Page 2/39

Table of contents Page

Introduction............................................................................................................................................................3

Safety Precautions ................................................................................................................................................4

The Checklist.........................................................................................................................................................5

Before Running the Turbine .....................................................................................................................5

After Stopping the Turbine........................................................................................................................5

Electrical connection diagramm (1/2)....................................................................................................................6

Electrical connection diagramm (2/2)....................................................................................................................7

Power Supply............................................................................................................................................7

Charging the Battery.................................................................................................................................7

Glow Plug .................................................................................................................................................7

Fuel / Fuel Care.....................................................................................................................................................8

Fuel System..............................................................................................................................................8

Hopper Tank.............................................................................................................................................8

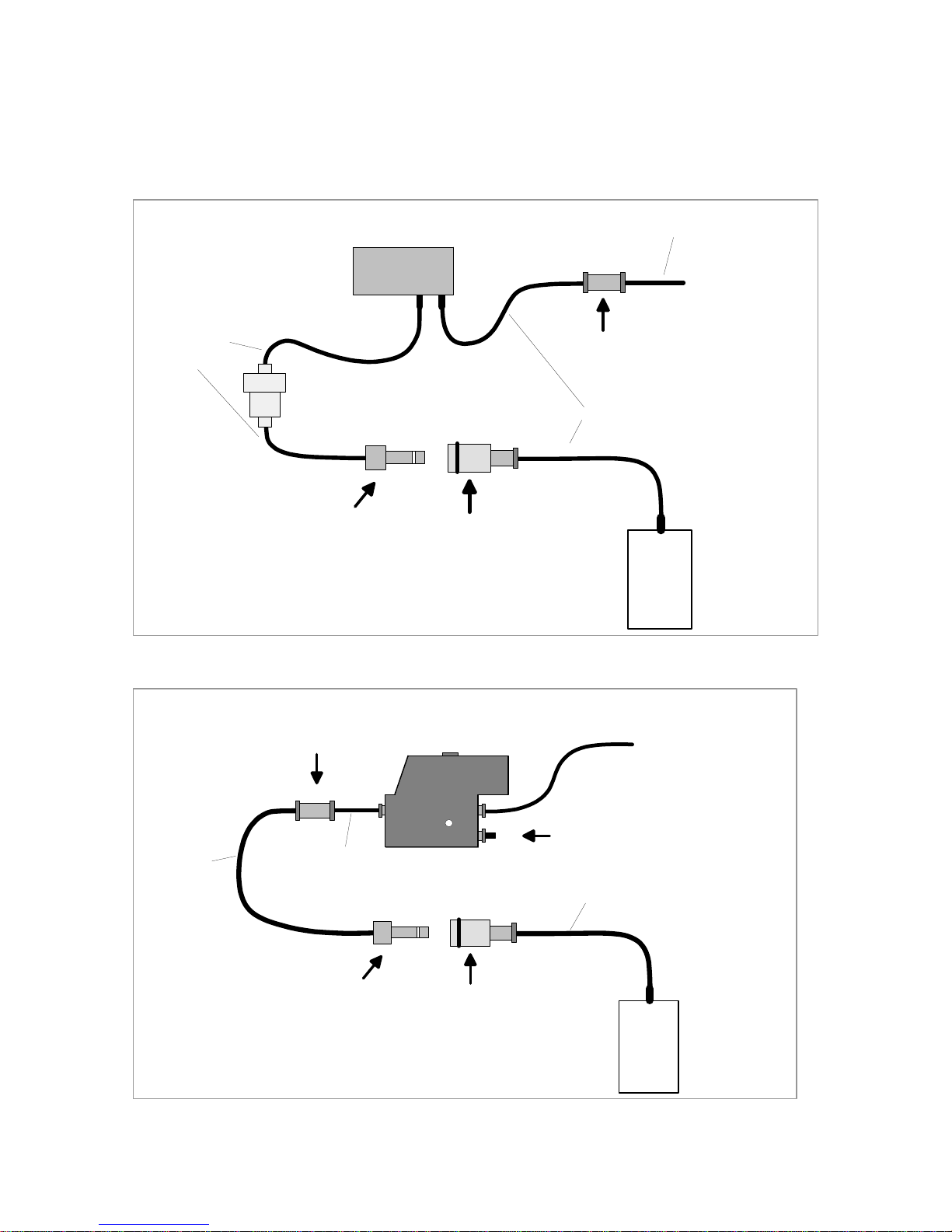

Fuel System Connection Diagram............................................................................................................9

Starting Gas Diagram.............................................................................................................................10

Filling the Starting Gas Tank:.................................................................................................................11

Mounting the Turbine...........................................................................................................................................12

Connections at the Turbine.................................................................................................................................13

The LED I/O Board..............................................................................................................................................14

Aligning the ECU to your R/C System.................................................................................................................15

Manual Mode.......................................................................................................................................................18

Turbine Starting / Running...................................................................................................................................19

Turbine Stopping / Cool Down.............................................................................................................................20

Manual Off..............................................................................................................................................20

Auto Off ..................................................................................................................................................20

Automatic Cooling Process ....................................................................................................................20

Battery / Fuel Warning Function..........................................................................................................................21

Turbine Running States.......................................................................................................................................21

Explanation of the Turbine States ..........................................................................................................21

Explanation for Turbine Shut Down........................................................................................................24

Ground Support Unit (GSU)................................................................................................................................25

GSU Control Panel Descriptions............................................................................................................25

GSU Switch Descriptions .......................................................................................................................26

GSU LED Descriptions...........................................................................................................................26

Menu Structure....................................................................................................................................................27

Menu Selections.....................................................................................................................................27

Selecting a Menu............................................................................................................................27

Change Values / Items ...................................................................................................................27

The RUN Menu.......................................................................................................................................28

The Min/Max Menu.................................................................................................................................28

The R/C Check Menu.............................................................................................................................28

The INFO Menu......................................................................................................................................29

The Statistic-Menu..................................................................................................................................30

The LIMITs Menu ...................................................................................................................................30

Troubleshooting...................................................................................................................................................31

Maintenance........................................................................................................................................................32

Parts List..............................................................................................................................................................33

Optional Accessories..............................................................................................................................33

Airspeed Sensor..................................................................................................................................................34