-6-

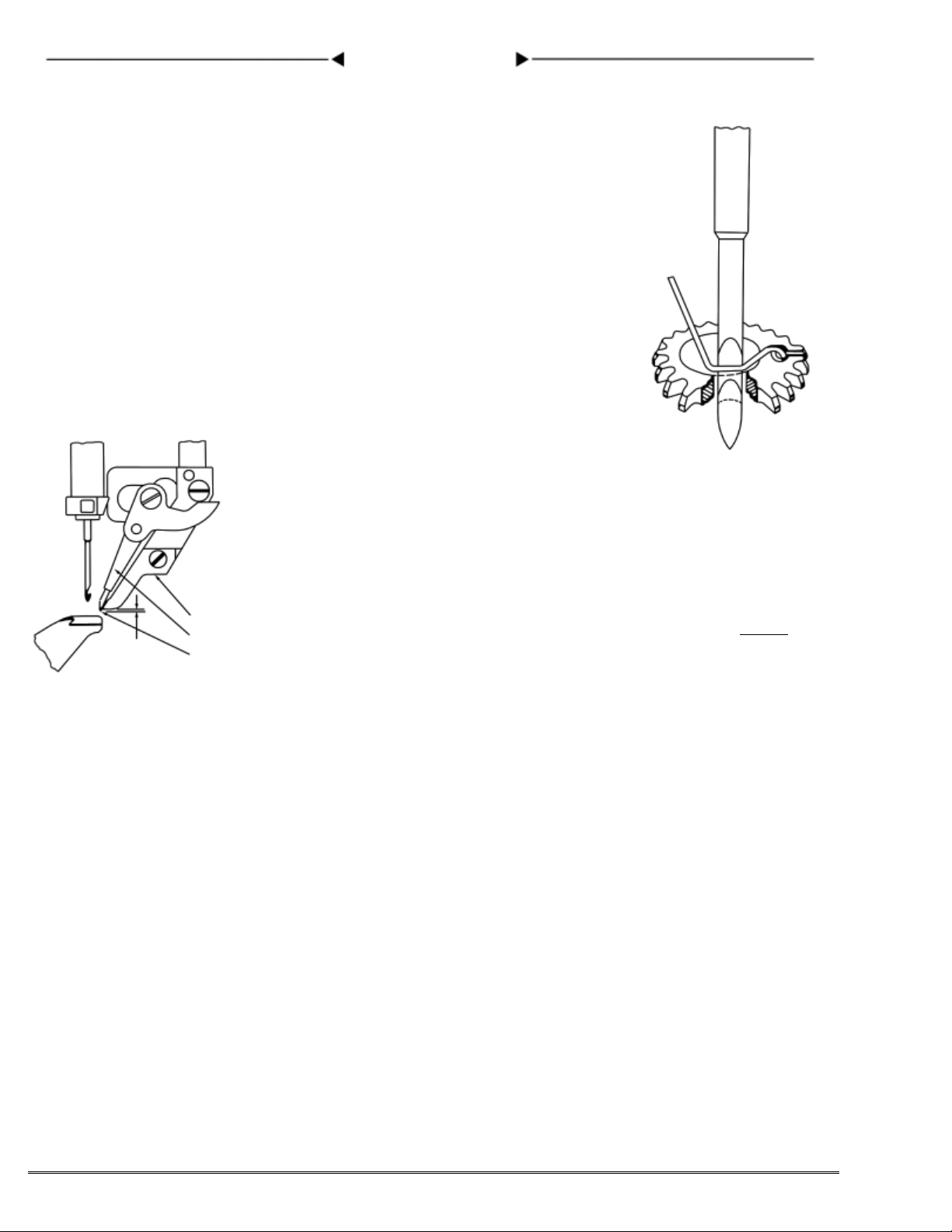

CAUTION:

Before mounting the sole on a shoe, it will be well to find and pull out two to four staples, which will

be found near the beginning of the toe curvature, where the upper puckers worst. These staples were put

in to hold the sole before the first McKay sewing. These staples will interfere with sewing and may even

break the needle. They are generally a little outside the row of lasting tacks.

STITCHING SHOES

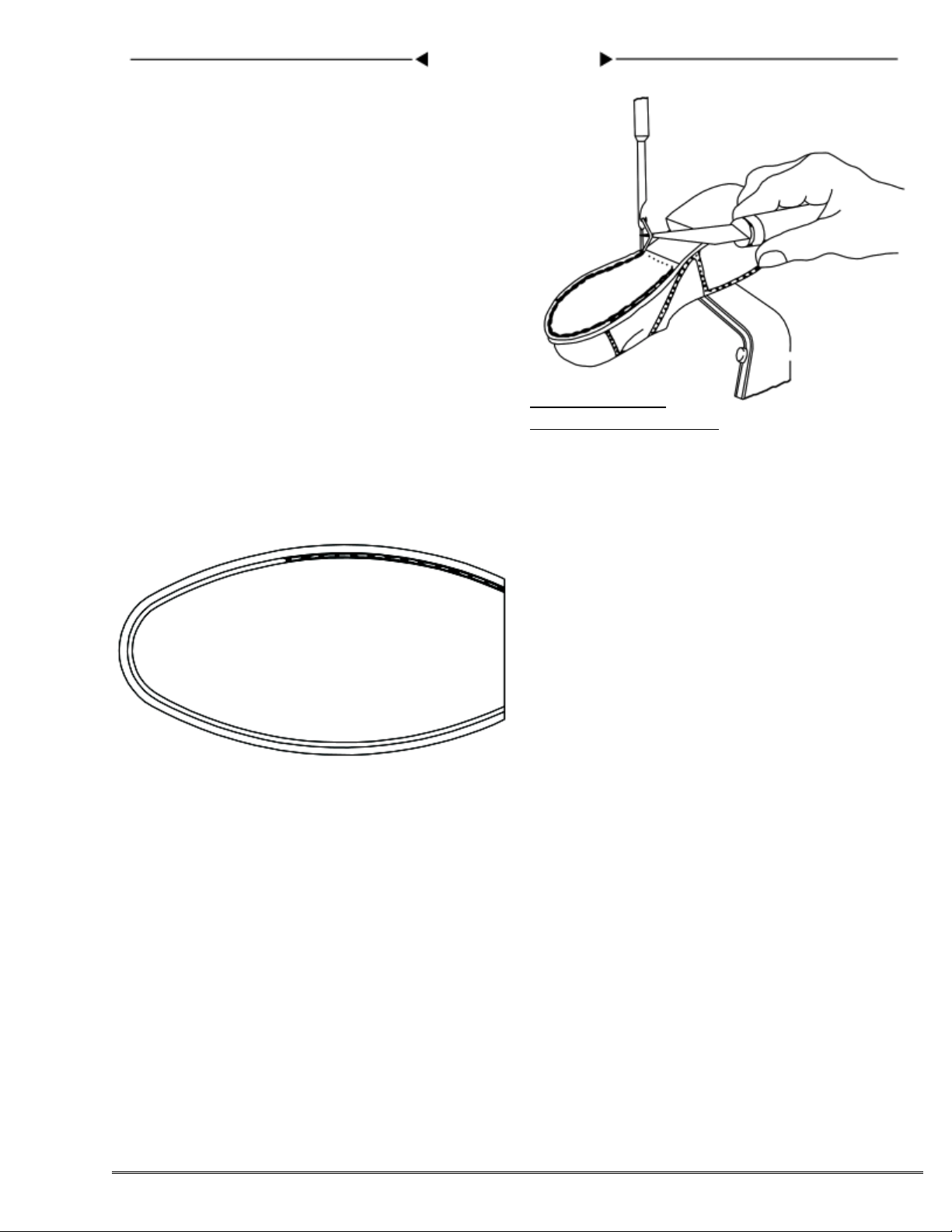

Shoes are stitched in the same order as on your other stitching machine; that is to say, the shoe is

put on the horn with the heel to the left and the stitches started in the shank, stitching up and around the

toe, turning the heel of the shoe from left to right, with the heel towards the operator, then sewing down the

opposite side of the shoe to the shank with the heel on the right. You will find this procedure extremely

easy.

With the different types of shoes, namely Welt, McKay and Turn, it will be found necessary to stitch

at different distances from the edges of the inner sole.

On McKays, the usual practice is to stitch along the old line of stitching if the make-up of the shoe

enables the line of stitching to catch the upper.

In stitching the Turn shoe, it is desirable to stitch outside of the inside channel of the turn shoe in

order to catch the upper.

In stitching the Welt shoe, it is desirable to stitch as close to the edge of the inner sole as the Horn

will permit. The same applies to the stitching of cement shoes.

It might be well to mention the fact that often on McKay shoes the uppers are not drawn or lasted as

close to the shank as they should be, in which case it would be good practice to sew a little outside the

regular line of stitching to catch the upper.

NOTE: With the channel cut the proper distance from the edge, this difference of stitching from

the edge of the inner sole can be accomplished by simply tipping the shoe up in back or down in front, as

the case may require, much on the order of the Straight Needle Stitcher. The tipping of the shoe has the

desired effect of setting the stitches in on the insole or out as may be desired.

Ordinarily the stitching is accomplished by simply holding the shoe in its place on the horn and

the presser foot in the groove, letting the machine feed the shoe around.

LANDIS “77”