2

1. General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

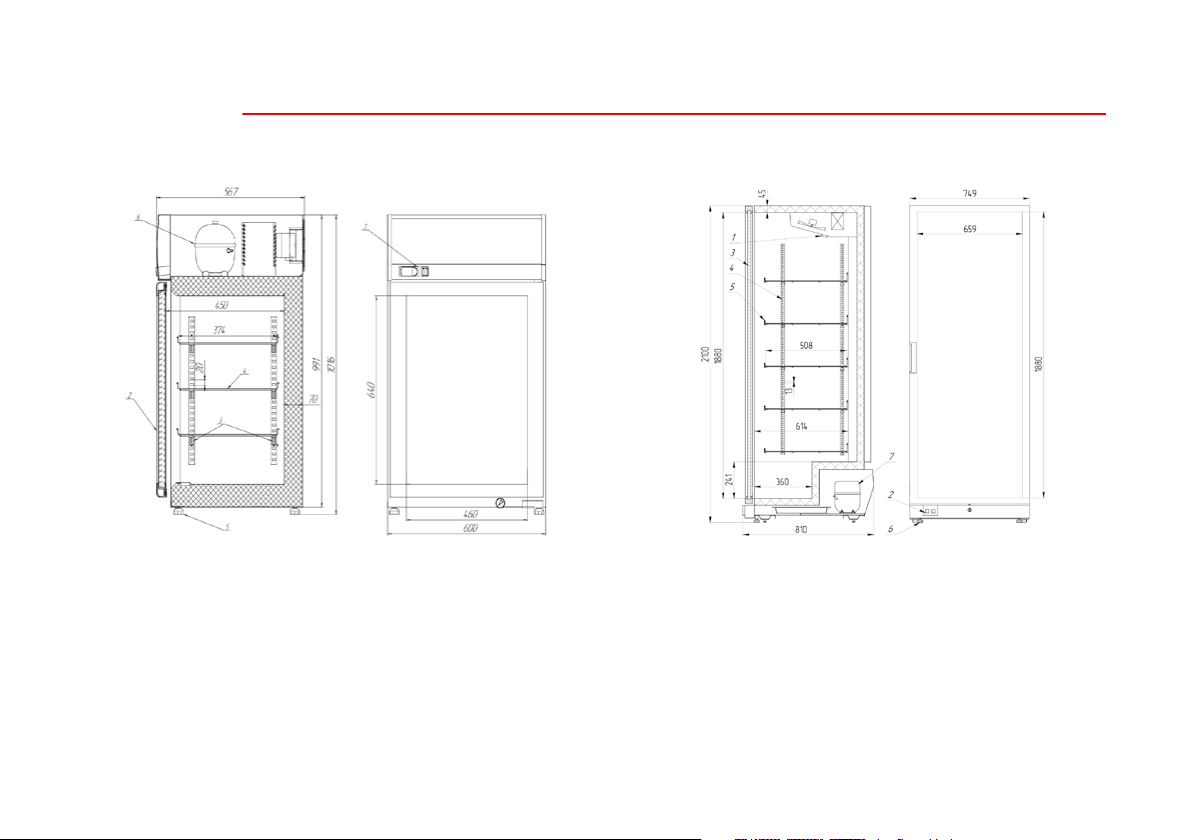

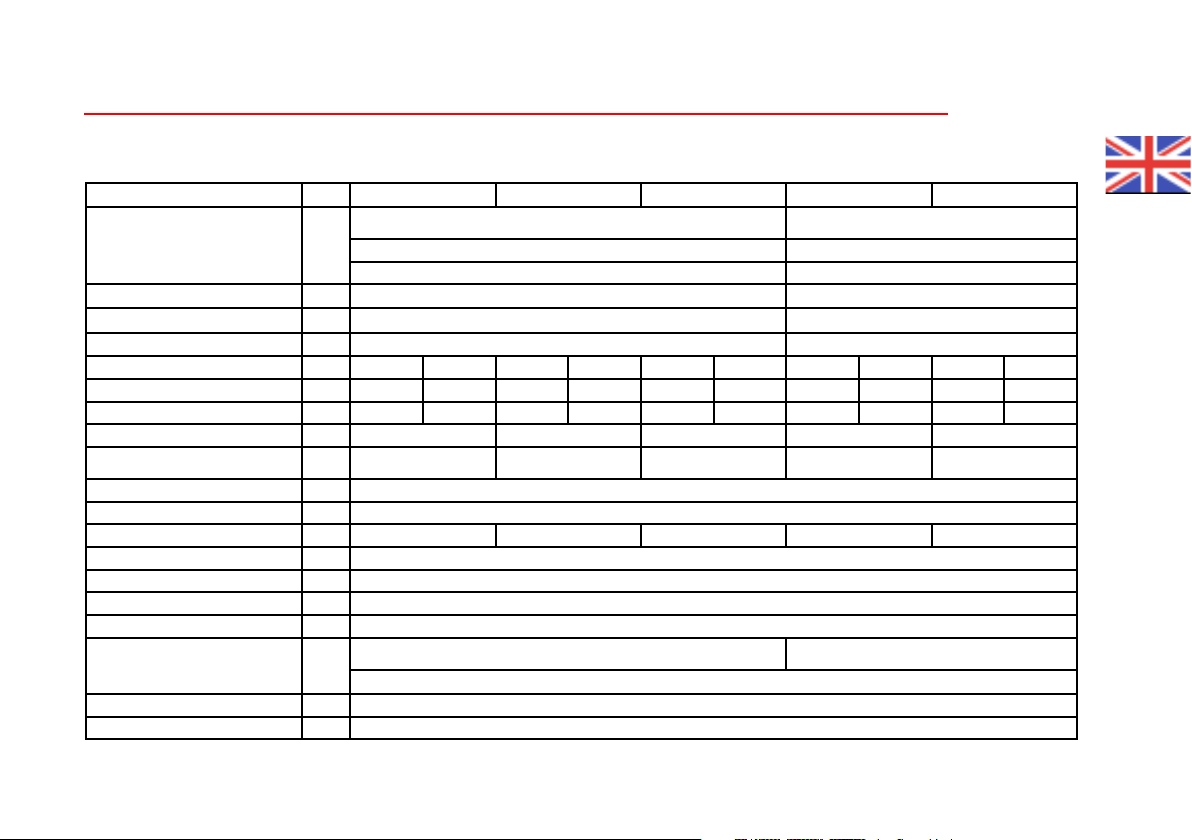

2. Technical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . .9

3. Transportation, Installation and Startup . . . . . . . . . . . . . . . . 12

3.1. Transportation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2. Storage of the Equipment. . . . . . . . . . . . . . . . . . . . . . . . 12

3.3. Requirements to the Place of Operation . . . . . . . . . . . . . . . 12

3.4. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.5. Connecting Electricity and Startup . . . . . . . . . . . . . . . . . . 13

4. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1. Operation Requirements . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2. Temperature Settings . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3. Electronic controller CAREL . . . . . . . . . . . . . . . . . . . . . 15

4.3.1. Light Signals on the Electronic Controller`s Display . . . . . . . 15

4.3.2. Setting of the Temperature . . . . . . . . . . . . . . . . . . . . . . 15

4.3.3. Additional Defrosting . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3.4. Warning Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.4. Electronic controller EVCO . . . . . . . . . . . . . . . . . . . . . . 16

4.4.1. Light Signals on the Electronic Controller`s Display . . . . . . . 16

4.4.2. Setting of the Temperature . . . . . . . . . . . . . . . . . . . . . . 16

4.4.3. Warning Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5. Electronic controller Dixell. . . . . . . . . . . . . . . . . . . . . . . 17

4.5.1. Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.5.2. Checking the set temperature . . . . . . . . . . . . . . . . . . . . 17

4.5.3. Changing the temperature.. . . . . . . . . . . . . . . . . . . . . . 17

4.5.4. Manual defrost request . . . . . . . . . . . . . . . . . . . . . . . . 17

4.5.5. List of alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1. Cleaning and Maintenance. . . . . . . . . . . . . . . . . . . . . . . 18

5.1.1. Cabinet Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1.2. Defrosting of the Evaporator. . . . . . . . . . . . . . . . . . . . . 18

5.1.3. Condenser Maintenance . . . . . . . . . . . . . . . . . . . . . . . 18

5.1.4. Door Seal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1.5. Other Terms and Conditions . . . . . . . . . . . . . . . . . . . . 19

6. Fault Identication and Repair. . . . . . . . . . . . . . . . . . . . . . 19

7. Disposal of Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . 20

COOLING AND FREEZING UPRIGHT CABINETS INSTRUCTION MANUAL

Dear customers! Please read this manual thoroughly before operating the equipment!

Following our instructions, you will ensure long and eective performance of the equipment.

Content