KOMMAN MAKİNA MEKATRONİK HAVA VE KARA TAŞITLARI A.Ş.

Tekeli Mahallesi İTOB Organize San. Böl. 10014 sk. No:28 Menderes/IZMIR / TURKEY

Tel: +90 (232) 799 03 85

E-mail: info@kommanmakina.com

6

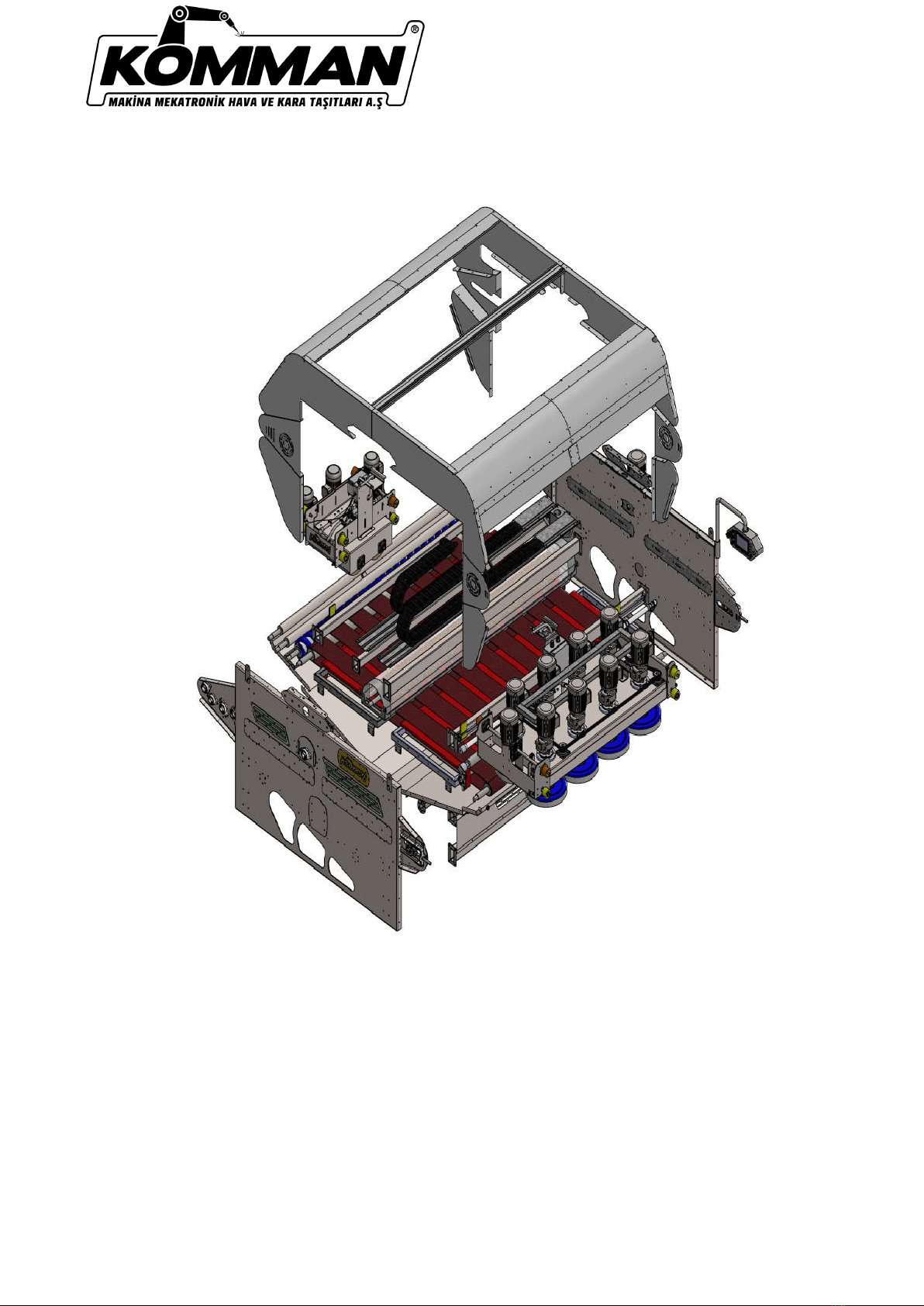

If the carpet, which is approached to the machine by using a carpet trolley, is

very dirty, the stains on the carpet are softened by using the carpet wetting

pool. After the carpet is placed in the working machine, the machine washing

process is expected to end.

After the washing process is finished, the carpet rolled by the rollers is taken

from the machine. The carpet conveyed from the machine is transported to the

squeezing/spinning machine by the trolley.

4.3.) Security Precautions

The operator is responsible for all safety precautions to be taken during the

operation of the machine.

The operator must ensure that there is no electrical leakage in the environment

where the machine is operating.

5.) Warnings and Precautions

Before using your machine, check whether the machine has been damaged or

not.

Please read the user manual carefully before using the machine. Use and

maintenance of the machine should be performed by authorized persons. The

machine must be used after all the necessary conditions are provided. It is

recommended not to exceed the working capacity of the machine.

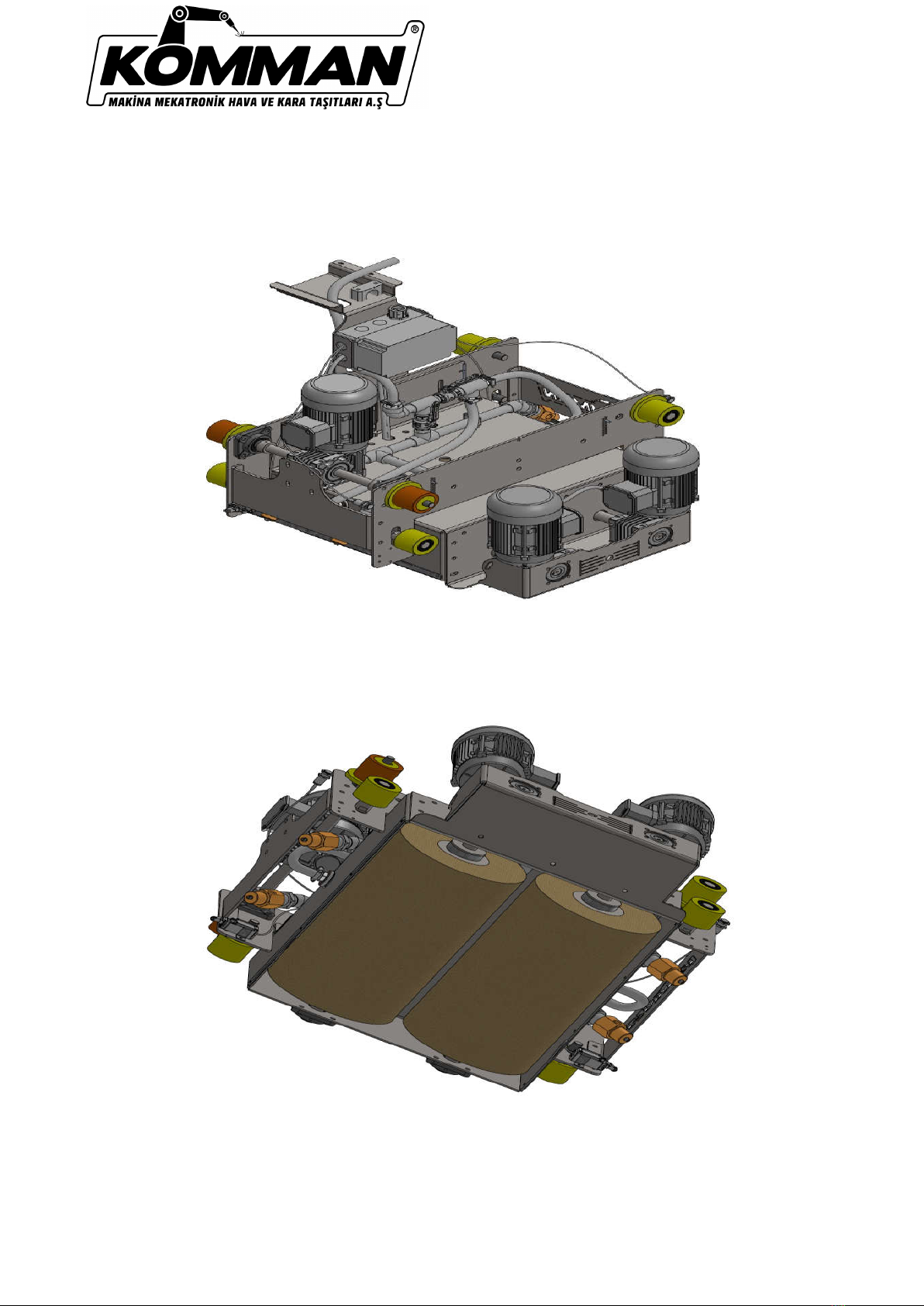

If the machine is used very intensively, after four hours of operation, the

machine should be rested for half an hour. When carpet washing is performed,

hand washing must not be performed manually when machine is running in any

part of machine due to base difference. Manual intervention may cause

serious injury. In such cases, the machine should be stopped completely and

the band should be used to adjust the direction of rotation of the tape on the

display box. Thus, the carpet is removed from the place where it is stuck.

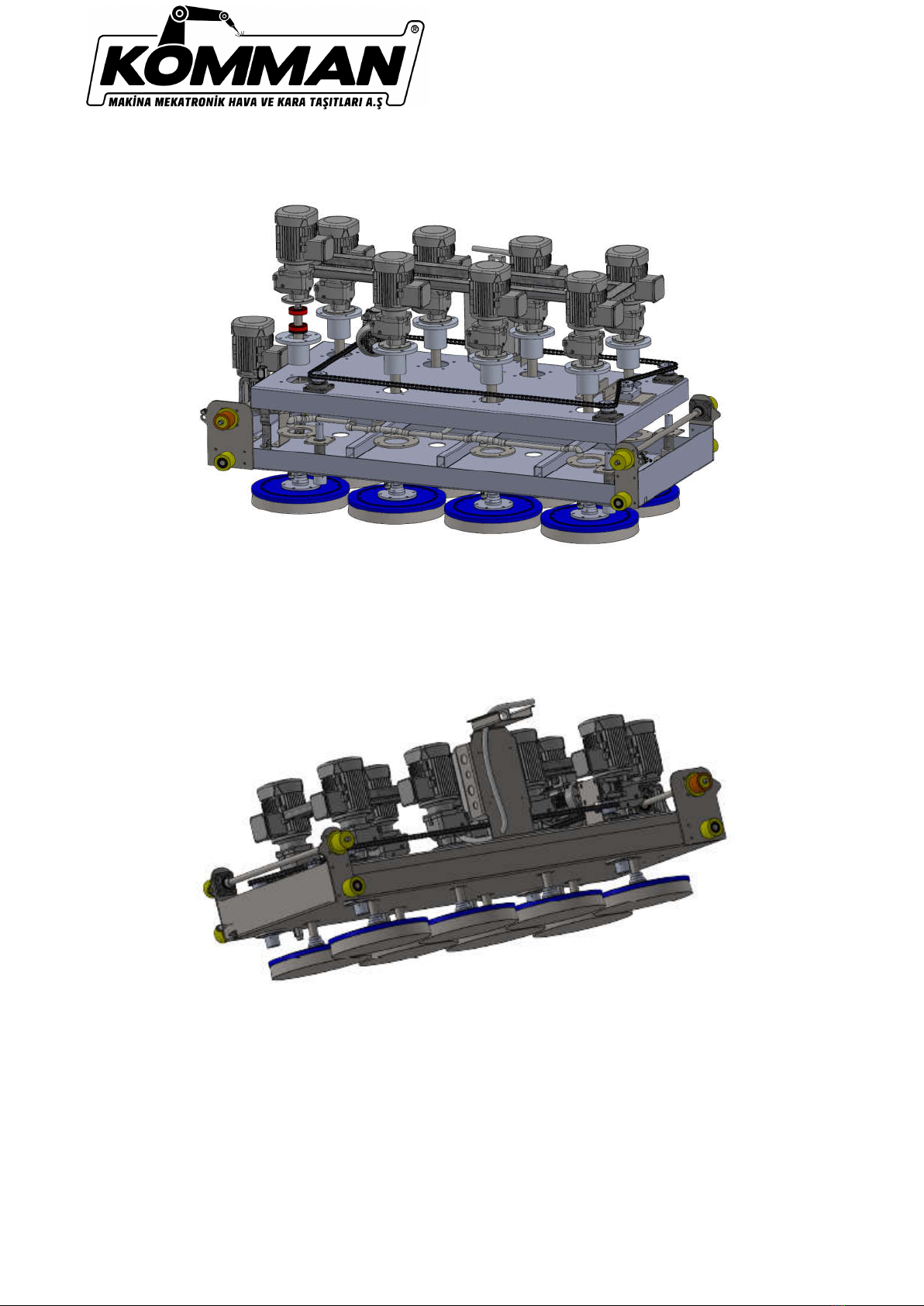

Even though the disc brush system is set to the maximum pressure point with

limit condition, these brushes should not be pressed on thick carpets. Doing so

may damage the substrate of the machine (See Figure 2).