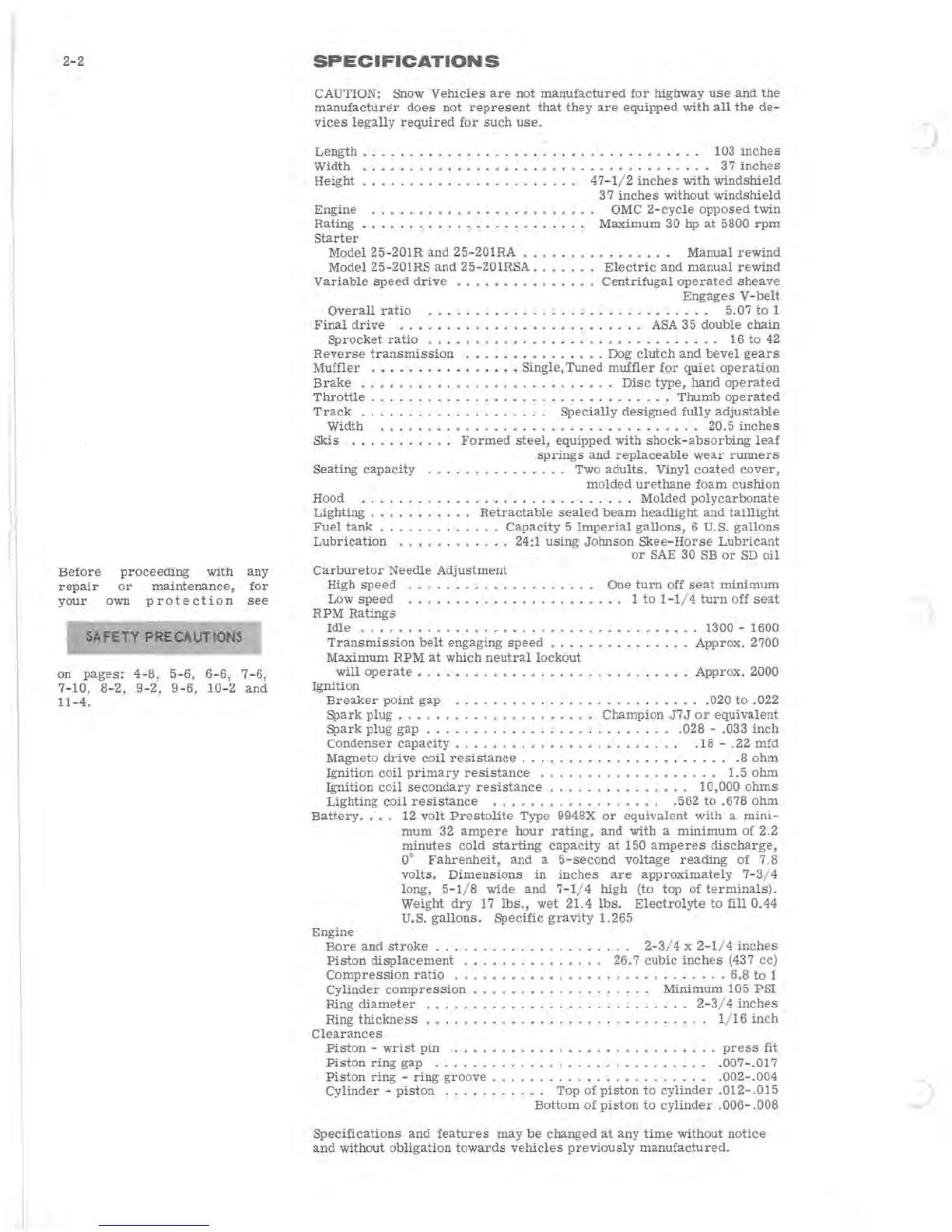

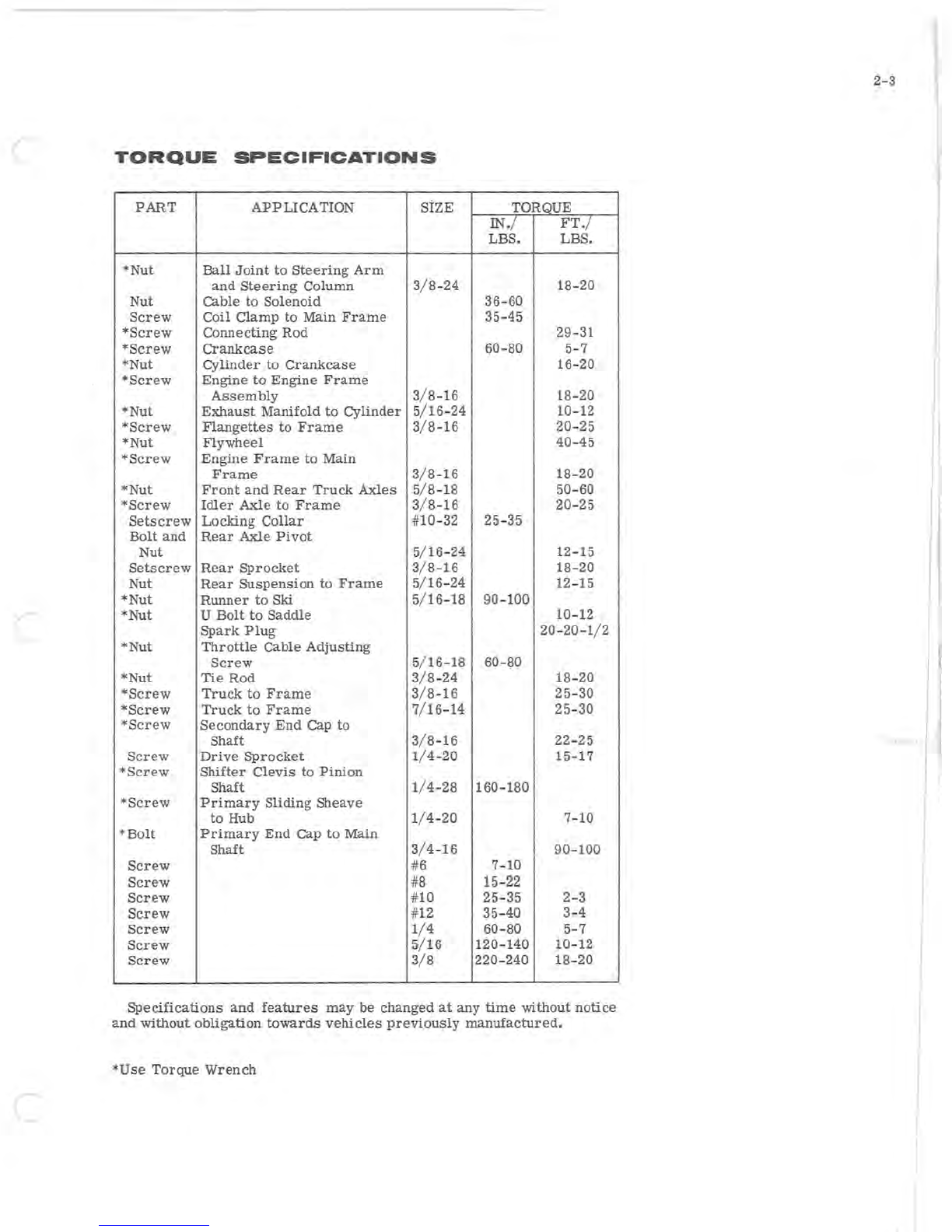

Johnson SKEE-HORSE 25-201R User manual

Popular Snowmobile manuals by other brands

BRP

BRP Ski-Doo MXZ 120 2023 Operator's manual

Arctic Cat

Arctic Cat ZR 900 Series 2006 Operator's manual

Arctic Cat

Arctic Cat Wildcat EFI Mountain Cat 1994 Service manual

Ski-Doo

Ski-Doo Formula Plus 1985 Operator's manual

BOMBARDIER

BOMBARDIER Ski-Doo Alpine 74 1959 owner's manual

Arctic Cat

Arctic Cat Cougar Service manual