FS-601 Theory of Operation Ver2.0 Sep. 2004

i

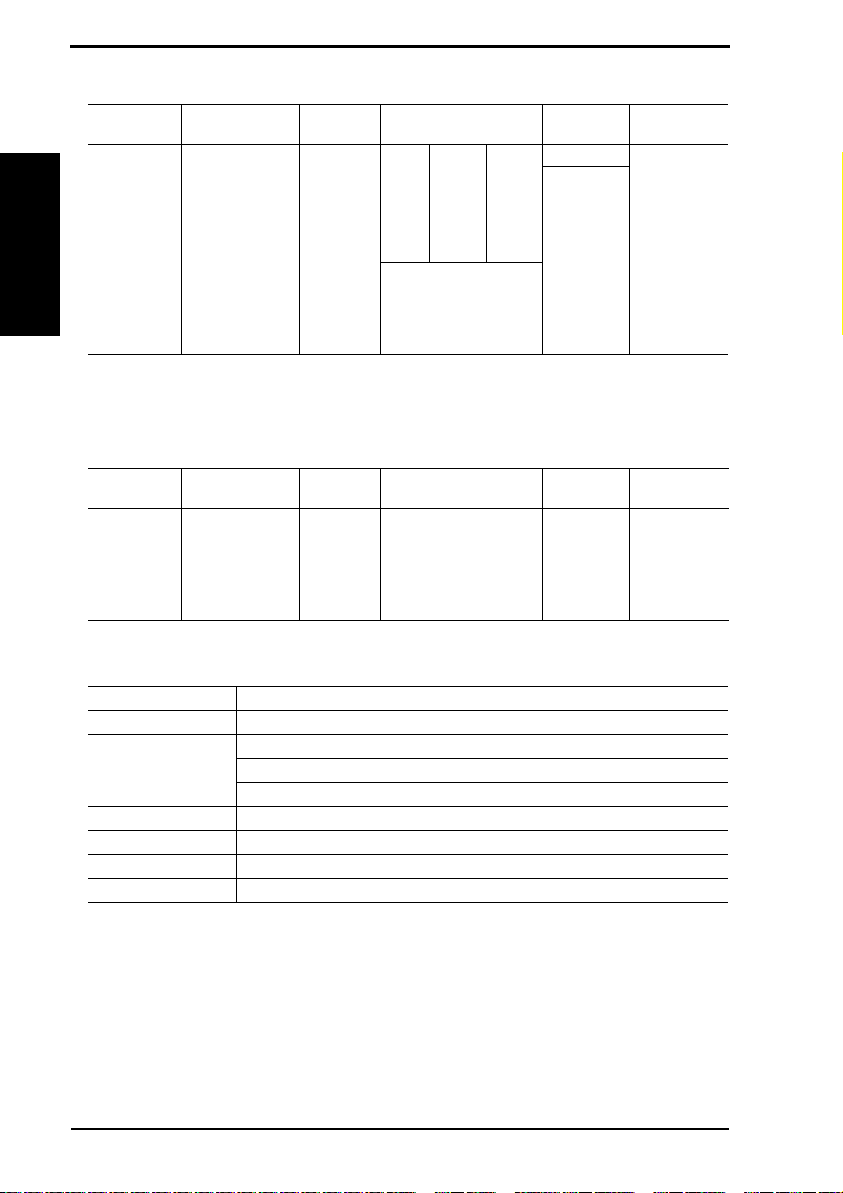

I Outline

II Composition/Operation

CONTENTS

IOutline

1. Product specification ............................................................................................1-1

1.1 Type ................................................................................................................... 1-1

1.2 Functions ........................................................................................................... 1-1

1.3 Paper type ......................................................................................................... 1-1

1.3.1 Non-Sort ....................................................................................................... 1-1

1.3.2 Sort............................................................................................................... 1-1

1.3.3 Sort staple ....................................................................................................1-2

1.3.4 Saddle staple................................................................................................1-2

1.4 Stapling.............................................................................................................. 1-2

1.5 No. of sheets to be stapled (sort staple)............................................................1-3

1.6 Machine specifications....................................................................................... 1-3

1.7 Operating environment ...................................................................................... 1-3

II Composition/Operation

1. Overall composition..............................................................................................2-1

2. Drive system ........................................................................................................ 2-2

3. Paper path............................................................................................................ 2-3

4. Mechanical operations ......................................................................................... 2-4

4.1 Horizontal transport mechanism........................................................................ 2-4

4.1.1 Paper path switching mechanism ................................................................. 2-4

4.1.2 Finisher paper transport mechanism ............................................................ 2-5

4.2 Finishing tray mechanism .................................................................................. 2-6

4.2.1 Non-sort mode..............................................................................................2-6

4.2.2 Sort mode ..................................................................................................... 2-7

4.2.3 Staple Mode ................................................................................................. 2-7

4.2.4 Center staple booklet mode.......................................................................... 2-8

4.2.5 Paper stacking with finishing tray.................................................................. 2-9

4.2.6 Aligning mechanism ................................................................................... 2-10

4.2.7 Offsetting operation .................................................................................... 2-11

4.2.8 Exiting operation ......................................................................................... 2-12

4.3 Stapling unit ..................................................................................................... 2-13

4.3.1 Types and positions of staples.................................................................... 2-13

4.3.2 Stapling unit moving mechanism ................................................................ 2-14

4.3.3 Staple operation ......................................................................................... 2-15

4.3.4 Stapling unit................................................................................................2-16