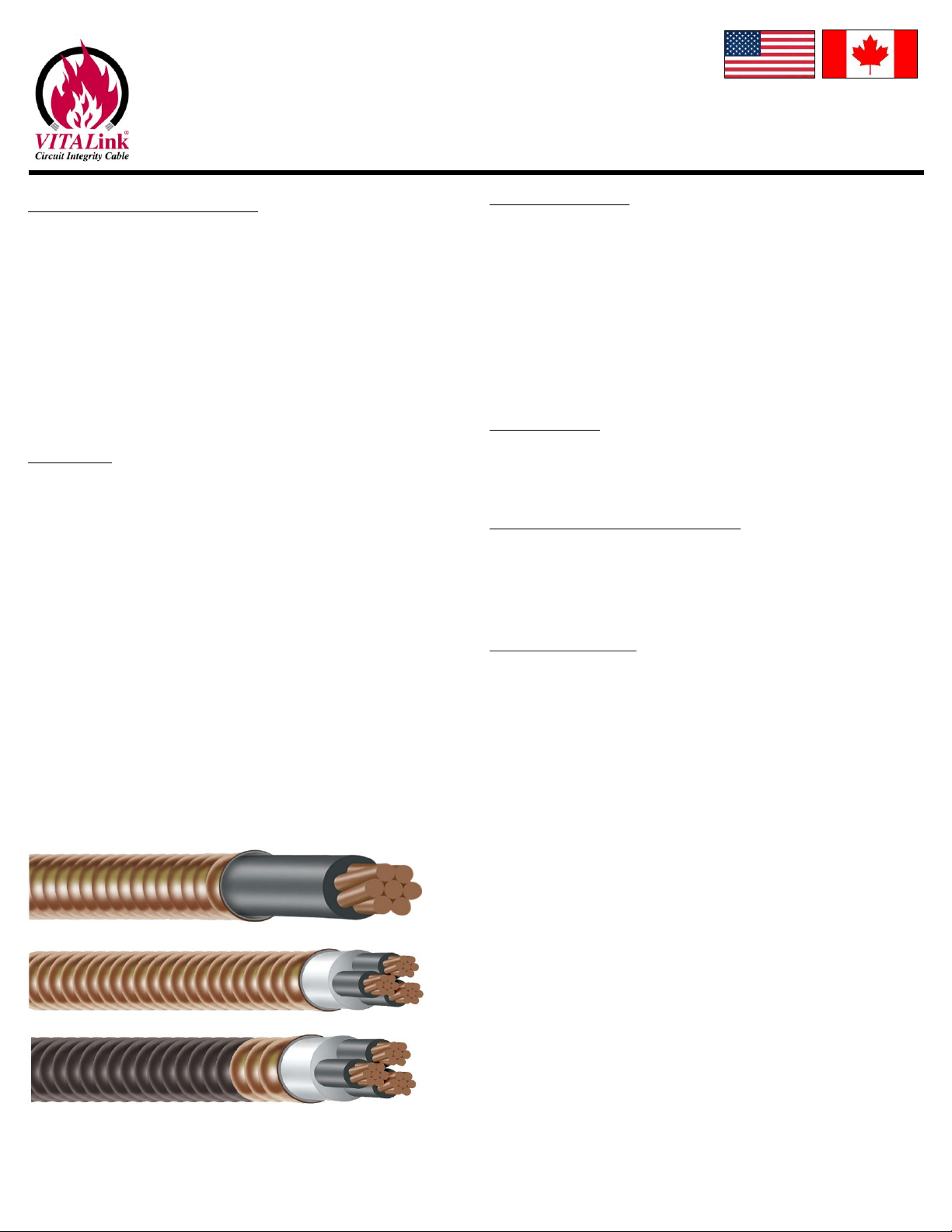

VITALink® MC/RC90

Fire-Resistive Cable Certified by UL and ULC IM-120-0

VITALink® MC/RC90 Cables Rev 0

Systems 120/120A/60 7/31/2020

RSCC Wire & Cable LLC © 2020 • 20 Bradley Park Road • East Granby, CT 06026 USA • 800-327-7625 Tel: 860-653-8300 • Fax: 860-653-8321 • r-scc.com 2/7

General

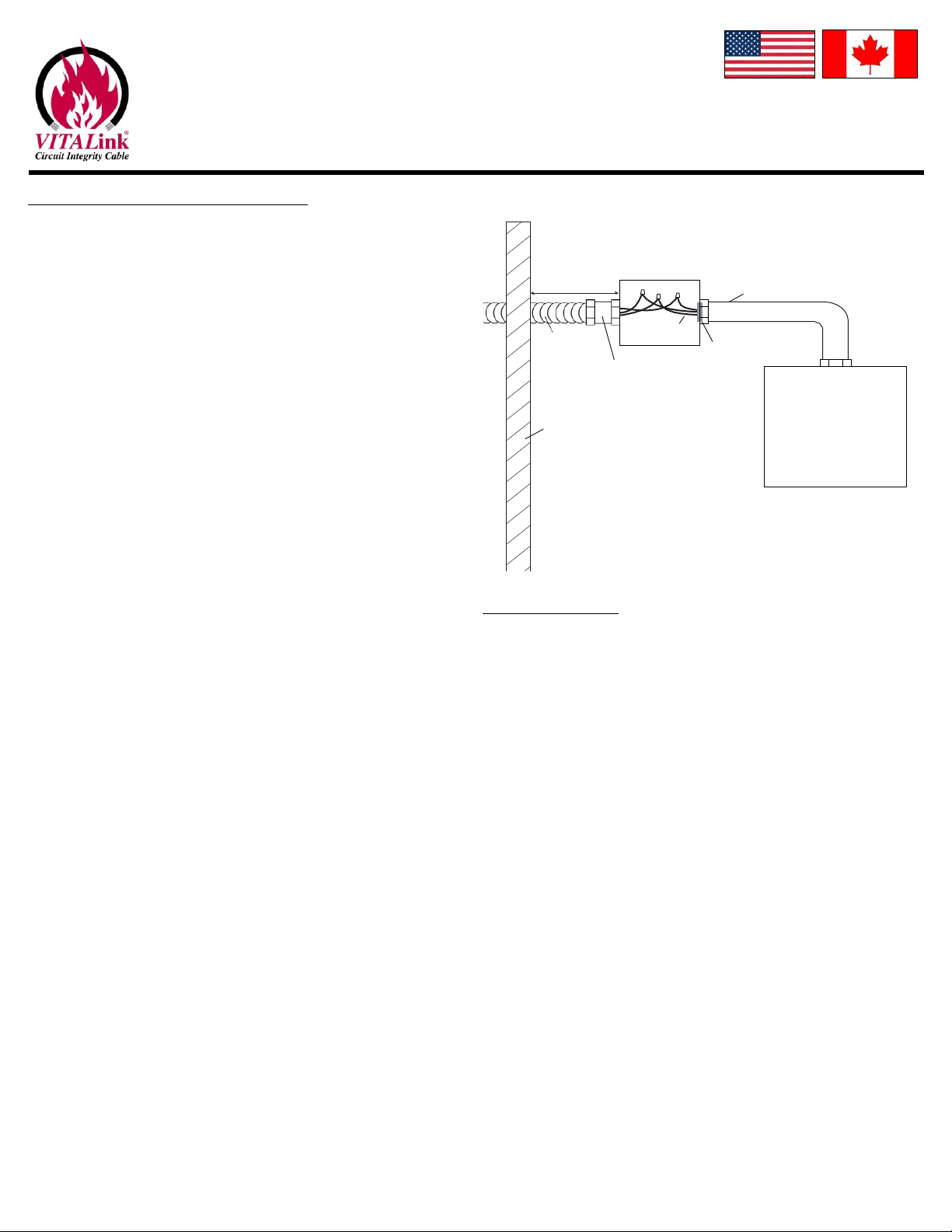

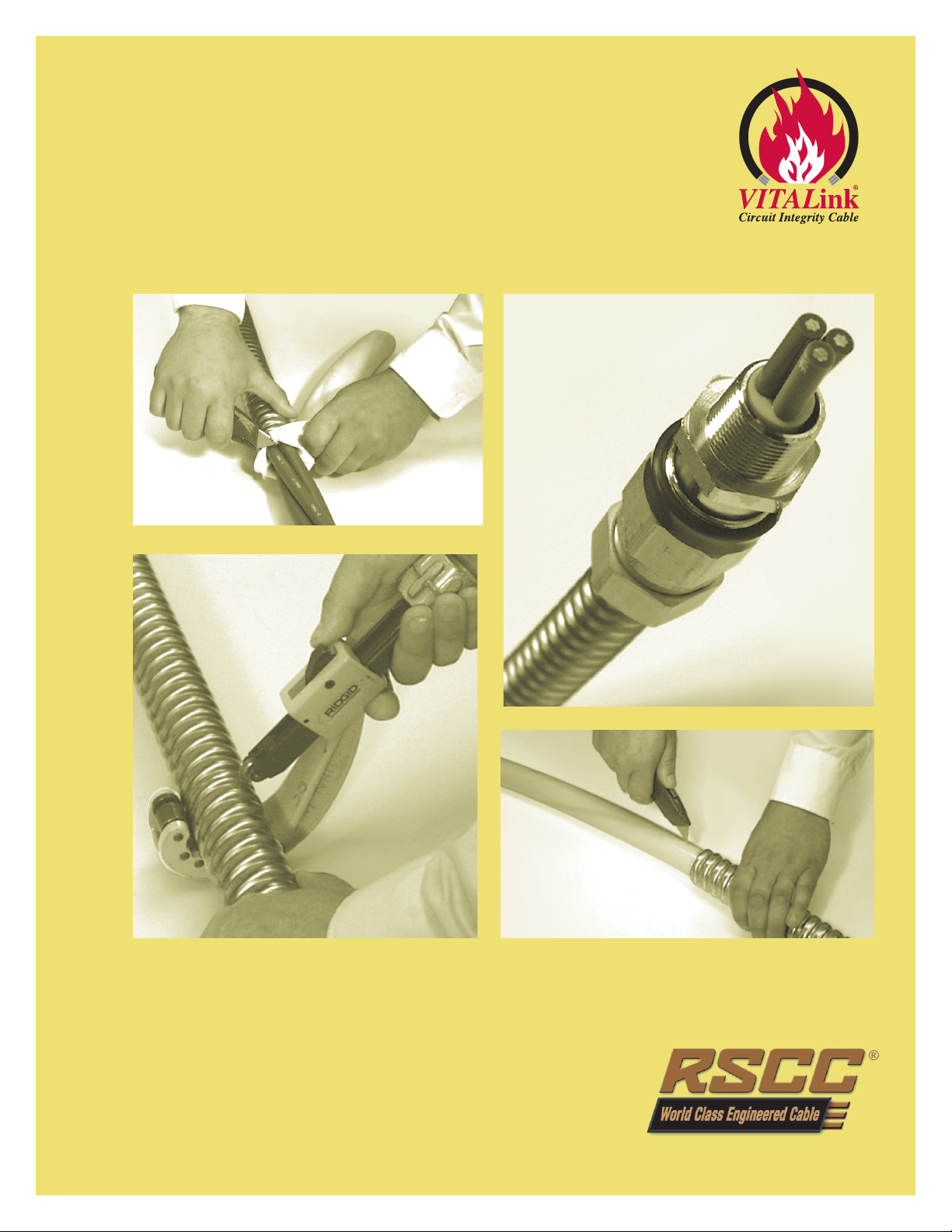

This document outlines the minimum installation requirements for installing a

cable to the systems described above.

Electrical Circuit Integrity Systems consist of components and materials that are

intended for installation as protection for specific electrical wiring systems, with

respect to the disruption of electrical circuit integrity upon exterior fire

exposure. The specifications for the protective system and its assembly are

important details in the development of the ratings.

These protective systems are evaluated by the fire exposure and water hose

stream test as described in UL 2196 / ULC S139. Ratings apply only to the entire

protective system assembly. Individual components and materials are

designated for use in a specific system(s) for which corresponding ratings have

been developed and are not intended to be interchanged between systems.

Ratings are not assigned to individual system components or materials.

Authorities having jurisdiction should be consulted in all cases as to the specific

requirements covering the installation and use of these Classified systems.

Cables and supports should be routed and supported separately from non-fire

resistive rated circuits. They should be positioned where any hazard of non-fire

resistive rated systems collapsing or failure will not disturb the system.

These requirements must be followed to maintain the hourly rating in the fire

area.

The VITALink® MC/RC90 cable system must be installed by qualified personnel

familiar with generally accepted construction techniques and safe electrical

practices.

Take all appropriate precautions when installing splices, including following

OSHA and other applicable regulations.

The installation must comply with all national and local electrical codes and all

the requirements of the UL Electrical Circuit Integrity System certification

requirements, and carefully follow the installation instructions.

Ensure the cable is in good condition prior to commencing splice installation.

Do not pull cables around corners that have sharp edges, such as corners in

cable trays, or other obstructions. See RSCC VITALink® MC/RC90 General

Installation and Handling Manual for more information.

Cable Support Distance

Cable shall be supported horizontally or vertically every four feet unless

otherwise stated in this document.

Cables shall also be supported on each side of a bend and not to exceed four

feet.

Support Methods

Drywall is not an acceptable means of support.

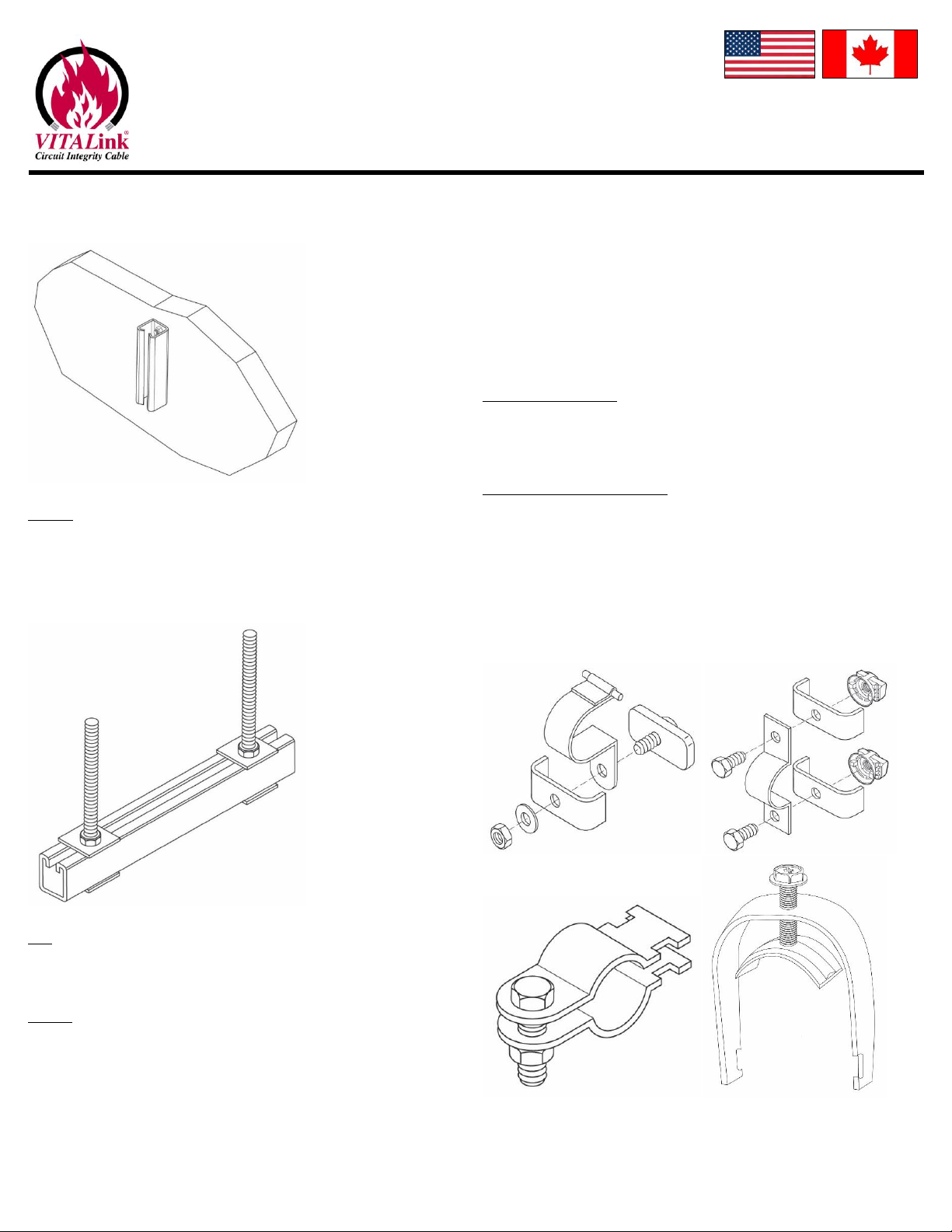

Strut

Box and Cables are mounted on 7/8” or larger 12 gauge slotted steel strut.

Painted or galvanized strut is acceptable.

Strut longer than 20” shall be a minimum of 1-1/2” 12 gauge steel.

Secure strut to concrete wall using a minimum 1/4 inch diameter steel

concrete screws by a minimum 2-1/4 inch in length.

Alternatively, Secure strut to concrete wall using a minimum 1/4 inch

diameter steel masonry anchor by a minimum 1-3/4 inch in length. The

deeper the penetration, the more secure the strut is mounted to the wall.

Please account for spalling.

Strut shall be secured to structure at a minimum on each end, and one in the

center for spans 5 feet or greater. Strut shall, at a minimum, be