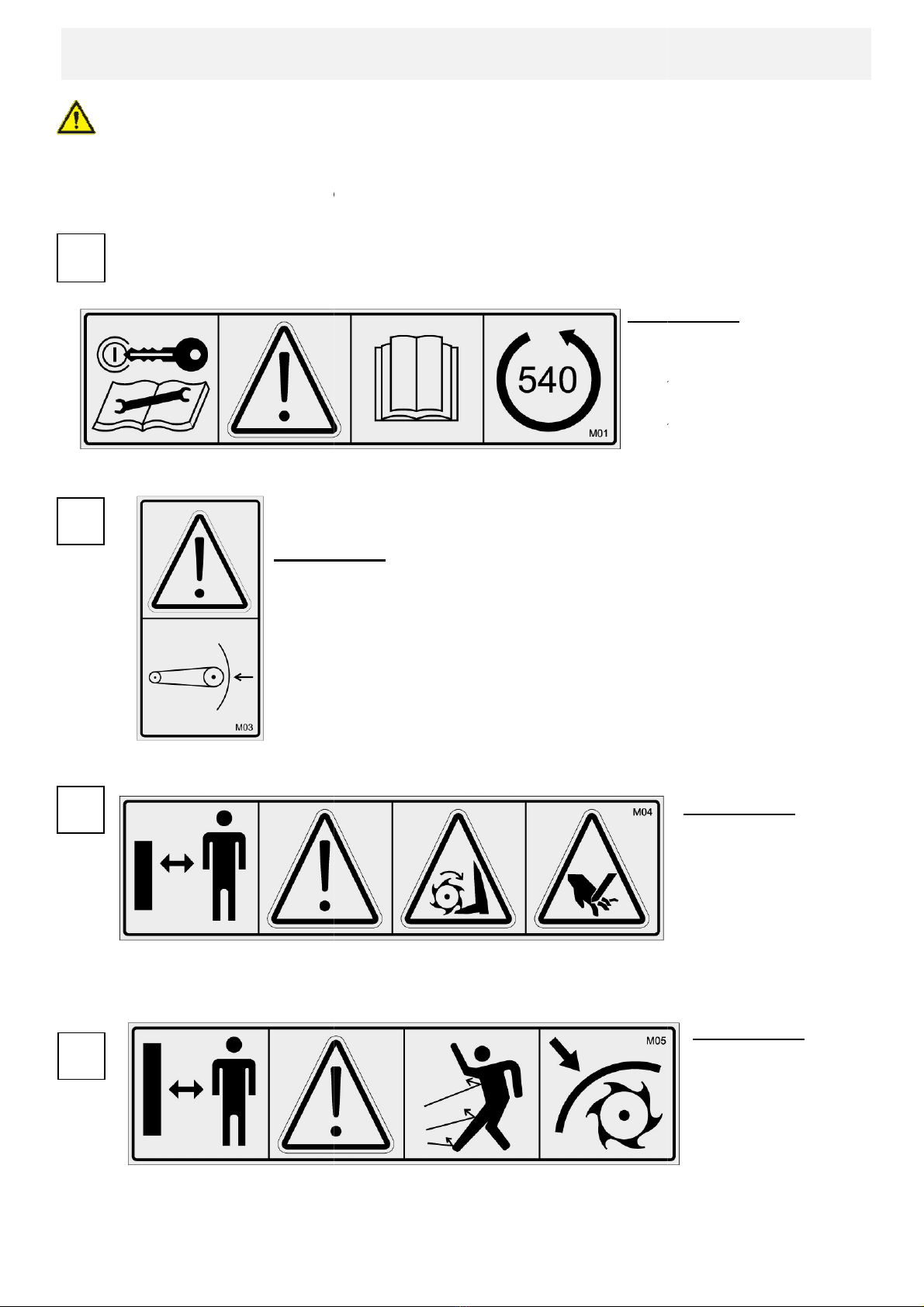

WARNING

Some illustrations may show the machine without

protective screen or shield. Never use the

machine without these devices.

•

Learn how to stop the machine in emergency

situation. Read this manual and the tractor

manual

• Neve

r let anyone else use this machine if the

person did not read and understand this

manual

•

It is absolutely forbidden to transport persons

or animals on the machine

•

Never let children use this machine

•

Always wear protective equipment for head,

ears, hands

and feet using this machine

• Stay away from the rotor

in use.

• Always wear close-

fitting clothing to avoid to

be snatched by the moving parts or to hang on

•

Clean the worksite from branches, stones or

debris which may be projected and caus

injury or damage

•

Always work on daylight or with good

artificial light

•

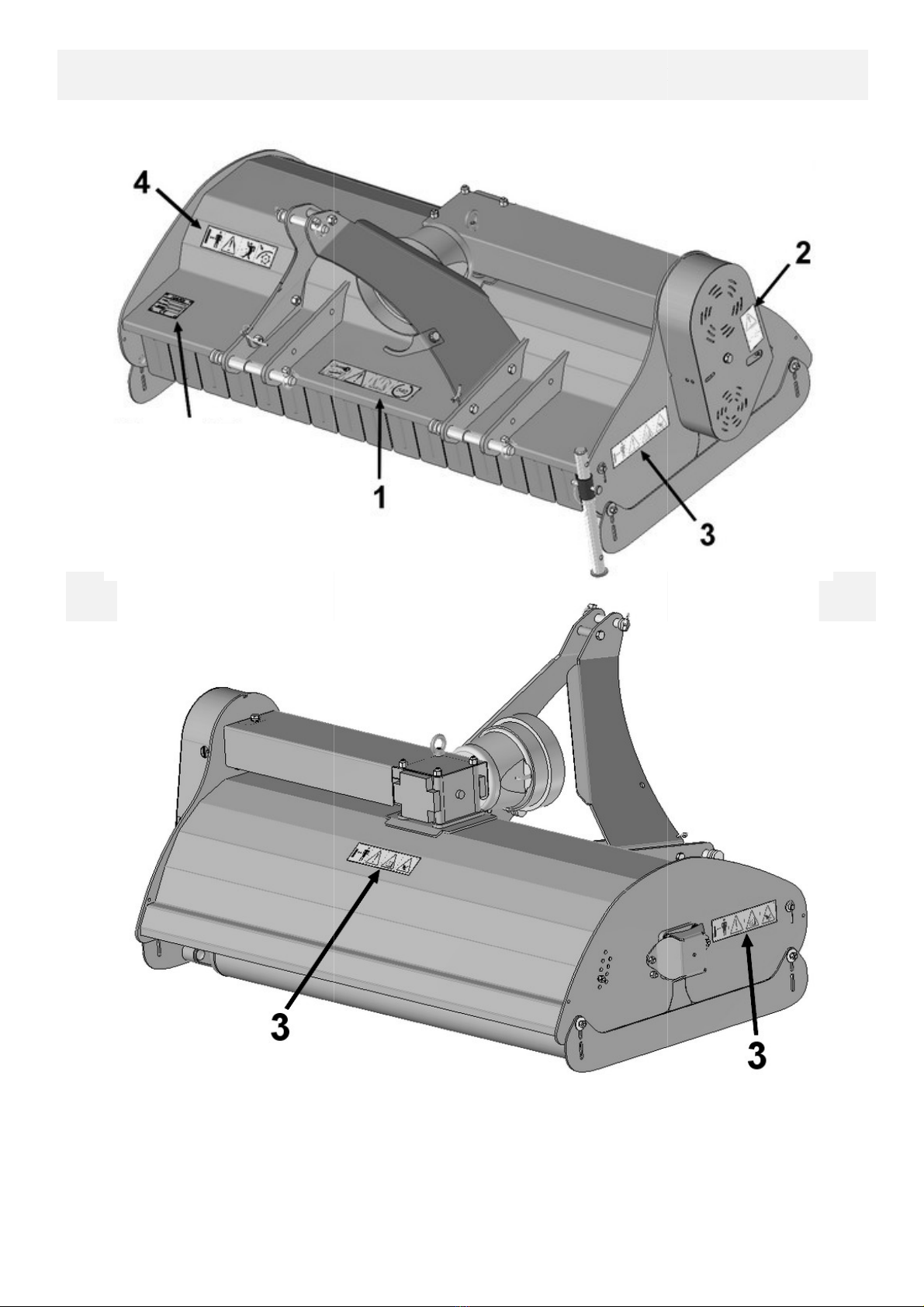

ake sure that the safety stickers are in place

and in good condition

•

Clean the grass and debris accumulations

•

ake sure that the machine is in good

working condition before using it

•

ake sure that all the safety screens, grids

and safety measures are in place and in good

condition

•

Do not use the machine in areas where you

cannot keep safety distance from the persons

or animals to avoid projection injury

• If the tractor has a ROPS Rol

Structure, fasten your seat belt

5

AFETY REGULATIONS

Some illustrations may show the machine without

protective screen or shield. Never use the

Learn how to stop the machine in emergency

situation. Read this manual and the tractor

r let anyone else use this machine if the

person did not read and understand this

It is absolutely forbidden to transport persons

Never let children use this machine

Always wear protective equipment for head,

and feet using this machine

fitting clothing to avoid to

be snatched by the moving parts or to hang on

Clean the worksite from branches, stones or

debris which may be projected and caus

e

Always work on daylight or with good

ake sure that the safety stickers are in place

Clean the grass and debris accumulations

ake sure that the machine is in good

working condition before using it

.

ake sure that all the safety screens, grids

and safety measures are in place and in good

Do not use the machine in areas where you

cannot keep safety distance from the persons

or animals to avoid projection injury

•

ake sure that nobody or anything is behind

•

Do not start or stop the engine abruptly on

slopes

•

Do not use the machine on too big slopes

•

Reduce speed on slopes to avoid a loss of

control

•

Be careful while driving along embankments

or ditches

•

Pay attention to the holes or other area

accidents on undulating terrains

• Stop the

pathways or ways with gravel

•

Disengage the power grip, stop the motor,

apply the han

dbrake and remove the key

before all settings, adjustments, maintenance

or disassembly

•

Never let anyone else to the driver’s cab

during adjustment interventions, maintenance

or disassembly of the machine

•

Check periodically tightening torques of all

fasteners

•

While maneuvering on slope always work up

and down, never across the slope

•

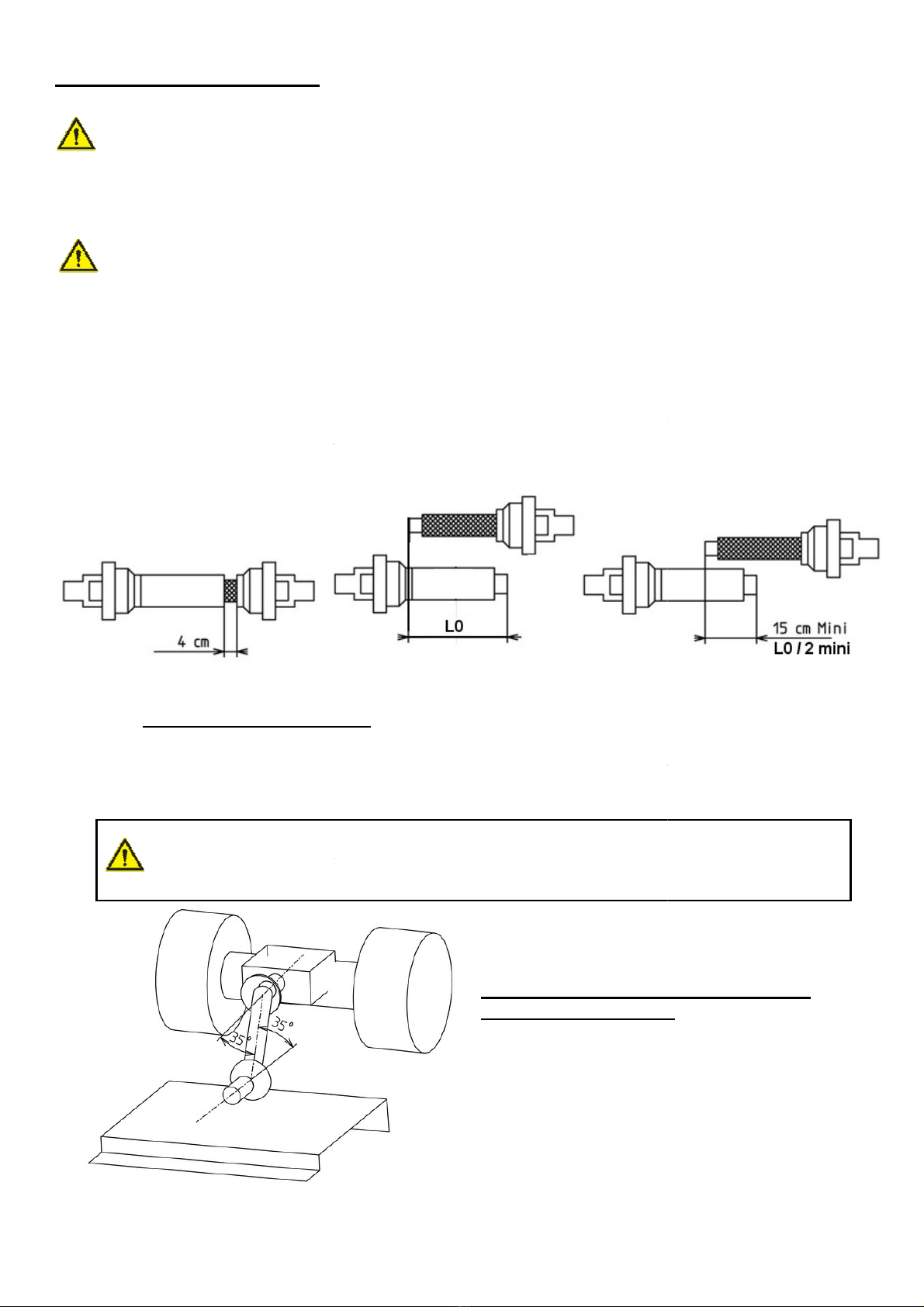

Place the wheels according to the setting

increase stability of the tractor

•

Avoid unstable embankments, rocks and

holes; this can be dangerous when moving

•

obstacles. Contact with power lines causes

•

Activate all the safety equipment

•

Only operate the control panel

correctly seated

•

Check visually hydraulic leaks and missing or

faulty parts.

Repair when necessary before

every manoeuvre

•

Check with the competent authorities that the

linkage complies with the national legislation

ake sure that nobody or anything is behind

Do not start or stop the engine abruptly on

Do not use the machine on too big slopes

Reduce speed on slopes to avoid a loss of

Be careful while driving along embankments

Pay attention to the holes or other area

accidents on undulating terrains

before crossing roads,

pathways or ways with gravel

.

Disengage the power grip, stop the motor,

dbrake and remove the key

before all settings, adjustments, maintenance

Never let anyone else to the driver’s cab

during adjustment interventions, maintenance

or disassembly of the machine

Check periodically tightening torques of all

While maneuvering on slope always work up

and down, never across the slope

.

Place the wheels according to the setting

increase stability of the tractor

.

Avoid unstable embankments, rocks and

holes; this can be dangerous when moving

high-voltage lines and

obstacles. Contact with power lines causes

.

Activate all the safety equipment

Only operate the control panel

when you are

Check visually hydraulic leaks and missing or

Repair when necessary before

Check with the competent authorities that the

linkage complies with the national legislation

.