LOCATION REQUIREMENTS

VENTILATION

IMPORTANT: Observe all governing codes and ordinances. Do not obstruct fl w of

combustion and ventilation air.

•It is the installer’s responsibility to comply with installation clearances specified

on the model/serial rating plate. The model/serial rating plate is located on the

left-hand side of the oven frame. Open oven door to view label. See label on back

panel of range for additional element and oven power ratings.

a

a Rating Plate

TEMPERATURE

IMPORTANT: This oven has been designed in accordance with the requirements of

UL and CSA International and complies with the maximum allowable wood cabinet

temperatures of 194F (90°C).

•Some cabinet and building materials are not designed to withstand the heat

produced by the oven for baking and self-cleaning. Check with your builder

or cabinet supplier to make sure that the materials used will not discolor,

delaminate or sustain other damage.

•Contact a qualified floor overing installer to check that the floor overing can

withstand at least 200°F (93°C).

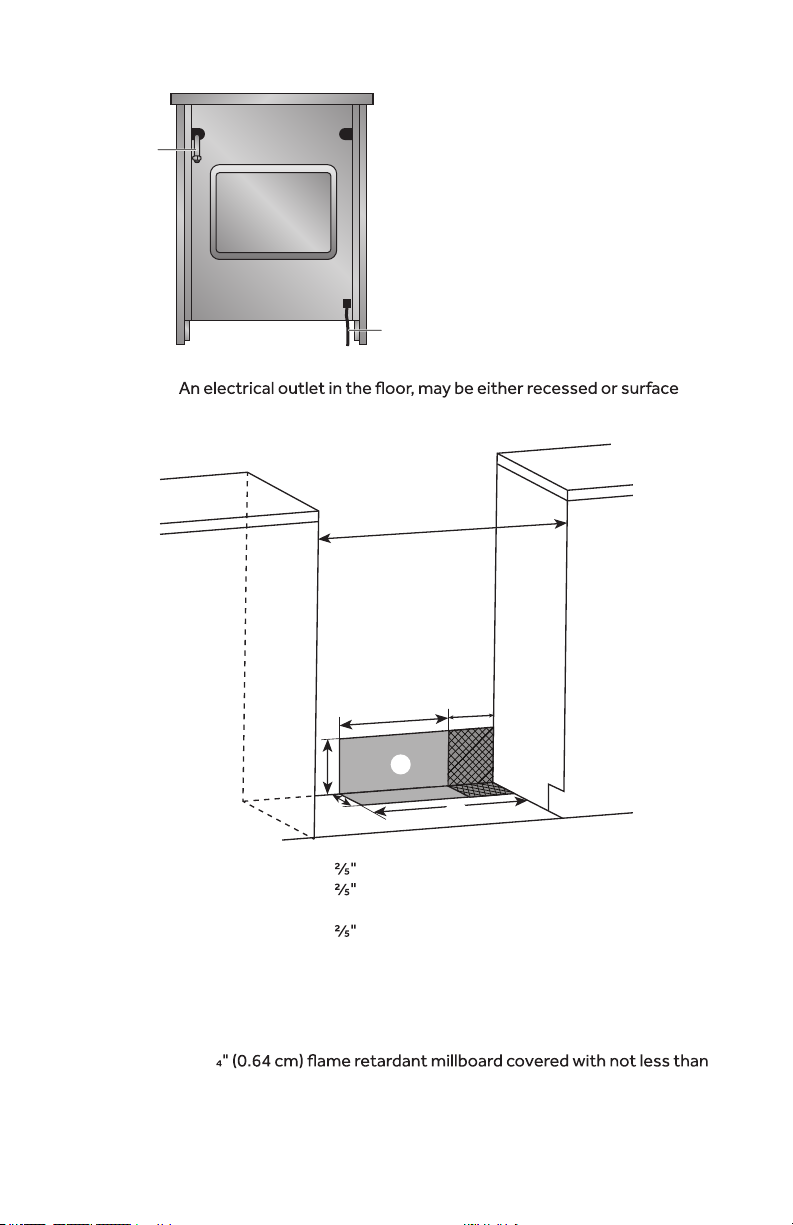

•Use an insulated pad or 1/4" (0.64 cm) ywood under range if installing range over

carpeting.

GENERAL

•The range should be located for convenient use in the kitchen.

•Recessed installations must provide complete enclosure of the sides and rear of

the range.

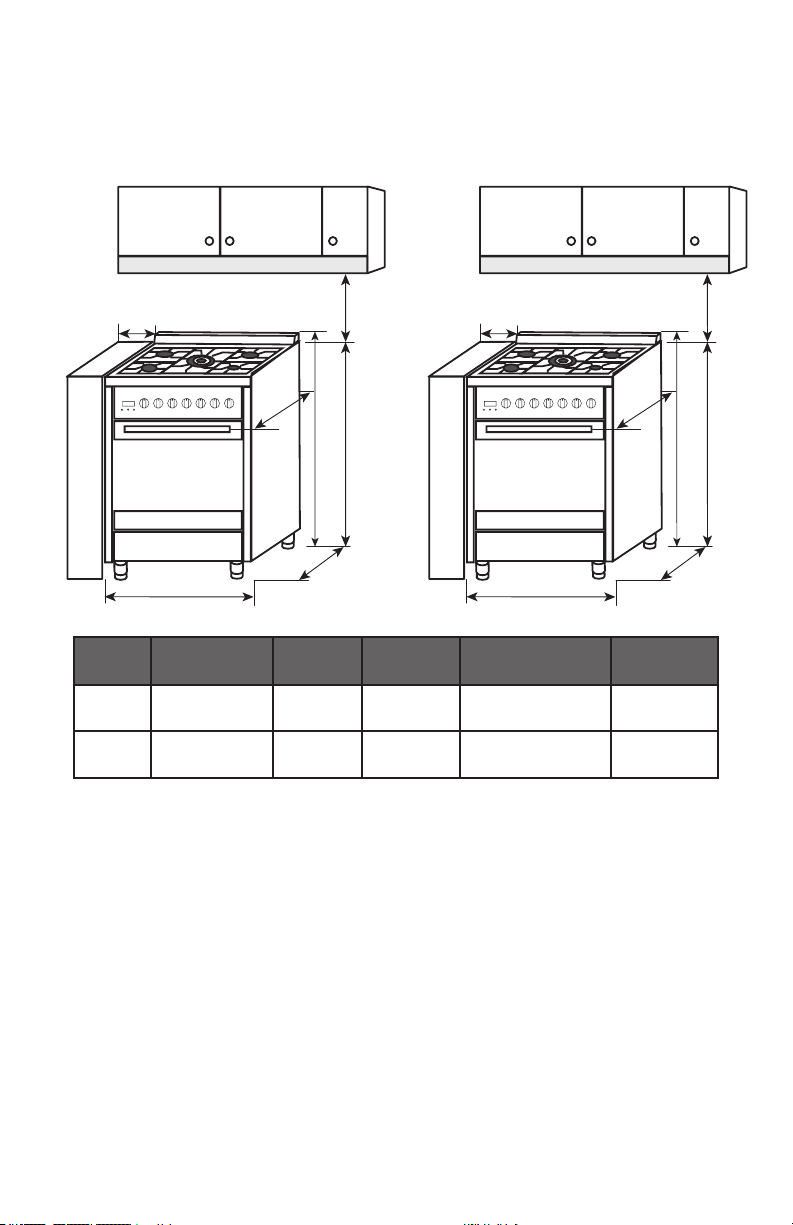

•To eliminate the risk of burns or fi e by reaching over heated surface units,

cabinet storage space located above the surface units should be avoided. If

cabinet storage is to be provided, the risk can be reduced by installing a range

hood or microwave hood combination that projects horizontally a minimum of 5"

(12.7 cm) beyond the bottom of the cabinets.

•All openings in the wall or floor whe e range is to be installed must be sealed.

•Do not seal the range to the side cabinets.

•Grounded electrical supply is required. See “Electrical Requirements” section.

•Proper gas supply connection must be available. See “Gas Supply Requirements”

section.