McDonald's C602 User manual

This manual is for the exclusive use of licensees and employees of McDonald's Corporation.

©2005 McDonald's Corporation May, 2005 (Original Publication) Printed in

All Rights Reserved (Updated August, 2020 ) The United States of America

EM SD11

Warranty

Warranty information is contained in this Equipment Manual. Refer to the warranty information listed in the Limited Warranty on

Equipment and Limited Warranty on Parts sections and to the warranty classifications listed in the Parts Identification/Function

section when service is performed on your machine.

It is recommended that the operator take the necessary time to carefully read through the complete warranty information.

Thoroughly understand your warranty protection before you begin operation.

For any questions pertaining to the Taylor warranty, please contact Taylor Company, Rockton, Illinois 61072.

Soft Serve/Shake Combination Freezer

Taylor Model C602

Place this chapter in the Shakes/Desserts

section of the Equipment Manual.

Manufactured exclusively for

McDonald's®by

Taylor Company

750 N. Blackhawk Blvd.

Rockton, IL 61072

Phone: (815) 624-8333

Toll Free Number

Outside Illinois:

1 (800) 228-8309

Inside Illinois:

1 (800) 851-5639

Fax: (815) 624-8000

Table of Contents

Introduction ....................................................................................................................................................... 1

Safety................................................................................................................................................................ 1

Parts Identification/Functions............................................................................................................................ 4

Important to the Operator................................................................................................................................ 31

Daily Opening Procedures .............................................................................................................................. 34

Syrup System.................................................................................................................................................. 39

Daily Closing Procedures................................................................................................................................ 42

Scheduled Maintenance - Syrup System ........................................................................................................ 46

Syrup Topping Pump ...................................................................................................................................... 49

Manual Brush-Cleaning .................................................................................................................................. 54

Equipment Setup ............................................................................................................................................ 59

VFD Screens................................................................................................................................................... 74

Manager's Menu ............................................................................................................................................. 78

Troubleshooting Guide.................................................................................................................................... 91

Parts Replacement Schedule ....................................................................................................................... 106

Limited Warranty on Equipment.................................................................................................................... 107

Limited Warranty on Parts ............................................................................................................................ 109

Ordering/Service Information ........................................................................................................................ 112

1

INTRODUCTION

The Model C602 is a combination shake and soft serve

freezer. The soft serve side uses a 3.4 qt. (3.2 L) freezing

cylinder with a single-spout door.

The shake side has a 7 qt. (6.6 L) freezing cylinder with a

four-flavor dispensing door. The touch panel has four

flavor symbols for selecting and drawing the desired

shake flavor. When dispensing a shake, the cup is placed

on the shake cup holder below the door spout. A shake

flavor symbol is selected to automatically raise the

draw valve, allowing frozen mix and syrup to enter the

door where they are blended and dispensed as a finished

shake.

A portion control device will sense the filling of the shake

cup and automatically close the draw valve upon filling

the shake cup to the correct level. The operator also has

the ability to override the portion control and stop

dispensing the shake by pressing any of the four shake

flavor symbols. The shake draw valve can also be raised

and lowered in the Wash and Off modes by selecting any

of the four flavor symbols to enable cleaning, sanitizing,

and priming.

Shake syrup is stored in the lower front compartment.

Each syrup flavor is delivered to the dispensing door by a

peristaltic pump. Syrup can be pumped directly from

disposable plastic jugs or stainless steel tanks, or

adapted to syrup-in-bag dispensing. The proper syrup

delivery rate is achieved by calibrating each syrup flavor.

The mix is located in the mix hopper and is pumped to

the freezing cylinder by an air/mix pump.

When your machine is delivered, or if it has been in the

OFF position for more than 24 hours, disassemble the

freezer following the Manual Brush-Cleaning procedures

on page 48. Follow the Equipment Setup procedures on

page 59 to reassemble your machine.

The machine must be disassembled, cleaned, sanitized,

and lubricated at least once every 2 weeks. Syrup lines

must be cleaned and sanitized weekly.

It is recommended that these operating procedures be

followed closely to ensure correct assembly and

disassembly of the freezer.

The C602 is designed for indoor use only.

Note: Only instructions originating from the factory or its

authorized translation representative(s) are considered to

be the original set of instructions.

SAFETY

Always follow these safety precautions when operating

the freezer:

NOTICE! DO NOT operate this machine

without reading this manual. Failure to follow these

instructions may result in machine damage, poor

dispenser performance, health hazards, or personal

injury.

IMPORTANT! This machine is to be used only

by trained personnel. It is not intended for use, cleaning,

or maintenance by children or people with reduced

physical, sensory, or mental capabilities, or lack of

experience and knowledge, unless given supervision or

instruction concerning the use of the machine by a

person responsible for their safety. Children should be

supervised to ensure that they do not play with the

machine.

WARNING! Avoid injury.

•DO NOT operate the machine unless it is

properly grounded.

•DO NOT operate the machine with fuses larger

than specified on the machine's data label.

• All repairs should be performed by a Taylor

service technician.

• The main power supplies to the machine must

be disconnected prior to performing installation,

repairs, or maintenance.

•For Cord-Connected Machines: Only Taylor

service technicians or licensed electricians may

install a plug or replacement cord on the

machine.

• Machines that are permanently connected to

fixed wiring and for which leakage currents may

exceed 10 mA, particularly when disconnected

or not used for long periods, or during initial

installation, shall have protective devices to

protect against the leakage of current, such as a

GFI, installed by the authorized personnel to the

local codes.

• Stationary machines which are not equipped

2

with a power cord and a plug or another device

to disconnect the machine from the power

source must have an all-pole disconnecting

device with a contact gap of at least 0.125 in.

(3 mm) installed in the external installation.

• Supply cords used with this machine shall be

oil-resistant, sheathed flexible cable not lighter

than ordinary polychloroprene or other

equivalent synthetic elastomer-sheathed cord

(code designation 60245 IEC 57) installed with

the proper cord anchorage to relieve conductors

from strain, including twisting, at the terminals

and protect the insulation of the conductors from

abrasion.

• If the supply cord is damaged, it must be

replaced by an Taylor service technician in order

to avoid a hazard.

• Secure the supply cord ground lead to the

machine in a location where if the cord is pulled,

the main power leads will become taut before

the ground lead can break loose.

Failure to follow these instructions may result in

electrocution. Contact your local authorized Taylor

distributor for service.

IMPORTANT! An equipotential grounding lug is

provided with this machine. Some countries require the

grounding lug to be properly attached to the rear of the

frame by the authorized installer. The installation location

is marked by the equipotential bonding symbol (5021 of

IEC 60417-1) on both the removable panel and the

machine's frame.

WARNING! Avoid injury.

•DO NOT allow untrained personnel to operate

this machine.

•DO NOT operate the machine unless all service

panels and access doors are fastened with

screws.

•DO NOT remove any internal operating parts

(including, but not limited to, freezer door,

beater, or scraper blades), unless all control

switches are in the OFF position.

Failure to follow these instructions may result in severe

personal injury, especially to fingers or hands, from

hazardous moving parts.

WARNING! DO NOT attempt to draw product

or disassemble the machine during the heat treatment

cycle (if equipped). The product is hot and under extreme

pressure. Severe burns from hot product may result if this

instruction is not followed.

WARNING! This machine has many sharp

edges that can cause severe injuries.

•DO NOT put objects or fingers in the door

spout. This may contaminate the product and

cause severe personal injury from blade

contact.

•USE EXTREME CAUTION when removing the

beater assembly. The scraper blades are very

sharp.

•USE EXTREME CAUTION when handling the

cup/cone dispenser (if supplied with machine).

Two people are required to handle the cup/cone

dispenser. The appropriate type of protective

gloves must be worn and the mounting holes

must NOT be used to lift or hold the dispenser.

Failure to follow these instructions can result in personal

injury or damage to the machine.

WARNING! Only install this machine in a

location where its use and maintenance is restricted to

trained personnel. Failure to comply may result in

personal injury.

CAUTION! This machine must be placed on a

level surface. Use caution when moving the machine.

Failure to comply may cause the machine to tip over and

result in personal injury.

NOTICE! Cleaning and sanitizing schedules

are governed by your federal, state, or local regulatory

agencies and must be followed accordingly. Please refer

to the cleaning section of this manual for the proper

procedure to clean this machine.

3

CAUTION! This machine is designed to

maintain product temperature under 41°F (5C). Any

product being added to this machine must be below 41F

(5C). Failure to follow this instruction may result in

health hazards and poor machine performance.

WARNING! This machine must NOT be

installed in an area where a water jet or hose can be

used. NEVER use a water jet or hose to rinse or clean

the machine. Failure to follow this instruction may result

in electrocution.

This freezer is designed to operate indoors, under normal

ambient temperatures of 70°F to 75°F (21°C to 24°C).

The freezer has successfully performed in high ambient

temperatures of 104°F (40°C) at reduced capacities.

Do not obstruct air intake and discharge openings: 3 in.

(76 mm) minimum airspace all sides. Install the deflector

provided to prevent recirculation of warm air. Failure to

follow this instruction may cause poor freezer

performance and damage to the machine.

Do not run the machine without product. Failure to follow

this instruction can result in damage to the machine.

NOTICE all warning labels that have been attached to

the freezer to further point out safety precautions to the

operator.

Water Connections

(Water-Cooled Machines Only)

An adequate cold water supply must be provided with a

hand shutoff valve. On the underside rear of the base

pan, two 1/2 in. Iron Pipe Size (IPS) water connections

for inlet and outlet have been provided for easy hookup.

Permanently connect the machine using 1/2 in.

(12.7 mm) inside diameter water lines. (Flexible lines are

recommended, if local codes permit.) Depending on local

water conditions, it may be advisable to install a water

strainer to prevent foreign substances from clogging the

automatic water valve. There will be only one water in

and one water out connection. Do not install a hand

shutoff valve on the water out line! Water should always

flow in this order: first, through the automatic water valve;

second, through the condenser; and third, through the

outlet fitting to an open trap drain.

IMPORTANT! A backflow prevention device is

required on the incoming water connection side. Please

see the applicable national, state, and local codes for

determining the proper configuration. Water pressure to

the unit must not exceed 150 psi (1034 kPa).

HAZARD COMMUNICATION STANDARD (HCS) - The

procedure(s) in this manual include the use of

chemical products. These chemical products will be

highlighted with bold faced letters followed by the

abbreviation (HCS) in the text portion of the

procedure. See the Hazard Communication Standard

(HCS) manual for the appropriate Material Safety

Data Sheet(s) (MSDS).

This machine is made in America and has American

sizes of hardware. All metric conversions are

approximate and vary in size.

NOISE LEVEL: Airborne noise emission does not

exceed 78 dB(A) when measured at a distance of 39 in.

(1.0 m) from the surface of the machine and at a height of

63 in. (1.6 m) from the floor.

IMPORTANT! If the crossed-out wheeled-bin

symbol is affixed to this machine, it signifies that this

machine is compliant with the EU Directives as well as

other similar end-of-life legislation in effect after August

13, 2005. Therefore, it must be collected separately after

its use is completed and cannot be disposed as unsorted

municipal waste.

The user is responsible for delivering the machine to the

appropriate collection facility, as specified by your local

code.

For additional information regarding applicable local

disposal laws, please contact the municipal waste facility

and/or local authorized Taylor distributor.

4

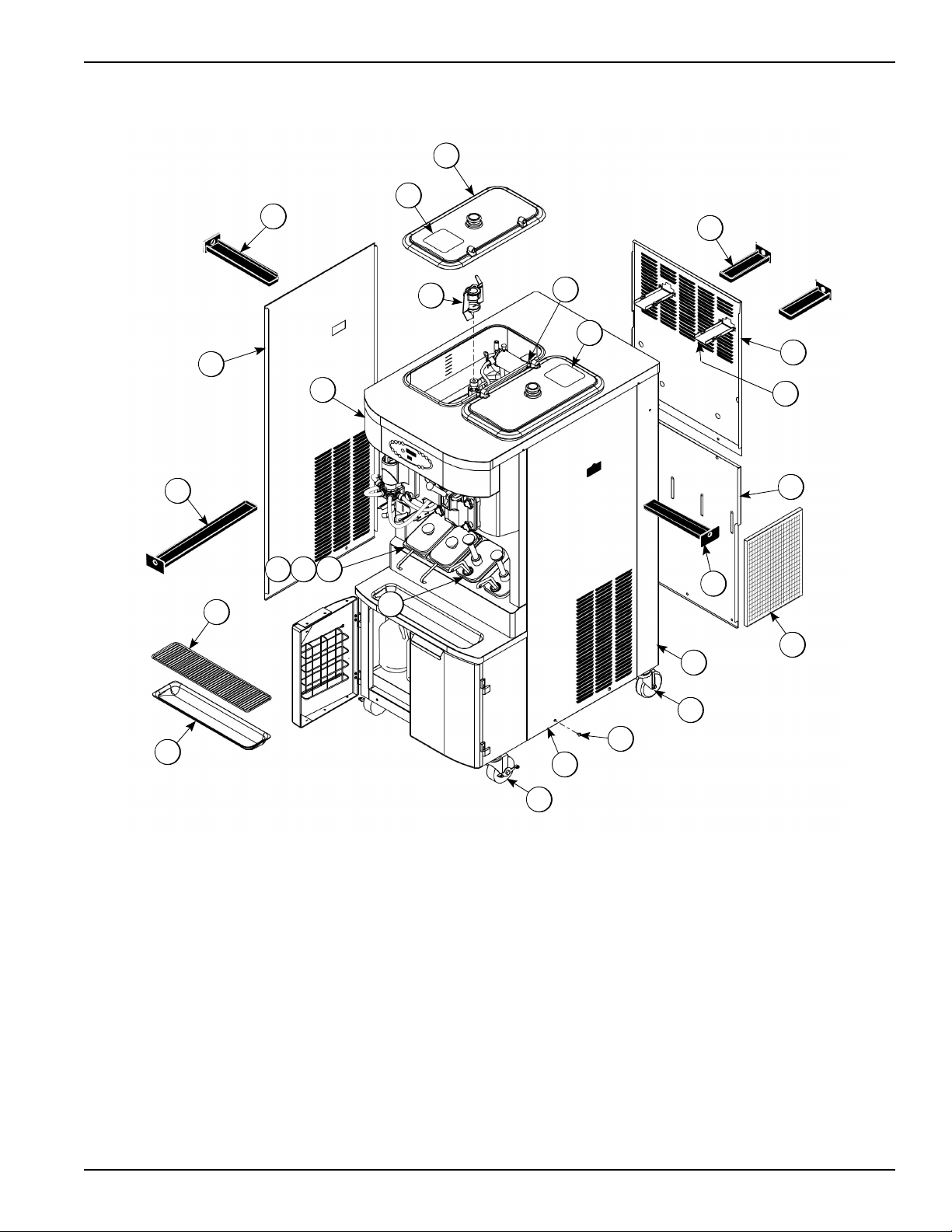

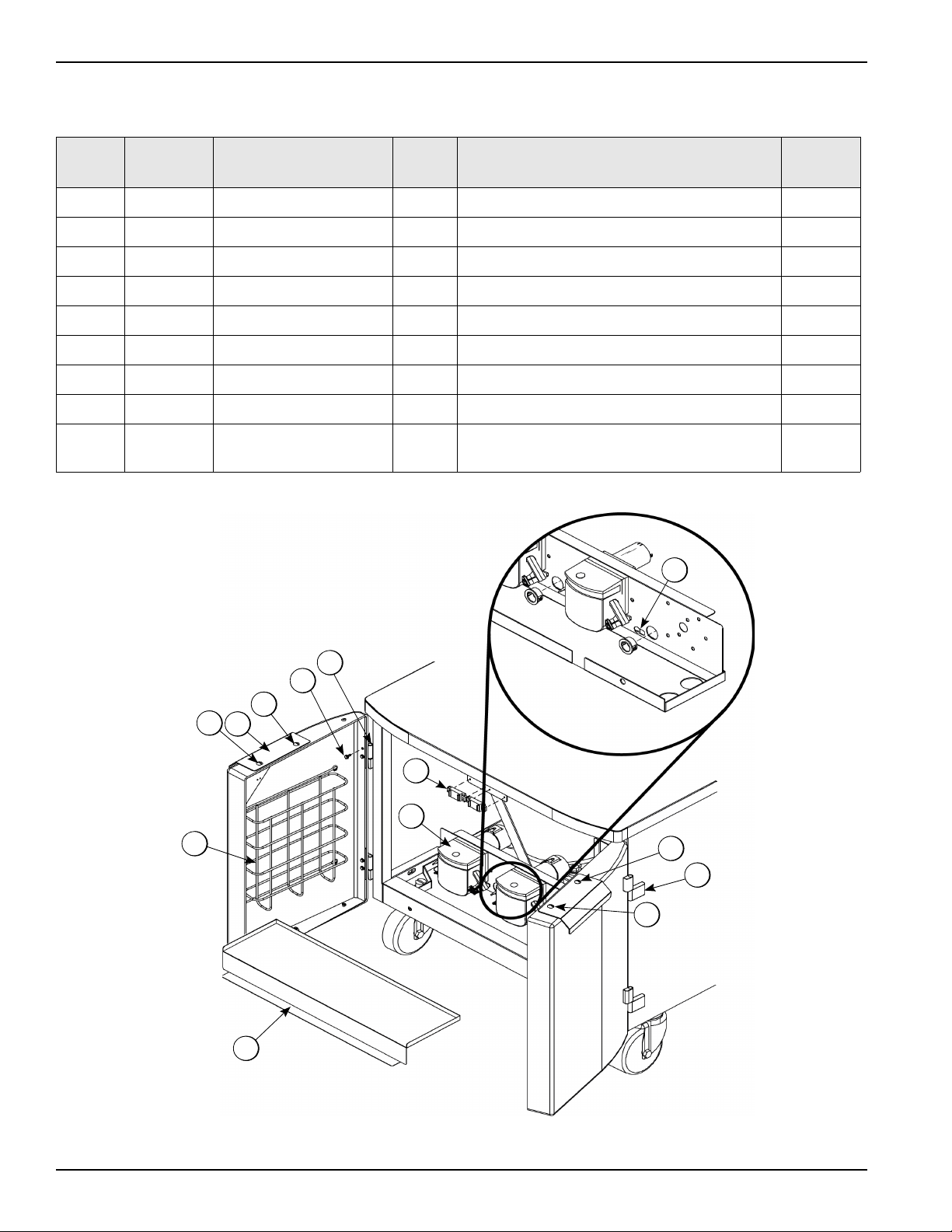

PARTS IDENTIFICATION/FUNCTIONS

Exploded View

*Items supplied by Taylor on machines manufactured prior to serial number M1080000.

Item Part No. Description Qty. Function Warr.

Class

1 X65368 Kit A.-Cover-Hopper *Single*

Black

2 Protects mix in mix hopper from debris and helps keep

temperature in the mix hopper uniform.

103

X65178 Kit A.-Cover-Hopper *Dual*

Black

* Note: If both hopper covers need to be replaced, order

X65178.

1a 045191 Label-Caution-Agitator 2 Warning label placed on each hopper cover. 000

2 X44797 Agitator Assembly 2 Stirs product in mix hopper to ensure even

temperature.

103

3 043934 Pin-Retaining Hopper Cover 2 Holds hopper cover while filling hopper with mix. 103

4 X56003 Pan-Drip-Rear 8-3/4” Long

(22.2 cm)

2 Used to catch any mix leakage from the mix pump. 103

5 066724 Panel-Rear-Upper 1 Provides access to internal components. 103

6 X48228 Guide A.-Drip Pan Mix Pump 2 Holds the mix pump drip pan in place. 103

7 055959 Panel-Rear-Lower 1 Provides access to internal components. 103

8 X56005 Pan-Drip-Side 12-3/4” Long

(32.4 cm)

2 Used to catch any mix leakage from the rear shell

bearing.

103

9 056692 Trim-Corner-Rear Right Side 1 Cosmetic trim. Seals the panels together. 103

056693 Trim-Corner-Rear Left Side 1 Cosmetic trim. Seals the panels together. 103

10 044106 Caster-4” 2 Wheels support the machine and allow easier

movement.

103

11 011694 Screw-1/4 - 20 x 3/8 10 Attaches the panels to the frame. 000

12 055950 Panel-Side Right 1 Panel provides access to internal components. 103

13 033812 Tray-Drip 1 Catches mix leakage from spout of freezer door. 103

14 033813 Shield-Splash 1 Helps prevent any mix leakage from splashing. 103

*15 042706 Lid-Syrup Jar 2 Lid for non-heated topping containers. 103

*16 036573 Jar-Syrup - Plastic Shallow 2 Holds non-heated sundae toppings. 103

*17 036574 Jar-Syrup - Stainless Shallow 2 Holds heated sundae toppings. 103

*18 033637-1 Ladle-1 oz. (30 ml.) 2 Used to dispense non-heated toppings. 103

19 035034 Pan-Drip 19-3/4” Long

(50.2 cm)

1 Used to catch any mix leakage from the rear shell

bearing.

103

20 056131 Plate-Dec 1 Touch sensor display panel on front of machine. 103

21 055957 Panel-Side Left 1 Panel provides access to internal components. 103

22 052779-3 Filter-Air 18.0 L x

13.5 H x 70 W

2 Filters dust and dirt from the main condenser. 000

23 046437 Caster-4” SWV 3/4-10 Stem

w/Brake

2 Wheels support the machine and allow easier

movement, with locks to stop movement.

103

5

C602 Exploded View

Figure-1

23

12

11

10

9

22

7

6

5

4

1

1a

3

1a

8

21

19

14

181615

17

13

20

8

2

6

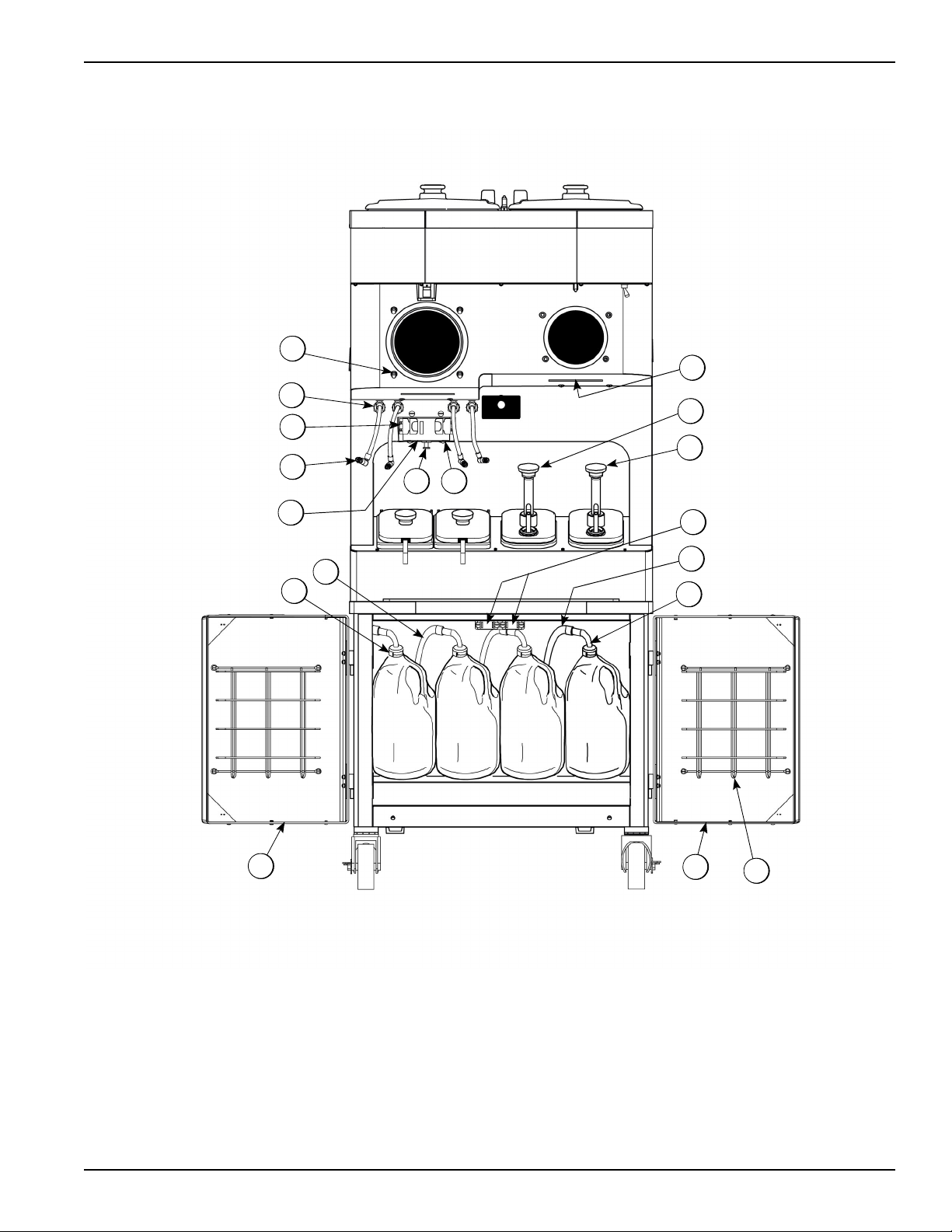

Front View

Not Shown

* Items supplied by Taylor on machines manufactured prior to serial number M1080000.

** Bag Syrup System (Not Shown)

† Prior to serial number K4091994, use 058630 Latch-Door-Magnetic.

Item Part No. Description Qty. Function Warr.

Class

1 055987 Stud-Nose Cone 8 Freezer door sits on these studs. Handscrews hold

door in place.

103

2 056674 Fitting-Panel Mount QD 4 Quick disconnect fitting for door syrup line. 103

3 068394 Clip-Spring Cup Holder 2 Holds the cup in place during dispensing. 103

4 X59304 Line A.-Syrup Door 4 Delivers syrup to the freezer door. Has a small slot

for thin syrup.

103

X56652 Line A.-Syrup Door 4 Delivers syrup to the freezer door. Has a large slot

for thick syrup and particulates.

103

5 064942 Shield-Pyroelectric Sensor 1 Plastic cover that protects the pyroelectric sensor. 000

†6 016121 Magnet-Catch Assy. 2 Holds the cabinet door closed. 103

7 X53353-BLU

X53353-BRN

X53353-RED

X53353-WHT

Fitting A.-Syrup Jug 1 per

tank

Transfers syrup from the syrup jug or tank to the

peristaltic pump.

103

**7 X58450 Line A.-Syrup 4 Transfers syrup from the syrup bag to the peristaltic

pump.

103

7a 053040-BLU

053040-BRN

053040-RED

053040-WHT

Cap-Ultimate Syrup 1 ea. Attachment covers for containers. 000

7b 053052-36 Hose-Beverage 4 Delivers syrup to peristaltic pump. 000

7c X53175 Tube A.-Syrup Pick Up 4 Transfers syrup from container to pump. 000

7d 053036 Ferrule-.625 ID 4 Clamps syrup hose on fitting. 000

8 X58607-SER Door A.-Cabinet 2 Insulates syrup cabinet. 103

9 059144 Basket-Door-Wire 2 Rack for storage. 103

10 051574 Screw-Adjustment 1 Adjusts the sensing eye to determine correct level of

shake.

103

11 056008 Holder-Cup Shake 1 Holds cup during dispensing. 103

*12 X53800-BRN Pump A.-Syrup- Heated

(Chocolate)

1 Dispenses heated sundae topping. 103

*13 X53800-TAN Pump A.-Syrup- Heated

(Caramel)

1 Dispenses heated sundae topping. 103

14 036435 Gasket-Drip Lip 2 Helps prevent liquid from dripping down front of

machine.

000

015971 Pin-Roll - 3/32 x 9/16 1 Secures spinner shaft in coupling assembly. 000

7

Front View

Figure-2

1

2

3

4

5

7

7a

10 11

889

7c

7b

6

12

13

14

8

Syrup Cabinet View

*Prior to serial number K4091994, use 058630 Latch-Door-Magnetic.

Figure-3

Item Part No. Description Qty. Function Warr.

Class

1 056016 Shelf-Syrup 1 Provides access to syrup pumps. 103

2 059144 Basket-Door-Wire 2 Rack for storage. 103

3 065933 Handle-Door Short 2 Handle for syrup cabinet door. 103

4 058613 Block-Hinge 4 Attaches door to syrup cabinet. 103

4a 058322 Screw 8-32 X 1/2 Socket Hd Secures block hinge.

*5 016121 Magnet-Catch Assy. 2 Holds the cabinet door closed. 103

6 052916 Pump-Peristaltic 4 Pumps syrup to freezer door. 103

7 058614 Block-Hinge 4 Attaches door to syrup cabinet. 103

8 024298 Screw-10-32 x 3/8 6 Four screws secure handle to syrup cabinet door;

two screws secure syrup pump bracket to cabinet.

000

1

2

83

8

4a

4

5

6

7

8

8

Pump Detail

8

9

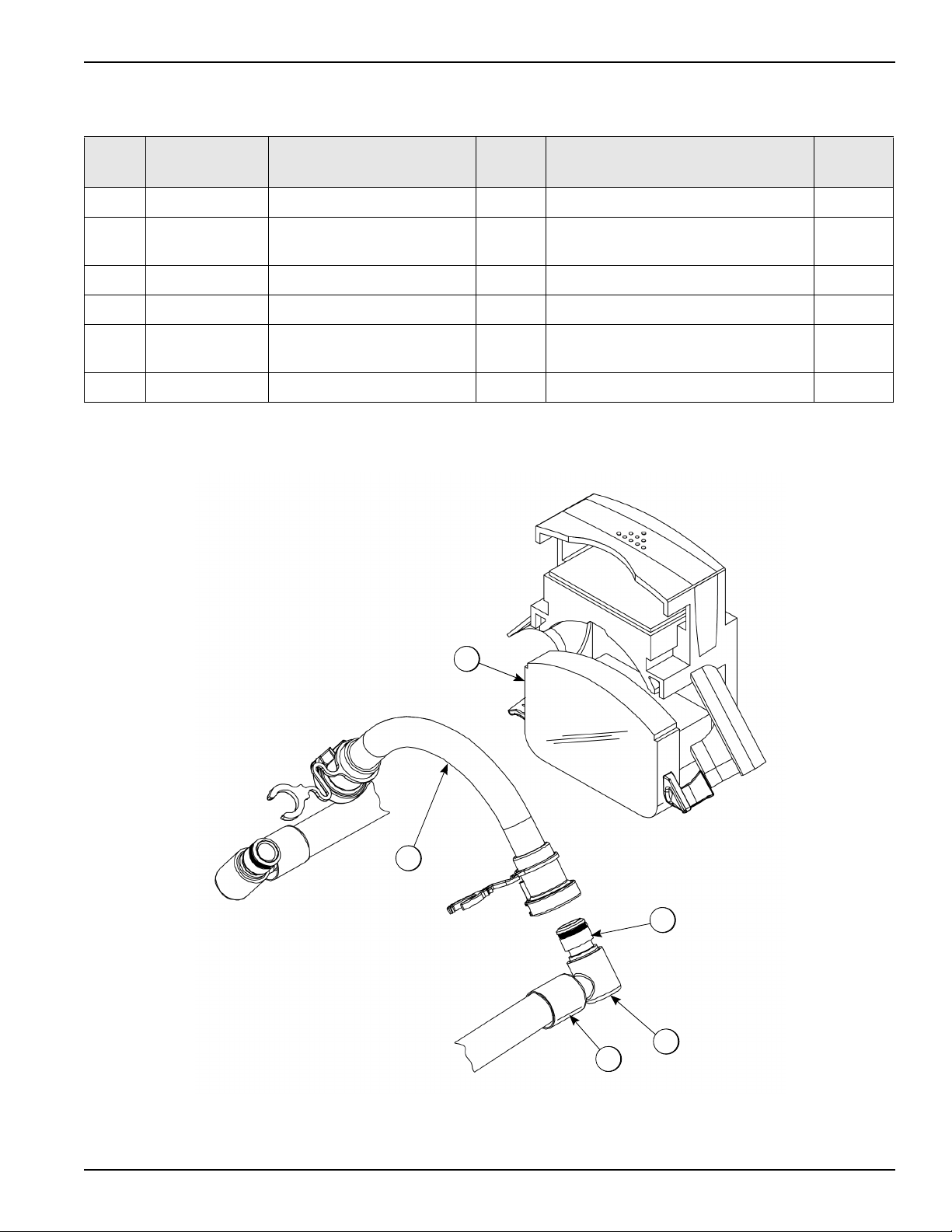

Mix Pump & Tubes

*Not Shown

Figure-4

Item Part No. Description Qty. Function Warr.

Class

1 052916 Pump-Peristaltic 4 Contains rollers to propel syrup. 103

2 X54978 Kit A.-Peristaltic Pump Tube 4 Compressed by pump rollers to propel

syrup.

000

3 053036 Ferrule-.625 ID 2 ea. Clamps syrup hose on fitting. 000

4 054526 Fitting-Peristaltic Pump 2 ea. Connects line to pump tube. 103

5 024278 O-ring 1/2 OD x .070 2 ea. Provides seal between fitting and pump

tube.

000

*6 X62426-8 Line A.-Syrup 4 Provides syrup flow from pump. 103

2

5

4

3

1

10

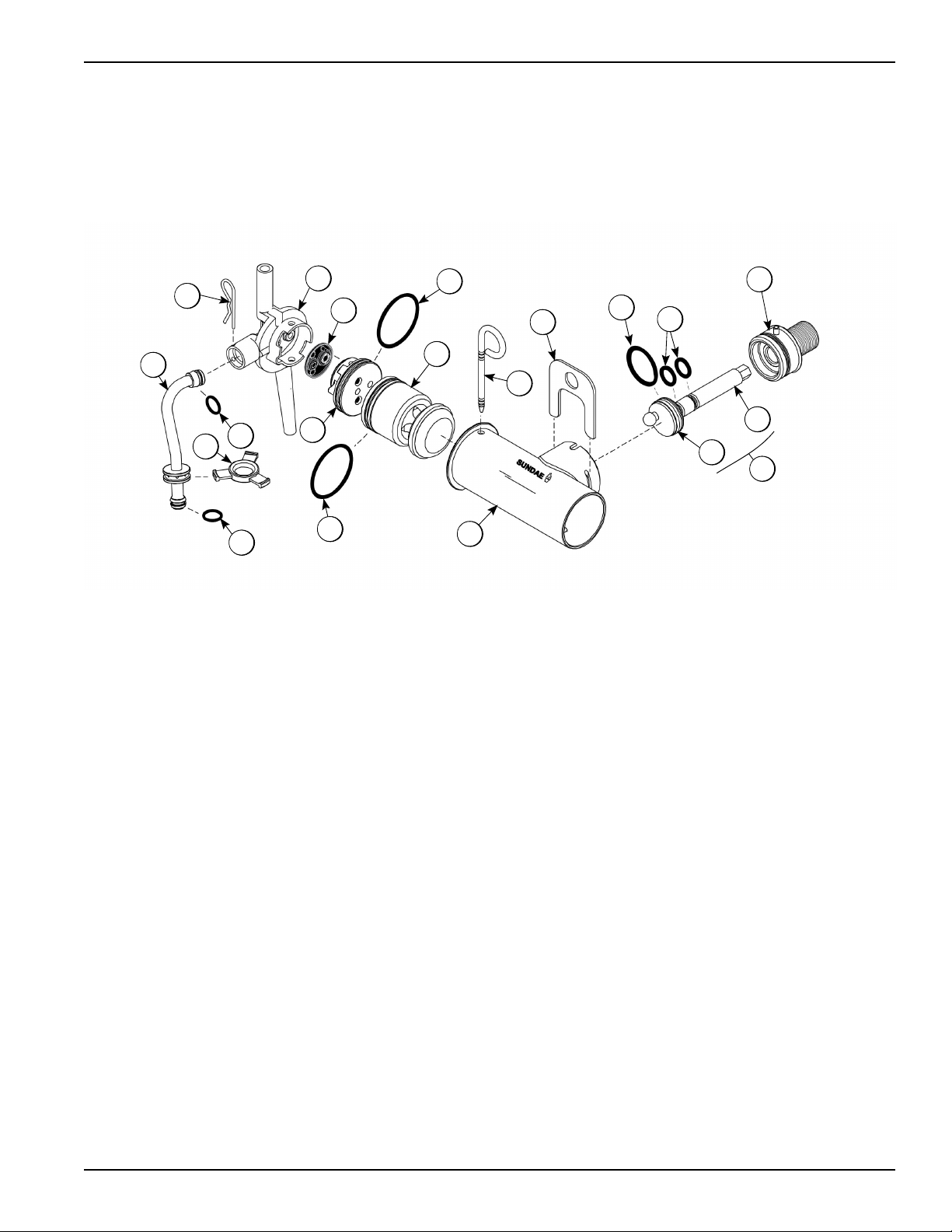

X57028-XX Pump A. - Mix Simplified - Shake

*016132 O-ring is ordered in packages of 50 - part no. 016132-SER.

Item Part No. Description Qty. Function Warr.

Class

1 - 7 X57028-XX Pump A.-Mix Simplified Shake 1 Delivers air and mix to the freezing cylinder. 103

1 057944 Cylinder-Pump- Hopper-Shake 1 Chamber to house the piston. 103

2 X55450 Pin-Retaining 1 Secures adaptor and valve cap in cylinder. 103

3 053526 Piston-Pump-Simplified 1 Moves back and forth to intake and discharge

air and mix.

103

4 020051 O-ring 2-1/8” OD- Red 2 Provides sealed cavity inside cylinder. 000

5 056873-XX Cap-Valve 1 Provides a metered passage for air and mix.

The suffix number indicates the air orifice size.

103

6 086097 Gasket-Simplified Pump 1 Controls the flow of air and mix through the

pump (do not lubricate).

000

7 054944 Adaptor-Mix Inlet Shake-Blue 1 Provides passageway for air/mix intake and

discharge.

103

*8 016132 O-ring-11/16 OD-Red 2 Provides a seal at each end of the mix feed

tube.

000

9 044731 Pin-Cotter-Hairpin 1 Secures mix inlet tube to pump adaptor. 103

10 X41947 Shaft A.-Drive Mix Pump 1 Rotates counterclockwise to move piston back

and forth.

103

10a 039235 Crank-Drive 1 Delivers motion to piston. 103

10b 041948 Shaft-Drive 1 Delivers motion from pump motor to crank. 103

10c 008904 O-ring 1-3/4 1 Provides seal between crank and pump sleeve. 000

10d 048632 O-ring-Drive Shaft 2 Provides seal to prevent mix from leaking into

rear drip pans.

000

11 044641 Clip-Mix Pump Retainer 1 Secures air/mix pump to drive hub in mix

reservoir.

103

12 X55973 Tube A.-Feed- Hopper Shake 1 Mix and air is pumped through this tube from the

pump to the freezing cylinder.

103

13 056524 Ring-Check .120 OD 1 Releases excess pressure from freezing

cylinder back to mix reservoir.

000

14 X44761 Sleeve A.-Mix Pump 1 Guide for pump driveshaft; creates a seal to

prevent mix from leaking into back of machine.

103

11

X57028-XX Pump A. - Mix Simplified - Shake

Figure-5

13 8

8

12

9

7

6

4

2

5

41

11

10c

10a

10b

14

3

10d

10

12

X57029-XX Pump A. - Mix Simplified - Soft Serve

Item Part No. Description Qty. Function Warr.

Class

1 - 7 X57029-XX Pump A.-Mix Simplified

Soft Serve

1 Delivers air and mix to freezing cylinder. 103

1 057943 Cylinder-Pump- Hopper-Soft

Serve

1 Chamber to house the piston. 103

2 X55450 Pin-Retaining 1 Secures adaptor and valve cap in cylinder. 103

3 053526 Piston 1 Moves back and forth to intake and discharge air and

mix.

103

4 020051 O-ring 2-1/8” OD -

Red

2 Provides sealed cavity inside cylinder. 000

5 056874-XX Cap-Valve 1 Provides a metered passage for air and mix. The

suffix number indicates the air orifice size.

103

6 086097 Gasket-Simplified Pump

Valve

1 Controls the flow of air and mix through the pump (do

not lubricate).

000

7 054825 Adaptor-Mix Inlet Soft

Serve-Red

1 Provides passageway for air and mix intake and

discharge.

103

8 016132 O-ring - 11/16 OD -

Red

2 Provides a seal at each end of the mix feed. 000

9 044731 Pin-Cotter 1 Secures mix inlet tube to pump adaptor. 103

10 X41947 Shaft A.-Drive-Mix Pump -

Hopper

1 Rotates counterclockwise to move piston back and

forth.

103

10a 039235 Crank-Drive 1 Delivers motion to piston. 103

10b 041948 Shaft-Drive 1 Delivers motion from pump motor to crank. 103

10c 048632 O-ring-1/2 ID x .139W

(Drive Shaft)

2 Provides seal to prevent mix from leaking into rear

drip pans.

000

10d 008904 O-ring 1-3/4 OD x

.139W

1 Provides seal between crank and pump sleeve. 000

11 044641 Clip-Retainer-Mix Pump 1 Secures air/mix pump to drive hub in mix reservoir. 103

12 X55974 Tube A.-Feed Hopper - Soft

Serve

1 Mix and air is pumped through this tube to the

freezing cylinder.

103

13 056524 Ring-Check-Feed Tube 1 Releases excess pressure from freezing cylinder

back to mix reservoir.

000

14 X44761 Sleeve A.-Mix Pump 1 Guide for pump driveshaft; creates a seal to prevent

mix from leaking into back of machine.

103

13

X57029-XX Pump A. - Mix Simplified - Soft Serve

Figure-6

4

2

11

10d 10c

14

10b

10a

1

4

8

8

13

12

9

7

6

5

10

3

14

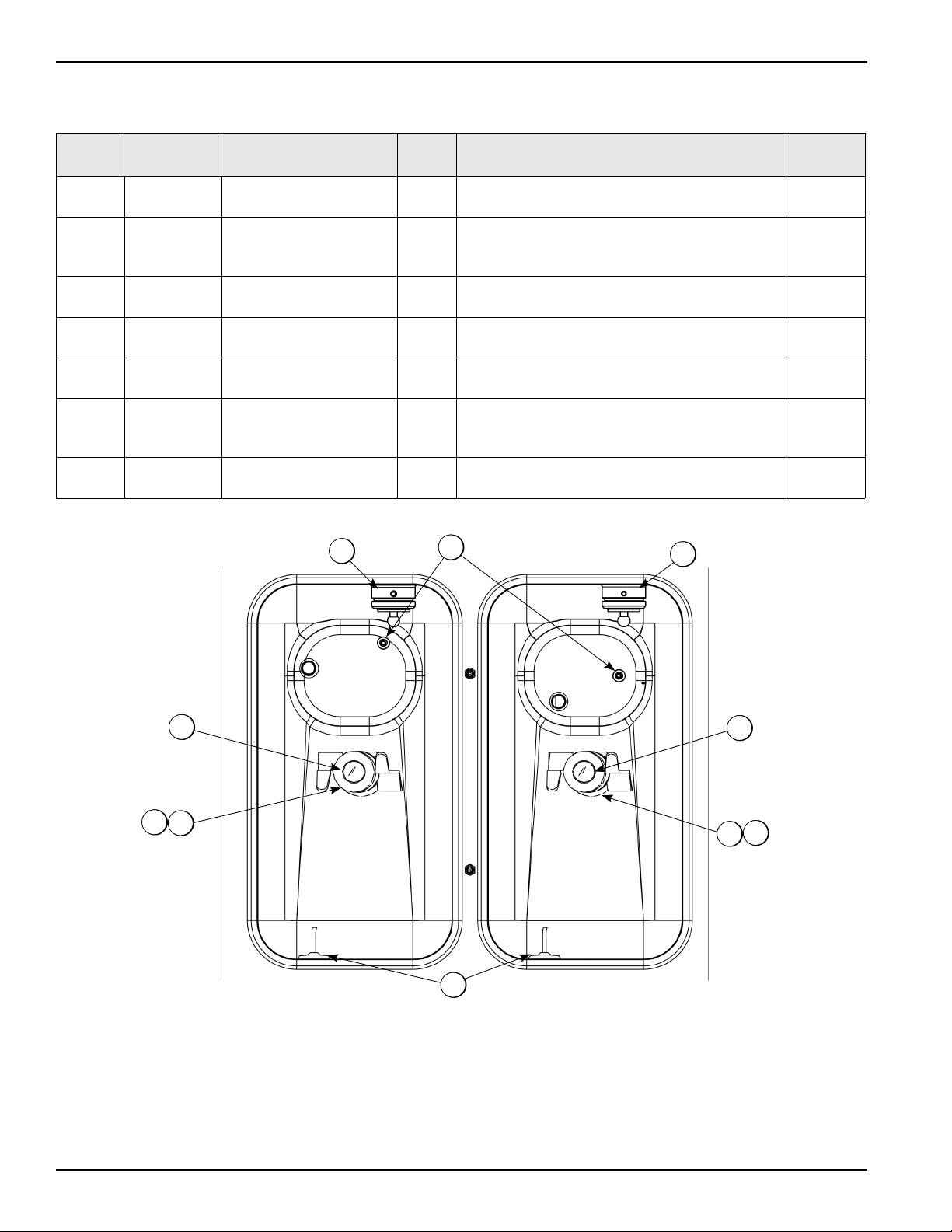

Mix Hopper - Top View

Figure-7

Item Part No. Description Qty. Function Warr.

Class

1 X44761 Sleeve A.-Mix Pump 2 Hub used to hold the air/mix pump in a locked

position.

103

2 X41348 Probe A.-Mix Out 2 Electrical device to indicate level of mix in the

hopper. Activates the Mix Out light on front of

freezer.

103

3 X51664 Housing A. Agitator

(Shake)

1 Provides magnetic force to rotate agitator

assembly.

103

3a

4a

066937 Magnet A.-Agitator-

Inner

2 Rotates the agitator paddles by magnetic force

(included with the agitator assembly).

103

4 X51661 Housing A.-Agitator -

(Soft Serve)

1 Provides magnetic force to rotate agitator

assembly.

103

5 X42077 Probe A.-Mix Low 2 Electrical device to indicate level of mix in the

hopper. Activates the Mix Low light on front of

freezer.

103

6 080826 Cap-Magnet 2 Secures the agitator paddles in place (included

with the agitator assembly).

103

5

3

6

2

11

6

44a

3a

15

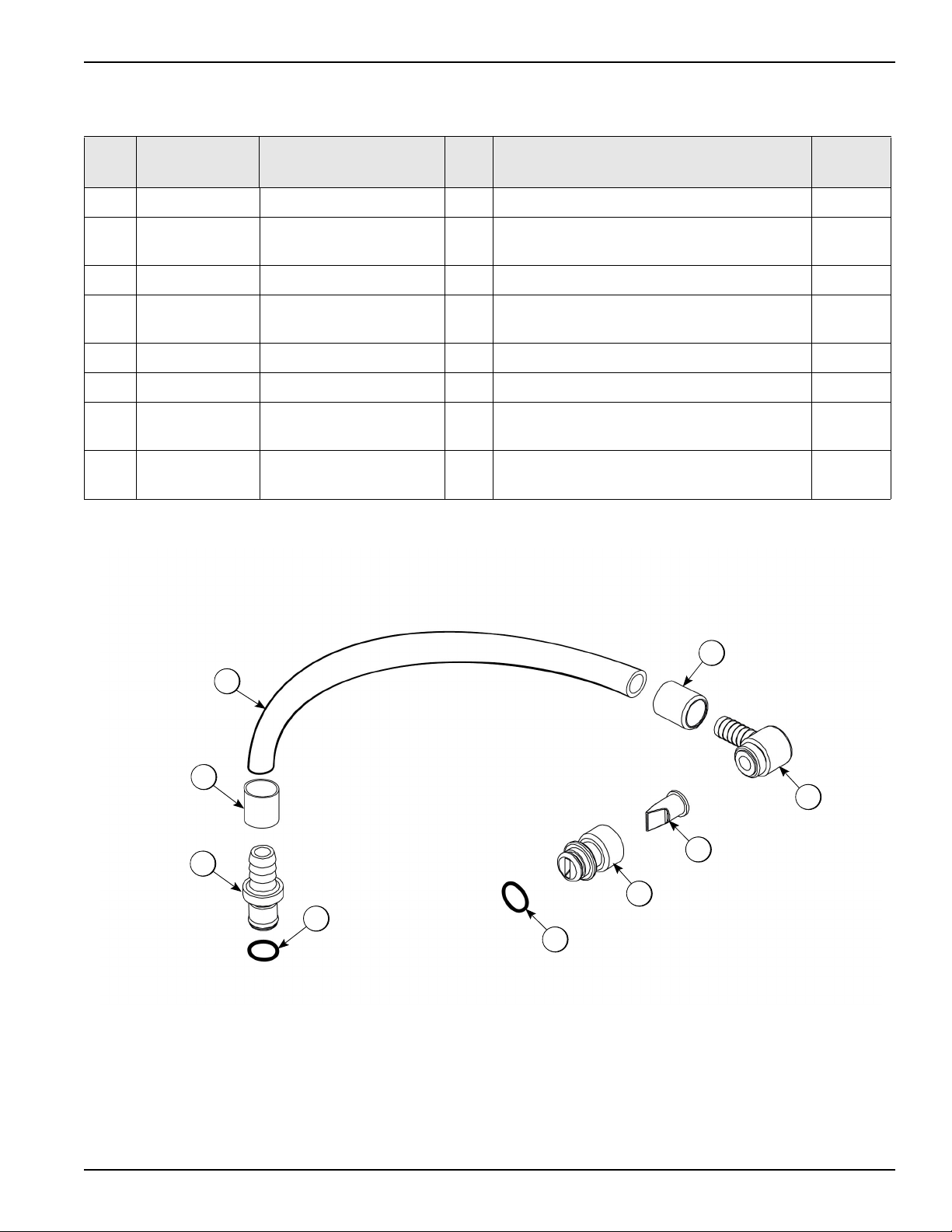

X56652 Syrup Line Assembly - Triple Thick Shake Syrup

*Not included in X56652.

Figure-8

Item Part No. Description Qty. Function Warr.

Class

1 053036 Ferrule-.625 ID 2 Clamps syrup hose on fitting. 000

2 056675 Insert-QD-CPC-3/8 Barb

Plastic

1 Connects syrup lines to front panel. 103

*3 500205 O-ring 1 Provides seal for quick disconnect fitting. 000

4 053052-9 Hose-Beverage 3/8 ID x 5/8

OD

1 Delivers syrup to freezer door (9”). 000

5 056651 Fitting-Syrup Elbow 1 Connects valve to syrup line. 103

6 500598 Valve-Check Duckbill 1 One-way valve to direct syrup flow. 000

7 056650 Fitting-Syrup Nose (Large

Slot)

1 Removable fitting allowing access to duckbill

valve.

103

8 053890 O-ring-11 mm Green (Syrup

Hole Plug)

1 Seals syrup hole plug in syrup port of freezer door. 000

8

7

6

5

1

3

2

1

4

16

X59304 Syrup Line Assembly - Thin Viscosity Syrup

*Not included in X59304.

Figure-9

Item Part No. Description Qty. Function Warr.

Class

1 029834 Ferrule-.650 ID 2 Clamps syrup hose on fitting. 000

2 056675 Insert-QD-CPC-3/8 Barb

Plastic

1 Connects syrup lines to front panel. 103

3 500205 O-ring 1 Provides seal for quick disconnect fitting. 000

4 500038-9 Tube-Vinyl 1 Delivers syrup to freezer door (9”). 000

5 056651 Fitting-Syrup Elbow 1 Connects valve to syrup line. 103

6 500598 Valve-Check Duckbill 1 One-way valve to direct syrup flow. 000

7 056649 Fitting-Syrup Nose (Small

Slot)

1 Removable fitting allowing access to duckbill

valve.

103

8 053890 O-ring-11 mm Green (Syrup

Hole Plug)

1 Seals syrup hole plug in syrup port of freezer door. 000

8

6

5

1

4

1

2

3

7

17

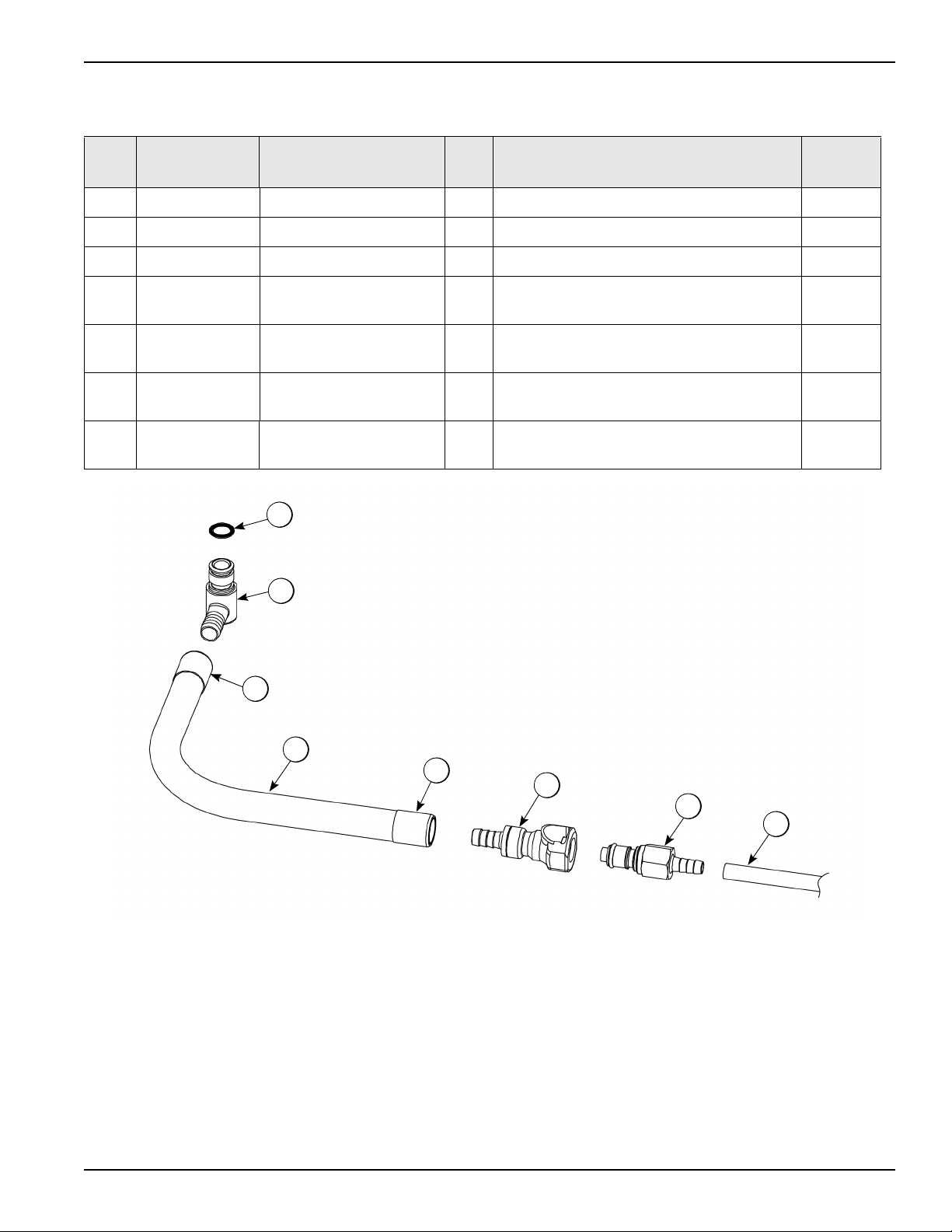

X58450 Syrup Line Assembly - Syrup-In-Bag Option

Figure-10

Item Part No. Description Qty. Function Warr.

Class

1 024278 O-ring-1/2 OD x .070 1 Provides a seal in the pump tube connection. 000

2 054526 Fitting-Male Peristaltic 1 Connects to the pump tube. 103

3 053036 Ferrule-.625 ID NP Brass 2 Secures the fitting on the hose. 000

4 058451 Coupling-QD Female 3/8

Barb

1 Quick disconnect fitting used for syrup bag

removal. Press the lever to detach.

103

5 058452 Coupling-QD Male 1/4 Barb 1 Connects the hose from the syrup bag to the

disconnect fitting.

103

6 R30314 Tube-Vinyl 3/16 ID x

1/16 Wall

1 Delivers syrup from the bag to the peristaltic

pump.

000

7 053052-36 Hose-Beverage 3/8 ID x 5/8

OD

1 Delivers syrup from the bag to the peristaltic

pump.

000

1

2

3

7

34

5

6

18

Beater Door Assembly - Shake Side

Item Part No. Description Qty. Function Warr.

Class

1 032560 Seal-Drive Shaft 1 Provides seal from product inside freezing cylinder

to internal areas of freezer.

000

2 050985 Shaft-Beater 7 Qt. Fluted

Blade

1 Connects beater assembly to gear unit. 103

3 041103 Blade-Scraper-16” 2 Scrapes frozen product off wall of freezing cylinder. 000

4 055605 Bearing-Door Front 1.390

OD

1 Allows beater assembly to turn freely in hub of

freezer door.

000

5 X50958 Beater A.-7 Qt. Fluted Blade 1 Blends air and mix inside the freezing cylinder and

provides force to dispense product.

103

6 033493 O-ring 6” - Freezer Door 1 Provides a seal between freezer door and freezing

cylinder.

000

7 X55825SER2 Door A.-Shake 1 Covers open end of freezing cylinder and provides

port for the product to be dispensed.

103

8 055989 Nut-Stud-Black 4 Tightening mechanism to secure freezer door to

freezing cylinder.

103

9 053890 O-ring -Syrup Port 11mm ID

x 2mm Green

4 Prevents leakage at syrup port plug. 000

10 053867 Plug-Syrup Port 4 Seals off syrup ports in the freezer door during the

Heat cycle.

000

11 054554 Retainer-Syrup Valve 4 Retainer pins that secure the syrup valves. 000

12 020571 O-ring - 1-1/16 OD x .139 W

(Draw Valve)

2 Provides seal for draw valve in freezer door cavity. 000

13 084696 Seal-Spinner Shaft 1 Provides a seal between draw valve and spinner

shaft.

000

14 034054 Spinner-Driven Complete 1 Helps to blend mix with syrup in freezer door cavity. 103

15 X59331 Blade A.-Spinner Aluminum-

HT

1 Blends mix with syrup in freezer door cavity. 103

16 033107 Cap- Restrictor 1 Snaps over door spout so blended product flows in a

stream.

000

17 059000 Valve A.-Draw 1 Seals off mix in freezer door cavity. When raised, the

port opens, allowing product in freezing cylinder to

be dispensed.

103

Other manuals for C602

1

This manual suits for next models

1

Table of contents