3

General ........................................................ 6

Product Description ..................................................6

Summary of Changes .......................................... .....7

Technical Information................................. 9

Mounting Instruction............................................ .....9

Classication ...........................................................................9

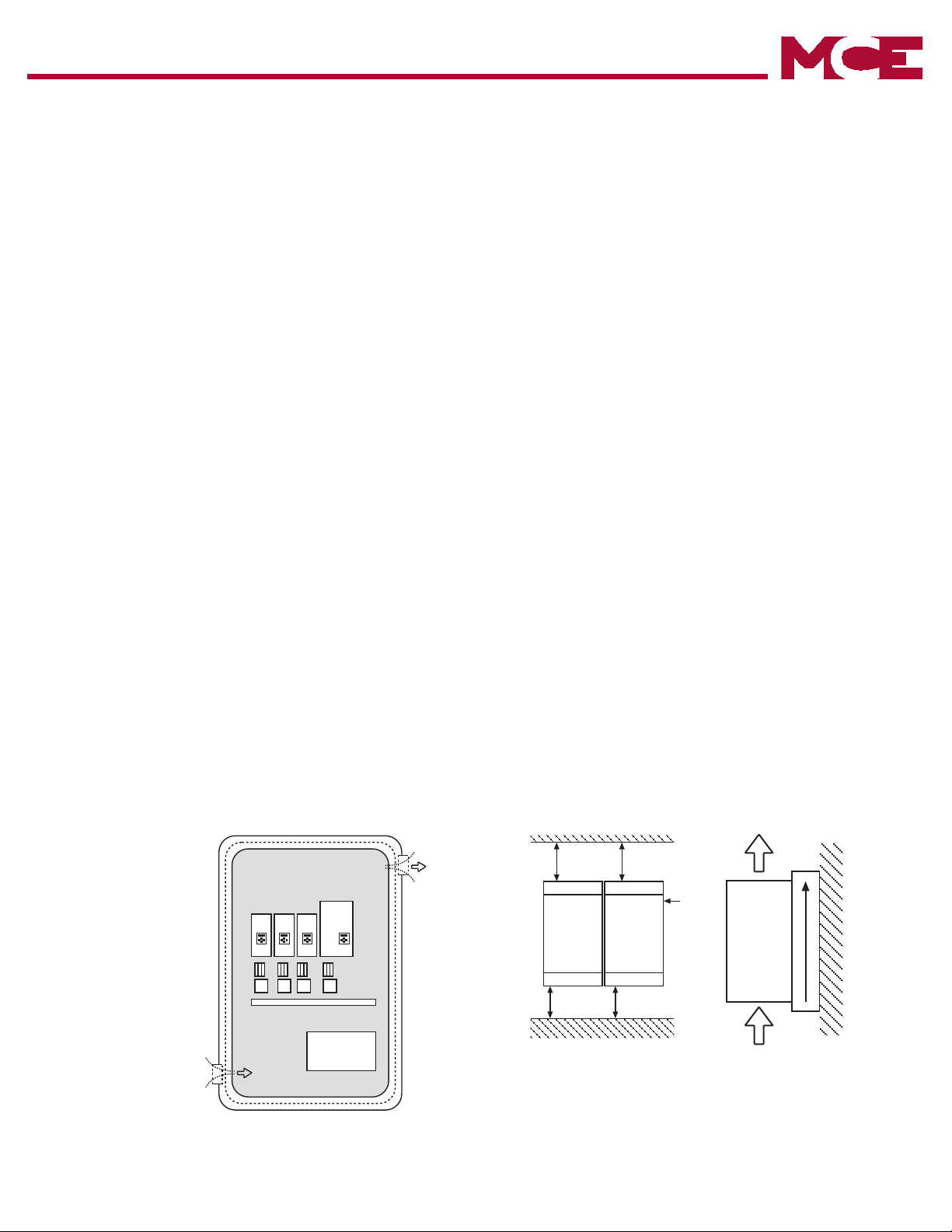

Physical Mounting...................................................................9

Harsh Environments......................................................... .....10

Ambient Conditions ......................................................... .....10

Electrical Connections....................................... .....11

Safety First ........................................................................ .....11

Voltage Supply.................................................................. .....11

Disconnect Switch............................................................ .....11

Fusing.....................................................................................12

Line Chokes ...........................................................................14

Motor Thermal Protection .....................................................14

Motor Cable Length...............................................................15

High Voltage Connections ....................................................16

Ground Connections.............................................................17

High Frequency Shielding ....................................................17

Storage of Unit.................................................................. .....19

Dielectric Testing ...................................................................20

Insulation Measurement .......................................................20

Brake Transistor Monitor.........................................21

Monitor Circuit Wiring Diagrams..........................................22

Temperature Sensor Wiring Diagrams.................................24

Model Number Information .....................................26

Technical data 230V (size 13 to 23)*.......................27

Technical data 480V (size 13 to 28)* ......................29

Dimensions and Weight ..........................................31

Power Connections ............................................ .....33

Connection of the power circuit........................ .....35

Ferrite Ring Installation...................................... .....36

Time dependent overload curve........................ .....39

Low Speed Overload ..............................................40

Control Connections ................................ 41

Control Circuit ........................................................41

Terminal Strip Connections F5-A.........................................41

Connection of the control signals .......................................42

Digital Input............................................................................42

Analog Inputs ........................................................................42

Voltage Input / External Power Supply ................................43

Digital Outputs.......................................................................43

Relay Outputs ........................................................................43

Analog Outputs .....................................................................43

Voltage Output .......................................................................43

Control Circuit - STO ......................................... .....44

Assembly of the wires (F5-K) ...............................................45

Terminal Strip Connections (F5-K) ......................................46

Digital Inputs (F5-K) ..............................................................48

Analog Inputs (F5-K) .............................................................48

Digital Outputs (F5-K) ...........................................................48

Relay Outputs (F5-K).............................................................48

Analog Outputs (F5-K) ..........................................................49

STO Conections (F5-K) .........................................................49

STO Inputs (F5-K) ...............................................................50

STO Output (F5-K) .................................................................50

STO Input Control Sequence (F5-K) ..................................50

Encoder Feedback Interfaces............................ .....51

Incremental TTL Encoder Interface X3A Screw

Terminals .......................................................................53

EnDat Encoder Interface X3A ..............................................55

Sin/Cos Encoder Interface X3A ...........................................58

SSi Encoder Interface X3A ..................................................61

BiSS / EnDat 2.2 Encoder Interface X3A ............................64

Hiperface Encoder Interface X3A.........................................67

UVW Encoder Interface X3A.................................................70

Incremental TTL Encoder Interface X3A SubD ..................72

X3B Output TTL Incremental .......................................... .....74

Operation of the unit ................................ 75

LCD Operator ...........................................................75

Keypad Buttons .....................................................................75

Serial/CAN Hardware Version ............................ .....76

LED Indicators .......................................................................76

Backward Compatibility ..........................................77

Menus and Navigation Overview....................... .....77

Home Screen............................................................77

Languages .......................................................... .....78

Programming Menu .................................................79

Parameter Adjustment...........................................................80

Setting the Password ............................................................81

Units .......................................................................................83

Diagnostics Screen .................................................84

Error Messages & Fault Log.................................................84

Fault Data Logging................................................................85

Date & Time ......................................................... .....86

Setting the date......................................................................86

Setting the time......................................................................86

Customizing Parameter Lists ........................... .....87

Customizing Defaults......................................... .....89

Initial Start Up ........................................... 90

Connecting the drive and operator ........................90

Default Operator and Drive...................................................90

Previously Programmed Operator or Drive.........................90

Manual Programming ......................................... .....91

Getting Started.......................................................................91

Elevator App...........................................................................92

Basic Setup ......................................................... .....93

Inputs/Output Conguration ..................................93

Inputs......................................................................................94

Ouputs....................................................................................94

Motor Data........................................................... .....95

Induction Motors ...................................................................95

Permanent Magnet Motors....................................................95

Encoder Data ...........................................................96

Machine Data ...................................................... .....96

Speed Prole....................................................... .....97

Prole Adjustment .................................................................97

Motor Learn ......................................................... .....99

Encoder Learn .................................................. .....100

SPI Encoder Learn.......................................................... .....101

Encoder Pole Position Learn......................................... .....102

Encoder Synchronization .............................................. .....103

Running the Motor............................................ .....103

Running at High Speed.................................................. .....103

Table of Contents