SER

VICE

MA

NUAL - 1976

MA

S

SE

Y WHIRLWIND

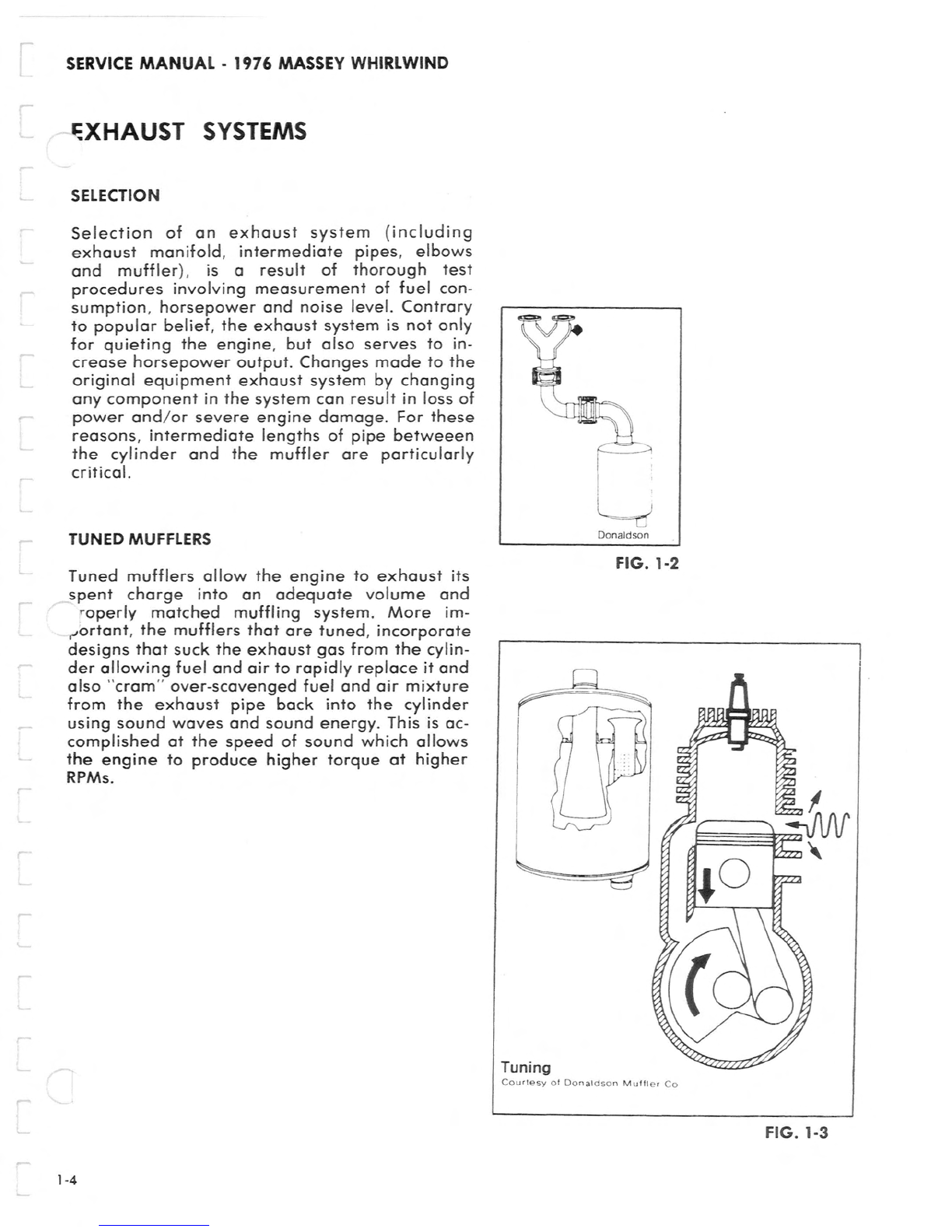

TABLEOF SPECIFICATIONS

JE

NG

INE

MODEl

DESCRIPTION CUYU

NA

3

40

CUYUNA 400 C

UYUNA

440

2.362

" 2

.55

9" 2.6 58 "

BORE (60

mm

) ( 65

.0mm

)(67.5m

m)

STROKE 2.362"

(60mm)

DISPLACEMENT IN cc

338

398

428

COMP

RESS

IO

N RAT

ION

(actu al) 12: 1 12:1 12:1

IGNITION SYSTEM Bosch Flyw

hee

l Magn

eto

LIGHTING COil VOLTAGEAND 12V-

150

W

12V

1

50W

1

2V

150W

OUTPUT

*TlMING B

EFORE

TDC (CENTRIFUGAL .102 - .112 .102 - .112 .102 - .112

WEIGHT

AD

VANCED

)

TI

MI

NG B

EFORE

TDC (CENTRIFUGAL .018" to .0

20"

.01 8" to .020" .01

8"

to

.02

0"

WEIGHT RETARDED)

BREAKERPOINT

GAP

.0 14" to .0 16"

SPARK PLUG THREAD 14mm. x 1.25 - 3/ 4" reach

.020

" .020"

.020

"

SPARK PLUG

GAP

(0.5

mm

.) (0.5mm.) (0.5mm.)

SPARK PLUG (ORIGINA L CHAMPION C

HA

MP

IO

NCHAM P

IO

N

E

QUIPM

ENT) N-3 N-3

N-3

TYPE

OF ENGINE

COO

LING

Ax

ial Fl

ow

Fan

ROTAT

ION

OF CRANKSHAFT Counte

rcloc

kw

ise

(PTO side)

CARBU

RE

TOR

Wa

l

br

o W F

FU

EL

/O

il RATIO A s Specif

ie

d on Mass

ey

app

roved

Oi

l Contai

ne

r

GASOLINE 95

octa

ne, mi n

imu

m (lead

fr

ee not acc

ept

ab

le)

ITYPEOF Oil Special 2-Cycle S

no

w mobile

Oi

l

* Do not exceed ind

icat

ed

advanc

e, as this w ill result in severe engine d

ama

ge.

1-6