Table of Contents

1SAFETY PRECAUTIONS........................................................................................................................................................................3

2SPECIFICATIONS...................................................................................................................................................................................4

2.1 Specification of Console Components ..........................................................................................................................................4

2.2 System Overview and General Specification................................................................................................................................7

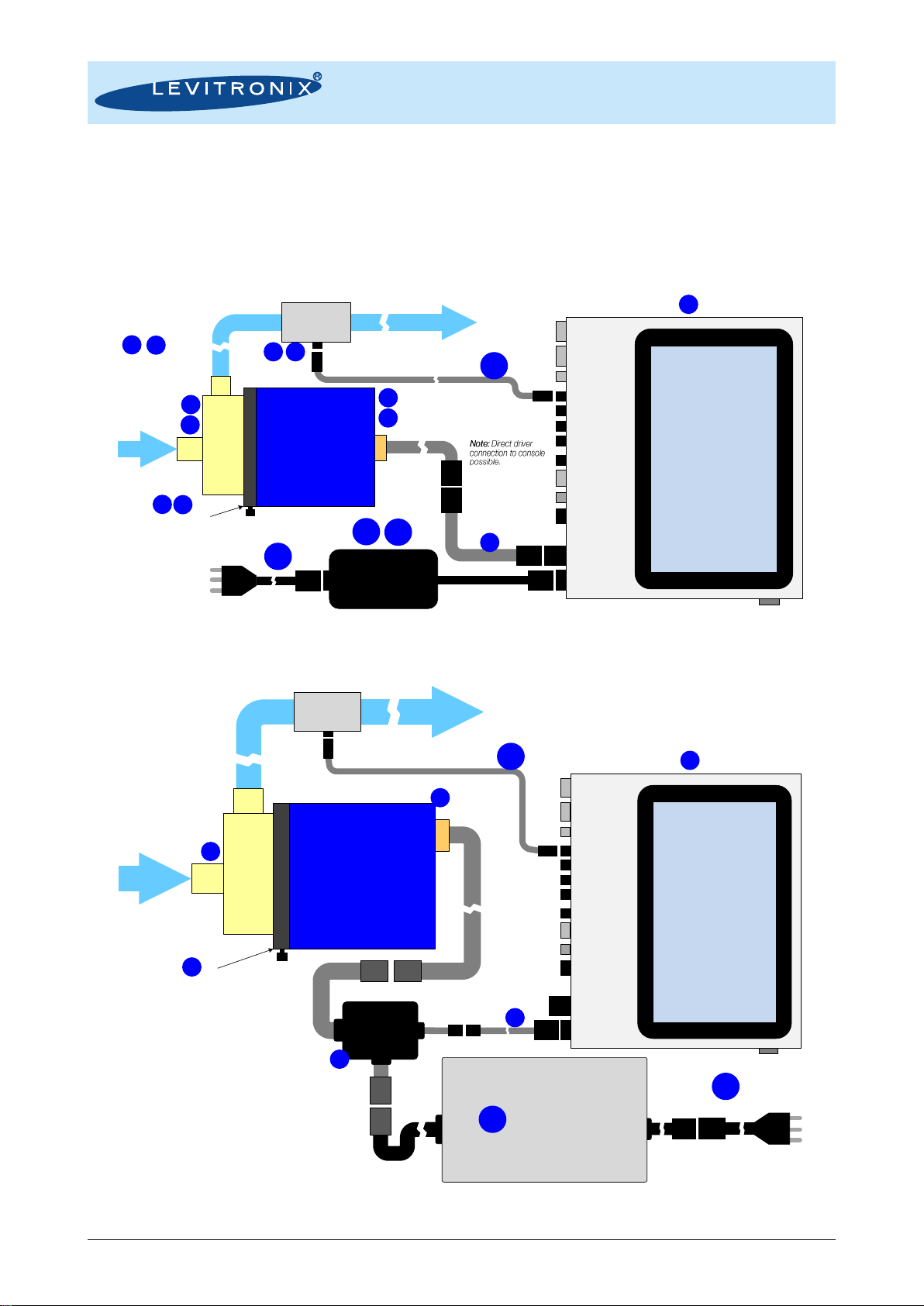

2.2.1 Basic Stand-Alone System Configuration..........................................................................................................................................................7

2.2.2 Extended System Configuration ........................................................................................................................................................................8

2.3 General Environmental Conditions................................................................................................................................................9

2.4 Basic Dimensions of Console........................................................................................................................................................9

3ENGINEERING INFORMATION ...........................................................................................................................................................10

3.1 IP Rating.......................................................................................................................................................................................10

3.2 Temperature Monitoring ..............................................................................................................................................................10

4INSTALLATION.....................................................................................................................................................................................10

4.1 Mechanical Installation.................................................................................................................................................................10

4.2 Electrical Installation ....................................................................................................................................................................11

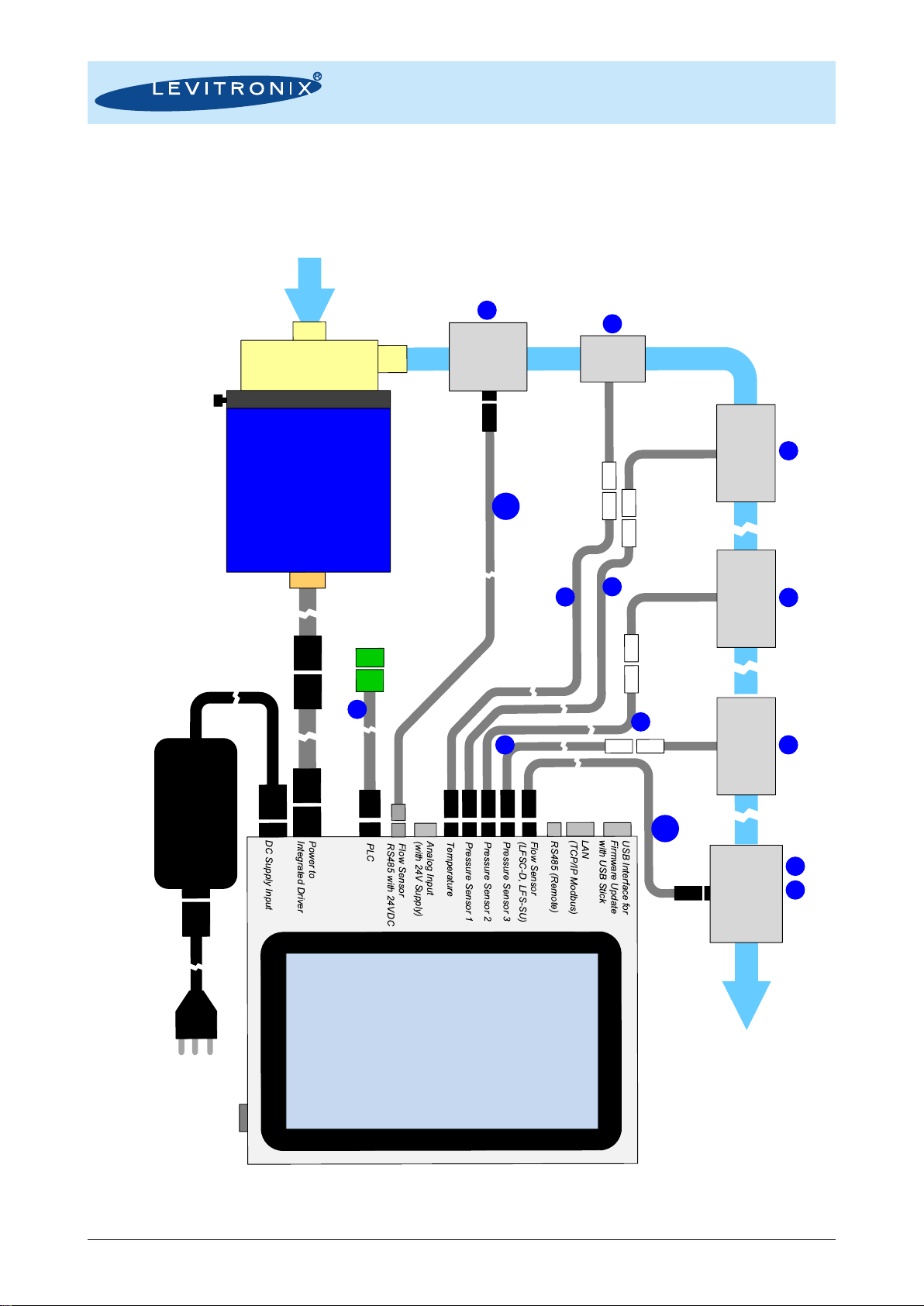

4.2.1 Connection Overview.......................................................................................................................................................................................11

4.2.2 PLC Interface...................................................................................................................................................................................................12

4.2.3 Analog Input with 24VDC Supply.....................................................................................................................................................................13

4.2.4 General Installation Instructions ......................................................................................................................................................................14

5OPERATION..........................................................................................................................................................................................15

5.1 Basic System Operation ..............................................................................................................................................................15

5.1.1 Start-Up............................................................................................................................................................................................................15

5.1.2 Power-Down.....................................................................................................................................................................................................15

5.1.3 Auto-Resume Feature......................................................................................................................................................................................16

5.1.4 Software Update ..............................................................................................................................................................................................16

6MAINTENANCE.....................................................................................................................................................................................17

6.1 Cleaning .......................................................................................................................................................................................17

7TROUBLESHOOTING ..........................................................................................................................................................................17

8TECHNICAL SUPPORT........................................................................................................................................................................17

9APPENDIX .............................................................................................................................................................................................18

9.1 Regulatory Status.........................................................................................................................................................................18

9.1.1 CE Marking ......................................................................................................................................................................................................18

9.1.2 IECEE CB Safety Certification.........................................................................................................................................................................18

9.1.3 NRTL/ETL Safety Certification and Marking....................................................................................................................................................18

9.1.4 Disposal of Equipment –WEEE Directive 2012/19/EU...................................................................................................................................18

9.2 Symbols and Signal Words..........................................................................................................................................................19