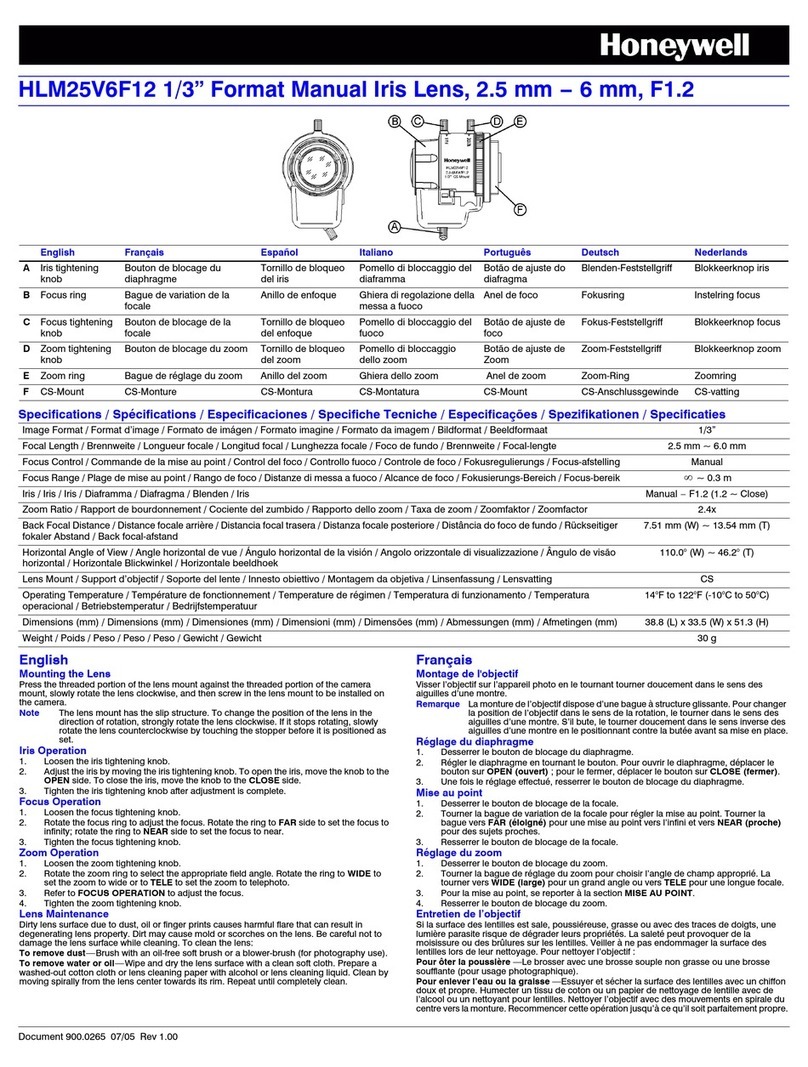

Dust and splash resistant Yes

Maximum diameter Φ84.4 mm (3.3 inch)

Angle of view 34°(Wide) to 12°(Tele)

Filter diameter

Maximum image magnification 0.25×

Image stabiliser Yes

Minimum aperture value

Maximum aperture F4.0

Recording range

Specifications

INTERCHANGEABLE LENS FOR DIGITAL CAMERA

“LUMIX S PRO 70-200 mm F4 O.I.S.”

Focal length f=70 mm to 200 mm

Mount Leica Camera AG L-Mount

F22

23 elements in 17 groups

0.92 m (3.02 feet) to ∞ (from the focus distance reference line)

ⓒ Panasonic Entertainment & Communication Co., Ltd. 2023.

Unauthorized copying and distribution is a violation of law.

Lens construction (1 aspherical lens, 1 UED lens, 3 ED lenses, 1 UHR lens)

Permissible relative humidity 10%RH to 80%RH

-10 ℃ to 40 ℃ (14 ℉ to 104 ℉)

Overall length

Recommended operating

temperature

Mass (Weight) Approx. 985 g (2.17 lb) (excluding the external tripod mount)

Approx. 179 mm (7.0 inch)

(from the tip of the lens to the base side of the lens mount)

77 mm

Aperture type 9 diaphragm blades/Circular aperture diaphragm

S-R70200

Service Training Manual

(Edition of Lens Cleaning) Ver.1.0

Internal use only