Table of Contents

PARKING SAFELY .....................................................2

SAFETY DECALS .......................................................2

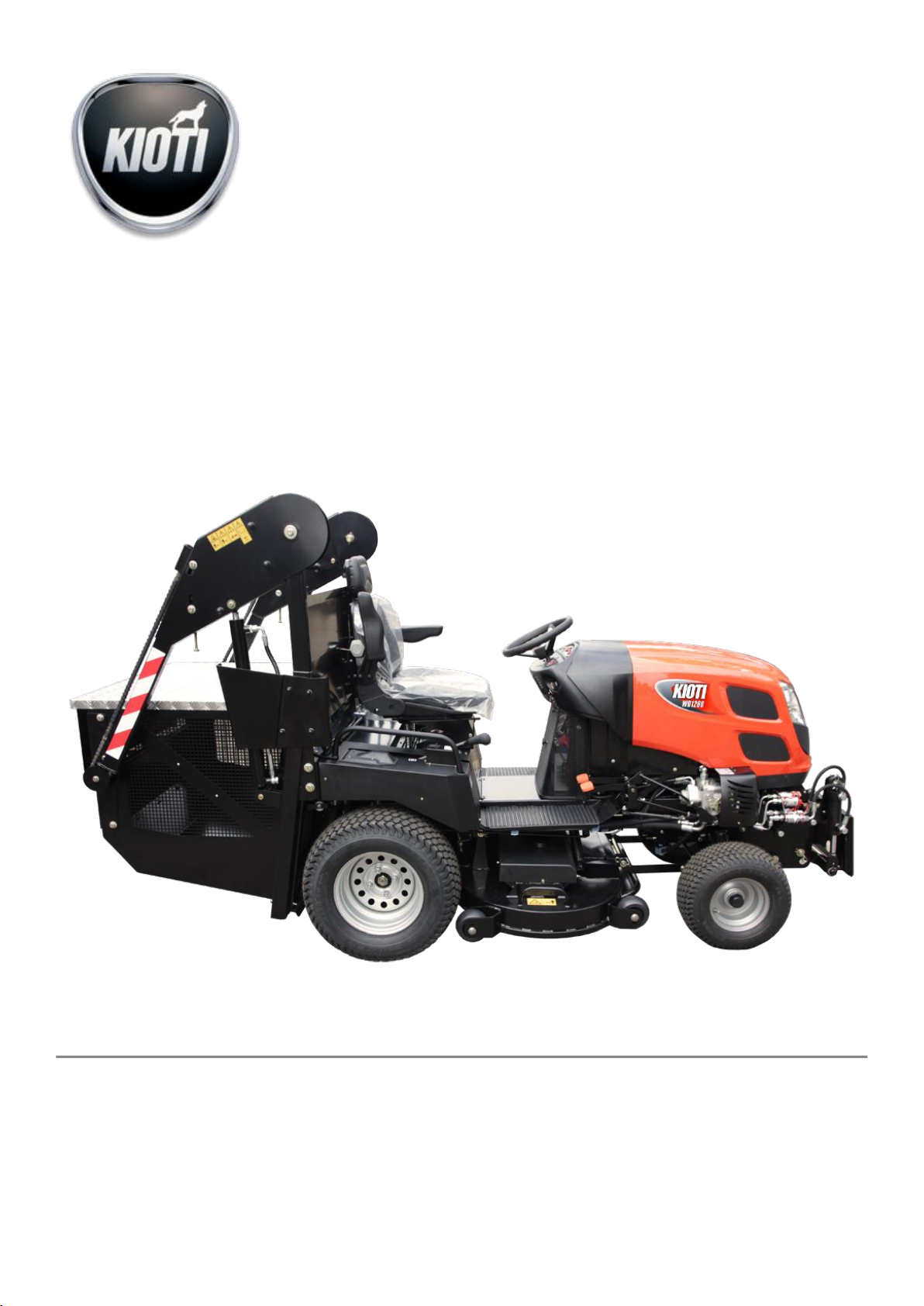

1. INTRODUCTION ..................................................5

CONGRATULATIONS ....................................................5

USING YOUR OPERATOR'S MANUAL.............................5

DISCLAIMER................................................................5

DELIVERY...................................................................5

UNAUTHORIZED REPLACEMENT PARTS ........................5

SPECIAL MESSAGES ...................................................5

2. WARRANTY AND SERVICE INFORMATION.....6

3. INTERNATIONAL CONTROL SYMBOLS...........7

4. INTERNATIONAL SAFETY SYMBOLS ..............8

5. SAFETY................................................................9

SIGNAL WORDS &SAFETY ALERTS..............................9

NOTATIONS ................................................................9

EQUIPMENT SAFETY GUIDELINES.................................9

SAFETY SHIELDS AND LABELS .....................................9

LEARN SAFE PRACTICES AND APPLICABLE LAWS........10

OPERATOR TRAINING IS REQUIRED............................10

ASSEMBLY SAFETY ...................................................10

OPERATIONAL SAFETY..............................................10

WORK AREA.............................................................10

DRUGS AND ALCOHOL...............................................10

CHILDREN AND ANIMALS............................................10

PASSENGERS ...........................................................11

STARTING,STOPPING,AND PARKING SAFELY.............11

PERSONAL SAFETY...................................................11

WEAR APPROPRIATE CLOTHING &SAFETY GEAR.......11

OPERATING SAFELY..................................................11

SLOPE OPERATION ...................................................12

MOWER SAFETY .......................................................12

TRANSPORTING SAFELY............................................12

SERVICE AND MAINTENANCE .....................................12

PREVENT FIRES........................................................13

HIGH PRESSURE FLUID SAFETY.................................14

ACCESSORY AND ATTACHMENT SAFETY.....................14

WASTE PRODUCTS AND CHEMICALS ..........................14

RETIRING TRACTOR ..................................................14

6. UNPACKING AND PREPARATION..................15

REMOVING PROTECTIVE FOIL....................................15

FUELING AND ENGINE SERVICE..................................15

INSTALL STEERING WHEEL:FIGURE 6-1.....................15

ADJUST SEAT:FIGURE 6-2........................................15

HYDRAULIC SYSTEM: ................................................15

INSTALL GRASS COLLECTOR .....................................15

INSTALL DISPERSION HOOD.......................................17

FUEL........................................................................17

INSTALL FRONT COUNTER-WEIGHT ............................17

ENGINE OIL ..............................................................18

ENGINE COOLING LIQUID............................................18

TIRE INFLATION:........................................................18

MOWING DECK AND BLADES......................................18

BELTS ......................................................................18

ANTI-SCALPING CASTERS: ........................................19

OPTIONAL EQUIPMENT..............................................19

CHECK SAFETY INTERLOCK SYSTEM..........................19

7. SAFETY INTERLOCK SYSTEM........................20

8. CONTROLS........................................................21

OVERVIEW OF MAIN COMPONENTS AND CONTROLS ...21

9. DESCRIPTION OF CONTROLS........................22

DASH PANEL............................................................22

DRIVE PEDALS .........................................................22

TRANSMISSION BYPASS VALVE..................................22

BRAKE PEDAL AND PARKING BRAKE..........................23

MOWING DECK HEIGHT ADJUSTMENT........................23

CHUTE SWEEP .........................................................23

THROTTLE................................................................23

IGNITION SWITCH......................................................24

PTO SWITCH ...........................................................24

INDICATOR LIGHTS &CONTROLS...............................24

FULL BAG SHUTOFF SYSTEM ....................................24

10. OPERATING...................................................26

FILLING FUEL TANK...................................................26

IMPORTANT:.............................................................26

PRESTART................................................................26

STARTING THE ENGINE .............................................26

WARMING AND IDLING THE ENGINE............................27

DRIVING THE TRACTOR TO THE WORK AREA.............27

MOWING ..................................................................27

OPERATE MOWER ....................................................27

STANDARD GRASS COLLECTOR OPERATION..............28

HIGH DUMP SYSTEM OPERATION ..............................28

HIGH DUMP SYSTEM COMPONENTS...........................29

REAR PANEL INTERLOCK SWITCH..............................30

MOVING THE UNIT MANUALLY ...................................30

SHUT OFF................................................................30

PARKING..................................................................30

SLOPES ...................................................................30

OPTIONAL EQUIPMENT..............................................31

MOWING HINTS ........................................................31

DIFFERENTIAL LOCK .................................................31

11. LAWN TRACTOR ACCESSORIES ...............32

FRONT BUMPER .......................................................32

SWEEPING BRUSH....................................................32

HYDRAULIC POWER PACK.........................................32

FRONT HITCH...........................................................32

SNOW BLOWER........................................................32

DISPERSING HOOD...................................................32

MULCHING KIT..........................................................32

UTILITY TRAILER.......................................................32

DOZER BLADES........................................................32

SPREADERS .............................................................32

BELT TENSION TESTER.............................................32

SERVICE TOOL KIT ...................................................32

SNOW CHAINS..........................................................32

12. CLEANING AND STORING...........................33

CLEANING................................................................33

TYPES OF CLEANERS................................................33

WASHING.................................................................33

HIGH PRESSURE WASHERS ......................................33

STORING..................................................................33

EXTENDED/SEASONAL STORAGE...............................33

13. MAINTENANCE, SERVICE, AND

ADJUSTMENTS........................................................34

FRONT AXLE AND DRIVE MAINTENANCE CHART .........34