Adressez toutes vos communications au Bureau

Ingersoll–Rand ou distributeur le plus proche.

Ingersoll–Rand Company 2000

Impriméaux É.U.

MANUEL D’EXPLOITATION ET D’ENTRETIEN

DES PERCEUSES D’ANGLE DE LA SÉRIE 6L

NOTE

Les perceuses d’angle de la Série 6L sont destinées aux opérations de perçage dans les industries

de l’aérospatiale, de l’automobile, des appareils ménagers, de l’électronique, de l’usinage et des

meubles.

Ingersoll–Rand ne peut être tenu responsable de la modification des outils par le client pour les

adapter àdes applications qui n’ont pas étéapprouvées par Ingersoll–Rand.

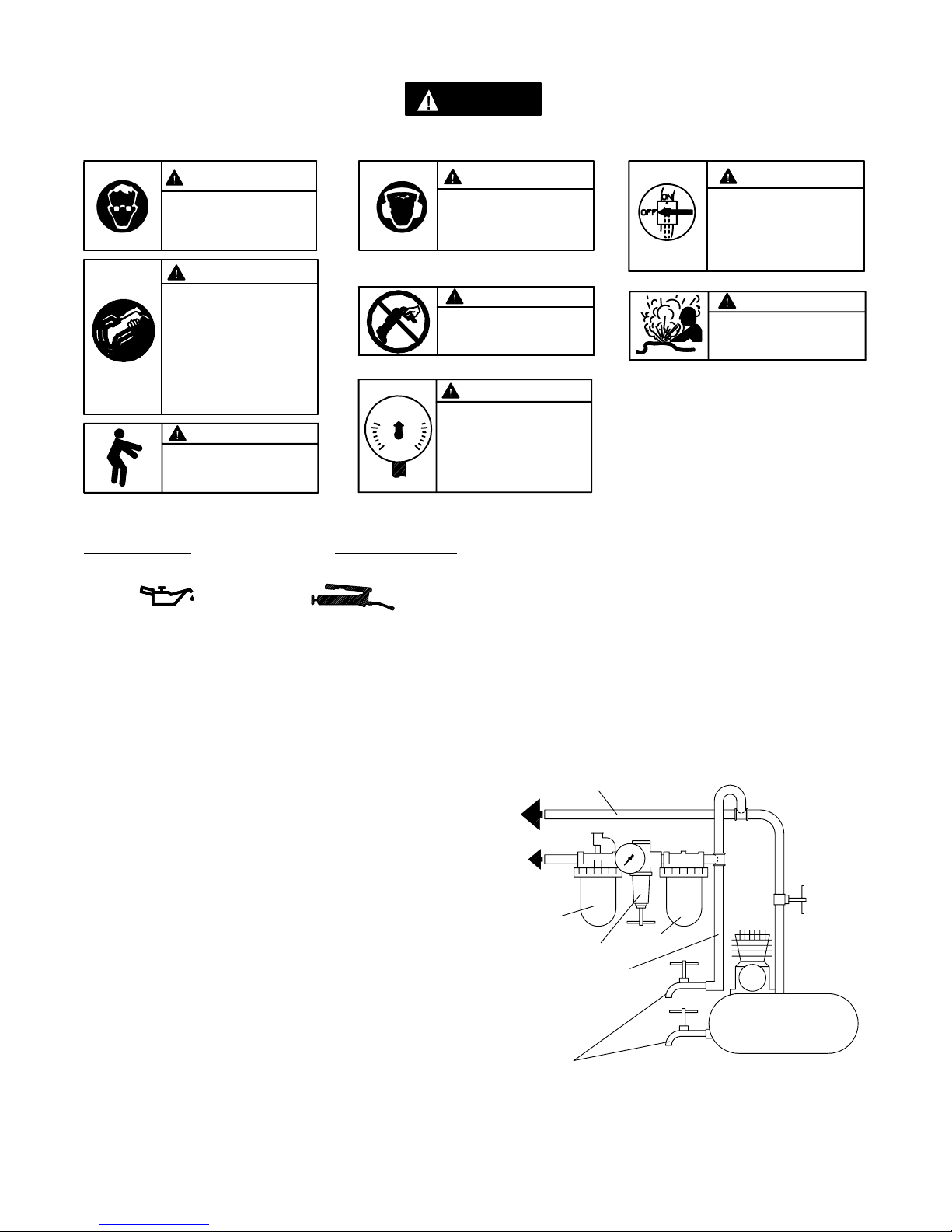

ATTENTION

D’IMPORTANTES INFORMATIONS DE SÉCURITÉSONT JOINTES.

LIRE CE MANUEL AVANT D’UTILISER L’OUTIL.

L’EMPLOYEUR EST TENU DE COMMUNIQUER LES INFORMATIONS

DE CE MANUEL AUX EMPLOYÉS UTILISANT CET OUTIL.

LE NON RESPECT DES AVERTISSEMENTS SUIVANTS PEUT CAUSER DES BLESSURES.

MISE EN SERVICE DE L’OUTIL

•Toujours exploiter, inspecter et entretenir cet outil

conformément au Code de sécuritédes outils

pneumatiques portatifs de l’American National

Standards Institute (ANSI B186.1).

•Pour la sécurité, les performances optimales et la

durabilitémaximale des pièces, cet outil doit être

connectéàune alimentation d’air compriméde 6,2 bar

(620 kPa) maximum àl’entrée, avec un flexible de

10 mm de diamètre intérieur.

•Couper toujours l’alimentation d’air compriméet

débrancher le flexible d’alimentation avant d’installer,

déposer ou ajuster tout accessoire sur cet outil, ou

d’entreprendre une opération d’entretien quelconque

sur l’outil.

•Ne pas utiliser des flexibles ou des raccords

endommagés, effilochés ou détériorés.

•S’assurer que tous les flexibles et les raccords sont

correctement dimensionnés et bien serrés. Voir Plan

TPD905–1 pour un exemple type d’agencement des

tuyauteries.

•Utiliser toujours de l’air sec et propre àune pression

maximum de 6,2 bar (620 kPa). La poussière, les

fumées corrosives et/ou une humiditéexcessive peuvent

endommager le moteur d’un outil pneumatique.

•Ne jamais lubrifier les outils avec des liquides

inflammables ou volatiles tels que le kérosène, le gasoil

ou le carburant d’aviation.

•Ne retirer aucune étiquette. Remplacer toute étiquette

endommagée.

UTILISATION DE L’OUTIL

•Porter toujours des lunettes de protection pendant

l’utilisation et l’entretien de cet outil.

•Porter toujours une protection acoustique pendant

l’utilisation de cet outil.

•Tenir les mains, les vêtements flous et les cheveux

longs, éloignés de l’extrémitérotative de l’outil.

•Prévoir, et ne pas oublier, que tout outil motoriséest

susceptible d’à–coups brusques lors de sa mise en

marche et pendant son utilisation.

•Garder une position équilibrée et ferme. Ne pas se

pencher trop en avant pendant l’utilisation de cet outil.

Des couples de réaction élevés peuvent se produire à,

ou en dessous, de la pression d’air recommandée.

•La rotation des accessoires de l’outil peut continuer

pendant un certain temps après le relâchement de la

gâchette.

•Les outils pneumatiques peuvent vibrer pendant

l’exploitation. Les vibrations, les mouvements répétitifs

et les positions inconfortables peuvent causer des

douleurs dans les mains et les bras. N’utiliser plus

d’outils en cas d’inconfort, de picotements ou de

douleurs. Consulter un médecin avant de

recommencer àutiliser l’outil.

•Utiliser les accessoires recommandés par

Ingersoll-Rand.

•A chaque fois que le renvoi d’angle est installéou

repositionné, le levier de commande doit être

positionnéde manière àce que le couple de réaction

n’ait pas tendance àmaintenir le levier de commande

en position “MARCHE”.

•Cet outil n’est pas conçu pour fonctionner dans des

atmosphères explosives.

•Cet outil n’est pas isolécontre les chocs électriques.

NOTE

L’utilisation de rechanges autres que les pièces d’origine Ingersoll–Rand peut causer des risques d’insécurité, réduire les

performances de l’outil et augmenter l’entretien, et peut annuler toutes les garanties.

Les réparations ne doivent être effectuées que par des réparateurs qualifiés autorisés. Consultez votre Centre de Service

Ingersoll–Rand le plus proche.

F