For Further Inquires Call:

1-800-227-7515

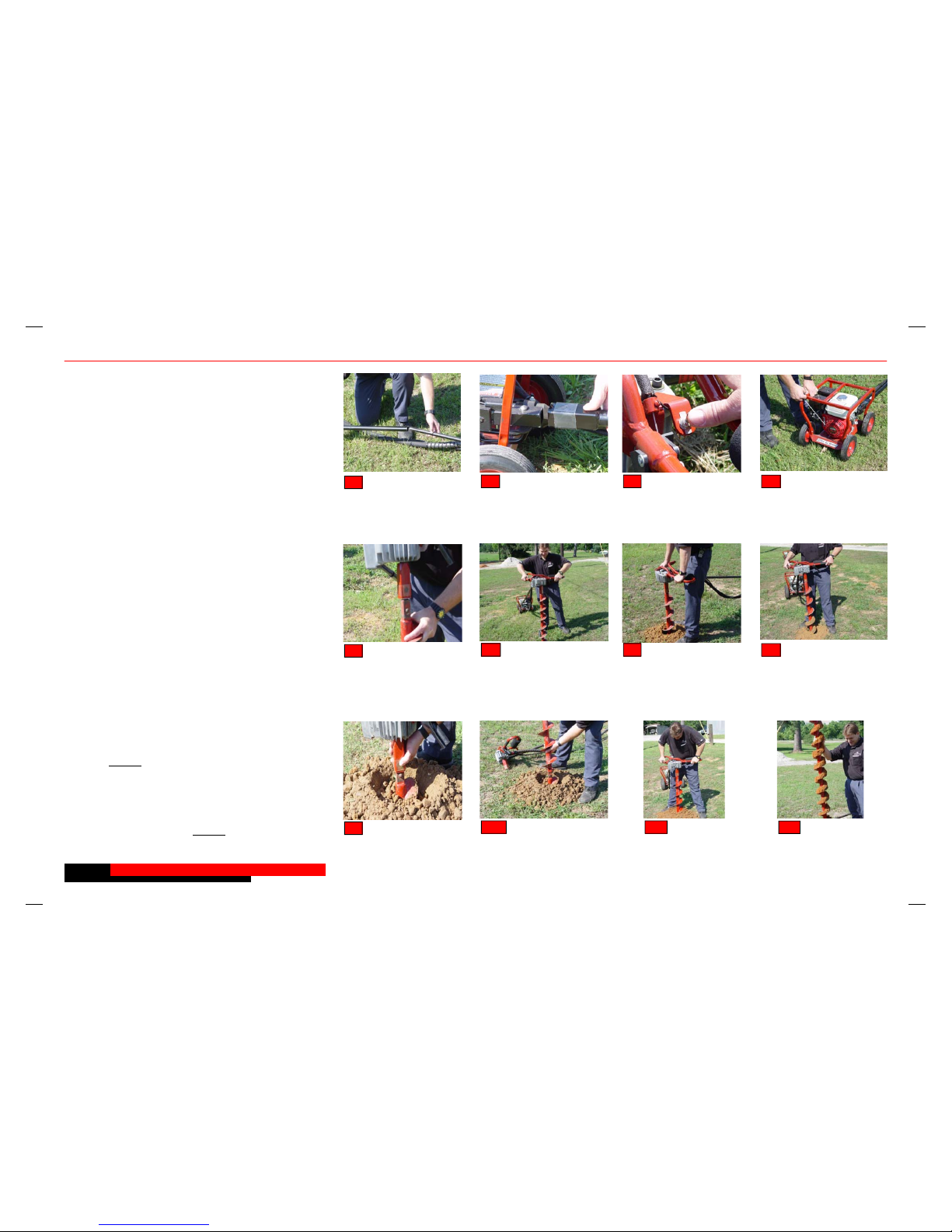

Little Beaver How-To Series

Basic Operating Instructions for

the Mechanical Earth Drill

P.O. Box 840

Livingston, TX 77351

936-327-3121 ph * 936-327-4025 fax

1-800-227-7515

LITTLE BEAVER

EARTH DRILLS & AUGERS

Mechanical Earth Drill

WARNING: Augers are not to be used as anchoring

devices.

CAUTION:

• READ and understand your operator’s manual and

the operator’s manual for the engine.

• NEVER Operate drill without correctly installing

torque tube.

• NEVER Remove auger from hole while auger is

turning.

• NEVER Operate auger at less than full throttle.

• NEVER Operate drill with damaged auger or other

damaged or missing parts.

• KEEP Hands, Feet and Clothing away from moving

parts while engine is running.

• KEEP All safety shields and devices in place.

• MAKE Certain everyone is clear before operating

the machine.

• KEEP leg pad against leg while drilling to maintain

safe control.

• WEAR SAFETY GLASSES.

• KEEP Bystanders away from work area.

• SHUT OFF Engine to adjust, service or clean the

machine.

SAFETY PRECAUTIONS

For over 40 years, the versatile Little Beaver

mechanical earth drill has been the #1

choice of professionals who require a one-

man auger that is safe and simple to oper-

ate. Thanks to our unique Torque Tube,

we’ve eliminated the kickback found in

other drills and made one-man post hole

drilling safe and productive. Follow the in-

structions in this guide to ensure proper op-

eration.

Cannot connect

or disconnect

auger.

1) Toggle kill switch on handle

is off.

2) Engine stop switch is in “OFF

or “O” position.

3) Torque tube is not connected

at the engine end.

4) Fuel level is too low in gas

tank.

5) On oil guard equipped

engine, oil level is too low.

6) Spark plug is fouled.

Motor will not

start

TROUBLE CAUSE

Auger with ex-

tension will not

dig.

Auger turns but

will not dig.

1) Foreign matter collected

around point.

2) Point or blade is dull.

3) Wrong type blade for soil

conditions. Contact dealer

or factory for Little Beaver

carbide blades.

Transmission

overheats.

1) Auger or extensions bent or

running out of line.

2) Number of extensions

exceeds machine capacity.

1) It is normal for the

transmission to run very

warm to the touch. If you feel

it is too hot, consult your

dealer or factory.

Auger turns when

engine idles.

1) Do not use. Contact your

dealer or factory.

Problems not

listed in table.

1) Contact your dealer or

factory.

1) Foreign matter clogging

adaptor.

2) Spring and button in top of

auger is bent or broken.

3) Adaptor is bent.

Auger turns too

slowly and will

not dig.

1) Too much down pressure or

binding on side of hole.

Hold back if necessary to

allow auger to turn at full

speed.

DANGER: Failure to observe

safety instructions and reasonable

safety practices can cause Property

Damage, Serious Bodily Injury and/or

Death. BE CAREFUL!! WATCH OUT FOR

BYSTANDERS!!

DANGER: NEVER run engine

inside building or enclosed area.

DANGER: NEVER drill holes

where there is a possibility of

underground power cables or other

hazards.