- 2 -

1. PACKING LIST & ACTUAL IMAGE

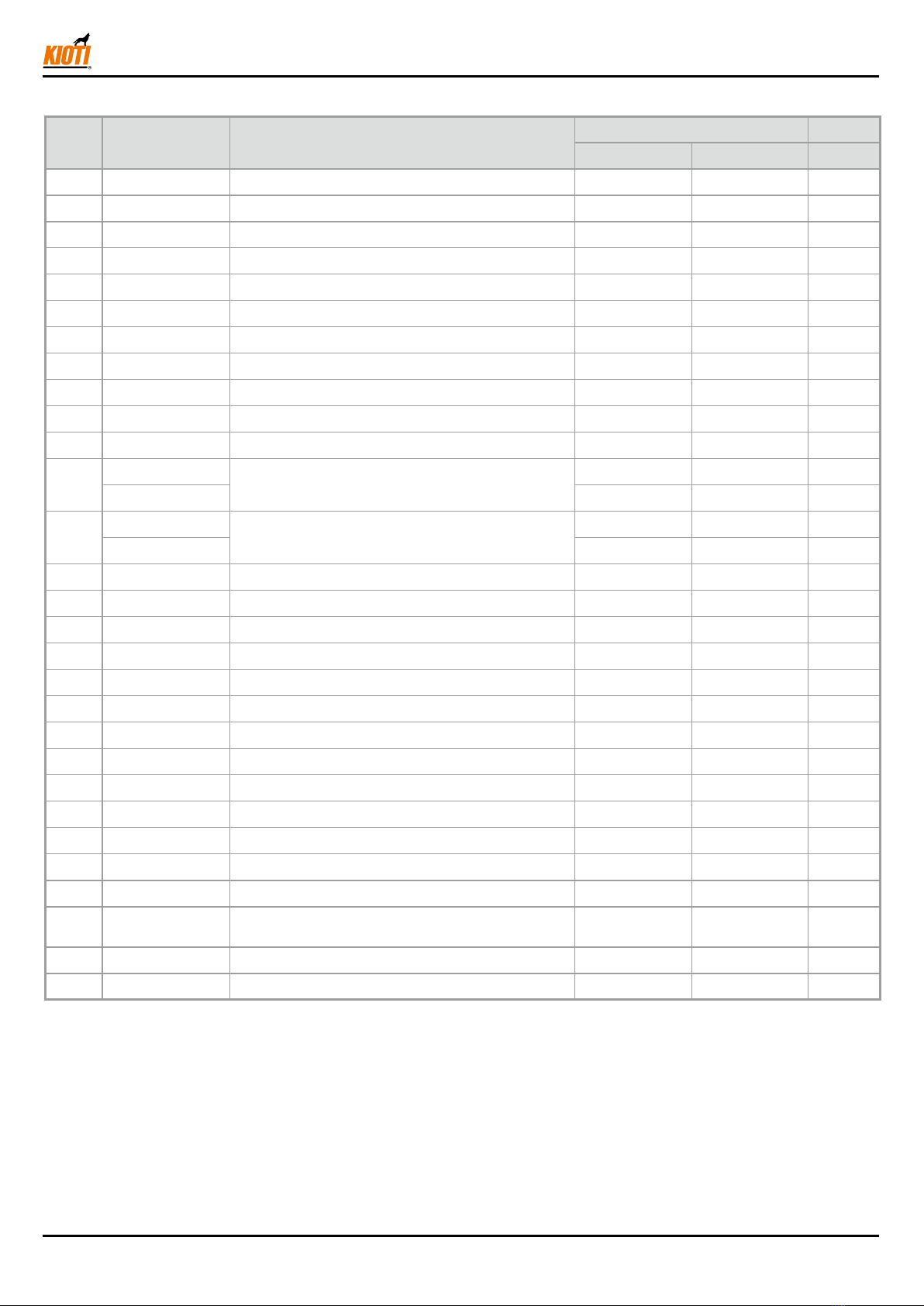

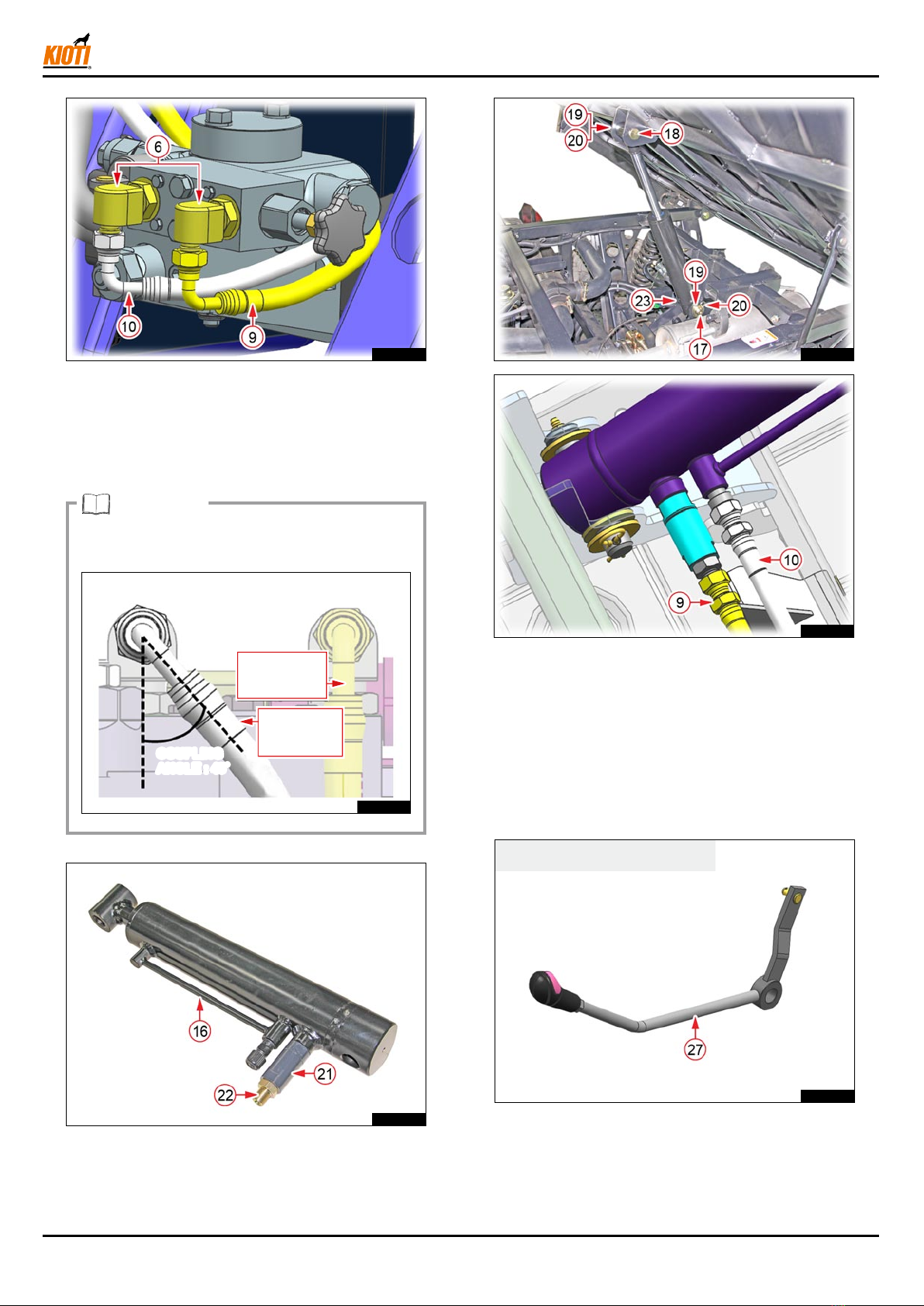

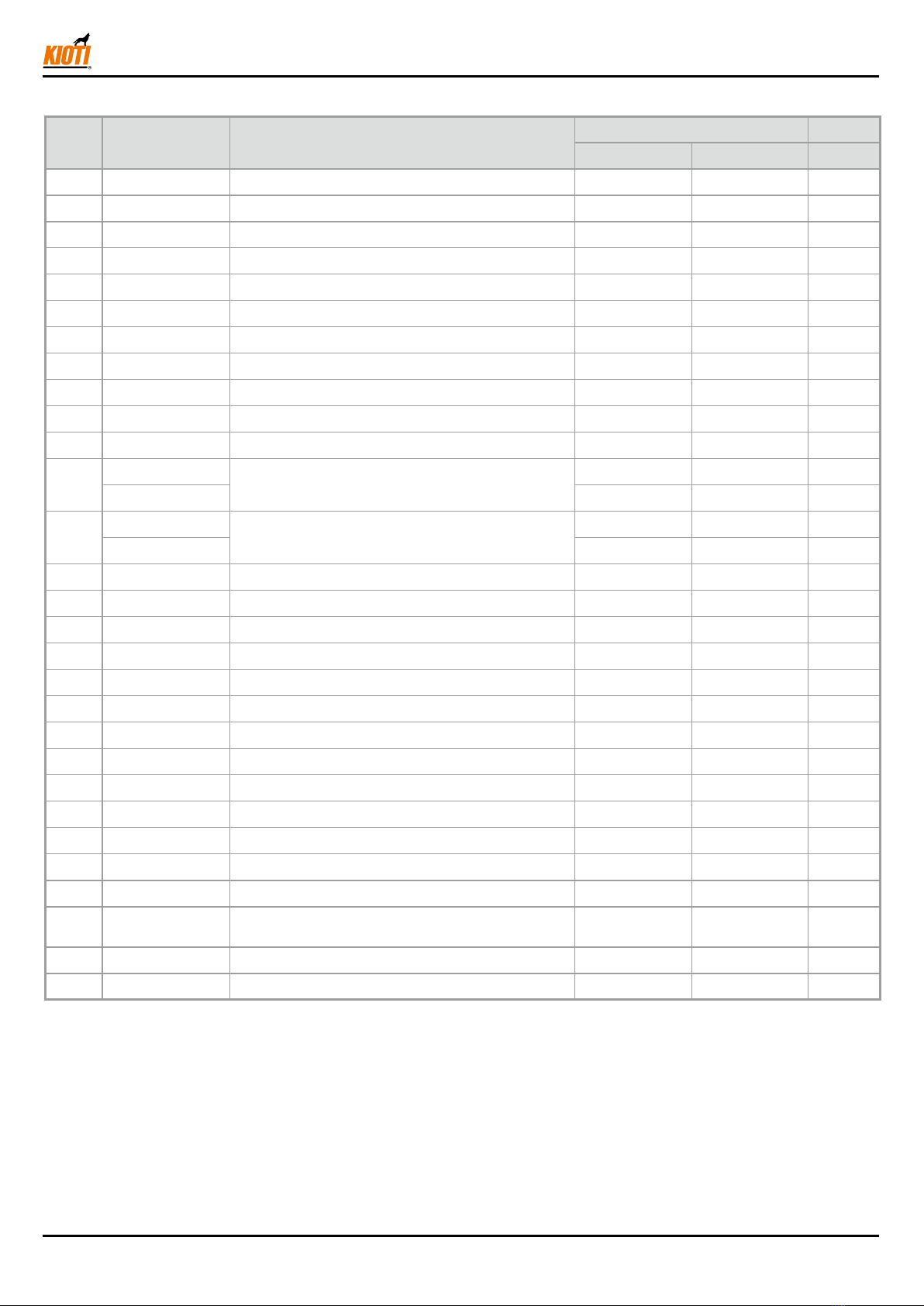

NO. Part No. Description Q'TY Remark

UD25-A0008A UD25-A0009A

1 U3400-34211 HYDRAULIC VALVE ASS`Y - C 1 1

2 U3215-32252 ADAPTOR - CONTROL VALVE 1 1

3 05411-00630A PIN, SPRING 1 1

4 T4810-46971 TUBE, CONNECTING 1 1

5 T4715-47071 TUBE, CONNECTING 1 1

6 T2350-66161 ELBOW 2 2

7 04512-50100A WASHER, SPRING 2 2

8 02176-50100A NUT 3 3

9 UD25-0012B ASS`Y HOSE, CYLINDER HYDRAULIC - A 1 1

10 UD25-0013A ASS`Y HOSE, CYLINDER HYDRAULIC - B 1 1

11 T2198-82561 BAND, CORD 1 1

12 UD25-0007A ASS`Y HOSE, HYDRAULIC - C1 1 -

UD25-0030A - 1

13 UD25-0002A HOSE, DRAIN 1 -

UD25-0027A - 1

14 F6800-91851 BAND, HOSE 2 2

15 T2198-82561 BAND, CORD 4 1

16 UD25-0017A ASS`Y CYLINDER, HYDRAULIC - DUMP 1 1

17 UD25-0016A PIN, CYLINDER 1 1

18 U3215-32972 PIN, JOINT 1 1

19 04013-50200A WASHER, PLAIN 4 4

20 05515-51600A PIN, SNAP 2 2

21 U3215-32001 ORIFICE 1 1

22 T4620-66161 TUBE, CONNECTING 1 1

23 06613-10010A NIPPLE, GREASE 1 1

24 T2610-39882 GRIP 1 1

25 UD22-12ACB HYDRAULIC LEVER COVER ASS`Y 1 1

26 U3215-81552 SCREW 2 2

27 UD22-

11AAA.03 DUMP LEVER ASS`Y, COMPLETE 1 -

28 U3215-85711 LABEL WARNING, HYDRAULIC LEVER LOCK 1 1

29 U3215-85491 LABEL, DOUBLE ACTING LEVER ENG 1 1