PAGE 5

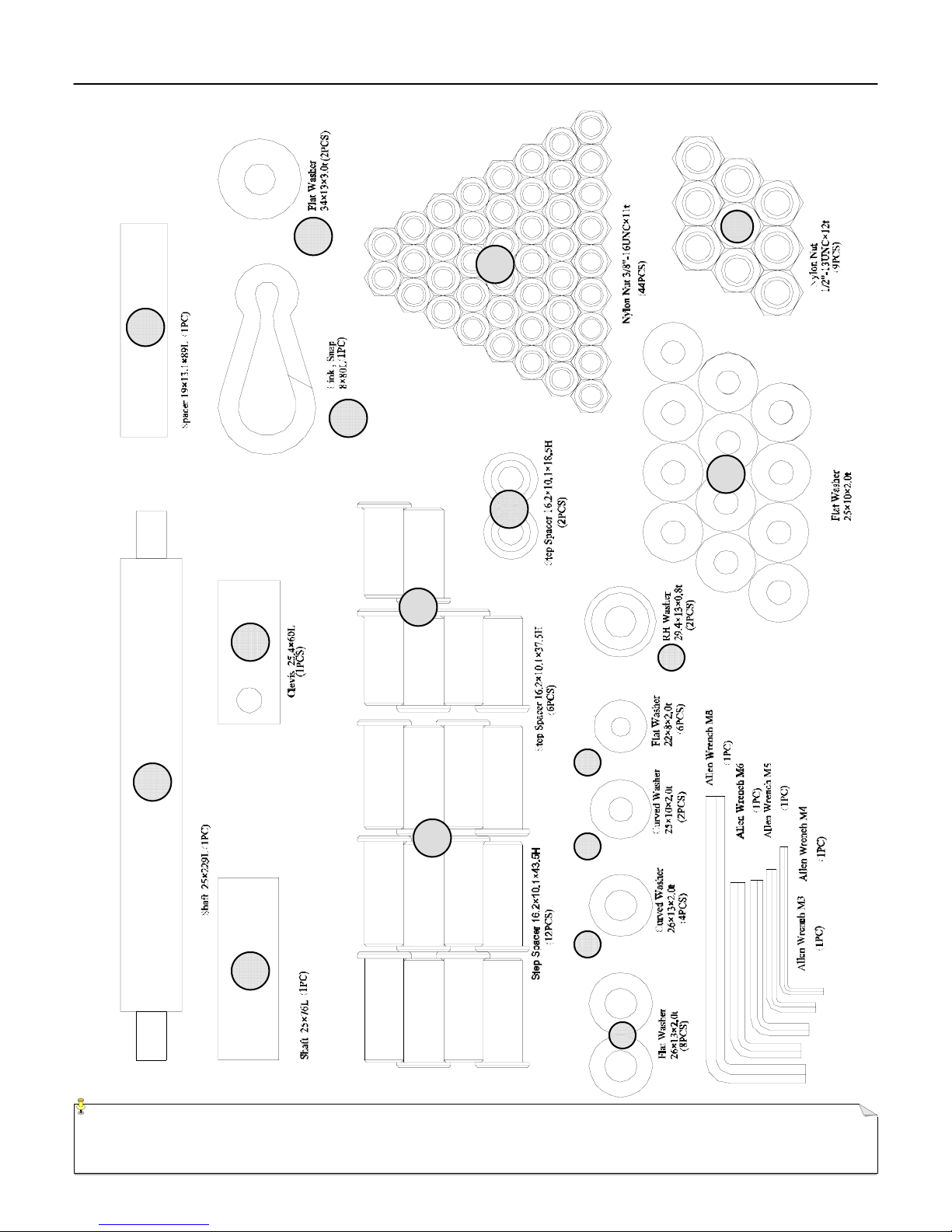

39 01207 Button Head Allen Screw 3/8"-16UNC x 3.25" Length

40 01173 Button Head Allen Screw 3/8"-16UNC x 2.75" Length

41 01193 Button Head Allen Screw 3/8"-16UNC x 2.25" Length

42 01195 Button Head Allen Screw 3/8"-16UNC x 2.00" Length

43 01072 Button Head Allen Screw 3/8"-16UNC x 1.00" Length

44 01165 Button Head Allen Screw 3/8"-16UNC x 0.75" Length

45 01076 Button Head Allen Screw 5/16"-18UNC x 2.50" Length

46 01226 Button Head Allen Screw 5/16"-18UNC x 1.25" Length

47 01208 Flat Head Allen Screw 3/8"-16UNC x 0.75" Length

48 01209 Flat Washer 1/2" x 26mm

49 01210 Curved Washer 1/2" x 26mm

50 01211 Flat Washer 3/8" x 25mm

51 01212 Curved Washer 3/8" x 25mm

52 01213 Flat Washer 5/16" x 22mm

53 01214 Cap Mounting Ring

54 01216 Nylon Nut 1/2"-13UNC

55 01217 Nylon Nut 3/8"-16UNC

56 01087 Plastic Washer 1.125" I.D.

57 01222 Hardware Cap

58 27028 Threaded Split (Clamp) Collar

59 05094 Weight Stack / Guide Rod Bumper 2.50" dia. X 1.50"

60 03045 Roller Pad

61 03042 Seat Pad

62 03043 Upper (Small) Back Pad

63 03044 Lower (Large) Back Pad

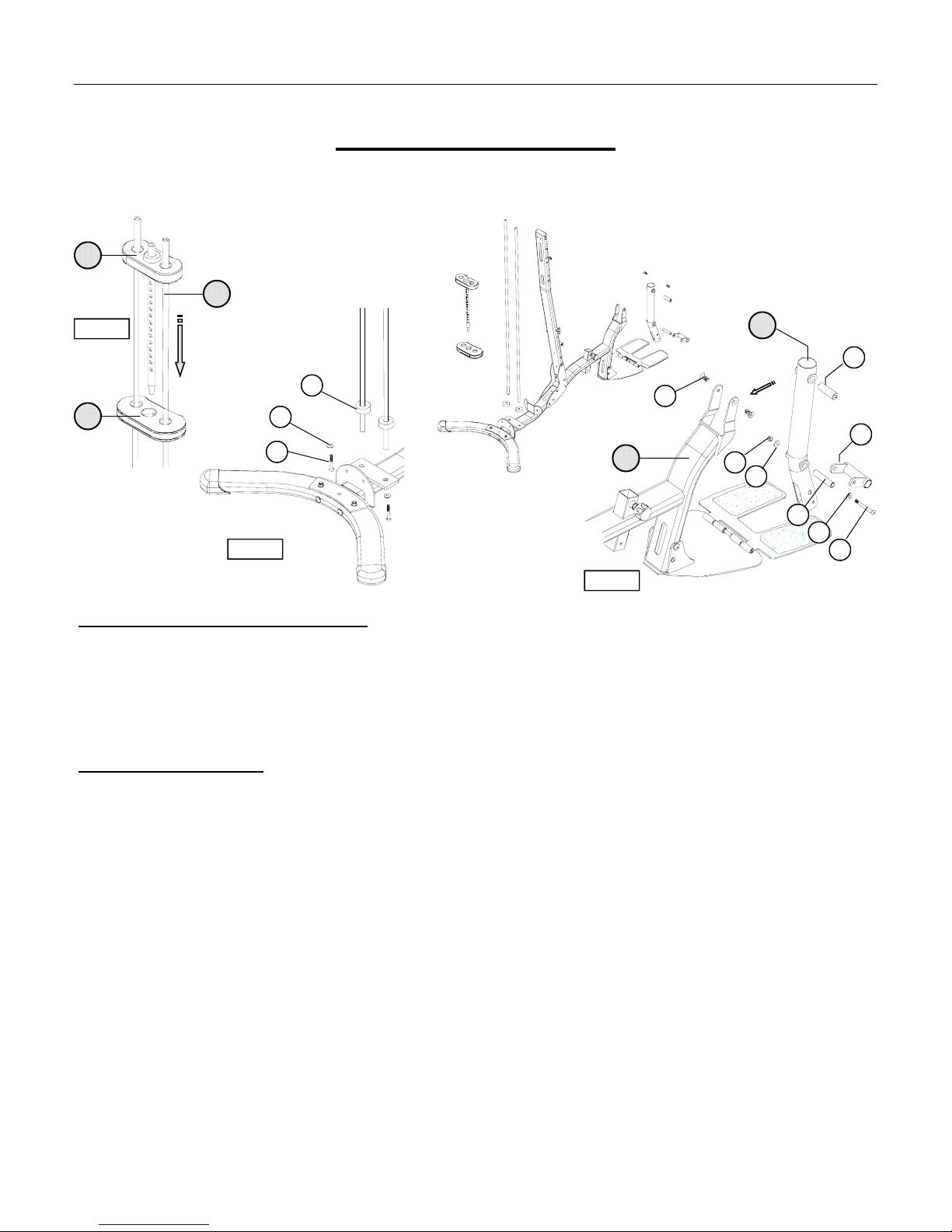

64 01219 Pulley Spacer 16.2 x 10.1 x 43.5

65 01220 Pulley Spacer 16.2 x 10.1 x 37.5

66 01221 Pulley Spacer 16.2 x 10.1 x 18.5

67 01215 Flat Washer 34 x 13 x 3.t (Pivot Shaft)

68 25006 Weight Plate (single)

69 05097 Selector Pin (Weight Plate)

70 20006 3.5 inch dia. Cable Pulley

71 20007 4.5 inch dia. Cable Pulley

72 32006 Lat / Press Arm Cable Assembly (Length: 151.58 inches )

73 32005 AB Crunch Cable Assembly (Length: 71.38 inches)

74 32003 Low Pull / Leg Extension Cable Assembly (Length: 110.63 inches)

75 32007 Free Motion Cable Assembly (Length: 143.31 inches)

Item # Part Number Description

76 01218 Snap Link (Accessory Mounting)

2

6

4

9

2

4

2

4

2

8

4

70

2

6

2

9

44

8

2

4

2

4

1

1

1

12

6

2

2

19

1

21

2

1

1

1

1

Quantity

1

LS 70 GYM