Read and understand thoroughly these safety instructions

before use. The items indicated here are very important

safety precautions, which must be followed. We cannot be

held liable for damage caused by non-compliance with the

warning and safety instructions or resulting from incorrect

use or operation.

Technical safety

Before setting up the washing machine, check it for any externally

visible damage. Do not install or use a damaged washing machine.

Before connecting the washing machine, ensure that the connection

data on the data plate (voltage and current) match the electricity

supply. If in any doubt, consult a qualified electrician.

The electrical safety of this washing machine can only be guaranteed

when continuity is complete between it and an effective earthing

system which complies with current local and national safety

regulations. It is most important that this basic safety requirement is

present and regularly tested, and where there is any doubt the

household wiring system should be inspected by a qualified electrician.

The manufacturer cannot be held liable for the consequences of an inadequate earthing system.

Do not connect the washing machine to the mains electricity supply by an extension lead.

Extension leads do not guarantee the required safety of the appliance.

Unauthorized repairs could result in unforeseen dangers for the user, for which manufacturer

cannot accept liability. Repairs should only be undertaken by an approved service technician.

Ensure current is not supplied to the machine until after maintenance or repair work has been

carried out.

If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualified persons in order to avoid a hazard.

when these parts are fitted can the safety standards of the machine be guaranteed.

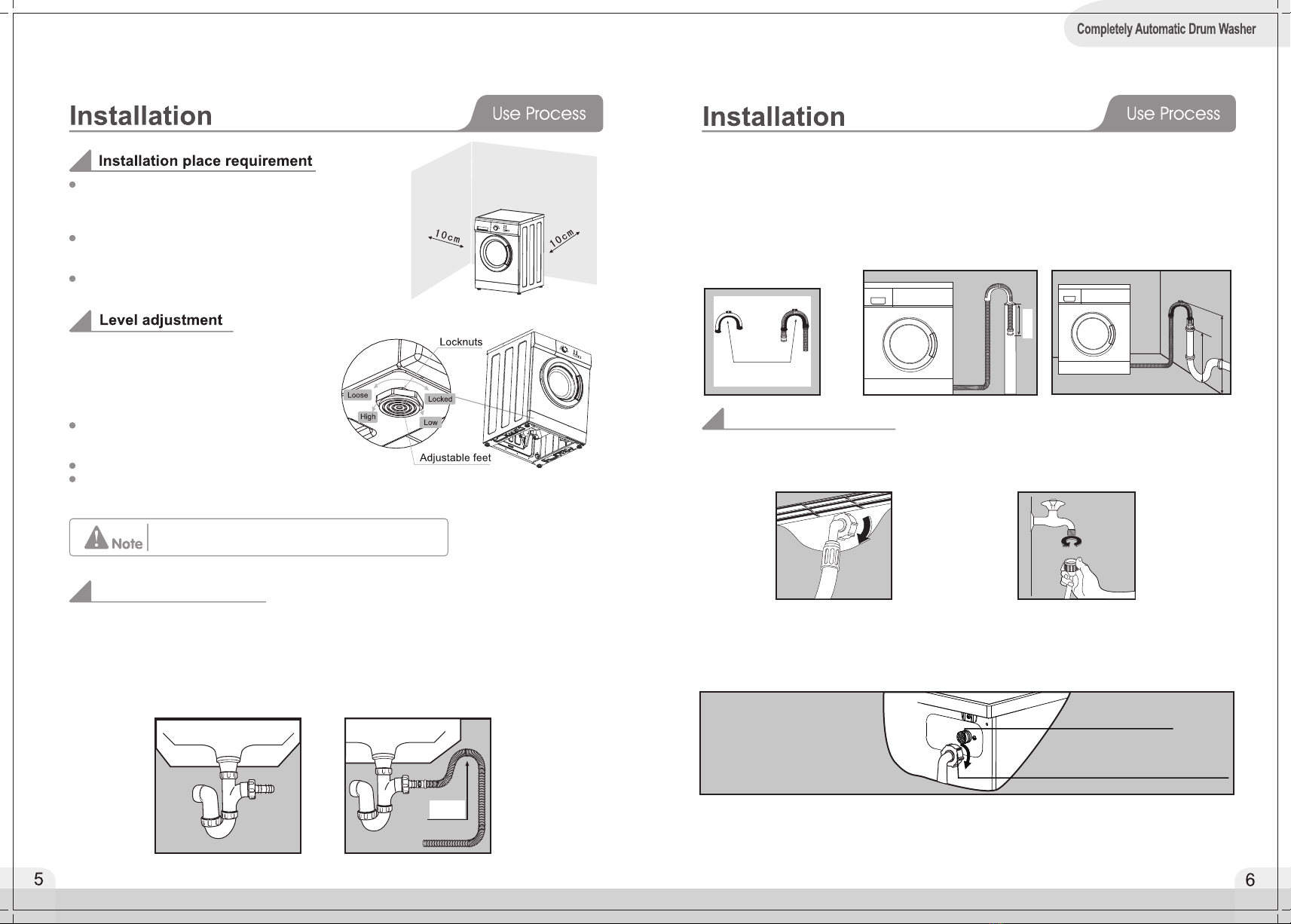

To avoid the risk of personal injury or damage to the washing

machine, do not install it in place where it is damp and where

it suffers from rainfall.

Do not install the washing machine in place where it suffers

from the sun directly, in which plastic or components will be

damaged. It will be shortened the life of your washing machine.

Do not install the washing machine in place where temperatures

below freezing may occur. Frozen hoses may burst or split. The

reliability of the electronic control unit may be impaired at

temperatures below freezing point.

Do not shoot the washing machine with water when you clean it.

Keep the washing machine away from fire or heat sources.

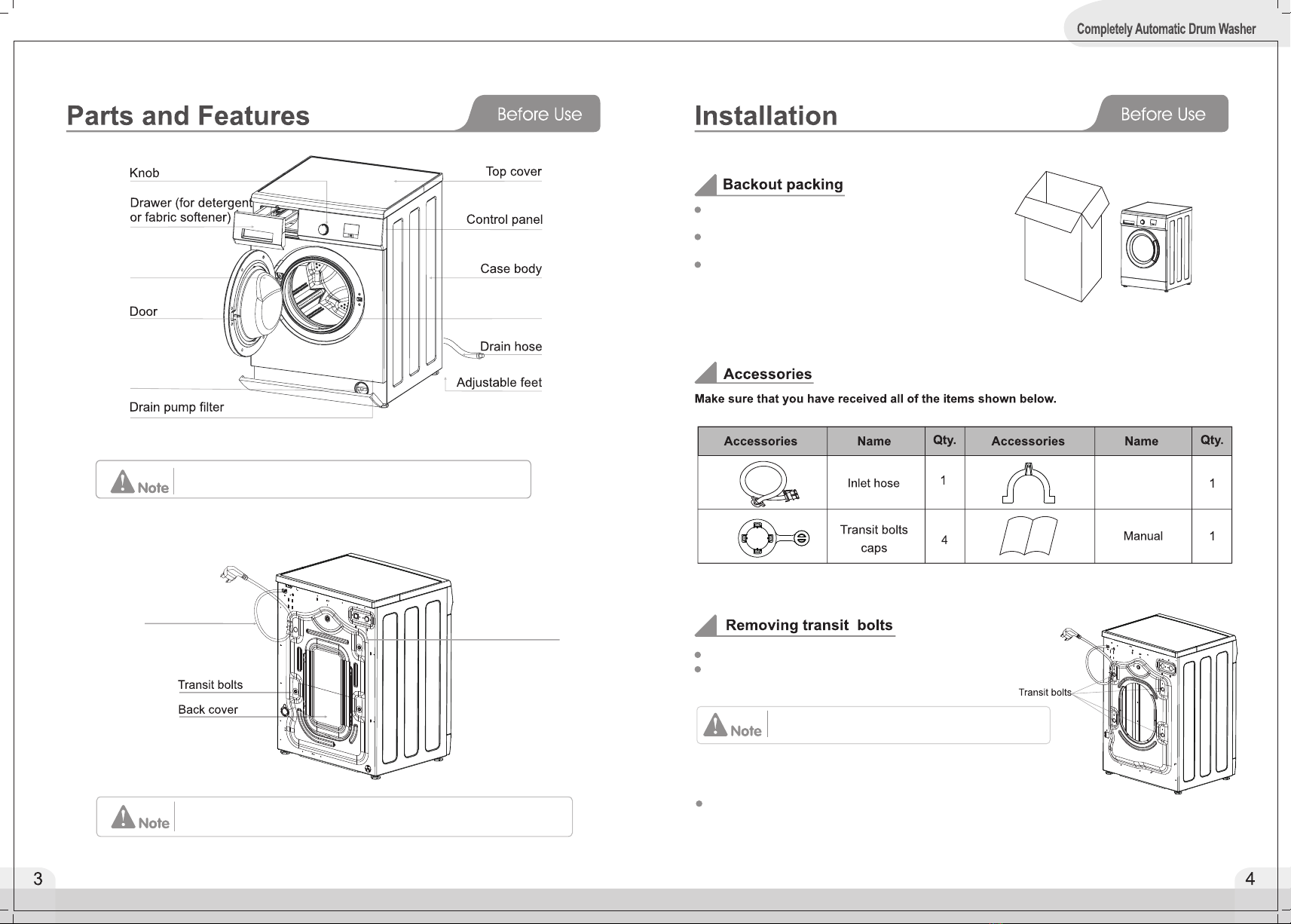

Before using the washing machine for the first time, check that the transit bolts

at the rear of the machine have been removed. During spinning, transit bolts which is still in place

may result in damage to both the machine and adjacent furniture or appliances.

Turn off the tap if the machine is to be left for any length of time (e.g. holiday), especially if there is

no floor drain (gully) in the immediate vicinity.

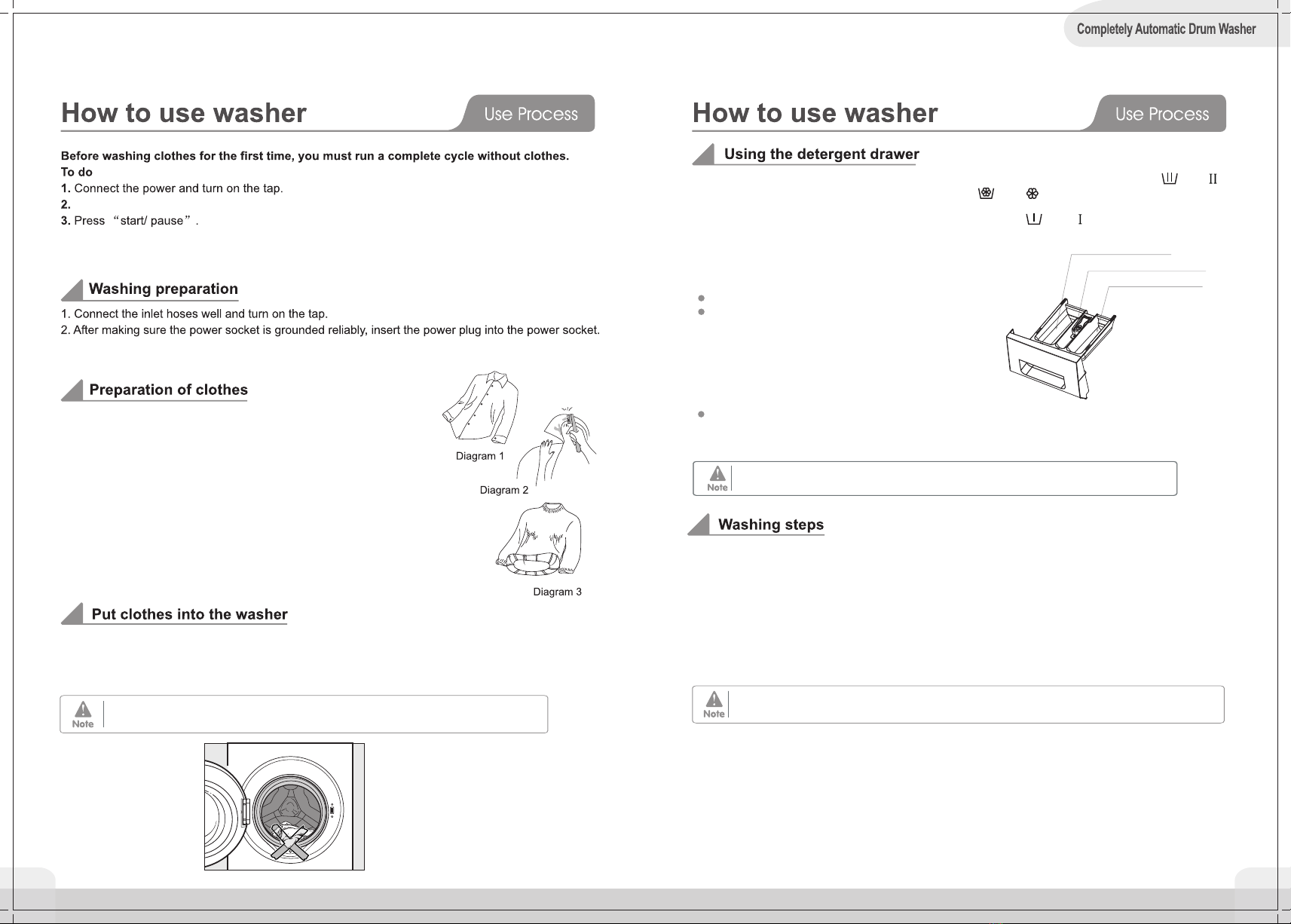

Take care to ensure that foreign objects (e.g. nails, pins, coins, paper clips) do not find their way

into the machine with the laundry. These may damage components of the machine (e.g. drum),

which in turn can result in damage to the laundry.

Do not wash water-repellent things(e.g. raincoats) with washing machine.

Only remove laundry from the washing machine once the drum has stopped turning. Reaching

into a moving drum is extremely dangerous and could result in injury.

For washing machines having ventilation openings in the base, the washing mechines can not be

working on the carpet.

Correct use

Safety with children

Keep children away from the washing machine at all times. To avoid

the risk of injury do not allow children to play on or near it or to

play with its controls. Supervise children whilst you are using it.

Older children may only use the washing machine if its operation has

been clearly explained to them and they are able to use it safely,

recognising the dangers of misuse.

For machines with a 'porthole' door, remember that the porthole glass

will be hot when washing at very high temperatures. Do not let children

touch it.

THIS WASHING MACHINE MUST BE EARTHED.

This appliance can be used by children aged from 8 years and above and

persons with reduced physical, sensory or mental capabilities or lack of

experience and knowledge if they have been given supervision or instru-

ction concerning used of the appliance in a safe way and understand the

hazards involved. Children shall not play with the appliance. Cleaning

and user maintenance shall not be made by children without supervision.

Children of less than 3 years should be kept away unless continuously

supervised.

The new hose-sets supplied with the appliance are to be used and that

old hose-sets should not be reused.