EK3 Frontier Boiler Manual, Gas Edition 18 August 2022

PREPARE FOR START UP

DANGER: MAKE CERTAIN THE FOLLOWING REQUIREMENTS HAVE BEEN SATISFIED BEFORE START UP:

12. The boiler and piping are completely filled with water.

13. Re-check wiring to ensure that it is correct and in accordance with appropriate wiring diagrams and codes.

14. Verify that proper nozzle is used and installed correctly.

15. Verify electrode settings.

16. Verify the burner settings for air band position and head position (see "Oil Burner Settings" Table).

17. Oil supply is connected to burner. Oil supply lines and shut-off valves are open.

18. CAUTION: DO NOT USE GASOLINE, CRANKCASE DRAININGS, OR ANY OIL CONTAINING GASOLINE.

19. Fuel pump and fuel lines are purged.

20. Verify operating oil pressure at gauge port.

21. Flue pipe properly connected from unit to chimney. All joints are secured and sealed.

22. Combustion air supply is available and sufficient. (See “Combustion Air”)

23. Adjust valve in domestic hot water circuit under circulator approximately ¾ of the way open.

24.

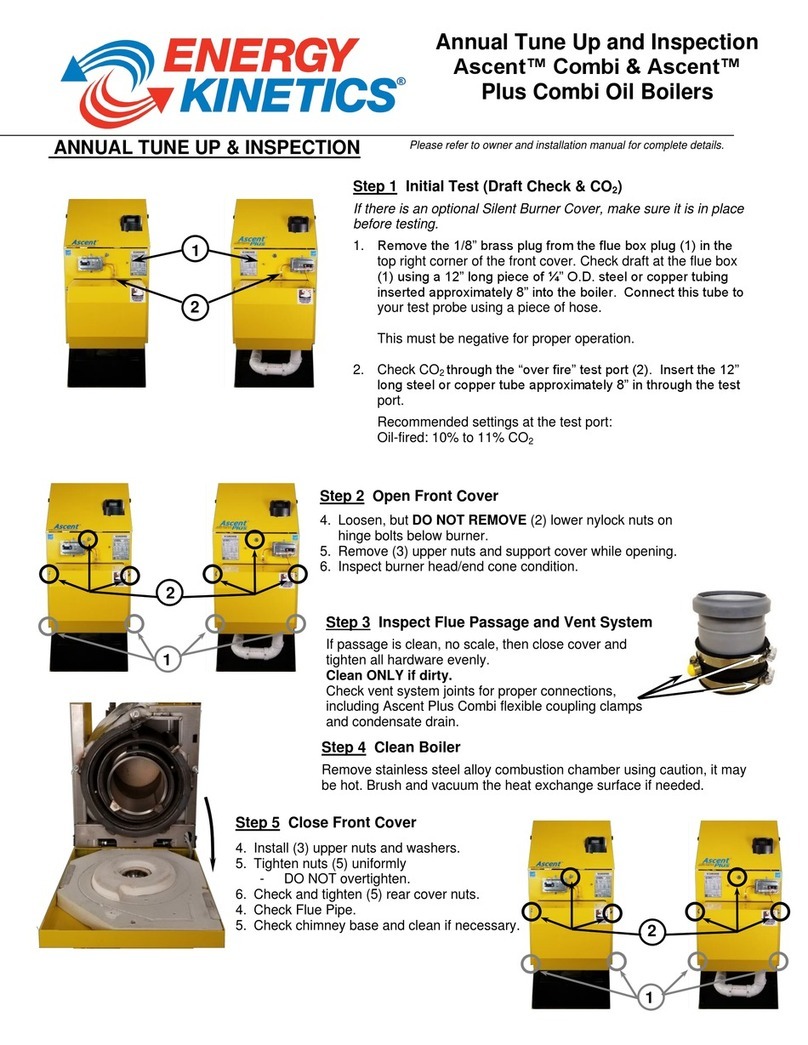

25. CAUTION: All covers, enclosures, and guards must be maintained in place at all times, except during

maintenance and servicing.

26. CAUTION: Do not start burner unless the front door is closed and the nuts have been properly tightened.

27.

ENERGY MANAGER

Install Energy Manager

The Energy Manager is shipped in its own protective shipping box. NOTICE: The option switches can be set very easily

before the Manager is installed. Locate the prewired quick connectors fastened to the front of the junction box by two cable

ties. Cut the two cable ties and discard. Fasten the Energy Manager to the junction box with the four corner screws. Slide

the two quick connectors onto the Energy Manager. Label each zone on the manager, using the adhesive labels supplied.

Low Voltage Wiring

Energy Manager Operates Only On 24 Volts 60 HZ Power

WARNING: Make All Connections With Power Off at Main Circuit Box

Typical low voltage wiring diagrams for the Energy Manager are shown along with piping schematics near the back of

this manual (refer to table of contents). Thermostats must be located on inside walls away from cold drafts, windows or heat

from fireplaces

request alternate low voltage wiring diagrams to handle special situations such as air handler wiring, heat pump wiring,

isolation relays for thermostats, and isolation relays for heat motors or circulators, etc.

The single 24-volt/50VA transformer is suitable for the Energy Manager and five zone outputs (zone valves or relays).

NOTICE: Additional load such as extra valves may require greater transformer capacity. To add transformers, wire in

Be

sure to verify 24VAC output from all transformers.

The Energy Manager is designed to heat domestic water and up to four (4) heating zones. Use Energy Kinetics supplied

zone valves with four wire connections. For more than four heating zones, use Energy Kinetics expanded 10 or 15 zone

Energy Manager, or call Energy Kinetics for alternatives.

START UP PROCEDURE

7. Turn on system supply switch and burner supply switch. The Energy Manager lights should come on briefly, the

circulator relay should close briefly, and then the Energy Manager should only show one red light next to 'power'.

8. The hot water tank aquastat should call for heat, if not, adjust a thermostat to call for heat. Burner and bypass circulator

should come on at the same time. If not, check primary control and reset it if necessary.

9. Check for burner light off. On an oil supply system with one pipe, it will be necessary to bleed air from fuel pump. On a

two pipe system, several starts may be required to clear air from fuel pump, or bleed air from pump.

10. On light off, water temperature and chimney temperature will start to rise. A slight odor is common on initial light off as

combustion flame former and converter surfaces warm for the first time.

11. NOTICE: Perform smoke test immediately after light off. Smoke test should show yellow after initial one minute of

operation due to the combustion flame former sizing heating up. If the smoke test shows dark grey or black after one

minute of operation, shut off boiler immediately and repeat "Prepare for Start Up" checklist.

12. As Unit reaches temperature, Energy Manager

first start up, this will usually be the hot water storage tank zone.) Once boiler water temperature reaches 160o180o

F., adjust hot water temperature flowing to storage tank. With hot water flowing fully from a domestic faucet, adjust valve

under domestic circulator pump so water temperature going into tank is approximately 140 o F. (Hand can be held on

pipe just briefly.) Water must be flowing fully from a household hot water tap to accurately adjust flow and temperature

entering tank.

13. Allow system to run about 15 minutes before testing and recording burner operation. (See "Oil Burner Operation")

14. CAUTION: Do not attempt to start the burner when excess oil has accumulated, when the unit is full of vapor, or when

the combustion flame former is very hot.

15. CAUTION: NEVER BURN GARBAGE OR PAPER IN THE UNIT, AND NEVER LEAVE COMBUSTIBLE MATERIAL

AROUND IT.