CONTENTS

WHAT TO DO WHEN....................................................................................................... 1 to 3

SERVICE ACCESS

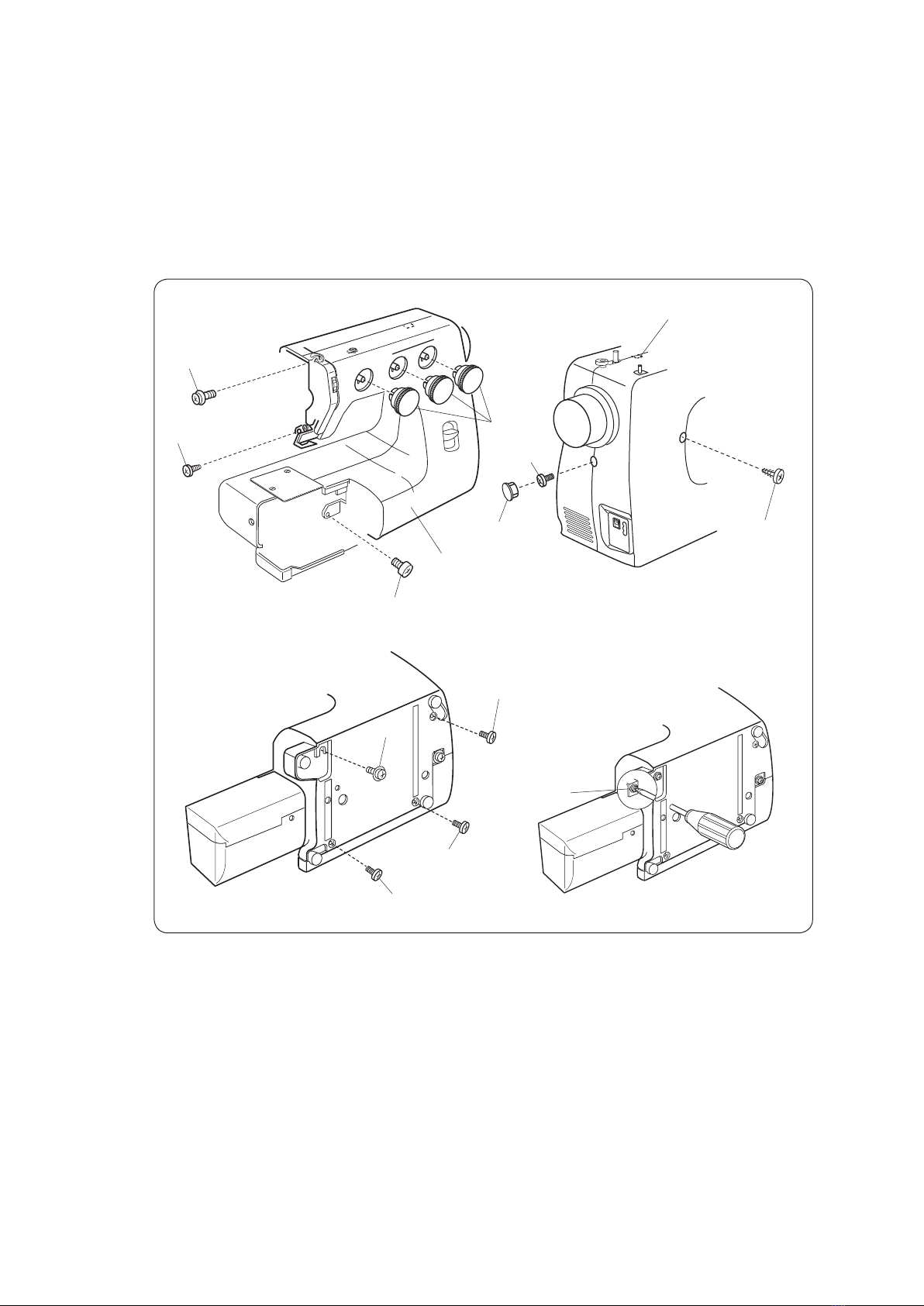

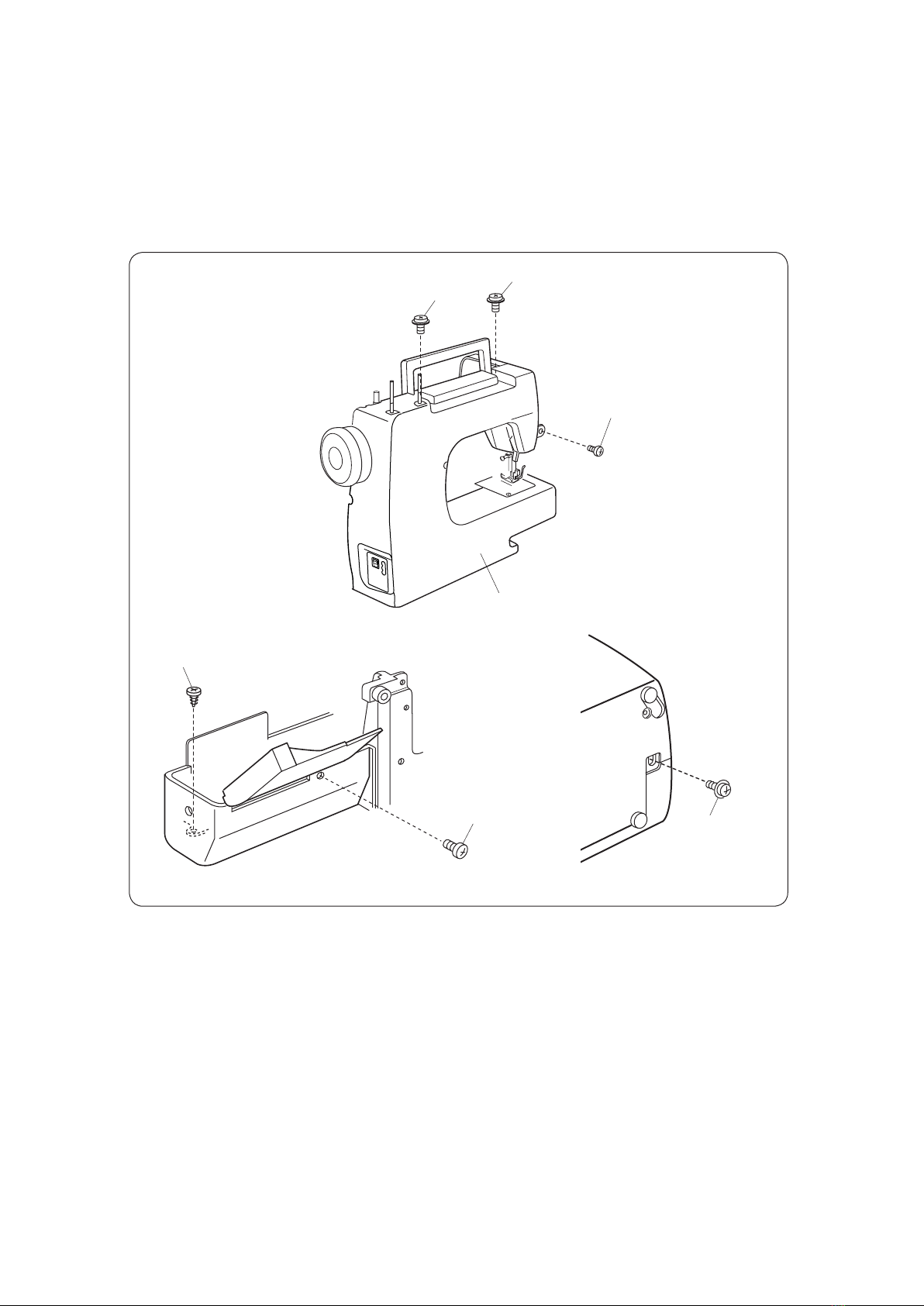

FACE COVER ........................................................................................................................ 4

FRONT COVER ...................................................................................................................... 5

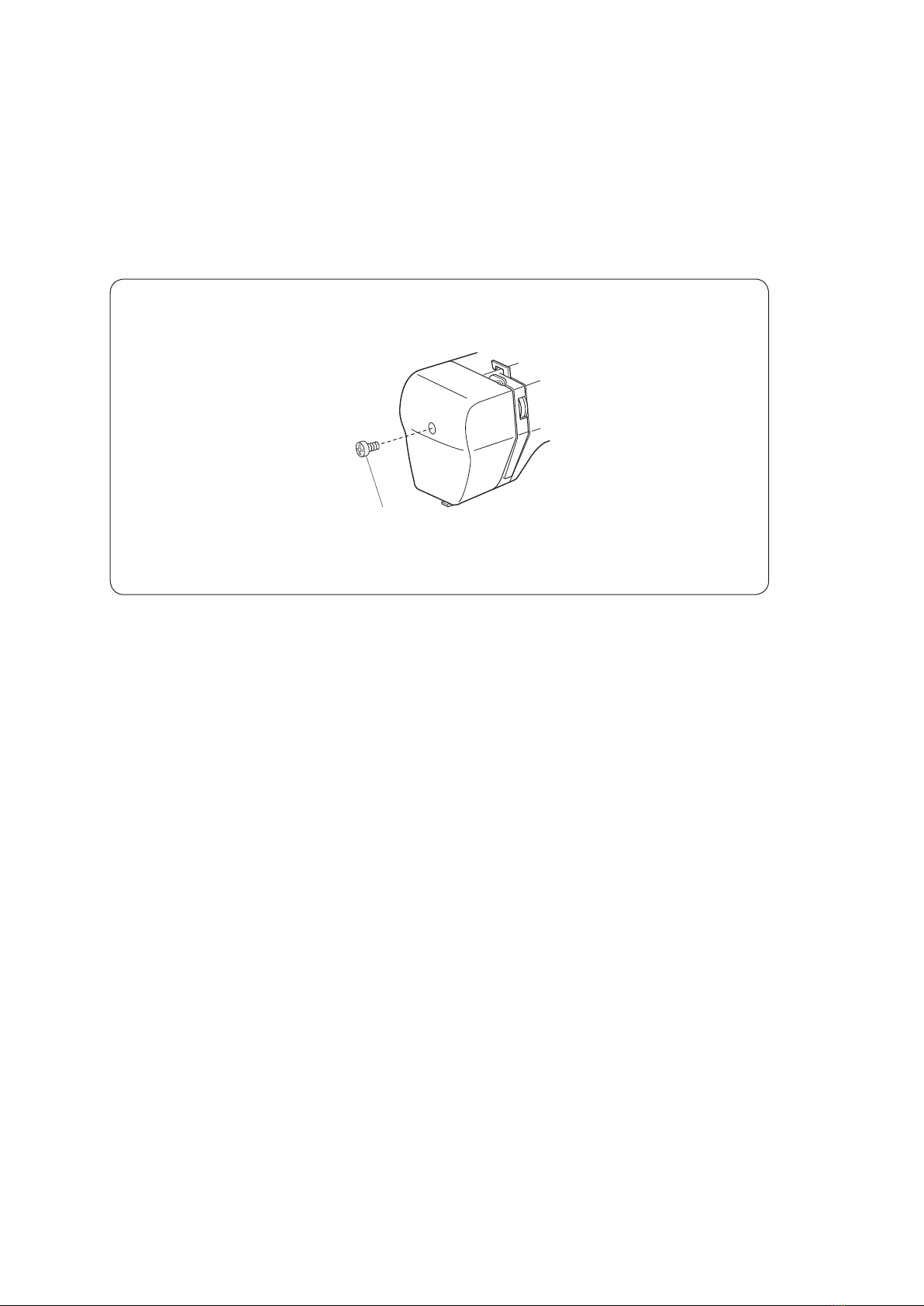

REAR COVER ........................................................................................................................ 6

MECHANICAL ADJUSTMENT

TOP TENSION ....................................................................................................................... 7

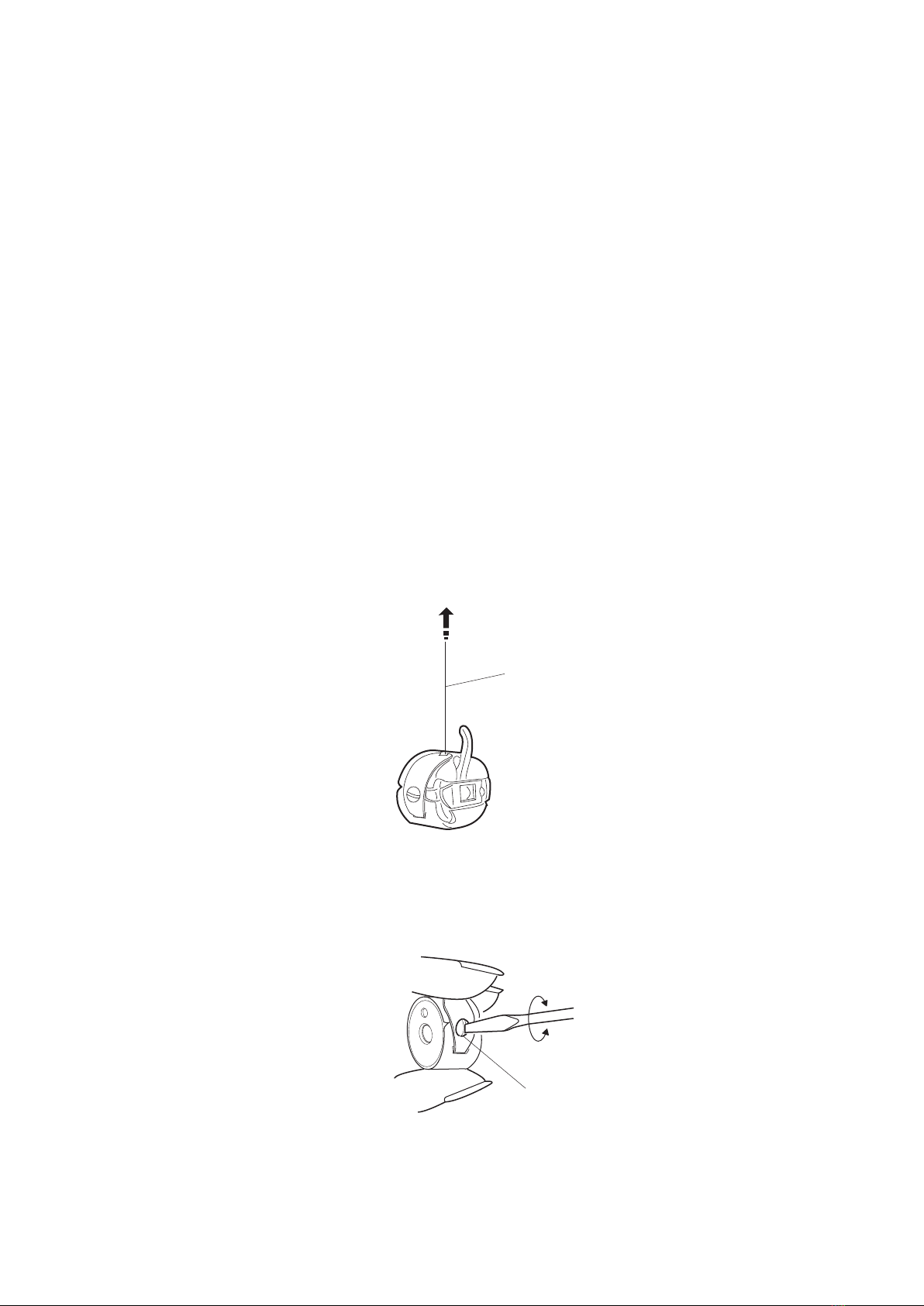

BOBBIN TENSION ................................................................................................................. 8

PRESSER BAR HEIGHT ALIGNMENT................................................................................... 9

NEEDLE SWING .................................................................................................................. 10

NEEDLE DROP ..................................................................................................................... 11

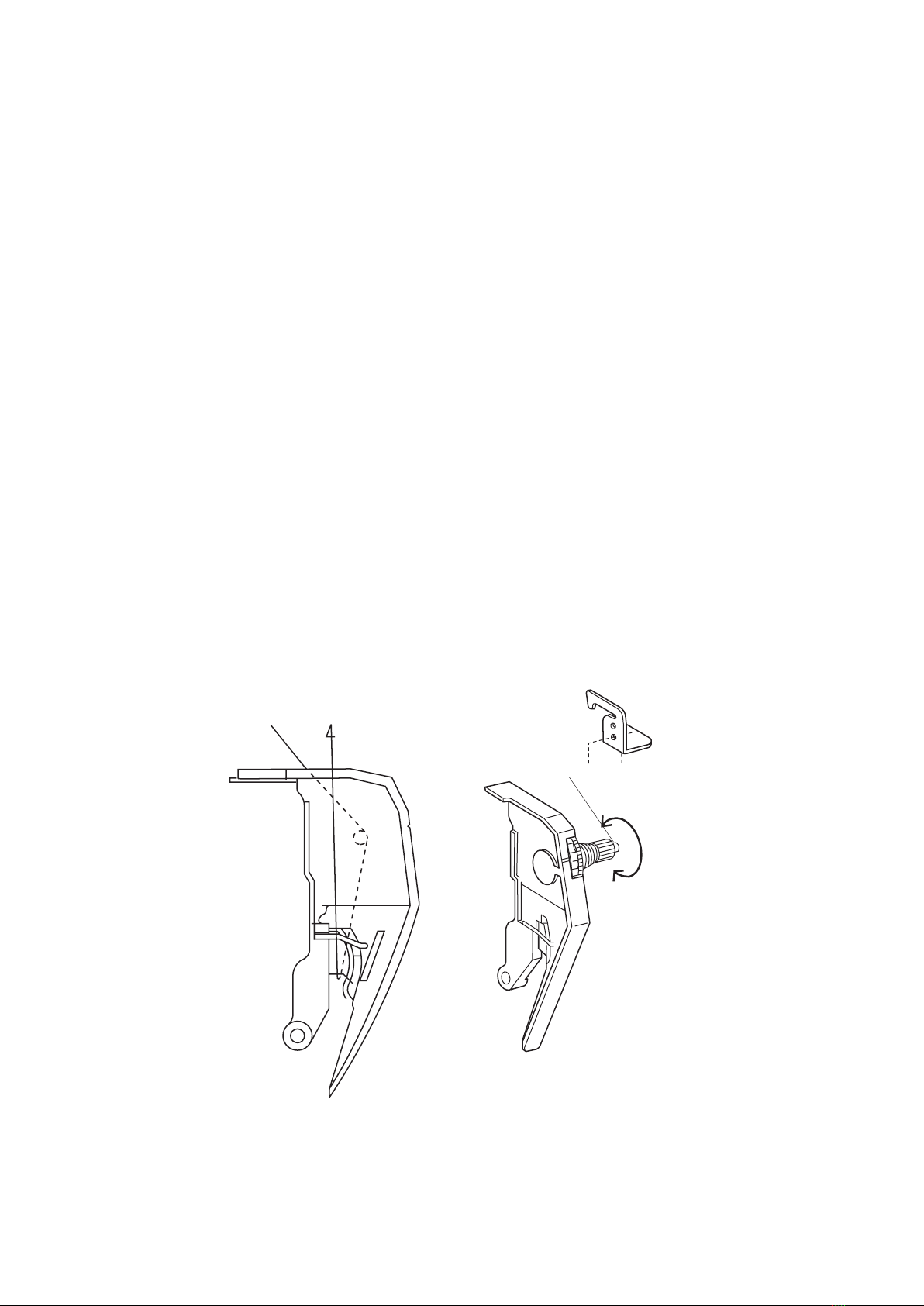

CLEARANCE BETWEEN NEEDLE AND SHUTTLE RACE

(ADJUSTMENT METHOD NO. 1).................................................................................... 12

CLEARANCE BETWEEN NEEDLE AND SHUTTLE RACE

(ADJUSTMENT METHOD NO. 2).................................................................................... 13

FEED DOG HEIGHT ............................................................................................................ 14

NEEDLE BAR HEIGHT ........................................................................................................ 15

NEEDLE TIMING TO SHUTTLE .......................................................................................... 16

BUTTONHOLE FEED BALANCE.......................................................................................... 17

FEED BALANCE ON STRETCH STITCH ............................................................................ 18

BUTTONHOLE FUNCTION ................................................................................................. 19

DISENGAGEMENT OF CAM FOLLOWER .......................................................................... 20

MOTOR BELT TENSION....................................................................................................... 21

WIRING ................................................................................................................................ 22

PARTS LIST.................................................................................................................. 23 to 41