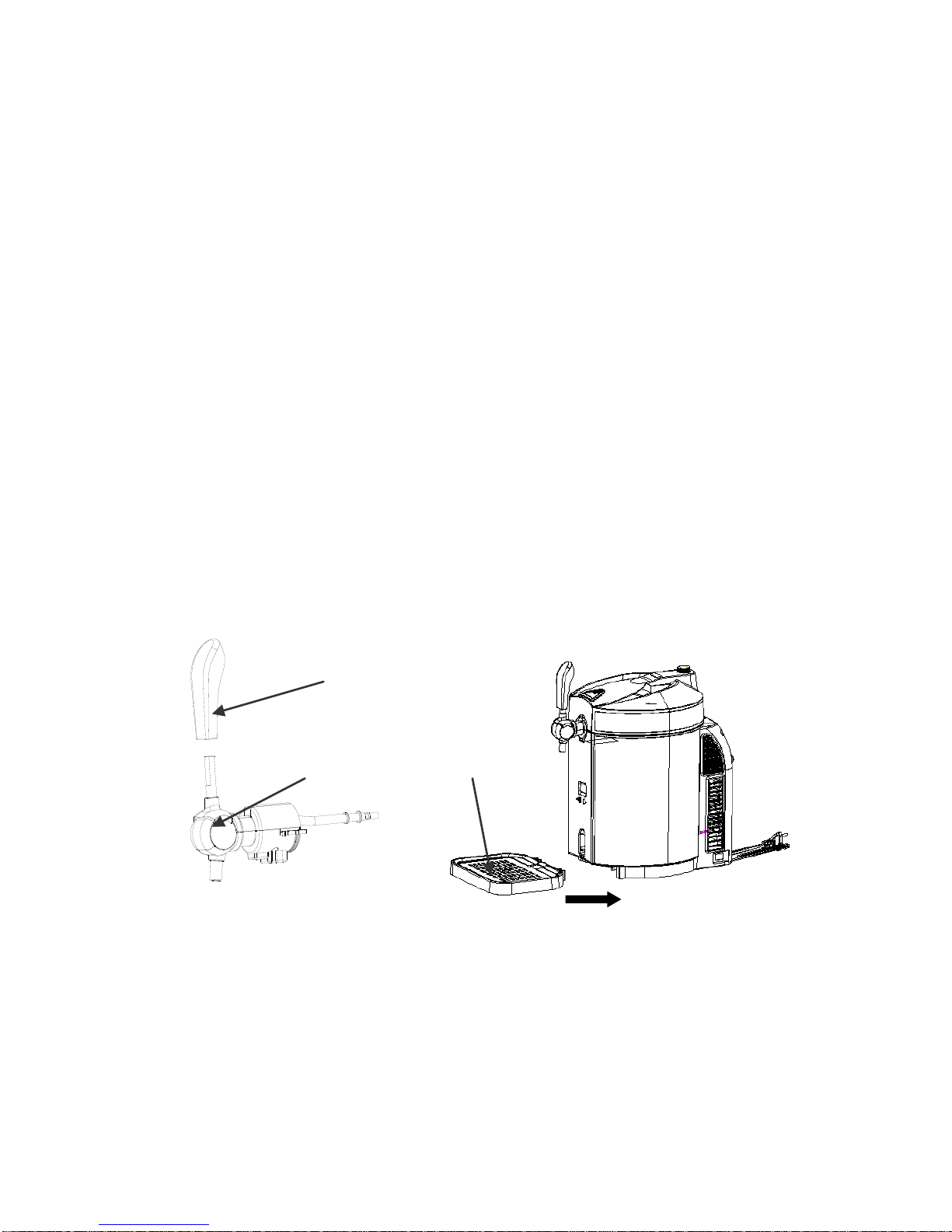

beer cooler is at least 5 inches / 10cm away on either side so as

to allow correct ventilation on the appliance.

Never put the beer cooler under the sunlight.

Never cover the beer cooler when it is operating by some other

object.

The beer cooler must be installed in an area protected from the

elements, such wind, rain, water spray or drips.

Before proceeding with cleaning and maintenance operation,

make sure the power line of the unit is disconnected. Failure to

do so can result in electric shock or death.

Do not immerse the beer cooler or power plug in the water or

other liquid.

Do not use coarse cloth, abrasive stuff to clear the beer cooler

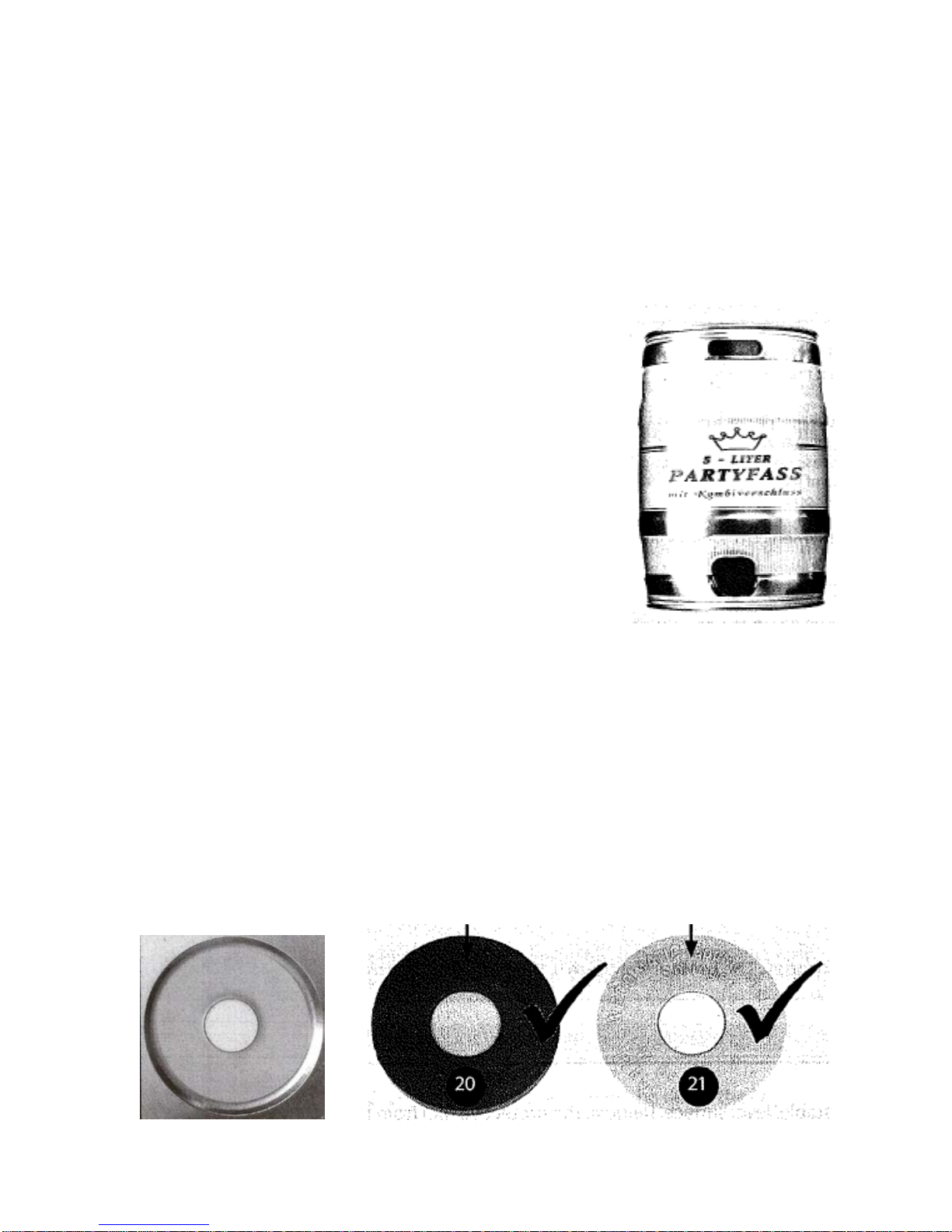

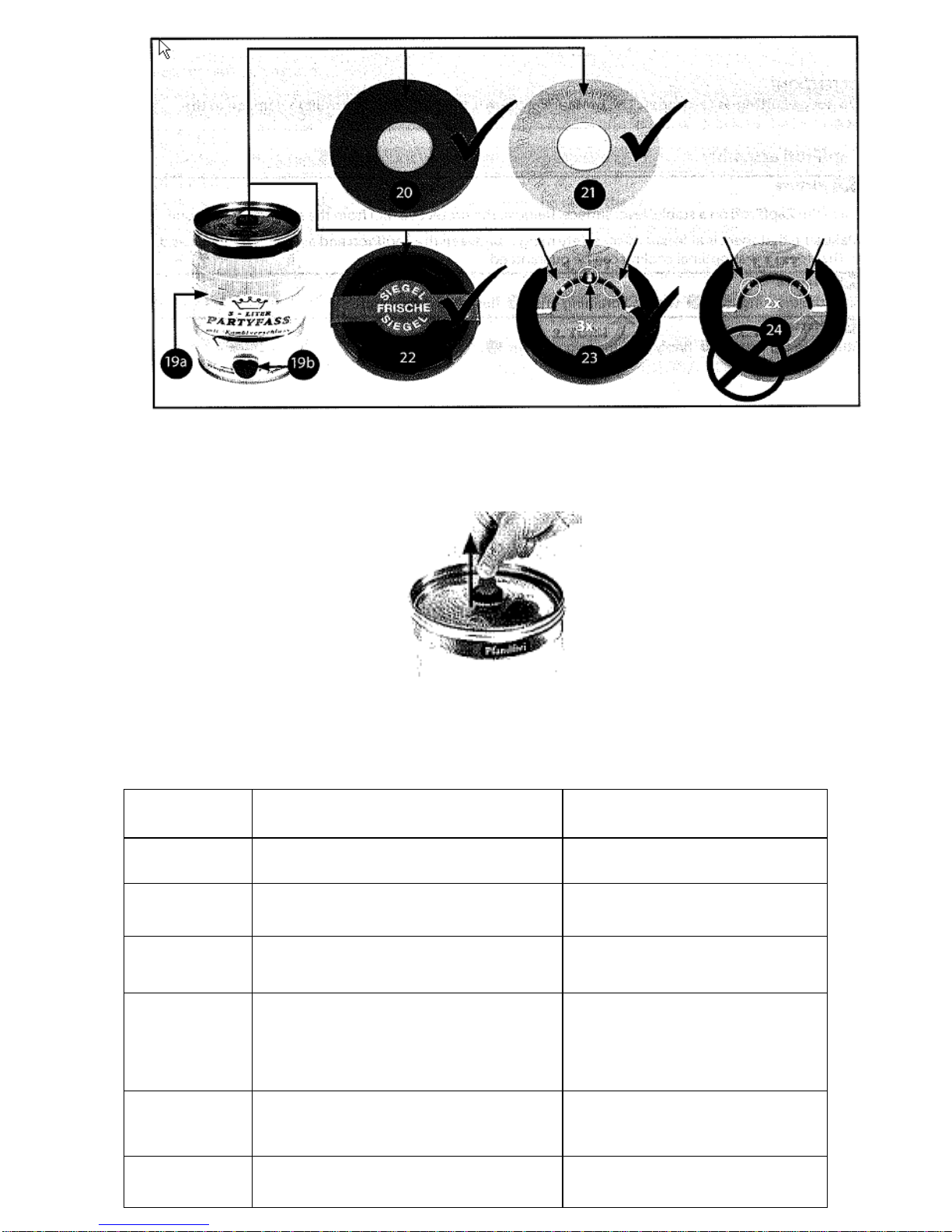

Do not take beer keg out from the beer cooler if the beer is not

drunk out completely.

Do not take the CO2 cartridge off before the inside CO2 use out.

Do not use the CO2 cartridge if the room temperature is over

49℃/120F. Failure to do so can result in explosion or death.

Never allow children to operate, play with or crawl inside the beer

cooler.

This device is not intended for use by persons with reduced

capacity on the physical, mental or sensory or lack of experience

and knowledge (including children), unless he has them was

asked to monitor or if they have had instructions on the use of the

appliance by a person responsible for their safety. Children

should be supervised to ensure they do not play with the device.

If the power cord is damaged, it must be replaced with an

after-sales service to avoid any danger.