CONTENTS

SERVICE ACCESS

FACE PLATE UNIT ............................................................................................................1

BACK COVER UNIT ..........................................................................................................2

FRONT COVER UNIT .......................................................................................................3

SIDE COVER UNIT ...........................................................................................................4

MACHINE BASE ................................................................................................................5

MECHANICAL ADJUSTMENT

MACHINE SOCKET...........................................................................................................6

NEEDLE BAR HEIGHT......................................................................................................7

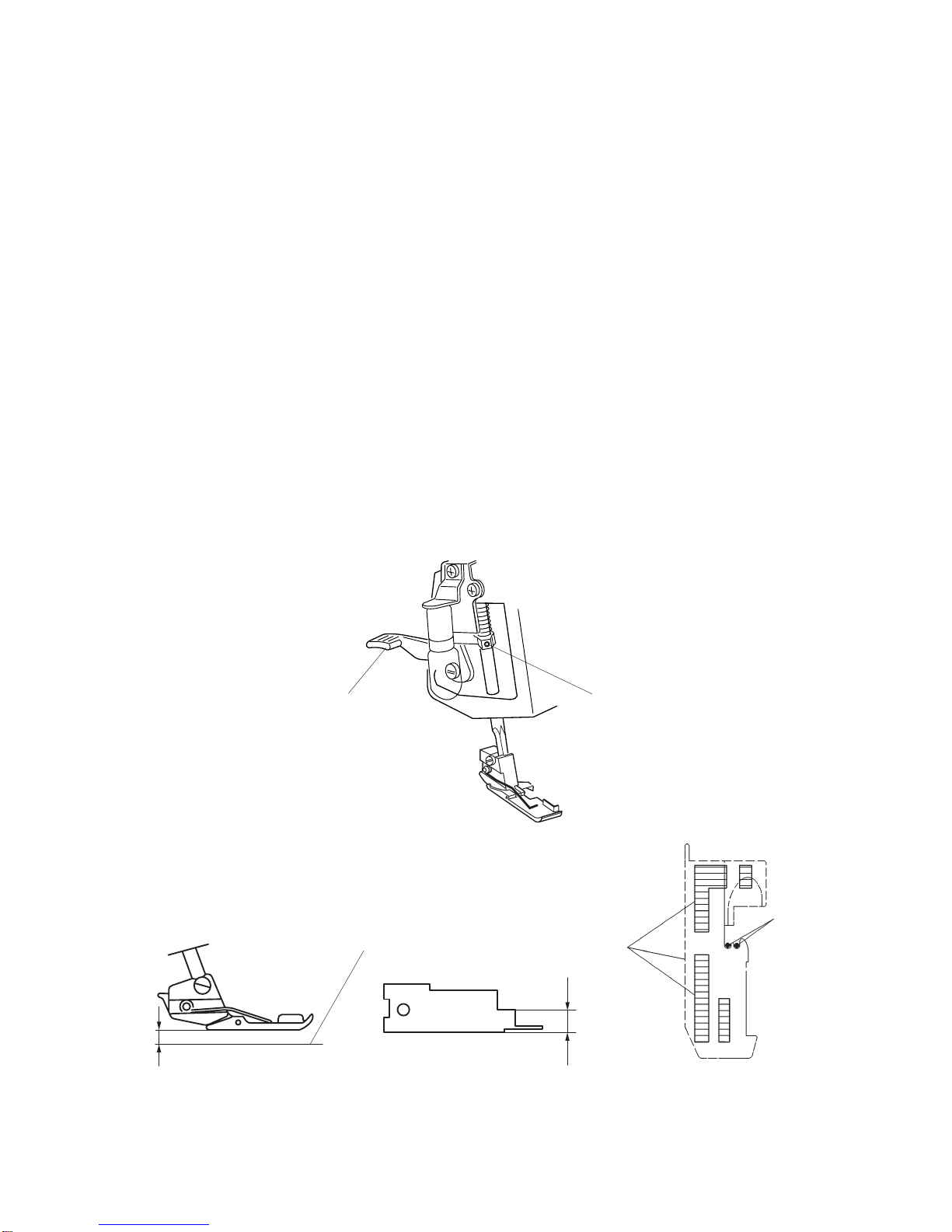

PRESSER BAR HEIGHT ...................................................................................................8

FEED DOG HEIGHT..........................................................................................................9

TIMING OF THE NEEDLE AND THE FEED DOG ............................................................10

TIMING OF THE NEEDLE AND THE UPPER KNIFE .......................................................11

HEIGHT OF THE LOWER LOOPER .................................................................................12

CLEARANCE BETWEEN THE NEEDLES AND THE LOWER LOOPER

/NEEDLE GUARDS ...................................................................................................13-15

CLEARANCE BETWEEN THE NEEDLES

AND THE FIXED NEEDLE GUARD .........................................................................16

POSITION OF THE CHAINING FINGER ..........................................................................17

POSITION OF THE UPPER LOOPER ..............................................................................18

TIMING OF THE NEEDLE AND THE LOWER LOOPER ..................................................19

TIMING OF THE UPPER AND LOWER LOOPERS ..........................................................20

CLEARANCE BETWEEN THE LOOPERS........................................................................21

CLEARANCE BETWEEN THE NEEDLE AND THE UPPER LOOPER.............................22

POSITION OF THE KNIVES .............................................................................................23

POSITION OF THE LOWER LOOPER THREAD GUIDE .................................................24

STITCH LENGTH ..............................................................................................................25

THREAD TENSION DIALS ................................................................................................26

PLAY OF MAIN SHAFT .....................................................................................................27

BELT TENSION .................................................................................................................28

OILING ........................................................................................................................... 29

GAUGES FOR SERVICING .......................................................................................... 30

PARTS LIST .................................................................................................................. 31-50