OPENING THE UNIT

3.2

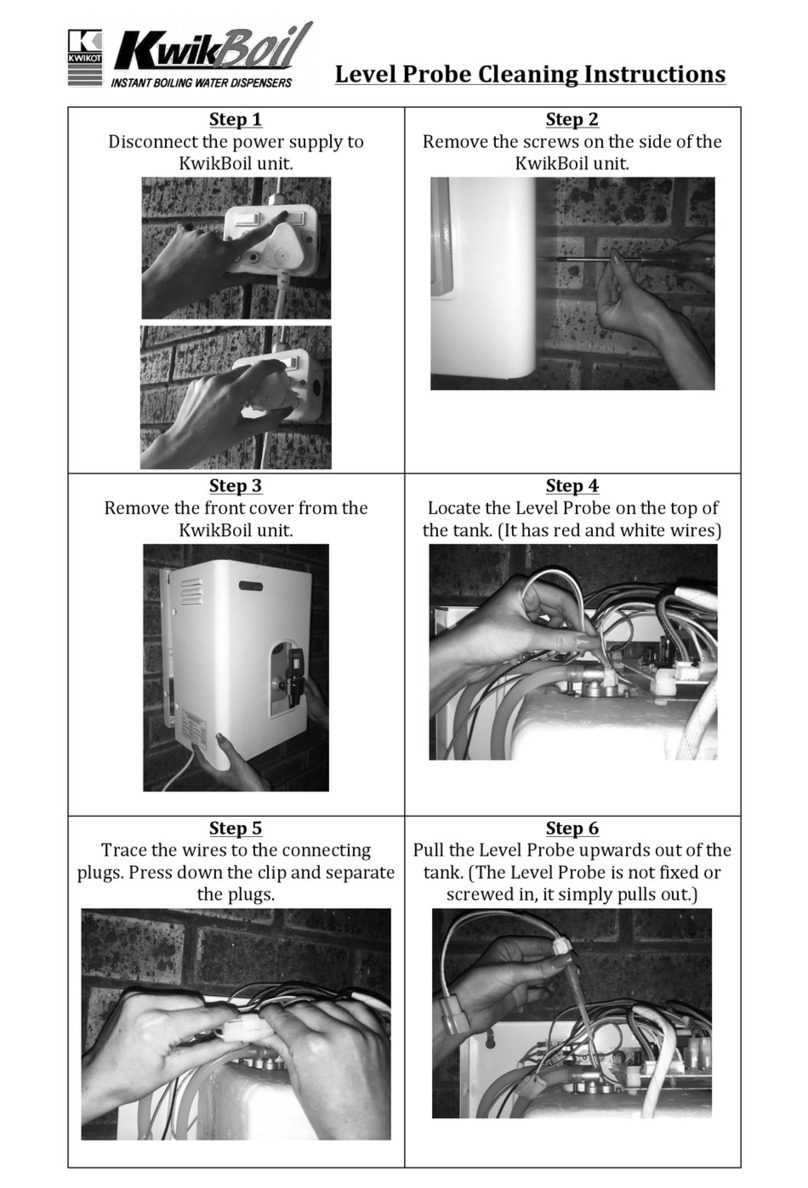

To remove the jacket from all models, remove

the retaining screws on the sides and pull the

jacket forward.

MINIMUM CLEARANCES

3.3

All units require a minimum clearance of 50

mm on all sides, however, we recommend you

leave sufficient clearance for servicing.

MOUNTING

3.4

The Kwikboil, when installed is suspended

from mounting screws located into keyhole

slots at the back of the unit (refer to the

dimension specification diagrams on pages

5,6 and 7 or the template on the carton). Be

sure that the mounting screws are securely

inserted into the keyhole slots. The screws

MUST be anchored in such a way, that they will

hold the weight of the unit when filled with

water,(refer to the weight tableon Page 8).

WATER SUPPLY

CONNECTION

3.5

Mains cold water supply ( refer to pressure

table on Page9 for operating water pressures )

must be piped and connected to the BSP

inlet fitting located on the left hand side

underneath the unit. An accessible isolating

valve must beinstalled near the unit.

1

2

''

This unit contairis a strainer on the water inlet

connection. To ensure continuing satisfactory

operation, it is suggested that theinlet strainer

be serviced every six months. Where poor

water quality is present it is recommended to

install an additionalauxiliary filter.

For rear entry connection, it is recommended

that you use a braided flexible hose with a

90 elbow for easeof connection.

VENT/OVERFLOW

CONNECTION

3.6

Connect a 15 mm (1/2") pipe to the

vent/overflow connection. (1/2" BSP). This

pipe must have a continuous fall, not

exceeding 3 metres in length, or contain no

more than 4bends.

During the normal operation of the Kwikboil

the vent/overflow connection may discharge

small quantities of steam and condensate, so

it is ESSENTIALthat the drainpipe is attached

to the vent/ overflow connection. This drain

pipe must discharge to waste at a point where

no scald injuryor inconvenience is caused.

Ensure that the vent/overflow line remains

open because the Kwikboil tank is not

designed to be pressurised. It is recom-

mended to install an air break in the

vent/overflow drain line, no more than 300

mm from theKwikboil unit.

DRAIN CONNECTION

3.7

There is a drain screw located on

the underside of the unit to

completely drain the tank for

servicing.

Before removing thedrain

screw, ensurethe appliance has

been switched off and thewater is not hot

enough to scald.

This unit is not suitable for

installation in an area where a water jet could

be used. This unit must no not

be cleaned using a water jet.

CAUTION:

TAP OUTLET

3.8

Toprevent damage during transportation,

the tap is bubble wrapped and placed

inside the carton.

The tap is fitted to the threaded tap outlet

extension with an "o" ring seal fitted and

fixing screw to secure in the vertical

position.

Installation and maintenanceof the

Kwikboil Boiling Water Unit shall

be carried outby a suitably

qualified service person.

PLEASE NOTE:

ELECTRICAL REQUIREMENTS

3.9

All models

230 VoltsAC, 50HZ,

Single Phase

ELEMENT RATING

1800Watts 2.5 Litre

2000Watts 5 to 10 Litre

2400Watts 15 Litre

3000Watts 25 Litre

A flexible cord complete with a plug is

supplied on all models. Do not loosen the

cord grip or pull excess cord into the Kwikboil.

If the supply cord is damaged, it must be

replaced by the manufacturer or its service

agent or similarly qualified persons in order

to avoid a hazard.

THIS APPLIANCE MUST BE

EARTHED

CAUTION:

4. OPERATION

When the installation is complete, first turn

on the water supply and then switch on the

power, which will engage the solenoid valve

and the unit will automatically begin to fill and

the heating sequencewill commence.

The water is heated in small quantities, so

boiling water isavailable at all times.

The electronic control unit constantly controls

the water leveland the water temperature.

4.1 MODE 1 OPERATION:

To follow through the sequence of events in

order , it is necessary that we consider the

unit is switchedon for the first time .

When the unit is swithed on , the controller

scans the Level Probe condition , and having

established that, then executes a sequenceof

events particular tothat mode.

1.The Controller scans the Level

Probe condition. Both Probes

(low and high)will be found to be

in an OPEN condition i.e. no

water present. This then places

the unitin MODE1 condition.

1.

The solenoid valve is then

energised and the "SL" LED on the

PC-Board will light up indicate

power sent to the solenoid valve,

allowing water toenter the tank.

2.

Page 03 Page 04