Code 9 9.900.900.763 3/19

U:\QA\Manualer\Arkiv\Manuals- Labogene-Origio-GKO\Manualer-WORD\ScanVac\CoolSafe XS

XL Usermanual-Rev A5.docx

Table of contents

1. Introduction -------------------------------------------------------------------- 4

2. Safety precautions-------------------------------------------------------------- 4

2.1. General information--------------------------------------------------------- 4

2.2. Safety --------------------------------------------------------------------------- 4

3. Installation ---------------------------------------------------------------------- 5

3.1. Installation of CoolSafe ----------------------------------------------------- 5

3.2. Installation of vacuum pump ---------------------------------------------- 5

3.3. Installation of Shelving module-------------------------------------------- 6

4. Functional description --------------------------------------------------------- 6

4.1. Mains----------------------------------------------------------------------------- 6

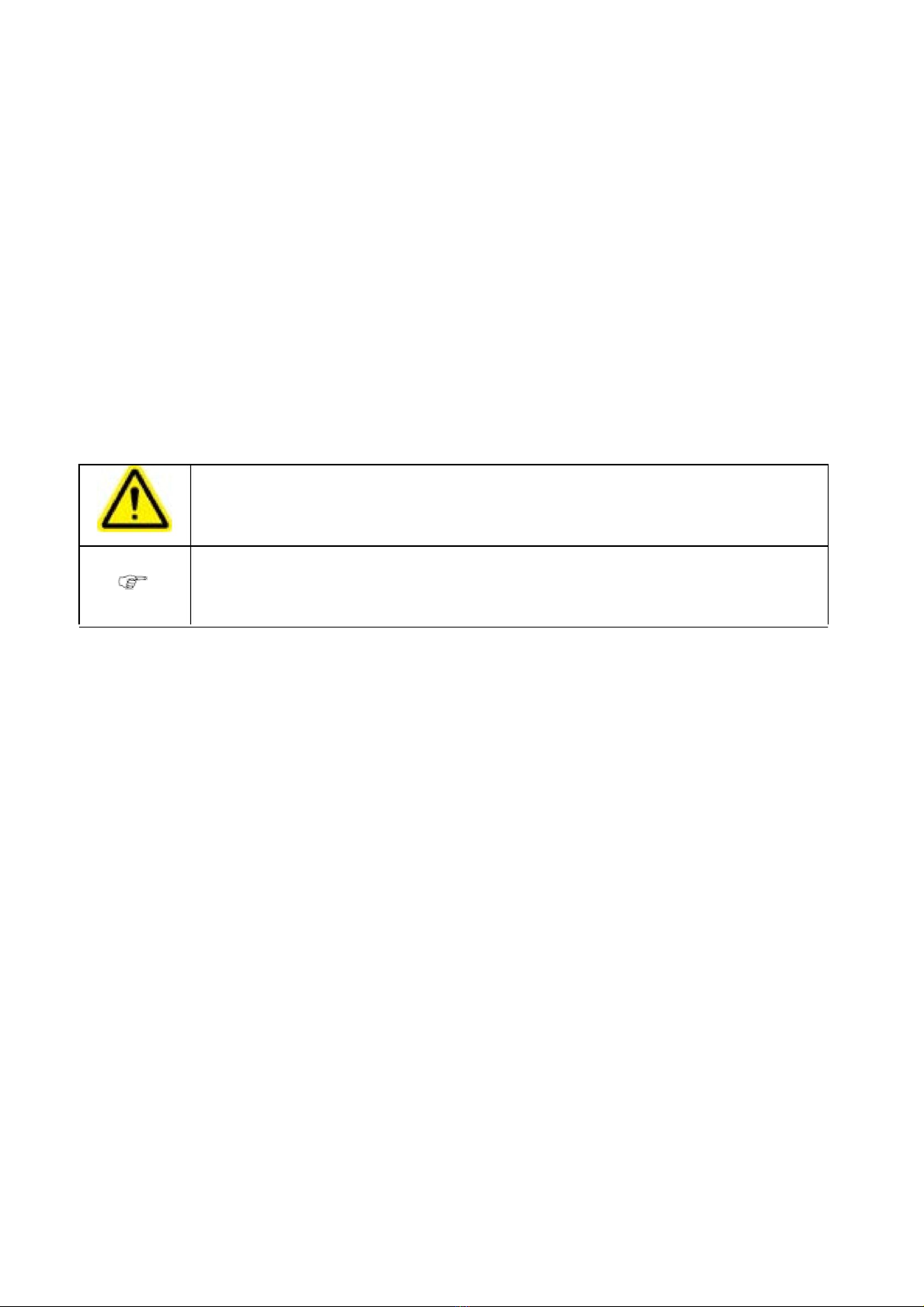

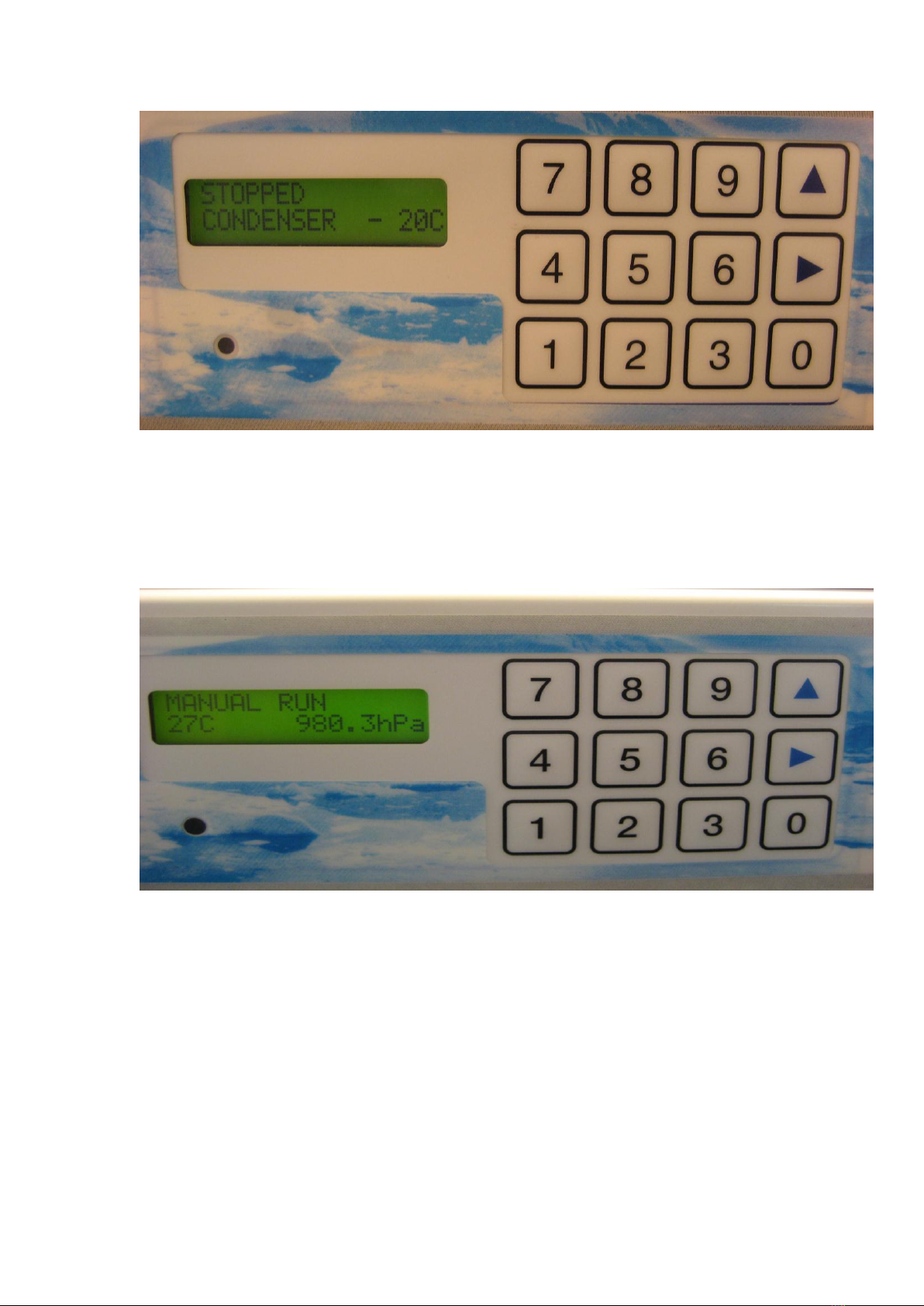

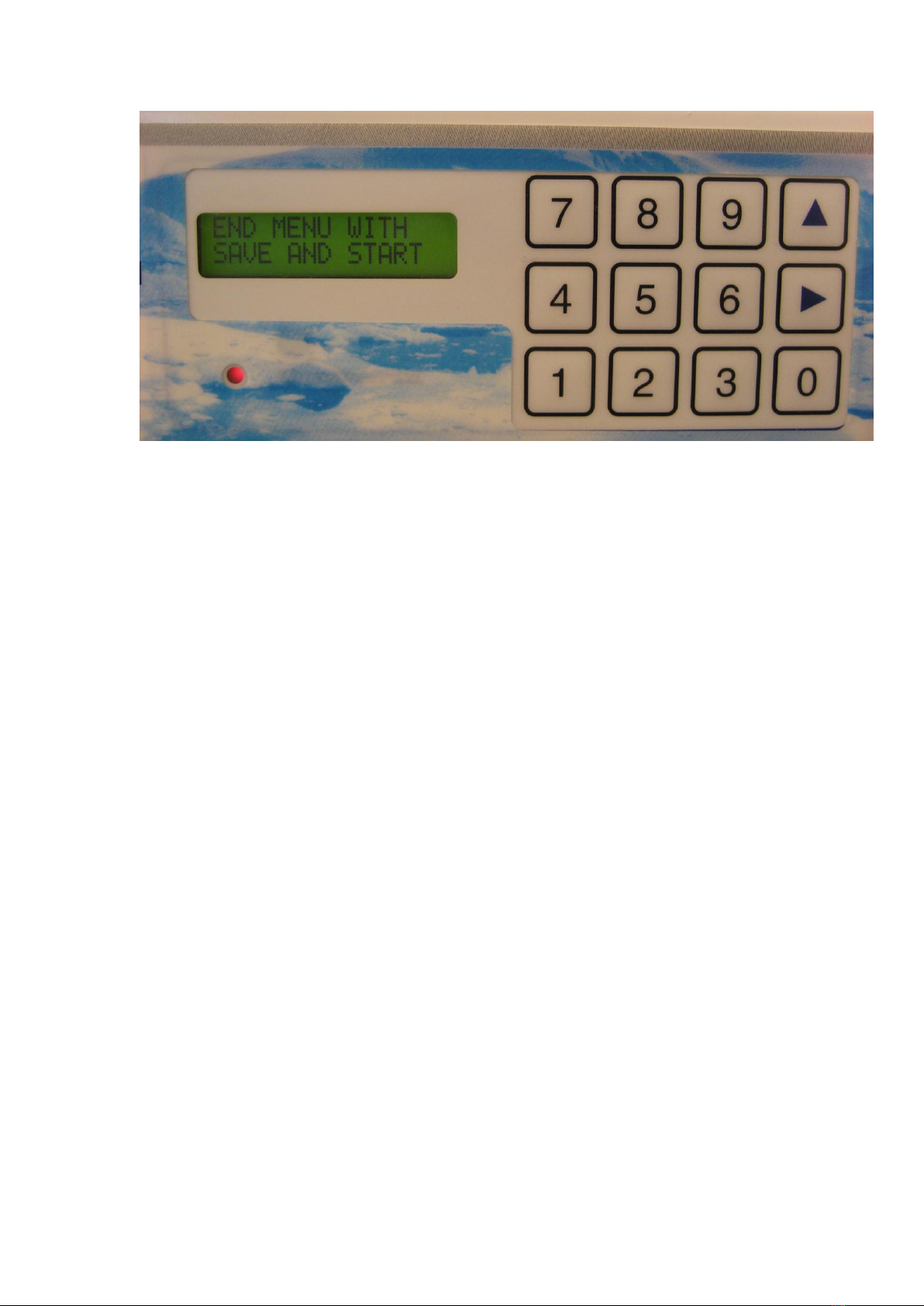

5.0. Control panel Pro ------------------------------------------------------------- 6-9

5.1. Operation --------------------------------------------------------------------- 9

5.2 Computer control option ---------------------------------------------------- 9

5.3 Preparation -------------------------------------------------------------------- 10

5.4.Pre-Freezing & Freeze Drying----------------------------------------------- 11

5.5 De-Icing--------------------------------------------------------------------------- 11

5.6 Stopping Vacuum pump---------------------------------------------------- 12

6. Alarms and errors------------------------------------------------------------- 12

7. Maintenance-------------------------------------------------------------------- 13

7.1 CoolSafe------------------------------------------------------------------------ 13

7.2. Vacuum pump -------------------------------------------------------------- 13

7.3. Cleaning ---------------------------------------------------------------------- 13

7.4 Checking for Leaks---------------------------------------------------------- 13

8. The Freeze-drying process--------------------------------------------------- 14

8.1 Hints & Tips------------------------------------------------------------------- 15

8.2 Bibliography------------------------------------------------------------------- 15

8.3 Pressure Table---------------------------------------------------------------- 17

9.0 Factory fitted options-------------------------------------------------------- 18

Enclosure: Declaration of conformity