Pag. 28

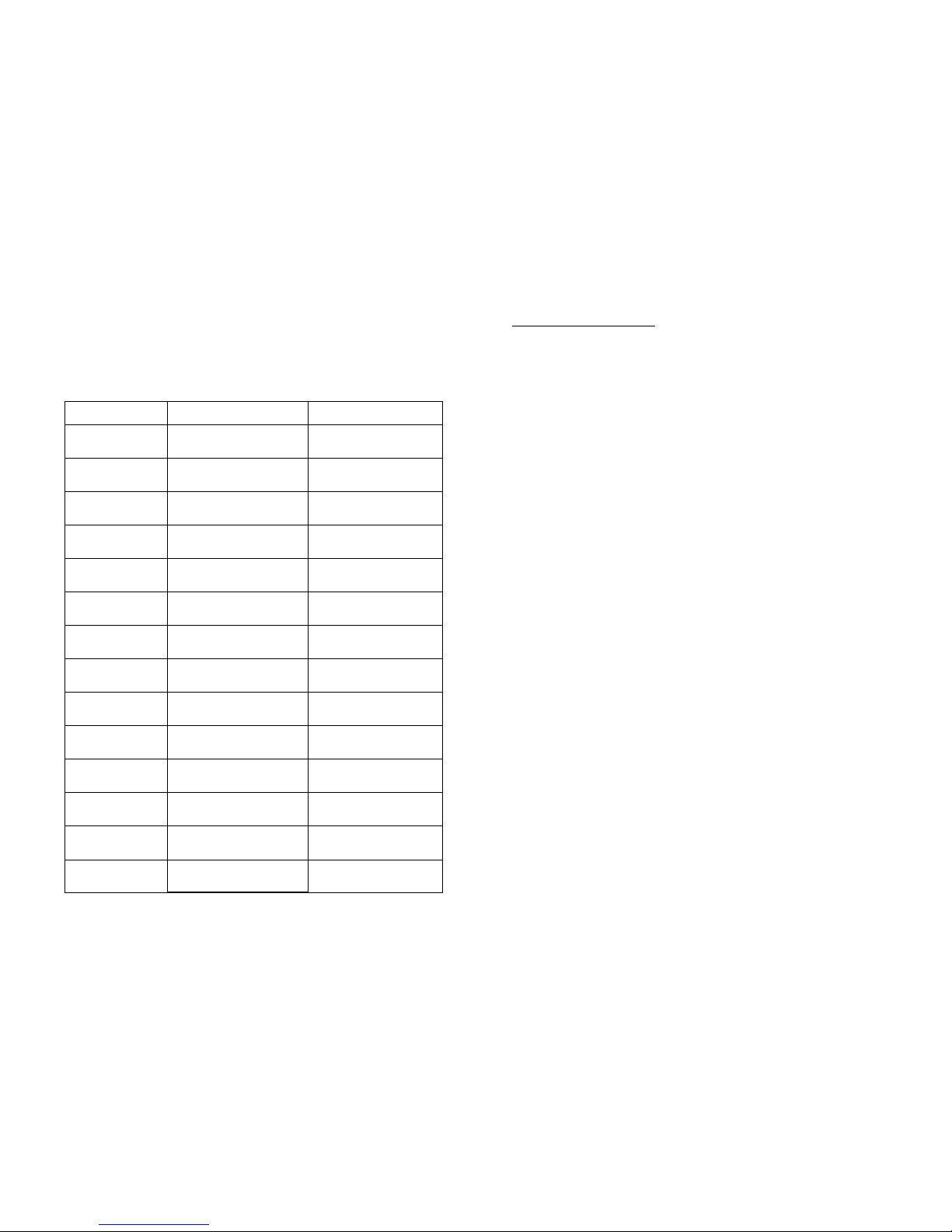

TROUBLESHOOTING GUIDE

The machine is provided with a program of self-diagnosis, that allows to visualize

on the display the messages of breakdown or machine stopped :

Message Description Probable cause

ERR. CUP-RELEAS. during the cup-releasing, the board has not

received the change of state of the cup-releaser

micro switch.

Fuses, cup-releaser motor, cup-releaser micro

switch, electronic board.

ERROR ARM 0 The electronic board has not received the “sugar

position” of the cup -arm signal by the relative

sensor on the cup-station board.

Fuses, cup blocked in the cup-arm, cup-arm

motor, position sensor, electronic board.

ERROR ARM 1 The electronic board has not received the “cup

position” of the cup -arm signal by the relative

sensor on the cup-station board.

Fuses, cup blocked in the cup-arm, cup-arm

motor, position sensor, electronic board.

ERROR ARM 2 The electronic board has not received the

“supply position” of the cup -arm signal by the

relative sensor on the cup-station board.

Fuses, cup blocked in the cup-arm, cup-arm

motor, position sensor, electronic board.

ERROR GROUP 1 the coffee-group has not reached the “supply

position” given by its right micro switch. Fuses, group right micro switch, group motor,

electronic board.

ERROR GROUP 0 the coffee-group has not reached the “normal

position” given by its left micro switch. Fuses, group left micro switch, group motor,

electronic board.

ERR. COFFEE FLOW During espresso supplying, the board has not

received signals from the flowmeter. Fuses, too finer coffee, coffee pump, coffee

electro valve, flowmeter, electronic board.

ERR. SOLUB.FLOW During soluble supplying, the board has not

received signals from the flowmeter. Fuses, solubile pump, solubile electro valve,

flowmeter, electronic board.

ERROR GRINDER 1 During the coffee grinding, the board has not

received the signal given by the doser-switch in

the maximum time of 25 seconds.

Too fine coffee, fuses, doser micro-switch,

grinder motor, grinder blocked by something

hard, electronic board.

LACK OF CUPS The board doesn’t receive the signal from the

cups sensor. Lack of cups, cups sensor, electronic board.

LACK OF WATER The board doesn’t receive the signal from the

float. Lack of water, float, water container micro

switch, electronic board.

ERROR BOILER 1 The board has not received the programmed

value temperature from the boiler probe in the

maximum time of 15 minutes.

Safety thermostat, boiler heating element,

electronic board.

EMPTY GROUNDS! The coffee grounds decounter has reached the

programmed value. Empty the grounds and execute the quick

function nr.5.

ERROR EXECUTIVE At the power-on, the board has not received

signals by the payment payment, Executive or

MDB, programmed.

Payement system, cables, electronic board..

Pag. 5

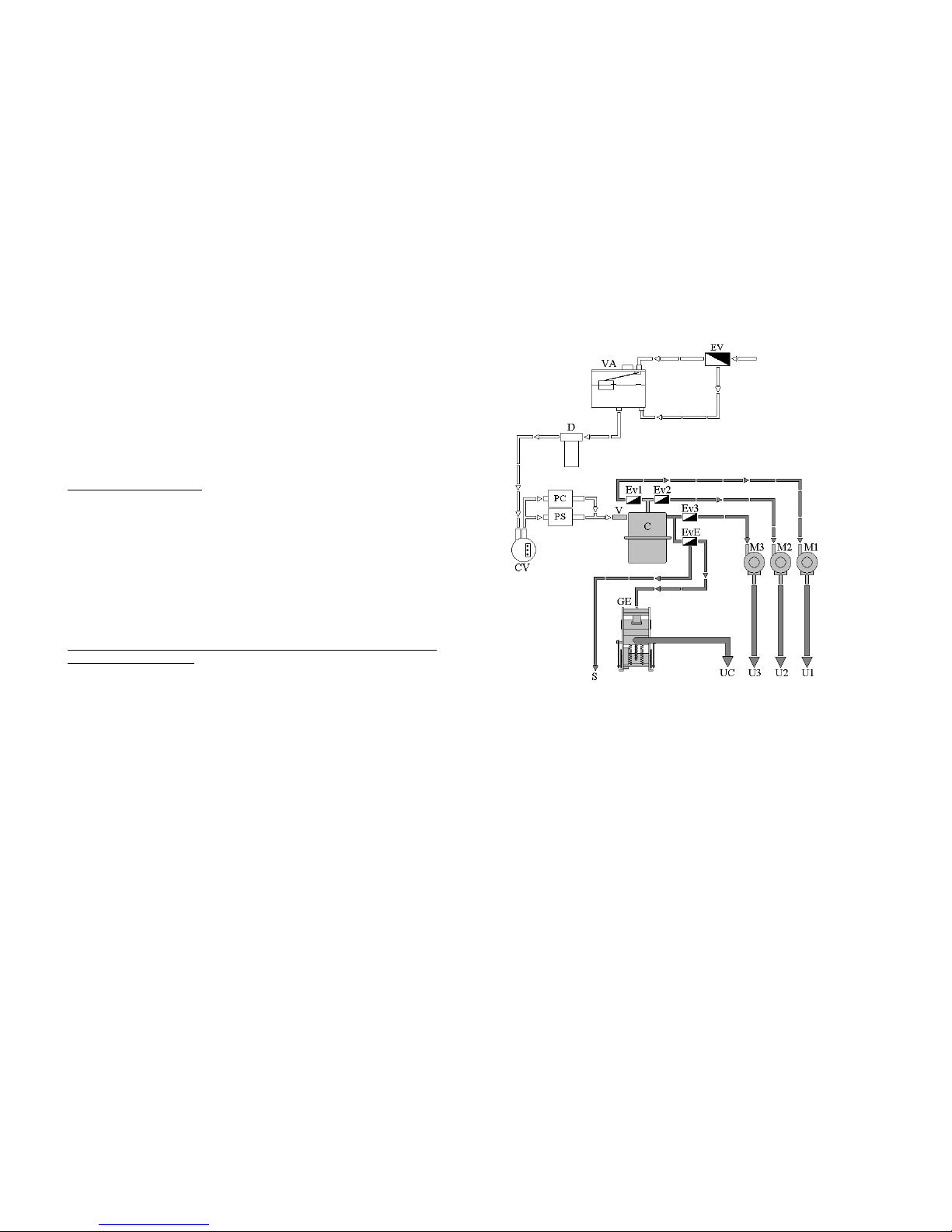

HYDRAULIC CONNECTION

INSIDE TANK

The machine is already set for the inside tank working.

WATER SYSTEM CONNECTION (OPTIONAL)

• disconnect the silicon pipe, which comes from the tank, from the limestone

filter.

• connect the silicon pipe coming from the water resevoir to the filter.

• connect the connector with the two grey wires coming from the water reser-

voir to the connector with two grey wires of the machine.

• disconnect the wires of the float and connect the black and green wires com-

ing from the water reservoir to the black and green wires into the machine.

• check that the net-system pressure doesn't overcome the 2 bars, otherwise it is

necessary to install a pressure reductor.

• Connect the water inlet tube to the inlet electrovalve with a ¾ " fitting.