- 4 -

3.2 Initial Start-up:-

a. Connect the power supply so that the unit immediately comes to working status.

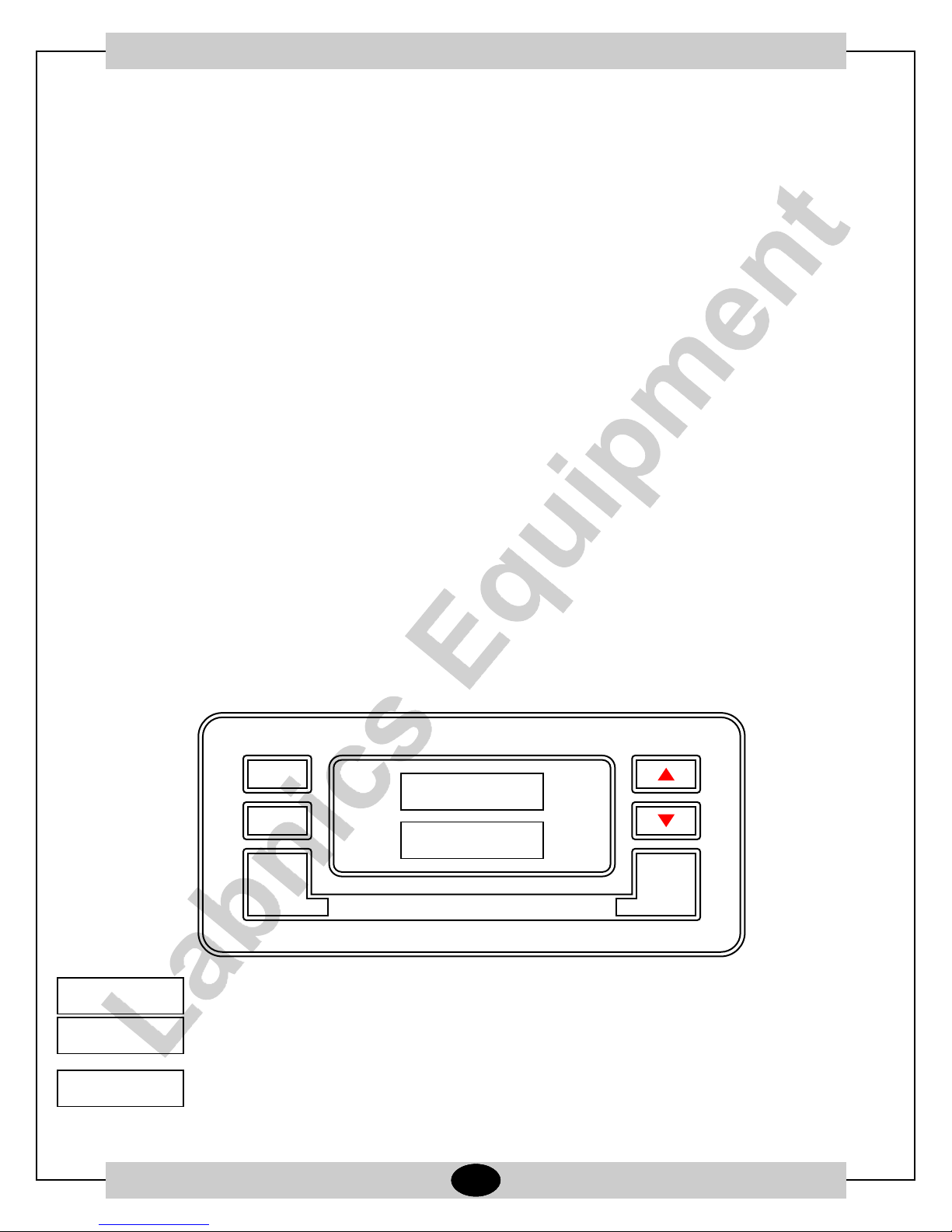

b. The initial password for locking keyboard is "0000" in factory. Before entering the password, the "set",

"6" and "5" keys are all disabled while "PA" displayed in LCD window.

c. Enter Password: Press "PA" to make the input window active. The LCD for up cabinet displays "PA"

and the LCD for down cabinet displays "000" with the mark blinking. Press "6" to change the input bit

which circularly blinks from the hundred to one bit in turn. Press the key once for one bit. Now press "5"

to enter your required number in the blinking bit, press the key to add 1 per touch to this bit which will

return to 0 after 9. After entering all three bits password, press "Enter". If the entered password is right,

LCD will stop blinking and display . Now the password is unlocked. If the wrong password is entered,

it will still keeps on lighting and blink for 6 seconds with a frequency of 2HZ. Only after releasing the

password all functions and parameter changes and setting are activated. Under unlocking status, if no

keys are pressed within 2 minutes, the system switches to locking condition.

d. Set Password: Under unlocking state press the "PA" key, so that LCD displays the current password

with the hundred bit blinking. Press "6" to change the setting bit which circularly blinks from hundred bit

to one bit in turn. Press the key once for one bit. Now press "5" to set your required number for the

blinking bit, press the key to add 1 per touch to this bit which will return to 0 after 9. When all new three

bits number is set, press "Enter" key. Then LCD stops blinking and displays the new password.

System will save your new password and 15 seconds later, the LCD returns to its normal displaying

state.

e. "Mute" : Press the "Enter" key, LCD displays "Mute" and the alarm buzzer switches to alarm locked

status. Now, the alarm buzzer will be closed under any error condition.

f. Disable "Mute": Press the "Enter" key again, the mute indicator lamp closes and the alarm buzzer

switches to open status. The buzzer may work and will stop only when the system recovers to its normal

working condition. Otherwise press the "Mute" key again to close the alarm buzzer. Then the mute

indictor lamp lights up and the buzzer come to alarm locked status.

g. Set Temperature:

Under unlocking state press the "Set" key to set different running temperatures. Press the key per

touch, the LCD displays "Temp → HTL → LTL → Time → Temp" respectively in turn. Set the

corresponding parameter when the required parameter lamp lights. If no keys have been pressed

within 15 seconds, the system exits the setting state and reverts to its normal display.

Press the "Set" key to change the system to "Temp" state and set the running temperatures for

up and down cabinets. LCD windows display the current setting value with the Ten bit of up cabinet

temperature blinking. Press "6" to change the blinking bit which changes in sequence

accordingly "Ten bit of up → One bit of up → Ten bit of up → Ten bit of down → One bit of down →

Ten bit of down → Ten bit of up". Now press "5" to add 1 per touch to the blinking bit which will

return to 0 after 9. When the setting finishes, press the "Enter" key to activate the setting. Then the

indictor lamp in temperature display window stops blinking and the mark "Temp" disappears.

Then the system exits the setting status, if no keys have been pressed within 15 seconds, system

exits the setting state without getting any data saved and reverts to its normal display.

o o

Notice : The default temperature is set as -35 C in factory. Please do not set any temperature lower than -40 C to

assure the performance and stability of unit.