IMPORTANT INFORMATION

1-1

SECTION 1

IMPORTANT INFORMATION

1.1 INTRODUCTION

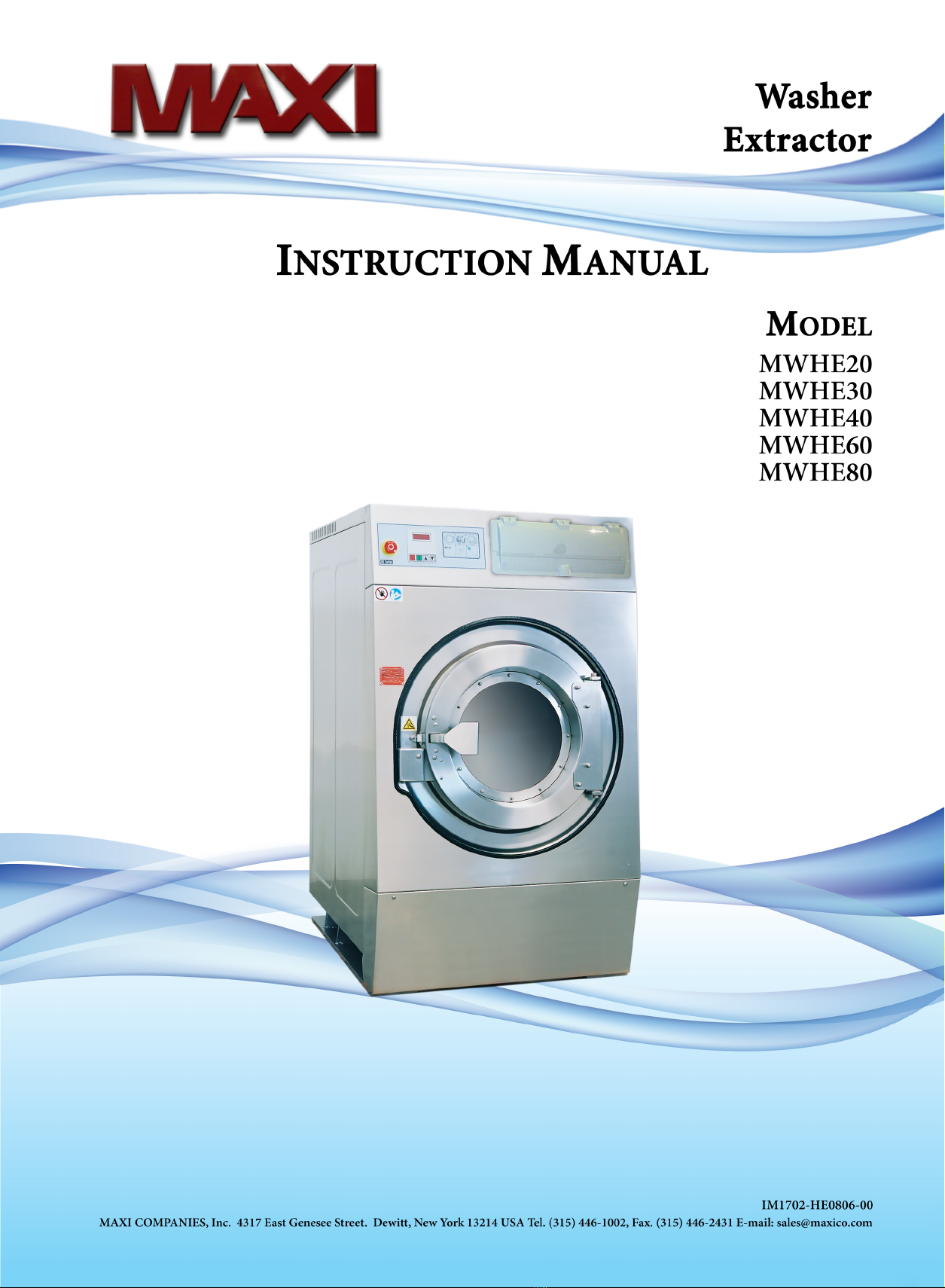

The HARDMOUNT line is the professional fixed mount washer – extractor series of

machines. It is an open pocket washer – extractor with a large and unloading. It has been developed

for the in premise market, and is suitable for commercial laundries, hotel and other places where

laundry might be processed.

The design allows for top performance at lowest possible operation cost and investment.

The flexible electronic control center ensures that maximum productivity is obtained.

The HARDMOUNT Series utilizes high quality material, such as 304 (18/8) stainless steel

in vital parts in contact with the wash solution. It has a stainless steel cabinet for long life with

easily removable panels.

The key advantages of this series are the simplicity of the microprocessor and the electronic

AC drive system, which utilizes only one motor. The system allows for washing and extraction at

suit any textile fiber used today and tomorrow. The high speed final extraction saves time and

energy in the finishing operation.

A multi compartment supply dispenser for powder and liquid detergents is standard and the

machine is designed to accept the connection of 4 external chemical lines and pumps.

1.2 SAFETY CHECK LIST

Before Initial start up of a washer – extractor perform the following safety check:

A. Make sure all electrical and plumbing connections have been made in accordance with

applicable codes and regulations.

B. Make sure the machine is grounded electrically.

C. Make sure the machine has flexible water fill and drain connections of the correct size,

length and type, with no kinks, and that they are securely attached and/or clamped.

Before machine is placed in operation, the door safety interlock must be checked for proper

operation as follows:

A. When the washer is energized electrically and in operation, the loading door must be

locked in the closed position. Verify this by attempting to open the loading door when the

machine is operating. If necessary, check the door safety interlock and sensors for proper

operation. Consult the service manual, or call a qualified service technician if necessary.

B. When the washers loading door is open, it should not be possible to start the machine.

Verify this by attempting to start the washer with the door open. Also, close the door

without locking it and verify that it is not possible to start the machine with the door not

locked. If necessary, check the door lock sensors for proper operation. Consult the service

manual, or call a qualified service technician. If additional information is required,

contact your local distributor or call the manufacturer of the machine.

•To provide personal safety and keep the machine in proper working order, follow all

maintenance and safety procedures presented in this manual. If questions regarding

safety arise. Contact the factory immediately.

•Use factory authorized spare parts to avoid safety hazards.