2

【Major Specification】

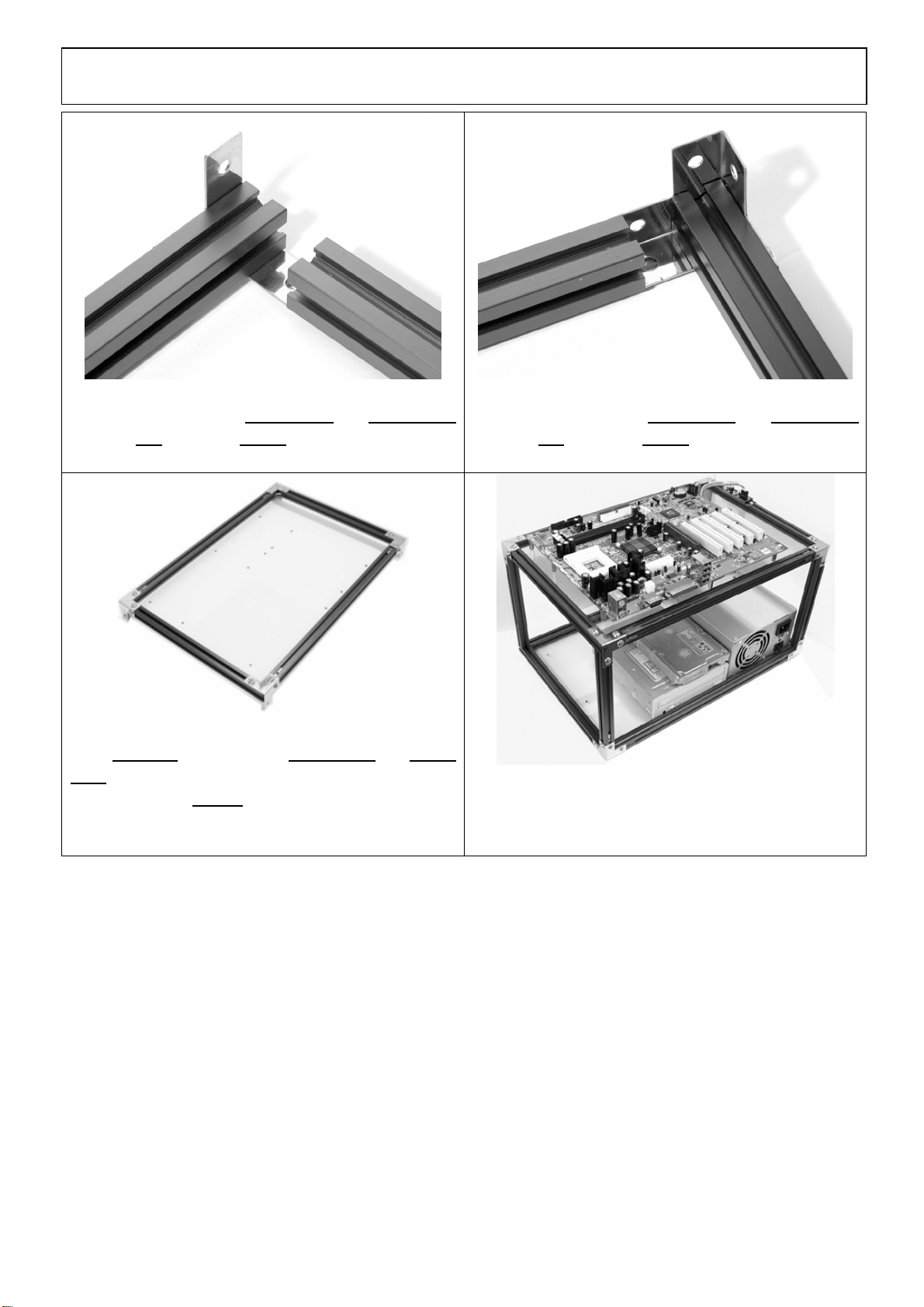

Lubic-BASIC NE Simplified PC Case/ PC Inspection Board

Outer Dimension 288mm (D) / 384mm (W) / 224mm (H) (For assembly example case)

<Disclaimer>

Although this product is created with close attention, an unnoticeable scratch may be found only occasionally.

We do NOT warranty for the scratches unless it degrades the functionality.

[Notes in advance to assembly work]

●Please read this manual carefully before starting an assembly work.

●Please check that all contents are all lined up. * Refer to the “Package Content List”.

If anything is missing, please contact to the support desk described on the cover page.

●Pleasemount the fixing brackets on the acrylic panels before use. Otherwise, the panels may be damaged if the brackets were

mounted after assembly.

[Notes during assembly work]

●Please work at horizontal and well-balanced place.

●Please wear the attached cotton gloves while working to prevent yourself from being hurt or prevent acrylic panel from being dirty.

●Please conduct work with following the work procedures. Incorrect process may lead to the potential cause of damages or

accidents.

●Please be careful not to scratch any surrounding furniture with frames or metallic material.

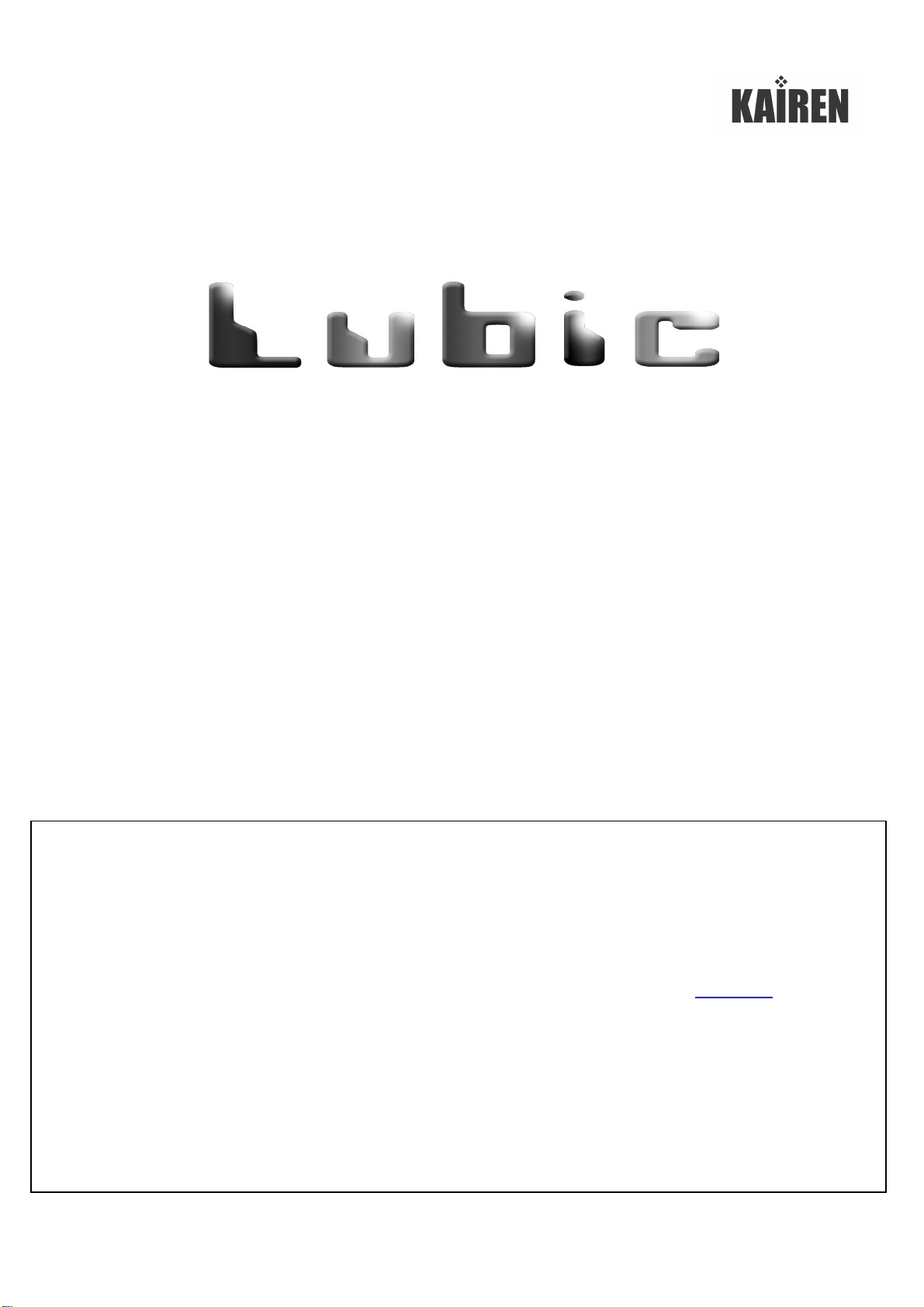

●Preparation of cross slot screwdriver and 6mm angle nut spinner is required for assembling the LUBIC BASIC kit.

●All accessories attached to this product are processed into the size that fits to the finished product created by following the work

procedures described in the instruction manual.

Please be careful with the size when assembling in the different work procedure, extension and remodeling.

●Protection film is coated on the metal fittings or acrylic panels. Please remove the film upon use.

●Please be very careful with the direct contact between frames or metal fittings and acrylic panels. It may lead to the potential

cause of damages or corruptions.

●Please keep the used tools or unused parts out of the reach of children after work.

[Installation Part]

Mounting screws on ACMB-AO.

ACMB-AO is an acrylic panel compatible with ATX, Micro-ATX, FLEX-ATX, Mini-ITX.

As spacer screws are not mounted on this panel upon product purchase, spacer screw mounting work is required.

Please use enclosed “nut spinner”for mounting spacer screws.