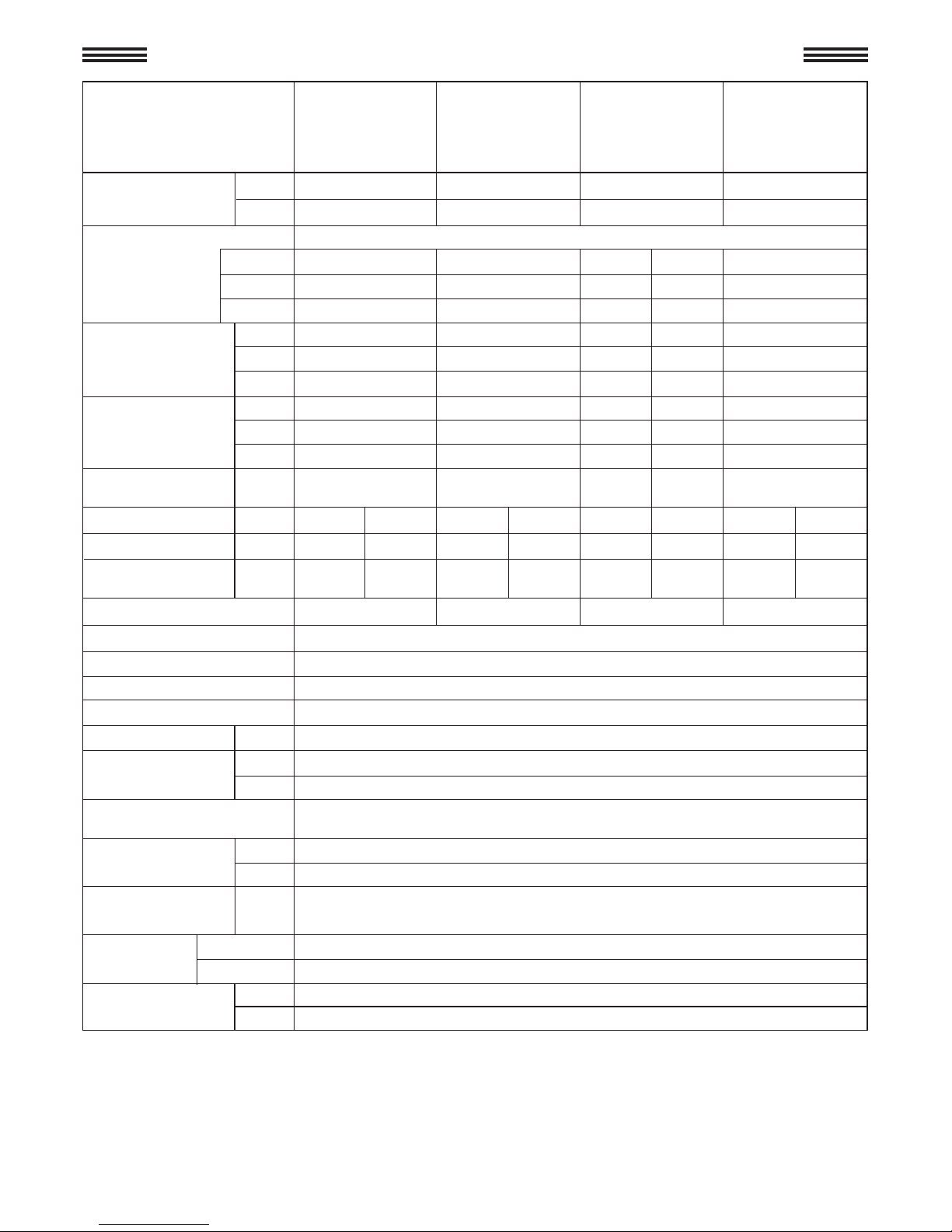

2 - Technical specifications of the IPX - IP series

high pressure cleaner..................................................................................8-9-10

3 - Product use....................................................................................................... 11

3.1 • Designated use................................................................................... 11

4 - Preliminary operations...................................................................................... 11

4.1 • Unpacking........................................................................................... 11

4.2 • Identification label............................................................................... 12

5 - Installation......................................................................................................... 12

5.1 • Connection high pressure outlet......................................................... 13

5.2 • Connection to water supply................................................................ 13

5.3 • Connection to electric system............................................................ 14

5.3.1 • Cut-out switch (Only the United States).......................................... 15

5.4 • Use of extention cord......................................................................... 15

5.5 • Start-up............................................................................................... 16

6 - General warnings.............................................................................................. 17

7 - Chemical product use...................................................................................... 20

7.1 • Suction from internal tank (IP) ........................................................... 20

7.2 • Suction from internal tank (IPX) ......................................................... 20

7.3 • Suction from external tank (IPX) ........................................................ 20

8 - Use of "ROTOTEK" or "MULTIREG 99"........................................................... 21

9 - Precautions againt freezing, and instructions for storage................................... 21

10 - Maintenance...................................................................................................... 22

10.1 • Oil change.....................................................................................22-23

10.2 • Inlet filter............................................................................................ 23

10.3 • Replacement of high pressure nozzle ............................................. 23

11 - Machine scrapping............................................................................................ 24

12 - Trouble shooting............................................................................................... 25

ENGLISH