CONTENTS

3

USE AND MAINTENANCE INSTRUCTIONS FOR THE USER

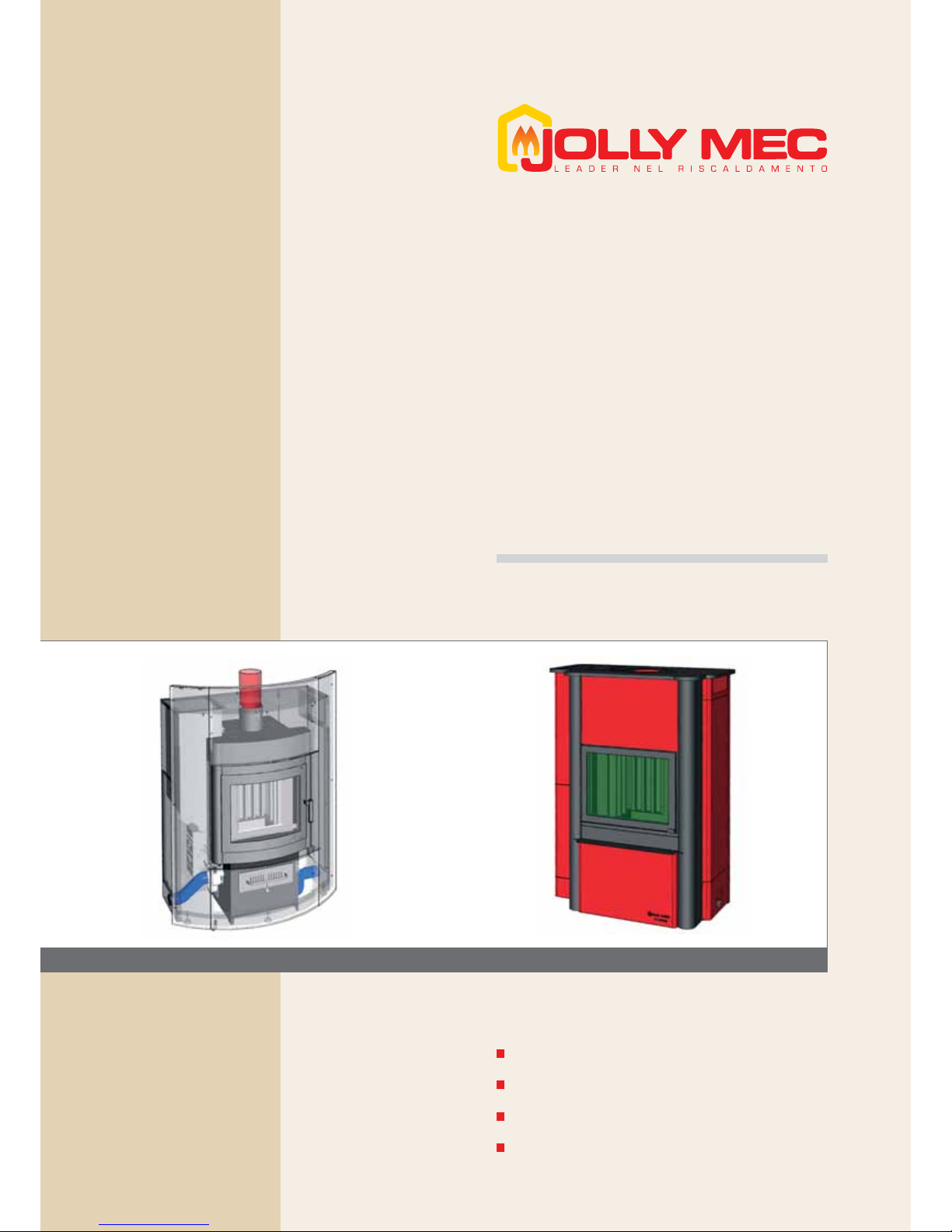

1.1 Introduction - AIR HEATING FOGO and FOGHEA

.........................................................................................................................................................................

4

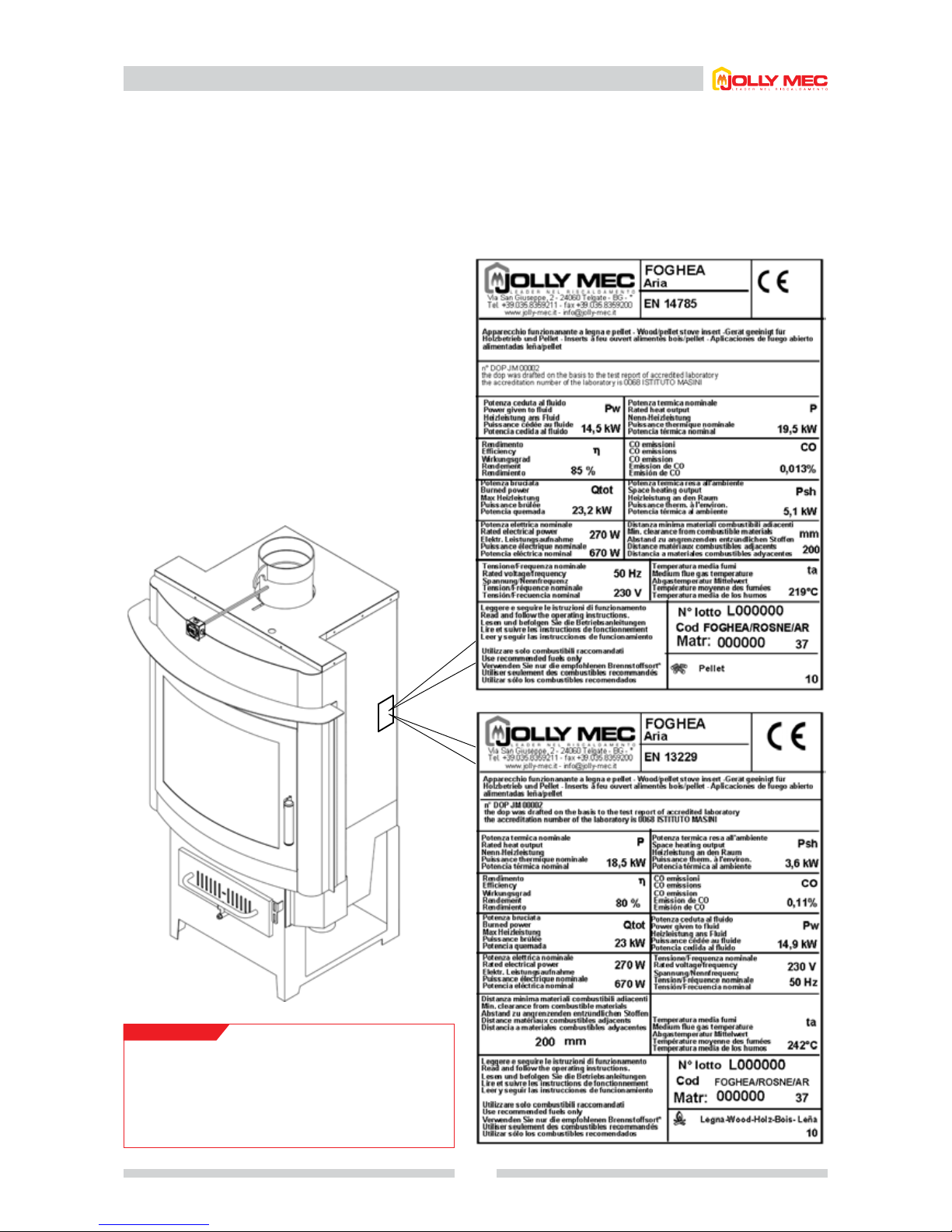

1.2 Stove identication

...............................................................................................................................................................................................................................................

5

1.3 Technical specications

.....................................................................................................................................................................................................................................

6

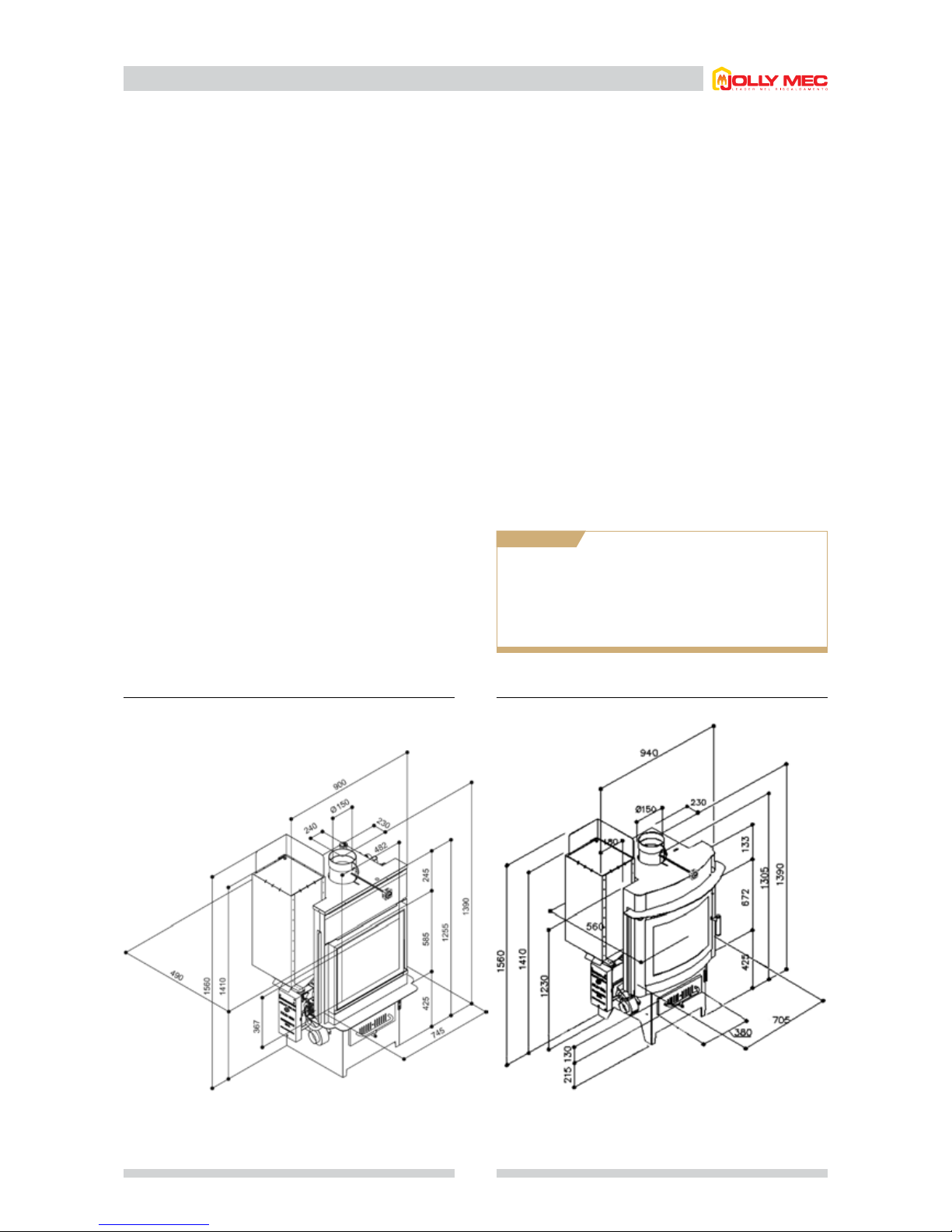

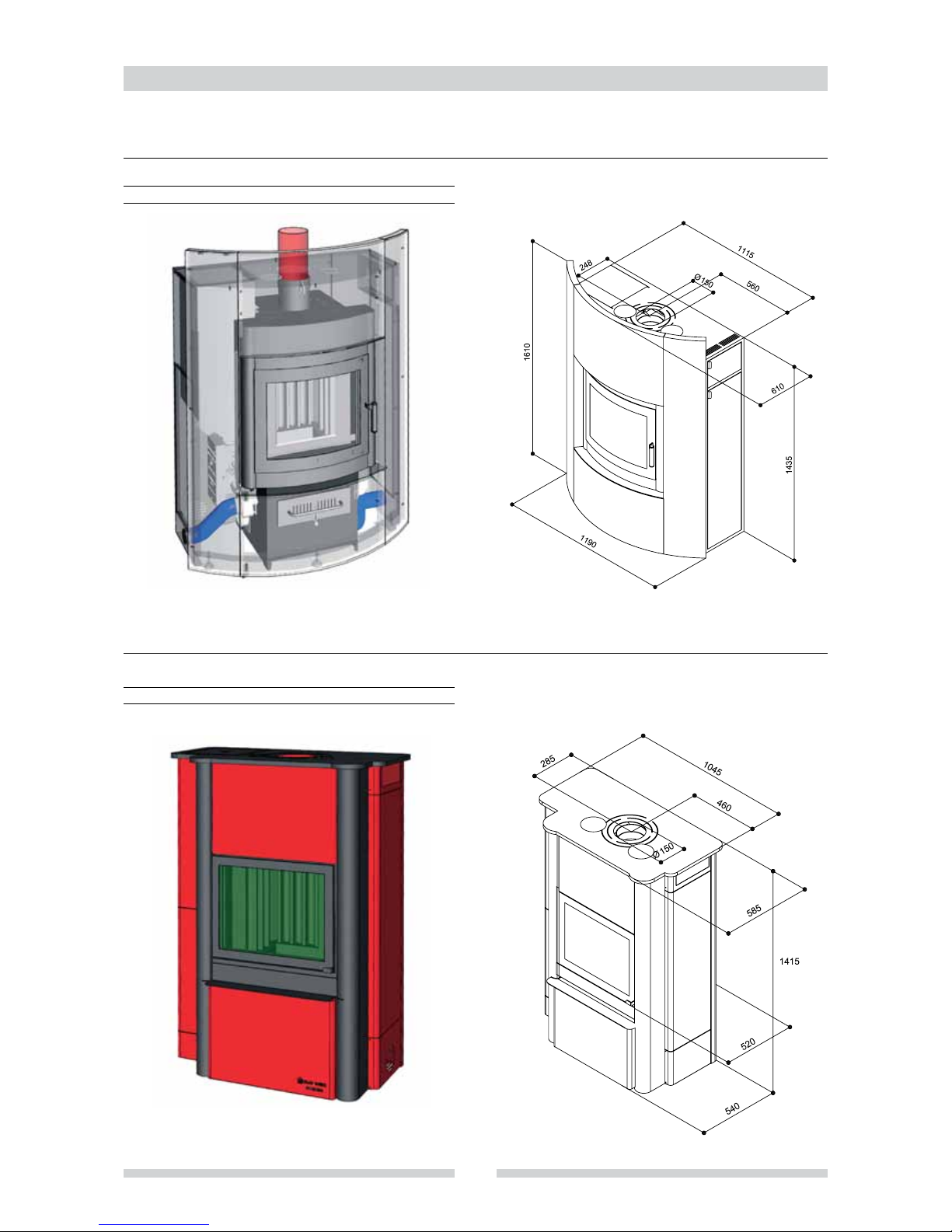

1.4 Dimensions and parts

.........................................................................................................................................................................................................................................

7

1.5 Examples of combined FOGO and FOGHEA with curved or straight front stove clad

.............................................................................................

8

1.6 Burner and pellet hopper parts

.....................................................................................................................................................................................................................

9

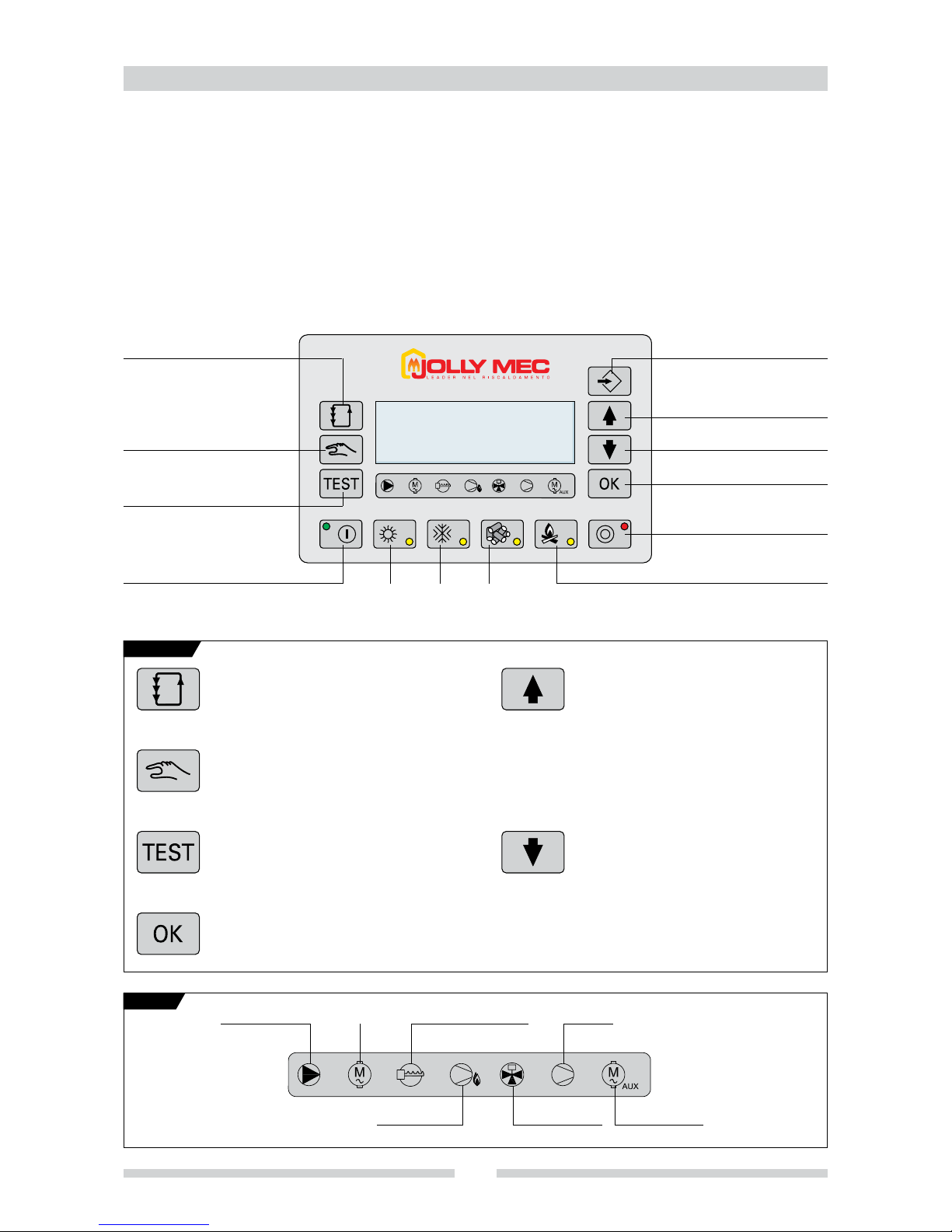

1.7 New-generation simplied electronic controller

...............................................................................................................................................................................

10

1.7.1 Description and use of simplied electronic controller for air heating

............................................................................................................

10

1.7.2 Setting the language

......................................................................................................................................................................................................................

11

1.7.3 Lighting in pellet mode, electronic controller

..................................................................................................................................................................

11

1.7.4 Quick menu

.........................................................................................................................................................................................................................................

13

1.7.5 Output setting for pellet mode

.................................................................................................................................................................................................

14

1.7.6 Room temperature setting for pellet mode

.......................................................................................................................................................................

14

1.7.7 Silencing an alarm

..........................................................................................................................................................................................................................

15

1.7.8 Summer ventilation

.........................................................................................................................................................................................................................

15

1.7.9 Humidier use

....................................................................................................................................................................................................................................

15

1.7.10 Eliminating problems regarding combustion

..................................................................................................................................................................

16

1.7.11 Electronic components test

.......................................................................................................................................................................................................

16

1.7.12 Chronothermostat

............................................................................................................................................................................................................................

17

1.7.13 Lighting in wood mode

.................................................................................................................................................................................................................

19

1.7.14 Service

....................................................................................................................................................................................................................................................

20

1.8 Optimising combustion and damper use

.............................................................................................................................................................................................

21

1.9 Advice and instructions

...................................................................................................................................................................................................................................

22

1.10 Cleaning the stove

.............................................................................................................................................................................................................................................

23

1.11 Parts that can be removed to clean the stove

.................................................................................................................................................................................

24

1.12 Fan removal

...........................................................................................................................................................................................................................................................

25

1.13 Troubleshooting

...................................................................................................................................................................................................................................................

26

1.14 Optionals

..................................................................................................................................................................................................................................................................

29

1.15 Supplementary larger capacity pellet hoppers

.................................................................................................................................................................................

30

1.16 Pellet quality

...........................................................................................................................................................................................................................................................

31

1.17 Use and keeping the installation and maintenance card

..........................................................................................................................................................

32

1.18 Ecological regulation

...............................................................................................................................................................................................................................

33

1.18.1 Waste materials and their disposal

..............................................................................................................................................................................

33

1.18.2 Disposal of the machine

......................................................................................................................................................................................................

33

ASSEMBLY INSTRUCTIONS FOR THE INSTALLER

2.1 Flue

.........................................................................................................................................................................................................................................................

34

2.2 Prearrangement for electrical connections, air intakes and positioning

..........................................................................................................................

35

2.3 Adjusting the feet

.................................................................................................................................................................................................................................................

36

2.4 Foghea air heating stove cladding assembly steps

.......................................................................................................................................................................

36

2.5 Fasi di montaggio rivestimento termostufa Fogo ad aria

..........................................................................................................................................................

38

2.6 Fitting the damper and regulating unit

.................................................................................................................................................................................................

40

2.7 Caldo control

.........................................................................................................................................................................................................................................................

41

2.8 Installing hot air ducting pipes

....................................................................................................................................................................................................................

42

2.9 Example of hot air ducting..........................................................................................................................................................................................................................................................................................43

2.10 Room recycling examples

.............................................................................................................................................................................................................................

44

2.11 Simplied electronic controller wiring diagram

.................................................................................................................................................................................

45