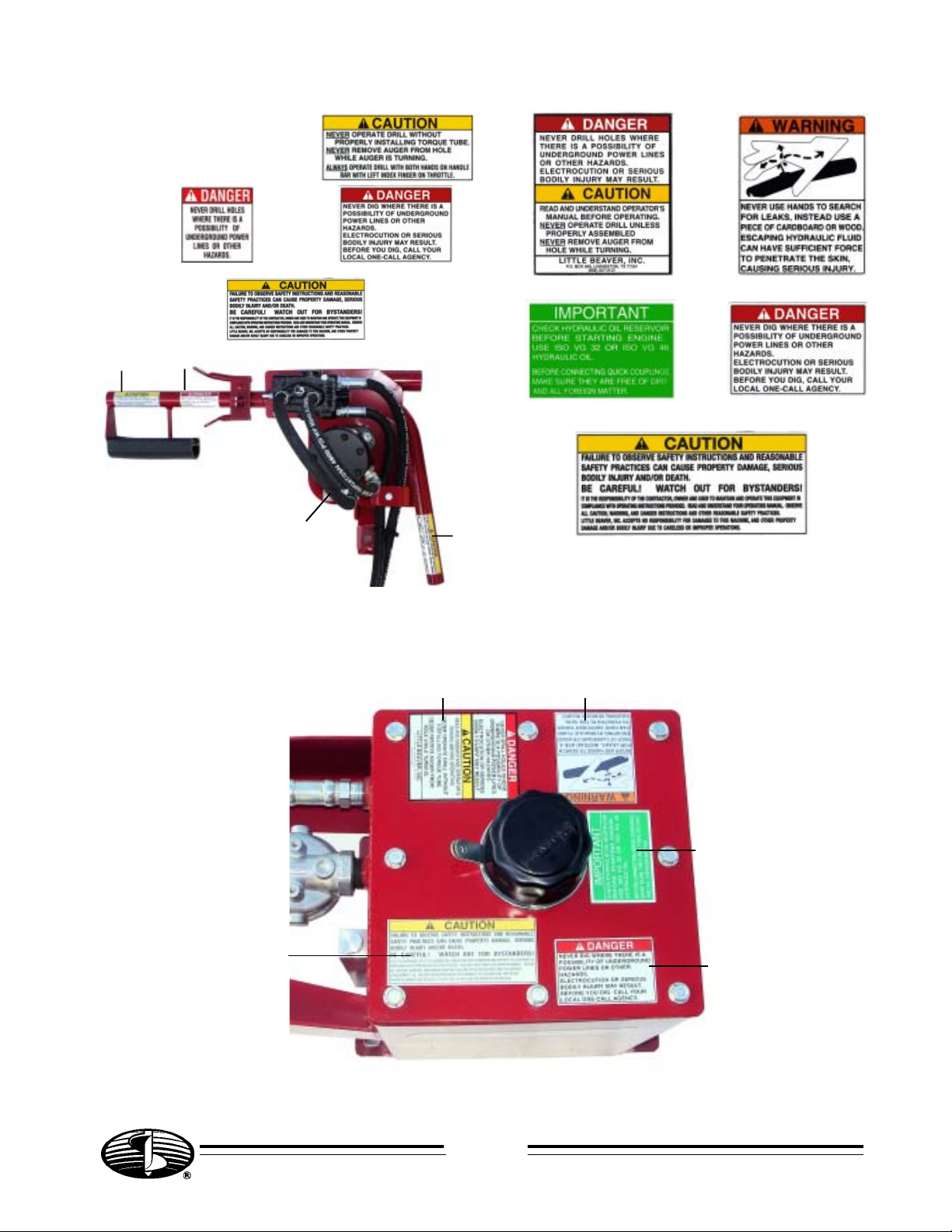

SAFETY INSTRUCTIONS

DANGER: Failure to observe safety instructions and reasonable safety practices can

cause Property Damage, Serious Bodily Injury and/or Death. BE CAREFUL!! WATCH OUT

FOR BYSTANDERS!!

DANGER: NEVER run engine inside building or enclosed area. Exhaust gases contain carbon

monoxide, an odorless and deadly poison.

DANGER: NEVER drill holes where there is a possibilityof underground power cables or other

hazards. The exact location of underground services must be determined prior to drilling.

Inadvertent severing of telephone, fiber optic or CATV transmission cable, or damage to sewer

pipe is costly; RUPTURING OF GAS OR WATER LINES CAN CAUSE SERIOUS BODILY INJURY AND/

OR DEATH. COMING INTO CONTACT WITH BURIED POWER LINES CAN CAUSE SERIOUS BODILY

INJURY, SEVERE BURNS, AND/OR ELECTROCUTION. Call local utility companies or your local "One-

Call" number at least 48 hours before digging and have underground utilities marked.

WARNING: Never use hands to search for leaks. Instead, use a piece of cardboard or wood.

Escaping hydraulic fluid under pressure can have sufficient force to penetrate the skin, causing

serious injury. Before disconnecting lines, be sure to relieve pressure. Before applying pressure,

be sure connections are tight and fittings and hoses are not damaged.

WARNING: Augers are not to be used as anchoring devices.

CAUTION:

1. READ and understand this operator’s manual and the operator’s manual for the engine.

2. NEVER Operate drill without correctly installing torque tube.

3. NEVER Remove auger from hole while auger is turning.

4. NEVER Operate auger at less than full throttle.

5. NEVER Operate drill with damaged auger or other damaged or missing parts.

6. KEEP Hands, Feet and Clothing away from moving parts while engine is running.

7. KEEP All safety shields and devices in place.

8. MAKE Certain everyone is clear before operating the machine.

9. KEEP Leg pad against leg while drilling to maintain safe control.

10. WEAR SAFETY GLASSES.

11. KEEP Bystanders away from work area.

12. SHUT OFF Engine to adjust, service or clean the machine.

NOTICE

It is the responsibility of the contractor, owner and user to maintain and operate the Earth Drill in

compliance with operating instructions provided. Observe all listed safety instructions and other

reasonable safety practices. LITTLE BEAVER, INC. accepts no responsibility for damages to this machine,

and other property damage and/or bodily injury due to careless or improper operations.

LITTLE BEAVER, INC. does not recommend or condone any modifications which would eliminate the torque

tube.

LITTLE BEAVER, INC. does not recommend use of replacement hydraulic motors which would result in

auger shaft torque greater than 400 ft.-lbs. If greater torque is required, please consult factory.

LITTLE BEAVER, INC. reserves the right to make changes in design and changes for improvements upon

its product without imposing any obligation upon itself to install the same upon its products theretofore

manufactured.

Your operators manual offers recommendations for prolonged and satisfactory service.

SPECIFICATIONS

11 HP Honda, 11 HP Briggs & Stratton OR 11 HP Wisconsin

6 GPM @ 2000 PSI

100 Micron Suction Screen

10 Micron Replaceable Return Line Filter

5 Gallon Hydraulic Reservoir

Page O-3

0196