J&E Hall JCC3 User manual

JCC3

CELLAR AND PRODUCT COOLERS

ISSUE: 01.06.2023

CELLAR COOLER RANGE

TECHNICAL MANUAL

R448A/R449A

Issue: 01.06.2023 Page II

IMPORTANT!

READ BEFORE PROCEED!

GENERAL SAFETY GUIDELINES

This guideline is intended for users to ensure safe installation, operation and maintenance of J & E Hall Cellar and Product

Coolers. This guideline is not intended to replace the system expertise available from the system manufacturers.

This equipment is a relatively complicated apparatus. During installation, operation, maintenance or service, individuals may be

exposed to certain components or conditions including, but not limited to refrigerants, materials under pressure, rotating

components, and both high and low voltage. Each of these items has the potential, if misused or handled improperly, to cause

bodily injury or death. It is the obligation and responsibility of operating/service personnel to identify and recognize these

inherent hazards, protect themselves, and proceed safely in completing their tasks. Failure to comply with any of these

requirements could result in serious damage to the equipment and the property in which it is situated, as well as severe personal

injury or death to themselves and people at the site.

This document is intended for use by owner-authorized operating/service personnel. It is expected that these individuals possess

independent training that will enable them to perform their assigned tasks properly and safely. It is essential that, prior to

performing any task on this equipment, this individual should have read and understood this document and any referenced

materials. This individual shall also be familiar with and comply with all applicable governmental standards and regulations

pertaining to the task in question.

SAFETY SYMBOLS

The following symbols are used in this document to alert the reader to specific situations:

WARNING

Warning! Risk of serious injury or

death to person!

CAUTION

Caution! Danger which can lead to

serious damages!

NOTICE

Notice! Risk of damage to equipment!

NOTICE

Disposal requirement

Your refrigeration product is marked with this symbol. This means that electrical and electronic products shall

not be mixed with unsorted household waste. Do not try to dismantle the system yourself: the dismantling of

the refrigeration system, treatment of the refrigerant, of oil and of other parts must be done by a qualified

installer in accordance with relevant local and national legislation. Refrigeration equipment must be treated

at a specialized treatment facility for re-use, recycling, and recovery. By ensuring this product is disposed of

correctly, you will help to prevent potential negative consequences for the environment and human health.

Please contact J & E Hall for more information.

Issue: 01.06.2023 Page 3

Contents

NOMENCLATURE.............................................................3

Figure 1: Product Nomenclature ...............................3

PRODUCT FEATURES .......................................................3

SPECIFICATIONS ..............................................................4

Table 1: Capacity Data ..............................................4

Table 2: System Data ................................................4

Table 3: Unit Dimensions and Weights .....................4

Table 4: Electrical Data and Requirements ...............5

HEALTH AND SAFETY.......................................................5

GENERAL INFORMATION.......................................................5

INSTALLATION.................................................................6

UNIT LOCATION AND FIXING..................................................6

Figure 2: Positioning of Condensing Unit ..................6

Figure 3: Air Circulation for Condenser .....................6

Figure 4: Installation Clearance (Outdoor Unit) ........6

Figure 5: Installation Clearance (Indoor Unit)...........7

FIELD PIPING......................................................................7

Figure 6: Piping Layout for Outdoor Above Indoor ...7

Figure 7: Piping Layout for Outdoor Below Indoor....8

PRESSURE TESTING..............................................................8

Table 5: Maximum Working Pressure .......................8

EVACUATION &CHARGING...................................................8

DRAINAGE.........................................................................9

Figure 8: Drain Fitting Assembly ...............................9

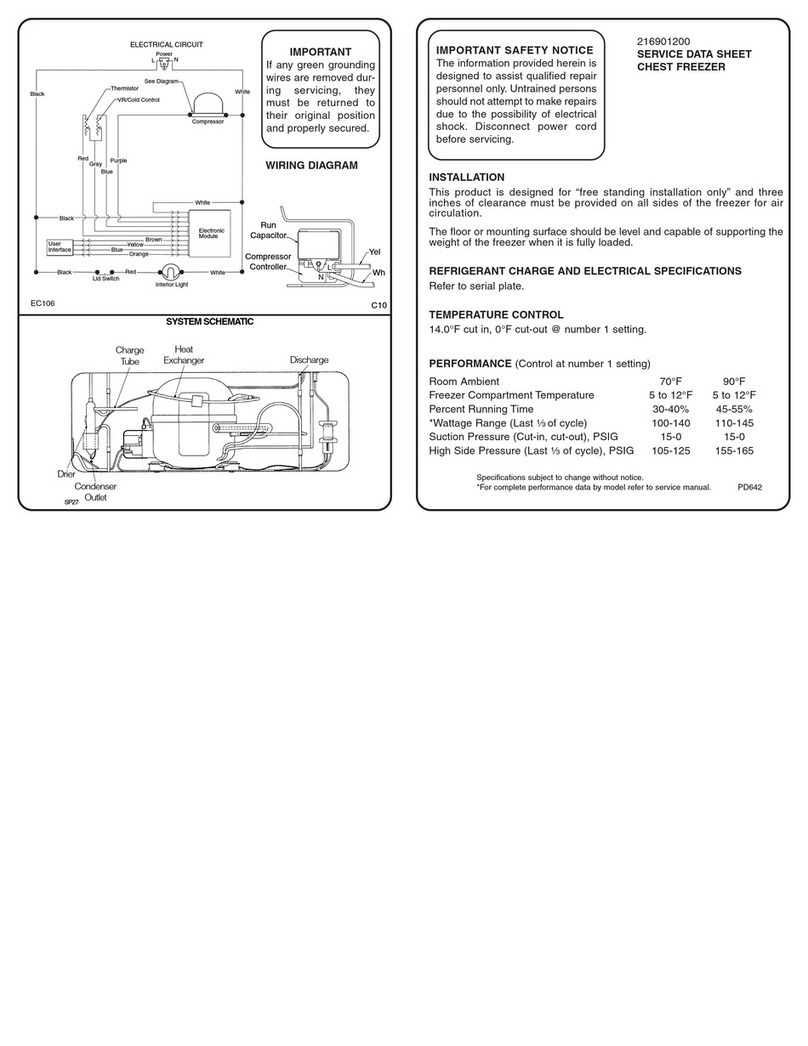

ELECTRICAL........................................................................9

COMMISSIONING............................................................9

SERVICE & MAINTENANCE ............................................10

F-GAS REQUIREMENT....................................................10

Table 6: Leak Inspection Frequency ........................11

TECHNICAL INFORMATION............................................11

ELECTRONIC CONTROLLER ..................................................11

Figure 9: Temperature Controller XR02CX ..............11

FAN SPEED CONTROLLER.....................................................12

Figure 10: Fan Speed Controller (Aspen FP2094) ....12

Figure 11: Sensor Location ......................................12

Figure 12: Wiring Diagram Outdoor Unit Integrate

FSC...........................................................................12

APPENDIX .....................................................................13

Figure 13: Dimension (Indoor Unit).........................13

Figure 14: Dimension (Outdoor Unit)......................13

Figure 15: Wiring Diagram (Indoor Unit) ................14

Figure 16: Wiring Diagram (Outdoor Unit) .............14

Figure 17: P&I Diagram for System.........................15

Table 7: Parameters (Controller XR02CX) ...............16

Table 8: Trouble Shooting .......................................17

Figure 18: Declaration of Incorporation (Outdoor

Unit) ........................................................................20

Figure 19: Declaration of Incorporation (Indoor Unit)

................................................................................21

Figure 20: EU Declaration of Incorporation (Outdoor

Unit) ........................................................................22

Figure 21: EU Declaration of Incorporation (Indoor

Unit) ........................................................................23

Nomenclature

Figure 1: Product Nomenclature

Product Features

J & E Hall Cellar and Product Cooler is a single split

refrigeration equipment consisting of indoor and outdoor

unit integrated with capillary (metering device). The

equipment is connected via copper pipes (not supplied) and

needs to be charged with R448A or R449A at field, to

cool and maintain a storage space temperature range

down to +4°C and up to +16°C. This range of temperature

makes it suitable for preservation of beers, wines, flowers,

fruit, vegetables etc.

Main features of the indoor and outdoor listed below:

The indoor unit consist of:

•6 fins/inch Al-Cu evaporator coil

•AC axial fan with run capacitor

•Digital thermostat with off cycle defrost

•Low pressure protection switch

•Polyester powder coated steel casing

•Accessories: 1”-14UNF drain pipe fitting

And the outdoor unit consist of:

•Single phase rotary compressor with

Permanent Split Capacitor (PSR wiring)

•AC axial fan with run capacitor

•Al –Cu condenser with inner groove 7mm

•Manual reset high pressure safety switch

(cartridge type)

•Acoustic insulation on compressor

•100 % molecular sieve core filter drier

•Capillary throttling device.

•Service valves with braze connection

Indoor Unit

Outdoor Unit

Product Type

JCC: J& E Hall Cellar Cooler (Indoor

Unit)

Nominal Cooling Capacity(kW)

25: 2.5kW

BOMVariance

E: Electronic Controller without TXV

EV: Electronic Controller with TXV

25 EJCC -3

Version

3: Capacity Rated for R448A

Product Type

J: J & E Hall Cellar Cooler (Outdoor Unit)

Nominal Cooling Capacity (kW)

26: 2.5kW

BOM Variance

26 CJ LC6

Refrigerant

6: R448A/R449A

Power Supply

V1: 230V/1phase/50Hz

V1

Throttling Device

LC: Capillary Tube

Issue: 01.06.2023 Page 4

Specifications

Table 1: Capacity Data

System

Indoor + Outdoor

Cooling capacities in kW at 32°C ambient temperature(1)

4°C (2)

6°C

8°C

10°C

12°C

12.7°C

14°C

16°C

JCC3-25E + J6LC26CV1

2.41

2.50

2.59

2.67

2.76

2.79

2.85

2.94

JCC3-40E + J6LC41CV1

3.47

3.62

3.76

3.91

4.06

4.11

4.20

4.35

JCC3-55E + J6LC56CV1

4.63

4.87

5.10

5.33

5.56

5.64

5.79

6.03

Notes:

(1) Cooling capacity rated at standard pipe length 7.6m.

(2) Room temperature of +4 ⁰C is only applicable with pipe lengths not more than 15m.

Table 2: System Data

Unit Model

Cooling

Capacity

kW (2)

System Pipe

Sizes

Maximum

Pipe Run (3)

Unit

Airflows

Indoor

Air

throw

(4)

Noise

Levels

(1)

Recommended

base charge

Additional

charge (6)

R448A/R449A

Liquid

Gas

Length

Rise

m³/h

m

dB(A)

kg

TCO2

g/m

JCC3-25E

2.79

1/4"

1/2"

25m

5m

2560

8

48

n/a

n/a

n/a

J6LC26CV1

2070

n/a

26

1.30

1.80

12

JCC3-40E

4.11

1/4"

1/2"

25m

8m

2270

8

48

n/a

n/a

n/a

J6LC41CV1

2225

n/a

26

1.75

2.43

6

JCC3-55E

5.64

1/4"

5/8"

25m

8m

2475

8

45

n/a

n/a

n/a

J6LC56CV1

2984

n/a

31

2.20

3.05

15

Notes:

(1) Noise levels are sound pressure levels @ 10m free field

(2) Cooling capacities are nominal duties @ 12.7°C DB / 10°C WB and 32°C ambient

(3) The pipe length has include the rise (the rise indicated is not an additional to the length).

(4) Indoor unit air throw distance is based on final air velocity of 0.4m/s.

(5) For piping exceeds 15m, fan speed controller is recommended to be installed in outdoor unit.

(6) An additional charge is required for pipe lengths more than 7.6m.

For applications where:

•Back-to-back installation, at least 1.5-meter pipe run with loop (to damp vibration) is required to avoid sound of outdoor

unit transferred to indoor unit via connecting pipe.

•The system pipe run exceeds 15m up to the maximum of 25m, a fan speed controller (not supplied as standard) is

recommended to be fitted to the condensing unit. Refer Section Fan Speed Controller for details. This is to eliminate too low

evaporating temperature which cause formation of thick frost on evaporator coil.

Table 3: Unit Dimensions and Weights

Model

Unit Dimensions (mm)

Fixing Centres

(mm)

Unit

Weights

Packing Dimensions (mm)

Packing

Weights

Width (2)

Depth

Height

Width

Depth

kg

Width

Depth

Height

kg

JCC3-25E

865

372 (1)

489

745

n/a

31

968

534

517

37

J6LC26CV1

855

328

651

603

362

38

990

415

693

41

JCC3-40E

865

372 (1)

489

745

n/a

33

968

534

517

39

J6LC41CV1

855

328

651

603

362

42

990

415

693

46

JCC3-55E

904

370 (1)

546

826

n/a

38

1006

534

576

45

J6LC56CV1

855

328

753

603

362

46

990

415

793

50

Notes:

(1) Unit depth does not include fan motor depth - add 120mm

(2) Unit width does not include pipe services - add approximately 70mm

Issue: 01.06.2023 Page 5

Table 4: Electrical Data and Requirements

Model

*Indoor

*Outdoor

Outdoor Unit

Compressor

Fan/Unit

Power

Supply

Mains

Power

To

Interconnecting

Power Cable

+ Control

Cable(5)

Suggested

Fuse

Rating

PI (1)

RRC (2)

LRA (3)

MOC (4)

PI (1)

RRC (2)

Qty

(kW)

(A)

(A)

(A)

(W)

(A)

V/Ph/Hz

(A)

JCC3-25E

n/a

n/a

n/a

n/a

232

0.99

1

230/1/50

Indoor

3C2.5mm2+

2C1.0mm2

16

J6LC26CV1

1.01

4.3

30

6.0

80

0.35

1

JCC3-40E

n/a

n/a

n/a

n/a

236

0.96

1

230/1/50

Indoor

3C2.5mm2+

2C1.0mm2

20

J6LC41CV1

1.64

7.2

36

10.9

80

0.35

1

JCC3-55E

n/a

n/a

n/a

n/a

210

0.95

1

230/1/50

Indoor

3C4.0mm2+

2C1.0mm2

25

J6LC56CV1

1.99

9.2

42

13.5

120

0.52

1

Notes:

(1) PI: Power Input at nominal duties @ 12.7°C DB / 10°C WB and 32°C ambient

(2) RRC: Rated Running Current at nominal duties @ 12.7°C DB / 10°C WB and 32°C ambient

(3) LRA: Locked Rotor Amps rated at 230V, 50Hz

(4) MOC: Maximum Operating Current

(5) Control cable need to be drawn from two terminals of indoor unit to connect to the high-pressure switch at outdoor unit for

compressor protection. Please refer to Figure 15 and Figure 16 on page 14 for wiring connections.

Health and Safety

Only a qualified refrigeration engineer, who

is familiar with refrigeration systems and

components including all controls, should

perform the installation and start-up of the

system. To avoid potential injury, use care when working

around coil surfaces or sharp edges of metal cabinets. All

piping and electrical wiring should be installed in

accordance with all applicable codes, ordinances, and

local by-laws.

General information

Before Installation

•Ensure the units received are the correct models for the

intended application.

•Ensure the refrigerant, voltage and MWP are all

suitable for the proposed application.

•Check there is no damage to the units. Any damage

should be reported to the supplier immediately.

•Check that the proposed equipment locations are

suitable and provide adequate support for the weight

of the units.

Offloading and Lifting

•Whenever a unit is lifted, it should be from the base

and, where possible, all packing and protection is kept

in position.

•If lifting equipment is required, ensure that it is suitable,

certificated, and that the operators are qualified to

use it.

•When using a fork-lift or pallet truck to lift the unit, the

two support points should be sufficiently apart to give

stability when lifting and suitably placed to distribute

the load on the forks.

•If slings are used, care should be taken to ensure that

the slings do not crush the casework or coil.

•Do not drop the unit. Should this inadvertently happen,

it should be immediately unpacked and inspected for

damage.

During Installation and subsequent

maintenance

•Installation and maintenance are to be performed only

by qualified personnel who are familiar with local

codes and regulations and experienced with this type

of equipment.

•Safe working methods are identified, and operatives

should have suitable PPE.

•Ensure the working area has adequate ventilation

during brazing procedures.

•The units contain moving machinery and electrical

power hazards, which may cause severe injury or

death. Disconnect and shut off power before

installation or service of the equipment.

•Refrigerant release into the atmosphere is illegal.

Proper evacuation, recovery, handling, and leak testing

procedures must always be observed.

•Units must be grounded to the screw terminal labelled

•No maintenance work should be attempted prior to

disconnecting the electrical supply.

•The electrical covers and fan guards must remain

always fitted.

•Use of the units outside of the design conditions and the

application for which the units were intended may be

unsafe and be detrimental to the units, regardless of

short- or long-term operation.

Issue: 01.06.2023 Page 6

Installation

Unit location and Fixing

Both indoor and outdoor units must be level in all directions.

Outdoor

•The installer must fix the unit securely on installation

using the M8 bolt holes in the unit feet to prevent

instability from accidental contact.

•It is recommended to install the outdoor unit on rubber

grommet or vibration dampers.

•The units are not designed to withstand loads or stress

from other equipment or personnel. Such extraneous

loads or stress may cause failure/leak/injury.

•The units are not designed to operate with any

restrictions such as heavy snowfall around them.

Additional measures (such as shielding of the units) shall

be implemented as required.

•To achieve maximum cooling capacity, the installation

location for the condensing unit should be carefully

selected.

•Install the outdoor unit in such a way so that hot air

ejected by the unit cannot be drawn in again (short

circuit of hot discharge air). Refer Figure 2.

Figure 2: Positioning of Condensing Unit

•Ensure that there is no obstruction to air flow into or out

of the unit. Remove obstacles which block air intake or

discharge. Refer Figure 3.

Figure 3: Air Circulation for Condenser

•Allow sufficient space for maintenance around the unit.

Refer Figure 4.

•The location must be well ventilated, so the unit can

draw in and distribute plenty of air thus lowering the

condensing temperature.

•To optimize the unit running conditions, the condenser

coil must be cleaned at regular intervals.

Special attention should be given to an

outdoor unit installed near to the sea as this

can reduce unit lifespan due to corrosion of

metal parts.

Indoor

•The indoor units can be mounted directly to a wall or to

the ceiling utilizing the fixing holes on the rear of the

unit or on the top of the unit. No additional brackets

are required.

•A minimum 10mm rawl bolt type fixing is required with

a large steel washer to bear the indoor unit weight. It

is important to ensure that the wall/ceiling can

withstand the unit weight and that all fixings are

secure.

•Position the indoor unit where the optimum airflow can

be achieved. Avoid locating in corners or in alcoves

which may restrict airflows.

•Avoid mounting indoor directly over door openings. It is

recommended to locate the indoor opposite door

openings to reduce infiltration and the amount of

warm, humid air drawn into the cold room. Also, to

locate indoors so that the distance to the opposite wall

does not exceed the unit's rated air throw distance.

•The installation location should allow sufficient space

for air flow and maintenance around the units. Refer

Figure 5.

Figure 4: Installation Clearance (Outdoor Unit)

OBSTACLE

OBSTACLE

AIR

INLET SERVICE

SPACE

OBSTACLE

OBSTACLE

AIR

INLET

AIR

DISCHARGE

CD

AB

Minimum Distance

Indicator

300 mm

A

1000 mm

B

300 mm

C

500 mm

D

✓

✓

X

X

Issue: 01.06.2023 Page 7

Figure 5: Installation Clearance (Indoor Unit)

Field piping

Pipe sizes and maximum lengths/heights

should be strictly as per the information

given on Table 2. All local codes of practice

must be observed in the installation of

refrigerant piping.

To ensure satisfactory operation and performance, the

following points should be noted for field piping

arrangements:

•Pipework routes must be as simple and as short as

possible.

•Use of incorrect pipe sizes can affect system

pressures/temperatures and gas velocity for proper oil

return.

•Avoid low points on pipework where oil can

accumulate.

•Use only clean, dehydrated refrigeration grade

copper tube with long radius bends.

•When brazing use brazing filler alloys containing

phosphorus such as BCuP-7 without flux for joining

copper tubes.

•Run braze without over filling to ensure there is no

leakage into the tube.

•To prevent oxidization, blow oxygen free nitrogen

through pipework when brazing.

•Protect the casing of the unit when brazing connections.

•Install insulation with a minimum wall thickness of 3/8”

on both liquid and suction lines.

•Adequately support all pipe work at a maximum of 2-

meter intervals.

•In vertical pipework, the use of U-trap is often

required. This suction riser must always be fitted with a

U-trap at the bottom and a P trap at the top and

never be higher than 4m unless a second U-trap system

is fitted. Maximum rise on Table 2 must be followed,

limited by compressor ability to handle pressure drop.

Refer Figure 6.

•Field piping for outdoor unit located below indoor unit:

Inverted P-trap is necessary to prevent refrigerant

from draining into the compressor during off-cycle.

Refer Figure 7.

•One of the main factors affecting equipment reliability

and compressor service life is refrigeration circuit

contamination. During installation, circuit contamination

can be caused by:

•Brazing & Welding Oxides

•Filings & Particles from de-burring

pipework

•Brazing Flux

•Moisture & Air

Figure 6: Piping Layout for Outdoor Above

Indoor

AIR

INLET AIR

INLET

Min. 1.8m from floor

OBSTACLE

FLOOR

AIR

THROWN

Min. 1.5m from

any obstacle

0.5m

0.5m

WALL

INDOOR

UNIT

OUTDOOR

UNIT

MAX. 4m MAX. 4m

8 TO 12 m/s

U-TRAP AS SHORT AS POSSIBLE

2cm/m SLOPE,

4m/s OR MORE

SUCTION LINE

2cm/m SLOPE, 4m/s OR MORE

RISE (REFER TABLE 2)

U-TRAP AS

SHORT AS

POSSIBLE

INVERTED P-TRAP

LIQUID MIXTURE LINE

Issue: 01.06.2023 Page 8

Figure 7: Piping Layout for Outdoor Below

Indoor

Pressure testing

Never use oxygen, dry air, or acetylene for

pressure testing of the system as these may

form an inflammable mixture.

The outdoor unit is NOT pre-charged with

refrigerant from factory.

Refer Table 2 for the recommended base

charge.

•Both the indoor and outdoor units are pressure tested

in the factory prior to dispatch. All units come with a

holding charge of oxygen free nitrogen ~2barg.

Remove the holding charge indication tag which is tied

on the service valve of outdoor unit before installation.

•Once the pipework installation is complete, it should be

pressure tested for the leaks prior to evacuation.

•A pressure leak test should be carried out using oxygen

free nitrogen (OFN). A calibrated nitrogen pressure

regulator must always be used. Before starting any

pressure testing, ensure the area surrounding the system

is safe, inform relevant personnel and fit warning signs

indicating high pressure testing. Also, use correct PPE as

required.

A simple procedure for testing is as follows:

▪Connect a pressure hose from the regulator to the

schrader connection on the service port (both suction

and liquid line) on the outdoor unit.

▪Pressurize the system slowly up to 3 bar (45 psi) for 5

minutes and check for any signs of leakage.

▪Increase pressure slowly up to 10 bar (150 psi) for 5

minutes and check for any signs of leakage.

▪Increase pressure slowly up to 20 bar (300 psi) and

check for any signs of leakage. Leave system under

pressure for 24 hours.

▪Listen for any possible leaks and check all joints with

bubble spray. If any leaks are discovered, release

pressure slowly from the system until empty, repair

leak and then repeat pressure testing procedure.

Never attempt to repair a leak on a pressurized

system.

A strength test should also be incorporated according to

local regulations. Never exceed maximum working

pressures shown in Table 5. Failure to obey the limit will

cause premature failure on the pressure safety device.

Table 5: Maximum Working Pressure

High Side, barg (psig)

Low Side, barg (psig)

28 (405)

19 (275)

Once testing has been completed satisfactorily, release the

pressure from the system gradually and safely to external

atmosphere.

Evacuation & Charging

Moisture prevents proper functioning of the

compressor and the refrigeration system.

Ensure that a good quality vacuum pump is

used to pull a minimum vacuum of 250

microns (0.25 torr).

Once pressure testing has been completed, the system can

now be evacuated to remove air and any moisture from the

piping. This can be done as follows:

•Ensure any nitrogen charge is safely released from the

system.

•Connect a gauge manifold to the schrader connection

on the service valve on the outdoor unit.

•Connect a vacuum pump and vacuum gauge to the

system.

•Evacuate the system until vacuum is below 250 microns

(0.25 torr).

A triple evacuation procedure is

recommended for all new systems or where

moisture is suspected.

•Once the system is isolated and the vacuum pump is

switched off, any rise in pressure indicates that either

there may be a leak in the system or moisture is still

present. In this case, recheck the system for leaks, repair

as necessary, and then repeat the evacuation

procedure.

•Once evacuation is completed satisfactorily, the vacuum

pump and vacuum gauge can be removed. At this point,

the refrigerant charge can be added to the system as

required. Refrigerant blend must be charged in liquid

form to avoid change of chemical properties.

•Ensure an adequate liquid charge (4~5barg) has been

introduced to the high side of the system before

starting the compressor.

•The remaining charge is slowly throttled into suction

side until the installation has reached a level of stable

nominal condition during operation. Charging liquid

into the suction side of the system should ONLY be

OUTDOOR

UNIT

INDOOR

UNIT

INVERTED P-TRAP

SUCTION LINE

LIQUID MIXTURE LINE

2cm/m SLOPE, 4m/s OR MORE

Issue: 01.06.2023 Page 9

done with a metering device. Ensure a minimum

operating pressure 0.5 barg is maintained when

adding refrigerant to the suction side, otherwise

overheating of the compressor may occur. Use

calibrated weighing scales to add base refrigerant

plus any additional charge required which specified in

Table 2.

•Stop the filling once obtain the correct charge amount

(at this point, there is sufficient suction superheat and

liquid subcooling), remove the cylinder from circuit.

Drainage

The evaporator drain pan fitting is supplied

loose and must be fitted on site.

Correct fitting is vital to ensure leak free operation. The lock

nut and the aluminium washer on the drain fitting MUST be

fitted the right way around; otherwise, it will not tighten

against the drip tray. One side of the nut has an angled

recess –this must be facing towards the drip tray. The fitting

does not require any sealant, but a small amount of silicon

sealant can be applied between the flared face of the fitting

and the drip tray if so desired.

The accessories bag is tied to the indoor unit’s fan guard and

consists of:

•instruction manual,

•1pcs aluminum alloy drain fitting 1”-14UNF male

thread,

•1pcs hexagon locknut and

•1pcs aluminium washer

To install the drain fitting, firstly unscrew the drain pan from

the indoor unit. Locate the drain fitting into drain pan, insert

washer and followed with locknut to secure the drain fitting

to the drain pan. Then refit the drain pan to the unit. Follow

Figure 8 to install the drain fitting in the correct way.

Figure 8: Drain Fitting Assembly

The locknut only requires hand tightening and then pinching

up with a spanner. Do not over tighten, else the threads may

strip from the nut and damage the tray.

Recommended minimum drainpipe diameter is 25mm or 1”.

The drainpipe material could be either copper or plastic. It

is not recommended to use flexible hose as it tends to kink

easily which might cause blockage and water to back up in

the unit.

Electrical

The mains electrical supply to the indoor unit

must be via a suitably rated isolator and

motor rated circuit breaker or fuse. There is no

isolator fitted to either the indoor or the

outdoor unit. The rocker switch on the front of the indoor

unit is for isolating the indoor fan and electronic controller

only.

J & E Hall cellar cooler systems require a 230 volt / 1 phase

/ 50Hz supply which must include a Neutral and Earth. They

are not suitable for any other supply voltages (other than a

deviation of +/- 10% of the above values) and are not

suitable for 60 Hz supplies.

•Cable type and sizing must be selected for the

application and the electrical installation should

conform to the current local standards. All indoor and

outdoor units are Single Phase.

•Cables to the indoor unit should be routed through the

‘U’ shaped cut-out in the bottom of the removable air

grille at the side of the unit and into the rear of the

electric box.

•Cables to the outdoor unit should be routed under the

plastic pipe / electrical connection cover on the end of

the unit.

•The interconnecting cable between the indoor and

outdoor unit should be 3 cores for power supply and 2

cores for control circuit connected to high pressure

switch.

•Connect the mains supply and interconnecting cables as

per the wiring diagrams in Figure 15.

•Access to the electrical terminals and components on

the indoor unit is via the removable cover plate on the

front of the unit. Removal of the cover plate gives

access to the outdoor unit contactor, the terminal block

as well as the electronic controller and rocker switch

connections.

Commissioning

To gain access to the electrical box on the indoor and

outdoor unit, isolate the power supply to the outdoor unit

and indoor unit by turning the remote motor rated circuit

breaker to the OFF position.

To access electrical box on the outdoor unit: Loosen the

screws from the plastic valve cover, slightly slide downward

to remove the plastic cover.

To access electrical box on the indoor unit: Loosen the

screws from the L shaped window panel.

Pre startup checks

Before starting the system, the following checks should be

carried out as a minimum:

•Check electrical supply is correct and all connections

are sound.

•All moving parts are free, and guards are fitted.

•All valves are in correct operating position.

•Refrigerant type is correct and the required charge

amount by referring to Table 2.

•Gauge manifold connected to both low and high sides

of system.

Issue: 01.06.2023 Page 10

Before starting the system, ensure that all

electrical connections are correctly made and

tight, service ports are in the correct position

and all covers and guards are fitted.

Unit startup

•Switch on the power at the mains isolator and then

switch on the rocker switch on the front of the indoor

unit.

•Set the required cold room temperature on the

electronic controller and check the system parameters

in the controller as required (the controllers are pre-

programmed in the factory to suggested settings).

•Run the system to the required temperature and check

system pressures, gas charge and running currents of

motors to ensure correct operation.

•Carry out a manual defrost (press the defrost button on

the controller for more than 2 seconds) to ensure the

defrost period is adequate to clear any frost build up

on the evaporator coil.

•Carry out final leak test and ensure all covers are

fitted and securing screws are tightened.

•Log all information along with system model and serial

numbers for future reference.

•Ensure that the customer / responsible person is

provided with basic operating instructions and where

electrical isolators are situated in case of emergency.

An anti-short cycle timer is built into the

indoor controller to prevent the compressor

from stop/starting too quickly, which can

result in the compressor tripping on its

internal overload. If the overload trips,

please allow time for it to cool down and auto reset

before restarting.

Service & Maintenance

Warning! –Disconnect the mains electrical

supply before servicing or opening the units.

The units are designed to give long life

operation with minimum maintenance. However, it should be

routinely checked, and the following service schedule is

recommended under normal circumstances:

1. Indoor and Outdoor units –Inspect at regular intervals

•Check for refrigerant leaks on all joints and

fittings.

•Check mountings for tightness and wear.

•Inspect pipework for any damage.

•Check all electrical connections.

•Ensure that no abnormal noise or vibration is

detected during the test run.

2. Condenser & Evaporator Fan Motors & Blades –Clean

and inspect at regular intervals

•Check for abnormal noise, vibration, and fan

imbalance.

•Ensure that the fan motors are clean and spin

freely.

•Check that the fan blades are clean and free from

restriction and damage/imbalance.

•Note: The Fan Motors are pre-lubricated, and

factory sealed so no maintenance is necessary.

3. Condenser & Evaporator Coils –Clean and inspect at

regular intervals

•Check and remove the dirt and debris between

the fins using a soft brush and/or a suitable

chemical coil cleaner then rinse with clean water.

•Check and remove any obstacles that may hinder

the airflow through the coils.

•Repair any damage to fins and ensure any guards

are fitted correctly.

•DO NOT USE HIGH PRESSURE WASHERS ON

COILS –THEY DAMAGE THE FINS.

4. Controls

•Check controller settings and operation.

•Check calibration of temperature probe reading.

5. Power Supply –Inspect at regular intervals.

•Check the running current and voltage for the units.

•Check the electrical wiring and tighten the wires

onto the terminal blocks if necessary.

6. Refrigerant Charge

•Check the refrigerant charge by ensuring that the

system is operating correctly, and the system

pressures are as expected.

•Carry out a full leak test.

7. Unit decommissioning and disposal

•At the end of the system’s useful life, a suitably

qualified engineer should decommission it. The

refrigerant and compressor oil are classed as

hazardous waste and as such must be reclaimed

and disposed of in the correct manner, including

completion of waste transfer paperwork. The

system components must be disposed of or

recycled as appropriate in the correct manner.

F-Gas Requirement

The equipment covered in this Technical Manual relies on

fluorinated greenhouse gases R448A and R449A for their

functioning.

J & E Hall Cellar and Product Cooler is a non-hermetically

sealed system where the outdoor unit is designed to use

with R448A and R449A. The outdoor and indoor unit

models come from the factory pressurized with OFN

(Oxygen Free Nitrogen) only. The system had to be

charged with the recommended charge specified in Table 2.

In F-Gas Regulation EU 517/2014, this type of system only

be able to be installed by engineers who hold an F Gas

qualification.

The requirement for leak testing is based on the charge size

in tonnes of CO2equivalent specified in below table.

Starting 1st January 2017, the requirement for leak

detection and maintaining system logs changes from 3kg

HFC to 5 tonnes CO2 equivalent.

Issue: 01.06.2023 Page 11

Table 6: Leak Inspection Frequency

System Charge

(Tonnes CO₂

Equivalent)

Leak Inspection Frequency

3.6 to 36.0 kg R448A

3.6 to 35.8 kg R449A

•At least once every year.

(5 to < 50 TCO2eq)

•At least once every 2 years

if a fixed leak detection

system is fitted.

A refrigerant charge label is supplied with each outdoor

unit. The refrigerant charge for the system must be filled on

the label along with the TCO2eq value with indelible ink

and must be adhered in the proximity of the product

charging port.

Total system charge = Recommended charge for pipe

length 7.6m and below + Additional refrigerant charge

added at site (for pipe length exceed 7.6m)

Enter TCO2eq value from calculation:

𝑇𝑜 𝑐𝑎𝑙𝑐𝑢𝑙𝑎𝑡𝑒 𝑇𝐶𝑂2 𝐸𝑞 𝑣𝑎𝑙𝑢𝑒

=𝑅𝑒𝑓𝑟𝑖𝑔𝑒𝑟𝑎𝑛𝑡 𝐶ℎ𝑎𝑟𝑔𝑒 (𝑘𝑔𝑠) × 𝑅𝑒𝑓𝑟𝑖𝑔𝑒𝑟𝑎𝑛𝑡 𝐺𝑊𝑃

1000

Technical Information

Electronic Controller

The indoor unit is equipped with a controller to control the

room temperature based on the setpoint temperature. The

controller parameter could be viewed and changed as

described in the section below.

Figure 9: Temperature Controller XR02CX

To check the setpoint temperature:

•Press and release the SET button.

To change the setpoint temperature:

•Press the SET button for more than 3 seconds

•The setpoint value is displayed and the °C or °F led

starts flashing.

•To change the setpoint value press the ▲or ▼button

within 10 seconds.

•To retain the new setpoint press the SET button again

or wait 10 seconds.

To start a manual defrost:

•Press the defrost button for more than 2 seconds.

To lock and unlock keyboard:

•Press the ▲and ▼buttons together for more than 3

seconds.

•When The ‘OF’ message displayed, the keyboard is

now locked.

•When the ‘ON’ message is displayed, the keyboards

will be unlocked.

To change a parameter value (selected parameters):

•Enter the programming mode by pressing the SET and

the ▼buttons together for more than 3 seconds (°C or

°F LED starts blinking). The first parameter (Hy) is

displayed.

•Press the SET button to display the parameter value.

•Use the ▲and ▼buttons to change the parameter

value.

•Press the SET button to store the new value and move

to the next parameter.

•To exit the programming mode, press the SET and ▲

buttons together or wait 15 seconds without pressing a

button.

To enter the hidden parameter menu (full parameter list):

•Enter the programming mode by pressing the SET and

▼buttons together for 3 seconds (°C or °F LED starts

blinking).

•Release the buttons, and then press the SET and ▼

buttons for more than 7 seconds. L2 will be displayed

followed by the first parameter (Hy). You are now in

the hidden menu.

•Select the required parameter.

•Press the SET button to display the parameter value.

•Use the ▲and ▼buttons to change the parameter

value.

•Press the SET button to store the new value and move

to the next parameter.

•To exit the programming mode, press the SET and ▲

buttons together or wait 15 seconds without pressing a

button.

Ref. GWP Charge (kg) TCO2Eq.

R448A 1387

R449A 1397

Issue: 01.06.2023 Page 12

Fan speed controller

The fitting of a fan speed controller is compulsory for

applications where the system pipe run is longer than 15m.

Refer to Table 2.

Aspen Cooling Only model as shown in Figure 10, is

recommended to be installed on the outdoor unit to

regulate fan speed based on condensing temperature. The

fan speed controller could be obtained either from your

unit distributor or various refrigeration stockists.

Figure 10: Fan Speed Controller (Aspen FP2094)

Aspen FP2094 fan speed controller comes supplied with full

fitting and set-up instructions. Refer to Figure 12 and

instructions below for the field wiring:

•Find a suitable mounting point for the controller within

the outdoor unit casing and fix it securely. (Aspen

FP2094 is not waterproof and should be installed in

the electrical compartment of the condensing unit).

•Connect the thermal sensor to the terminals red/blue on

the controller and fix the sensor side to a bend of the

condenser coil in the middle between an entrance point

and outgoing point of the refrigerant tubing, refer

Figure 11. In case of any doubt, measure the

condensing temperature and select the point which is

closest to the saturation point.

•If possible, put a thermal paste on the sensor or isolate

it, to obtain the best measurements and working results.

•Remove the condenser fan Live wire (Black) from the ‘L’

connection on the unit and connect to ML on the FSC.

Remove the condenser fan Neutral wire (Blue) from the

connection at the compressor run capacitor and connect

to MN on the FSC.

•Make up a new wire to connect ‘L’ (on unit) to L (on

controller) and another new wire to connect ‘N’ (on unit)

to N (on controller). Provide a new Earth wire between

the unit and E on the controller.

•Tighten all wiring connections and secure all wires as

necessary. The wiring is now complete.

•Run the unit and adjust controller as per instructions to

give required condensing temperature (35°C~40°C).

Figure 11: Sensor Location

Figure 12: Wiring Diagram Outdoor Unit Integrate FSC

Min

Speed

Cooling

version only

Set

Point

N L E ML MN T2 T1

Temp

Red

Temp

Blue

NL 1 2

P>

S1PH

BLK BLK

FROM INDOOR UNIT

220-240V/~/50Hz

RESET

M1F

M

1~

C2

M1C

1~

RD

M

BLK

BLU

TSR

PE

C1

BLK

RD

BLU

PE

BLK

TO INDOOR

P3 P4

Q1R

Issue: 01.06.2023 Page 13

Appendix

Figure 13: Dimension (Indoor Unit)

MODEL

A

B

C

D

E

F

G

H

I

J

K

L

M

JCC3-25E

JCC3-40E

865

745

745

489

479

433

207

31

51

417

492

372

46

JCC3-55E

904

826

826

546

535

452

205

30

68

472

491

370

44

Figure 14: Dimension (Outdoor Unit)

MODEL

A

B

C

D

E

F

G

H

I

J

K

L

M

N

J6LC26CV1

J6LC41CV1

855

628

328

508/520

181/179

44/46

93

149

101

113

603

126

164

17/15

J6LC56CV1

855

730

328

513/520

182/179

44/46

93

149

101

113

603

126

164

17/15

MODEL

O

P

Q

R

S

J6LC26CV1

J6LC41CV1

49/34

23

362

73

75

J6LC56CV1

47/34

23

362

73

75

Issue: 01.06.2023 Page 14

Figure 15: Wiring Diagram (Indoor Unit)

Figure 16: Wiring Diagram (Outdoor Unit)

Manual reset on the cartridge type

high pressure switch is required

after the fault is removed.

INDICATOR

C1: FAN CAPACITOR

K1M: CONTACTOR

M1F: EVAPORATING FAN

S1PL: LOW PRESSURE SWITCH

S1S: ON/OFF SWITCH

- - - -: FIELD WIRING

MODEL C1 (uF)

JCC3-25/40/55E 6.0

C1

M1F

1~

M

K1M

1 3 5

22

21

42 6

CLL N CN P1

P<

A2

A1

BLU

BRN

C

LN

S1PL

BRN

P2

BLK

RD

K1M

E

P3

52

41

CLNROOM

1 2 3 4 6 7 8 9

BLK

HOT KEY XR02CX

S1S

BRN

BRN

BLU

BLU

240V~

RD

RD

BLK

BLU

RD

PLATE

WINDOW

CASING

POWER SUPPLY TO

OUTDOOR UNIT

INCOMING SUPPLY

220-240V/~/50Hz

SUPPLY

NOTE

(1)LINK WITH JABC:

REMOVE JUMPER WIRE

P2-P3, TO CONNECT

WIRE FROM TERMINAL

A, B OF JABC UNIT.

(2)LINK WITH

J6LC026/41/56CV1:

REMOVE JUMPER WIRE

P3-P4, TO CONNECT

WIRE FROM TERMINAL

1, 2 OF OUTDOOR

UNIT.

(3)LINK WITH

BSCU-30/35/40-M1/3:

BYPASS S1PL WITH

JUMPER WIRE CONNECT

TO P1-P2.

REMARK:

S1PL: 0.35/1.38barG

AUTO RESET

NOTE 1

BRN

P4

RD

NOTE 2

NOTE 3

LN

INDICATOR

C1: RUN CAPACITOR

C2: FAN CAPACITOR

M1C: COMPRESSOR

M1F: CONDENSER FAN

S1PH: HIGH PRESSURE SWITCH

Q1R: COMPRESSOR THERMOSTAT

- - - -: FIELD WIRING

MODEL C1 (uF) C2 (uF)

J6LC26CV1 50 3.0

J6LC41CV1 60 3.0

J6LC56CV1 50 3.5

N

L 1 2

P>

S1PH

BLK BLK

FROM INDOOR UNIT

220-240V/~/50Hz

NOTE

S1PH: 28/22barG MANUAL RESET

Q1R: 110/95°C AUTO RESET

RESET

M1F

M

1~

C2

M1C

1~

RD

M

BLK

BLU

CSR

PE

C1

BLK

RD

BLU

PE

BLK

TO INDOOR

P3 P4

Q1R

Issue: 01.06.2023 Page 15

Figure 17: P&I Diagram for System

JCC3-25E + J6LC26CV1

JCC3-40E + J6LC41CV1

JCC3-55E + J6LC56CV1

LEGEND

SERVICE VALVE

LOW PRESSURE SWITCH

HIGH PRESSURE

SWITCH

THERMISTOR

CHARGING PORT

CAPILLARY TUBE

ROTARY

COMPRESSOR

CONDENSER:

AIR-COOLED

FINNED TUBE HEAT

EXCHANGER WITH

AXIAL FAN

EVAPORATOR:

AIR-COOLED FINNED

TUBE HEAT EXCHANGER

WITH AXIAL FAN

PSL

SUCTION

VALVE

LIQUID

VALVE

INDOOR

(ROOM TEMPERATURE 4~16°C)

T

Refrigerant:

(1) R448A

(2) R449A

DWG NR: RJ7003010013992

OUTDOOR

(AMBIENT UP TO 38°C)

PSH

FILTER

DRIER

SYSTEM

PSL

PSH

T

Issue: 01.06.2023 Page 16

Table 7: Parameters (Controller XR02CX)

Label Description Range Default setting JEH Setting

Hy Differential 0.1 ~ 25°C / 1 ~ 45°F 2.0°C / 4°F 2.0°C

ot Probe calibration -9.9 ~ 9.9°C / -18 ~ 18°F 0.0 0.0

AC Anti Short Cycle Delay 0 ~ 50 minutes 1 3

CH Kind of Action (Cool / Heat) cL ~ Ht cL cL

rE Resolution (°C only): dE = decimal between -9.9 ~ 9.9°C; in = integer dE ~ in dE in

id Interval between defrost cycles 0 ~ 99 hours 8 6

Md Maximum defrost length 0 ~ 99 minutes 20 30

AU Maximum Alarm Temperature ~ 99°C / ~210°F 99°C / 99°F 99°C

AL Minimum Alarm Temperature -55°C / -67°F -55°C / -55°F -55°C

iP

Digital input polarity: oP = activated by closing the contact; cL = activated by opening the contact cL ~ oP cL cL

iF

Digital input configuration: EA = external alarm; EA message is displayed: bA = serious alarm; CA

message is displayed: do = door switch function: dF = defrost activation: Au = not used: Hc =

inversion of the kind of action

EA / bA / do / dF / Au / db /

Hc

EA EA

di

Digital input delay. With iF = EL or bA delay between the detection of the external alarm condition

and its signalling. With iF = do it represents the delay to activate the door open alarm

0 ~ 99 minutes 5 5

LS Minimum Set Point -55°C / -67°F -55°C / -55°F 4°C

US Maximum Set Point 99°C / 210°F 99°C / 99°F 16°C

od Output activation delay at startup 0 ~ 99 minutes 0 0

Cy Compressor on time faulty probe. Cy = 0 compressor always OFF 0 ~ 99 minutes 15 5

Cn Compressor off time faulty probe. Cn = 0 compressor always active 0 ~ 99 minutes 30 10

CF Measurement units: °C = Celsius; °F = Fahrenheit °C / °F °C °C

dY Display delay 0 ~ 15 minutes 0 0

dF

Display during defrost: rt = real temperature; it = start defrost temperature: St = SET POINT: dF =

label dF

rt / it / St / dF it it

Ad Temperature alarm delay 0 ~ 99 minutes 15 15

dA Exclusion of temperature alarm at startup 0 ~ 99 minutes 90 90

dC

Compressor and fan status when door open: no = normal; Fn = Fans OFF; cP = Compressor OFF; Fc =

Compressor and fans OFF

no / Fn / cP / Fc no no

rd

Regulation with door open: n = no regulation if door is opened; Y = when di is elapsed regulation

restarts even if door open alarm is present

n ~ Y Y Y

Pt Parameter code table Read Only - -

rL Firmware release Read Only

--

Parameter Menu (selected parameters)

Hidden Parameter Menu (Full list including above parameters)

Dixell XR02CX Parameters

Issue: 01.06.2023 Page 17

Table 8: Trouble Shooting

FAULT

POSSIBLE CAUSE

CHECK

SOLUTION

COMPRESSOR

Compressor will

not start

Power supply

Is power switched on?

If not - switch on

Phase and neutral present?

Check/rectify

Voltage within tolerance?

Check/rectify

Compressor contactor not

pulled in (contactor in

indoor unit)

Is there correct voltage to

contactor coil? (Terminals A1 &

A2)

If yes - coil faulty. Replace

contactor

If no - check for break in control

circuit

Is the controller calling for cooling?

(Cooling LED lit)

If yes - check for break in control

circuit

If no - is controller set correctly?

Is the controller on defrost?

(Defrost LED lit)

If yes - wait for defrost to finish

or terminate defrost and check

operation

Is there an alarm condition shown

on the controller display?

Refer to manual for alarm

identification and resolution

Has a safety switch tripped out?

Check cause and rectify

Compressor contactor

pulled in but compressor

not running

Is voltage being switched across

contactor? (Terminals L1 & T1)

If yes - check voltage present at

compressor terminals. If correct -

compressor may have tripped

internal overload or be faulty

If no. Replace faulty contactor

LP switch tripped (on

indoor unit)

Low pressure condition

Low refrigerant charge/icing of

evaporator coil/evaporator fan

failure/blockage in piping. Check

& rectify cause

Compressor internal

overload tripped

Is the correct voltage at

compressor terminals?

Compressor has overheated -

allow time for reset (up to 3

hours) and rectify cause

Faulty compressor run

capacitor

Check visual condition of capacitor

and check capacitance reading with

capacitor meter.

Replace capacitor as required

Motor windings faulty

Check resistances of windings

Windings that show open circuit

could be due to internal overload

trip. Wait for reset and recheck.

If continually open circuit - motor

faulty. Replace compressor.

Compressor seized

Does compressor attempt to start

but does not run correctly (makes

humming sound)? Are amps

equivalent to LRC rating?

If all electrical checks on

components as above are OK -

Change compressor

Compressor runs

but no effect on

suction/discharge

pressures

Mechanical failure within

compressor

Are compressor motor amps lower

than expected? If so - potentially

valve damage or other internal

wear/damage

Try pump test on compressor. If

test fails - replace compressor.

Compressor

starts and stops

too quickly

Operating on safety

controls

Check LP switch and compressor

internal overload

Rectify cause and recheck

Refrigerant levels

Is there too little refrigerant in the

system causing LP switch tripping?

Check refrigerant level and

adjust accordingly

Faulty contactor (if fitted)

Are the contacts chattering on the

contactor?

Contacts may be dirty or worn.

Check and replace contactor as

necessary

Anti short cycle time in

controller is set too low

Anti short cycle time should be set

for minimum of 3 minutes

Check and rectify

Temperature differential in

controller set too low

Differential should be set for

minimum of 2°C

Check and rectify

Room temperature rising

too quickly

Are doors open to room?

Check and rectify

Issue: 01.06.2023 Page 18

FAULT

POSSIBLE CAUSE

CHECK

SOLUTION

Loose / broken wiring

connection

Make sure all electrical

connections are sound

Compressor is

noisy

Vibration

Rubber feet mountings worn or

bolts are loose/missing

Replace mountings and

tighten/replace bolts as

necessary

Liquid refrigerant

Does compressor 'knock' when

starting up or running? Liquid

refrigerant may be present in oil

and compression chambers

Identify cause of liquid return to

compressor and rectify

Overloaded

Are suction and discharge

pressures too high? There may be

too much load on the compressor.

Identify cause of increased load

and rectify

High discharge pressure

Blocked condenser / faulty

condenser fan

Check and rectify

Refrigerant overcharge

Check and rectify

Non-condensable in system

Reclaim refrigerant, evacuate &

recharge

Internal wear / damage

Noise is always present even if all

operating conditions are OK?

Replace compressor

Compressor body

too hot

System load too high

Are suction and discharge

pressures high?

Reduce load at evaporator

High discharge pressure

Blocked condenser / faulty

condenser fan / airflow around unit

restricted

Check and rectify

Lack of compressor cooling

Suction superheat too high

Check refrigerant charge is

correct

Too much heat load at

evaporator - reduce

Are refrigerant lines correctly

insulated?

Compressor starting too

frequently

Refer section above ' Compressor

starts and stops too quickly'

Refer section above ' Compressor

starts and stops too quickly'

Discharge gas bleeding into

suction side

Does suction pressure rise

abnormally quickly when

compressor stops.

Compressor valves may be

damaged - replace compressor

CONDENSER FAN

Condenser fan

not running

Power supply

See compressor will not start

section

See compressor will not start

section

Compressor contactor not

pulled in

See compressor will not start

section

See compressor will not start

section

Compressor contactor

pulled in

Is voltage being switched across

contactor? (Terminals L1 & T1)

If yes - check voltage to fan

motor. If correct voltage present

at motor - fan faulty. Replace fan

motor

If no. Replace faulty contactor

Fan being controlled by Fan

Speed Controller (if fitted)

Is system operating pressure below

FSC setting?

If yes - all OK (check fan operates

when pressure rises)

Fan capacitor fault

Check visual condition of capacitor

and check capacitance reading with

capacitor meter.

Replace capacitor as required

Motor fault

If FSC fitted - bypass FSC to test

motor. If motor still does not run -

motor is faulty

Replace fan motor

Condenser fan

runs but only

slowly

Fan capacitor or motor fault

See above

See above

Is fan being controlled by a

FSC?

Adjust FSC setting - does fan speed

up?

If yes - all OK

Issue: 01.06.2023 Page 19

FAULT

POSSIBLE CAUSE

CHECK

SOLUTION

FSC faulty

If fan runs slowly even after

adjusting FSC with head pressure

rising - FSC may be faulty

Replace FSC

INDOOR UNIT

Indoor Fan not

running

Power supply

Is power switched on?

If not - switch on

Is rocker switch on unit switched

on?

If not - switch on

Motor fault

Is there correct voltage at motor

terminals?

If yes - motor faulty. Replace

motor

If no - check supply / wiring

connections

Check fan capacitor

Replace as required

No display on

controller

Power supply

Is power switched on?

If not - switch on

Is rocker switch on unit switched

on?

If not - switch on

Is there correct voltage at

controller

If yes - controller faulty. Replace

controller

If no - check supply / wiring

connections

Power to

controller but no

cooling from unit

Is unit in defrost mode?

Check if defrost LED is displayed

If yes - all OK. Wait for defrost to

end

If no - further checks required

Is unit in cooling mode

(cooling LED displayed)

Is room at required temperature?

All OK

Room above required

temperature?

Further checks required

Reduced airflow

Fan motor

Is fan rotating slowly?

Further checks required on fan

(see above)

Air inlets blocked

Is anything blocking air inlet grilles

at side of unit

Clear items from around unit

Evaporator coil dirty

Check condition of coil

Clean as necessary

Evaporator coil iced up

Switch off unit and allow to defrost

Checks required to determine

cause of icing

SYSTEM

Insufficient

cooling

Lack of refrigerant

Remove charge and note weight

Leak test / pressure test system,

repair leak and top up with

correct refrigerant charge

Condenser coil dirty

Visual check of coil condition

Clean condenser coil

Lack of ventilation to

outdoor unit

Any obstructions around unit?

Clear same to ensure good

ventilation

Evaporator coil dirty

Visual check of coil condition

Clean evaporator coil

Evaporator coil iced up

Switch off unit and allow to defrost

Checks required to determine

cause of icing

System settings

Controller set correctly?

Adjust as necessary

Service valves do not open

correctly

Are valves fully open?

Adjust as necessary

Restriction in capillary

device

Low suction pressure / sweating on

capillary

Clear restriction or replace

capillary

Damage to piping

Restricted refrigerant flow

Replace piping as required

Issue: 01.06.2023 Page 20

Figure 18: Declaration of Incorporation (Outdoor Unit)

This manual suits for next models

6

Table of contents

Other J&E Hall Freezer manuals

Popular Freezer manuals by other brands

Frigidaire

Frigidaire GLFC2528FW - 24.9 cu. Ft. Manual Defrost Chest... Service data sheet

AEG

AEG SCB818E6TS user manual

Waeco

Waeco CoolMatic CB-36 operating manual

Maytag

Maytag GFU2046GRW owner's manual

Silver King

Silver King SKFMW50-ESUS1 Technical manual and replacement parts list

Hotpoint

Hotpoint RFR51V User instructions