Mecaterm Arctiq User manual

Ver 1.5

Updated: 2013-10-25

MANUAL SOLO

P a g e | 2

Contents

Introduction ........................................................................................4

The heat pump ...................................................................................4

ArctiQ & ArctiQ EVI .................................................................................................................4

Aqua........................................................................................................................................5

Delivery ...............................................................................................6

Safety regulations..................................................................................................................6

Component overview..........................................................................7

ArctiQ ......................................................................................................................................7

ArctiQ EVI................................................................................................................................8

Aqua........................................................................................................................................9

Installation of ArctiQ & ArctiQ EVI ................................................... 10

Positioning........................................................................................................................... 10

Pipe installation .................................................................................................................. 13

Installation of Aqua ......................................................................... 15

Positioning........................................................................................................................... 15

Pipe installation .................................................................................................................. 15

Brine medium ..............................................................................................................................................15

Heating medium ..........................................................................................................................................19

Electrical installation....................................................................... 20

Overview .............................................................................................................................. 20

High voltage supply............................................................................................................. 21

Main supply..................................................................................................................................................21

external heat source control .......................................................................................................................21

Low voltage connections.................................................................................................... 22

Overview low voltage connections..............................................................................................................23

Control Modes ................................................................................. 24

SoloBasiC ............................................................................................................................ 24

CONTROLLING OF EXTERNAL HEAT SOURCE.............................................................................................27

SoloDigitaL .......................................................................................................................... 28

P a g e | 3

The display....................................................................................... 29

Rest mode ........................................................................................................................... 29

Actual values....................................................................................................................... 29

Setting values ..................................................................................................................... 29

Errors ................................................................................................................................... 30

Factory reset ....................................................................................................................... 30

Table - Actual values........................................................................................................... 31

Table - Set values................................................................................................................ 33

Table - Errors....................................................................................................................... 36

Quick start guide ............................................................................. 41

SoloBasiC –Set condensation .......................................................................................... 42

SoloBasiC –floating condensation ................................................................................... 43

SoloDigitaL .......................................................................................................................... 44

Service and maintainance .............................................................. 45

ArctiQ & ArctiQ EVI .............................................................................................................. 45

Manual defrost.................................................................................................................... 46

Aqua..................................................................................................................................... 47

R/T tables sensors ............................................................................................................. 48

Technical data ................................................................................. 49

ArctiQ ................................................................................................................................... 49

ArctiQ EVI............................................................................................................................. 50

Aqua..................................................................................................................................... 51

Spare part list .................................................................................. 52

ArctiQ and ArctiQ EVI .......................................................................................................... 52

Aqua..................................................................................................................................... 52

Commissioning report ..................................................................... 53

Electrical diagram ........................................................................... 54

P a g e | 4

INTRODUCTION

This manual is intended for use with the heat pump models, Mecaterm ArctiQ, ArctiQ EVI and

Aqua when used as standalone units together with arbitrary boiler/accumulator system.

When installing the heat pump together with a Mecaterm boiler, for example MasterQal, please

refer to the manual packed with the boiler unit

THE HEAT PUMP

Congratulations!

You are now the owner of a top-quality product that will reduce your electricity bills and save you

money that can be spent on much more enjoyable things.

The heat pump is manufactured by Mecaterm in Malmö, Sweden, who have extensive experience

of manufacturing heat pumps. All heat pumps, before leaving the factory, have first been tested

for functionality and technical performance. All stages of manufacturing from the plated chassis

to the finished heat pump are monitored continually to maintain quality.

The chassis of the heat pump, and all included screw and rivets, are manufactured from stainless

steel, which requires minimum maintenance and offers a long-lasting durable structure. The

components used in the pumps are supplied by renowned suppliers, based on functionality and

quality which, in turn, results in a minimum of service.

ARCTIQ&ARCTIQEVI

The ArctiQ and ArctiQ EVI models are so-called air/water heat pumps that utilise energy from the

outdoor air (indirect solar energy) and, using a cooling process, transfer heat to your boiler

system, thereby providing you with inexpensive energy.

The Mecaterm ArctiQ model is a very reliable heat pump that operates at temperatures as low as

–15ºC and produces water temperatures of up to 60ºC. The effectively sound-insulated

compressor and the optimized heat exchanger offer high operating efficiency.

The Mecaterm ArctiQ EVI model is the result of innovative solutions and technical progress

regarding compressors, which allows you to extract cheap heat from the atmosphere, even if the

outdoor temperature is as low as -25ºC.

P a g e | 5

AQUA

The Aqua model is a so-called liquid/water heat pump which means energy is extracted from a

collection pipe that is installed, for instance, in the bedrock, under the surface of the earth, in

lakes etc.

Aqua uses the same reliable components as the related ArctiQ and ArctiQ EVI models, as well as

being fitted with extra-thick sound insulation to reduce disturbing noise levels.

P a g e | 6

DELIVERY

Check the following points when your pump has been delivered and when installing the pump:

• The ArctiQ, ArctiQ EVI and Aqua pumps must be transported and stored in a vertical position.

• Remove packaging and check that the product has not been damaged in transit. Report any

transit damage to the freight agent.

• Make sure that at least one metre of space is available in front of the product for service

access.

SAFETY REGULATIONS

The following safety regulations must be observed when handling, installing and using the

product:

• Disconnect the power supply in the control box prior to carrying out any form of maintenance

and service work on the products.

• Make sure that all lifting equipment, eye bolts and other components are undamaged when

handling heat pumps fitted with eye bolts or similar items. Never stand under a product when it is

in an elevated position.

• Never compromise on safety by removing housings, hoods or similar that are screwed in place.

• Never compromise on safety by disconnecting safety equipment.

• Only authorised personnel are allowed to modify or service the product.

P a g e | 7

COMPONENT OVERVIEW

ARCTIQ

Expansion valve

Sight glass

Check valve

Filter drier/receiver

Defrost sensor

Evaporator

Primary flow temp sensor

Condensor

Air vent valve

Fan

Control unit

Return flow temp sensor

Bulb expansion valve

4-way valve

¼” schrader high pressure

¼” schrader low pressure

High pressure switch, 29bar

Low pressure switch, 0bar

Discharge gas temp sensor

Compressor

P a g e | 8

ARCTIQEVI

Defrost sensor

Main expansion valve

EVI expansion valve

Check valve

Economizer

Evaporator

Sight glass

Solenoid valve EVI

Filter drier/receiver

Fan

Control unit

Return flow temp sensor

Primary flow temp sensor

Bulb main expansion valve

4-way valve

¼” schrader high pressure

¼” schrader low pressure

High pressure switch, 31bar

Low pressure switch, 0bar

Discharge gas temp sensor

Compressor

¼” schrader EVI pressure

P a g e | 9

AQUA

Brine in temp sensor

Expansion valve

Filter drier/receiver

Compressor

Condensor

Evaporator

Variable speed charge pump

Return flow temp sensor

Drain plug condensor

Sight glass

¼” schrader low pressure

Low pressure switch, 0bar

Control unit

Primary flow temp sensor

Discharge gas temp sensor

¼” schrader high pressure

High pressure switch, 29bar

Brine circulation pump

Drain plug evaporator

Brine out temp sensor

P a g e | 10

INSTALLATION OF ARCTIQ&ARCTIQEVI

This chapter is intended for installers of the heating system. It describes how to install the ArctiQ

and ArctiQ EVI air-water heat pump models.

►Please note that the commissioning report in the end of this manual must be

filled in once the product is installed.

POSITIONING

The heat pump must be positioned outdoors and may not be installed, for instance, in a

carport or any type of outhouse. The heat pump must stand freely without a roof or

anything similar above it.

In general, make sure that the heat pump is ventilated sufficiently.

It is recommended that the heat pump be installed in close proximity to the boiler as this

reduces the length of pipes to be drawn, thereby minimising heat loss.

Even though the Mecaterm Arctic and the Arctic EVI models are well soundproofed, select an

installation location that minimises noise levels for those living in the household and for

neighbours. Note that the sound from the pump resonates more if it is placed on asphalt,

concrete, stone paving, etc., while grass, for instance, absorbs some of the noise. Contact

your local council for advice on sound levels stipulations in your area.

The heat pump automatically reduces the fan speed during the summer depending on the

break temperature set in the control panel, which in turn lowers the noise level.

It is recommended to place the heat pump on a solid base, such as garden paving,

concrete or similar material. It may be necessary, depending on where you are located, to

install the pump in a higher position to cope with large volumes of snow.

The distance from the outer wall to the heat pump must be at least 150 mm. If the pump

is to be placed at a corner, maintain a minimum distance of 300 mm to the gable-end.

P a g e | 11

Defrosting can entail a certain amount of condensation from the battery, which must be

drained off, for instance, using a gravel bed and to prevent the water from running off to

form ice on open surfaces.

Make sure that the heat pump is tilted slightly forwards to prevent water from running

down into the evaporation coil and causing problems with ice. Use the height-adjustable

legs to easily set the tilt angle.

Positioning the heat pump

P a g e | 12

P a g e | 13

PIPE INSTALLATION

As this manual is intended for the docking of heat pumps into existing boiler systems or different

types of new installations, the procedure of installing the pipework is unique for each system

involved. Certain general guidelines should be adhered to.

Copper pipes should be connected to/from the heat pump. Depending on heat pump

model the dimension will differ. For correct dimension see table below.

Nominal flow values (when using non variable speed charge pump) for each heat pump

model can be found in the table below. When using variable speed charge pump (pwm-

controlled) a desired delta temperature will be able to set and the flow will be controlled

in the software.

Pipe dimensions

Model

Size

Connection heat

pump

Minimum connection

pipe dimension

Nominal flow

ArctiQ

7,5

cu28

22mm

800l/h

10,5

1100l/h

16

28mm

1600l/h

ArctiQ EVI

10

cu28

22mm

1000l/h

14

28mm

1300l/h

20

1900l/h

Pressure drop condenser ArctiQ and ArctiQ EVI

P a g e | 14

A metal-enclosed hosing can easily be coupled between the connecting pipe and the heat

pump's condenser to prevent any vibrations/noise from being transferred to the radiator

system in the house.

Note the coupling direction of the connecting pipes/hoses on the heat pump that is

displayed on the side of the condenser as outlined in figure below.

Pipes and hoses used outdoors should be insulated with at least 15 mm of insulation,

such as armaflex or likewise. The insulation must be primed against moisture to prevent it

from becoming wet from the outside. On the inside, at least 8 mm of insulation should be

used, but the piping does not have to be insulated if you wish to heat the boiler room

instead.

In general, pipes must be fitted in such a manner that makes the system as good as self-

aerating. An aerating valve is fitted at the highest point of the condensor in the heat

pump. The aerating valve is a requirement if pipes are drawn anywhere above the level of

this valve.

Coupling direction of water to the heat pump.

Air vent valve

Condensor

Water from boiler

Water to boiler

P a g e | 15

INSTALLATION OF AQUA

This chapter is intended for installers of the heating system. It deals with the installation of the

Aqua model.

►Please note that the commissioning report found in the end of this manual must be

filled in once the product is installed.

POSITIONING

The Aqua model must be positioned indoors on a solid base, preferable on a concrete

floor.

Place the heat pump, if possible, with its back to an outer wall to prevent unnecessary

noise.

Avoid, if possible, positioning the pump close to a bedroom or other area that is sensitive

to noise.

PIPE INSTALLATION

As this manual is intended for the docking of heat pumps into existing boiler systems or different

types of new installations, the procedure of installing the pipework is unique for each system

involved.

Note! Aqua has already flexible hoses connected to the heat exchangers to prevent

vibrations why connections to the heat pump can be performed directly with

pipes.

BRINE MEDIUM

Dimensioning

The collector for earth/bedrock/ground water/lake heat, etc. is dimensioned according to

a computerised calculation program. Mecaterm can assist with this type of calculation.

Insulation

The indoor brine medium piping must be insulated with a moisture barrier material to

prevent condensation from dampness.

Note that extra insulation is required to prevent freezing or ground frost if the collector is

placed close to water piping or the ground.

P a g e | 16

Brine fluid

The brine medium should contain antifreeze medium, such as propylene glycol, to

maintain fluidity down to temperatures of -15ºC.

Collector hose

The collector hose, PEM 40 x 2.4 PN 6.3, is used as standard. Every metre of hosing holds

about 1 litre of fluid.

Air drainage

The earth heat collector should be installed in a manner that facilitates self-aerating

without any air pockets. If this is not possible, aerating valves will have to be fitted to the

highest points in the collector.

Filling valve

Pre fabricated filling valves, e.g. LK 520 Multifill 25, with integrated shut off valves/dirt

filter is recommended for easy and safe installation and filling of the brine fluid.

Expansion vessel

The expansion vessel or level tank should be installed as high as possible in the system

on incoming brine pipe (brine in), see picture below.

Safety valve

Safety valve with opening pressure of max 3 bar should be installed

P a g e | 17

1

2

3

4

5

6

6

8

7

9

1

2

3

4

5

6

6

8

7

9

Schematic connection diagram

Nr

Description

1

Brine to heat pump (in)

2

Brine from heat pump (out)

3

Filling valve (including shut off valves & dirt filter)

4

Safety valve, 3 bar

5

Level tank (expansion)

6

Shut off valve

7

Water from heat pump (primary flow)

8

Water to heat pump (return flow)

9

Arbitrary boiler/accumulator tank

P a g e | 18

Pressure drop evaporator Aqua with 30% ethylene glycol in carrier

Circulation pump curve for Aqua 5/8

Circulation pump curve for Aqua 10/12/17

Aqua 5/8

Aqua 10/12/17

P a g e | 19

HEATING MEDIUM

As this manual is intended for the docking of heat pumps into existing boiler system or different

types of new installations, the procedure of installing the pipework is unique for each system

involved. Certain general guidelines should be adhered to.

Copper piping, 22 mm or 28mm should be connected to and from the heat pump and

boiler.

Aqua has preinstalled metal-enclosed hosing on the condenser to prevent

vibrations/noise, why no further installation of hoses between tank and heat pump is

necessary.

Pipes should be insulated with 8 mm of insulation but this is not required if the

surrounding area needs to be heated.

In general, pipes must be fitted in such a manner that makes the system as good as self-

aerating.

The charge pump in the Aqua unit is a low energy variable speed circulation pump.

Depending on system settings in the control unit the flow can vary. For example, a set

constant delta temperature over the condenser can be set. In this case the software will

control the speed of the charge pump in order to achieve the desired value. (If a

Mecaterm boiler is used the speed will vary depending on the boilers need.)

Pressure drop condensor Aqua.

Aqua 5/8/10/12

Aqua 17

P a g e | 20

ELECTRICAL INSTALLATION

The electrical installation must be carried out by an authorised electrician and according to local

regulations.

OVERVIEW

Contactor compressor

12VDC power supply

230V relays

Current transformer

Soft starter NTC thermistors

Power supply connection

230V connection

Low voltage connections

Display+buttons

This manual suits for next models

2

Table of contents

Popular Heat Pump manuals by other brands

Dimplex

Dimplex SIKH 9 ME Installation and operating instructions

Carrier

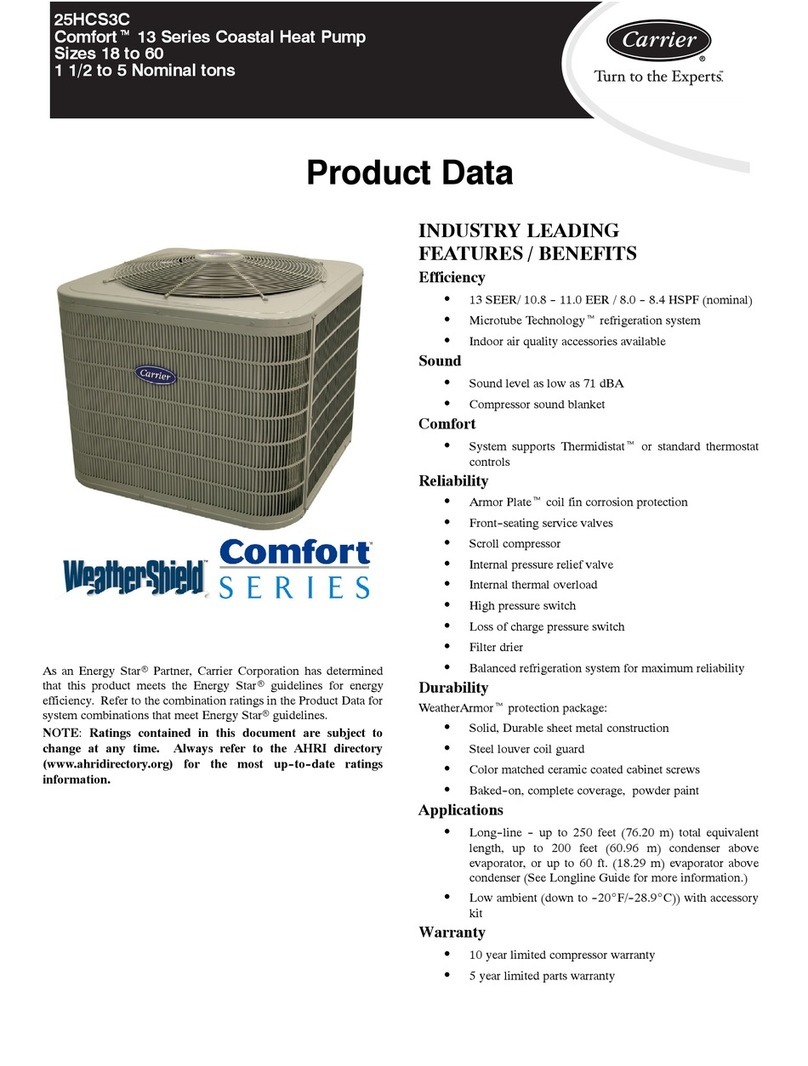

Carrier 25HCS3C Product data

Waterstage

Waterstage Air to Water Operation manual

Carrier

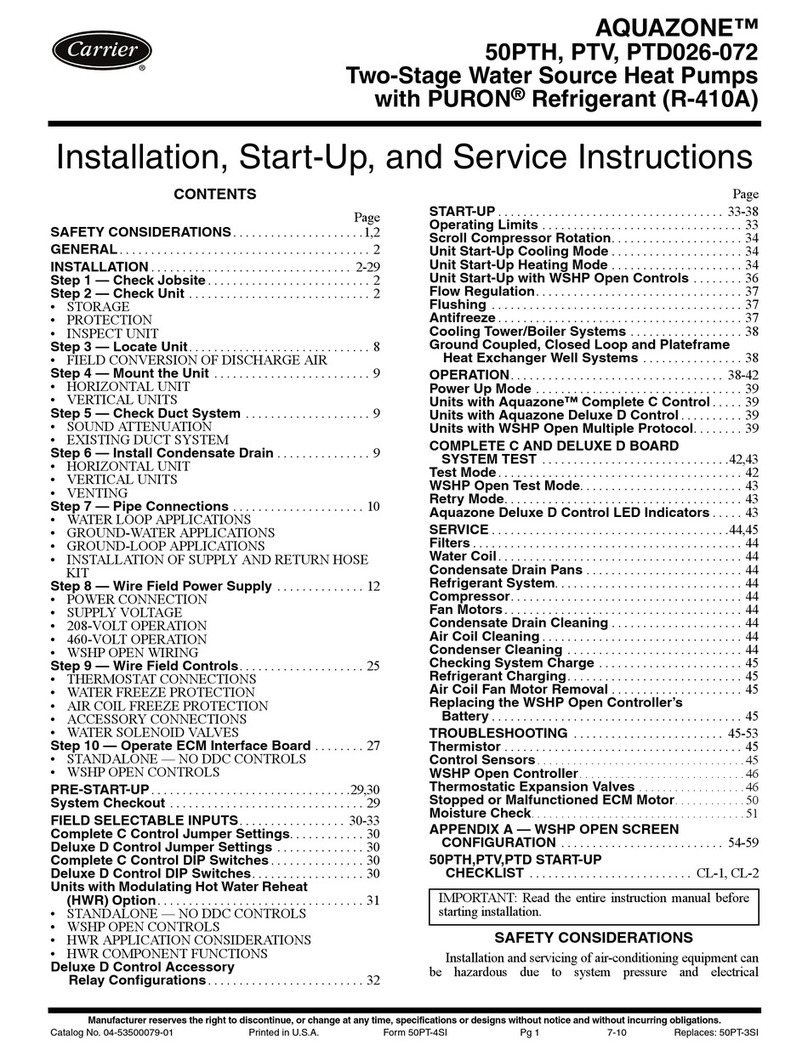

Carrier AQUAZONE 50PTH Installation and service instructions

Bard

Bard QTEC QH303D installation instructions

Carrier

Carrier 25HPA6 installation instructions