5

GENERAL

We remind you that the use of products that use fuels

and electricity involves compliance with a number of

basic safety rules such as:

Children and unassisted disabled persons are

prohibited from using the appliance.

It is forbidden to operate electrical devices or

appliances such as switches, appliances, etc. if

there is an odour of fuel or of combustion fumes or

unburnt substances.

In this case:

• ventilate the room by opening doors and windows;

• close the fuel shut-off device;

• promptly involve the Manufacturer's Technical

Assistance Service or professionally qualied

personnel.

Any cleaning operation before complete cooling of

the appliance is prohibited, therefore disconnect

the power supply by turning the main switch of the

system to "OFF” or unplug (if present).

It is forbidden to pull, detach or twist the electrical

cables leaving the appliance even if it is disconnected

from the mains power supply.

It is forbidden to place on the appliance objects such

as towels, dishcloths, doilies, etc. that could cause

malfunctions or even danger.

It is forbidden to disperse, discard or leave within

reach of children the packaging material (cardboard,

staples, plastic bags, etc.) as it can be a potential

source of danger and pollution.

After removing the packaging ensure the integrity

and completeness of the contents. In case of non-

compliance, contact the Agency that sold the appliance.

Installation of the appliance must be carried out by a

company authorised in accordance with the Law. At

the end of the work, it must issue to the owner the

declaration of conformity of installation carried out in

a workmanlike manner, that is in compliance with the

current Standards and the indications provided by

the Manufacturer in the manual for the installer that

is supplied with the product

The appliance is designed for the use intended by

the Manufacturer for which it was manufactured.

Any contractual and non-contractual liability of

the Manufacturer for damage caused to persons,

animals or property, due to errors in installation,

adjustment and maintenance or improper use of the

appliance is excluded.

In the case of non-use for a lengthy period:

• turn the main switch of the appliance to “off”;

• turn the main switch of the system, if present, to

“off” or disconnect the plug from the power socket

if present;

• remove the batteries from the control unit on the

appliance;

• turn off the gas valvve.

This manual is an integral part of the appliance and

must therefore be stored carefully and must ALWAYS

accompany the appliance even if it is sold to another

owner or user or transferred to another system.

In case of damage or loss, request another copy

from the Technical Assistance Service of the Local

Manufacturer.

This appliance is equipped with a re bed with

embers and ceramic blocks containing refractory

ceramic ber, consisting of articial bers of vitreous

silicate. It is therefore advisable to minimise the

release of dust during handling of these materials.

Prolonged exposure to these materials may cause

irritation to the eyes, skin and respiratory system. In

case of replacement of one of the components of the

embers or blocks, it is advisable to seal the removed

parts in a bag and to take them to a waste disposal

centre.

ATTENTION! BEFORE TURNING ON THE

APPLIANCE, CAREFULLY READ ALL THE

INSTRUCTIONS AND WARNINGS CONTAINED IN

THIS MANUAL.

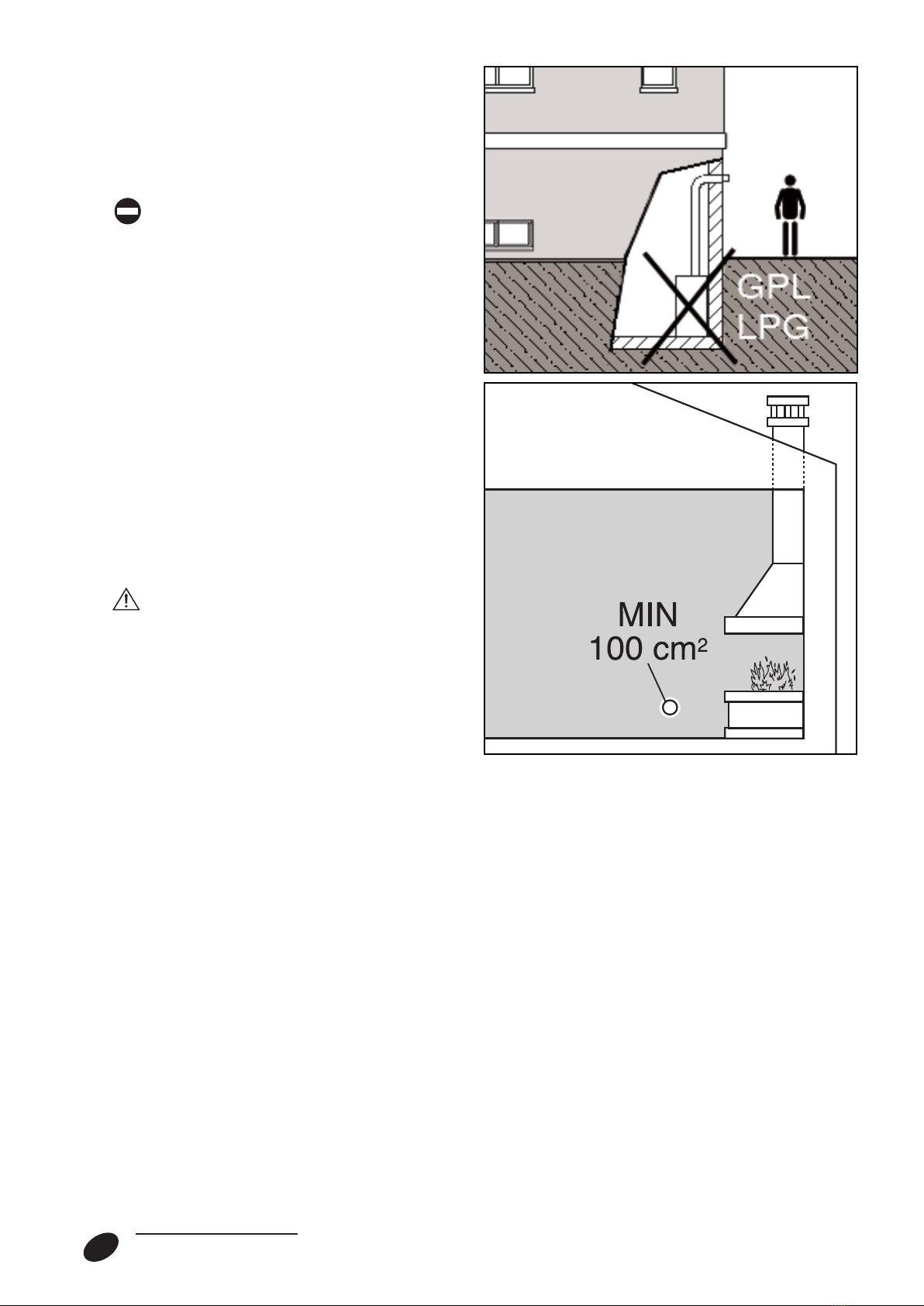

The appliance can be used indoors in both domestic

and commercial environments.

GENERAL WARNINGS

BASIC SAFETY RULES