Metrol GN User manual

GM-10-2E-GN-K001

High-vacuum resistance Switch GNGuide Manual

*1 Both On→Off, Off→On/ 0.003 (range)(At operating speed 50-200mm/min) *2 Adjust the installed location of the switch by the signal switching point.

■

unit : mm

Normally open (NO) Normally closed (NC)

Blue

Brown

Blue

Brown

Slipping after push-in

Shorter than stroke Shorter than stroke

Stopper surface

Stopper

Workpieces Workpieces

Make contact with detected objects at right angle

(within deflection angle ±3°)

Straight touch type

Suitable for angled touchAngled touch type

If there is a possibility to press the plunger

to the stroke end, install a stopper separately

to prevent the malfunction.

When using for rotation indexing, adjust

the position in consideration of

eccentricity and core blurring accuracy

of rotating objects.

The degree required to turn on the switch

when the detected object doesn't meet the switch

end fully.

■

GN-PT5M3A

GN-PT5M3A-R

GN-PT5M3B

GN-PT5M3B-R

GN-CSK141B

A : NO

B : NC

0.003

0.01

1.5

5.0

about 0.3

0*2

0.5N

0.8N

Straight

90°(-R)

Straight

90°(-R)

Straight

G

N-PT5M3A-

R

G

N-PT5M3B-

R

9

0

°

(

-

R

)

9

0

°

(

-

R

)

Straight

touch type

Angled

touch type

GN-BP5MA

GN-BP5MA-R

GN-BP161B

A : NO

B : NC

1.0

2.9

about 0.3

about

0.2

0.01

1.0N

1.5N

Straight

90°(-R)

Straight

How to useProduct name Stroke Cable directionOutput mode Repeatability*1PretravelContact force

GN-PT/GN-CSK

GN-BP

Standard specification

Common specification

■How to use■Circuit diagram

Switch structureDry contact

10-5PaCompatible vacuum

Allowable baking

temperature

Movement differential 0Impact 300m/s2X,Y,Z each direction

CablePTFE Core-wire cable0.5m AWG30

〈AT01B030〉made by Junkosha Inc.

Contact rating DC5V-DC24V Steady current : 10 mA

or less(rush current: 20 mA or less)

Contact life time

Protective structure

3 million

IP40

Standard accessoryTwo fixing nuts

(If no specified bungle caused by vibration

and used under voltage and current rating.)

120°C

Oscillation10 - 55Hz total amplitude 1.5

for X, Y, Z each direction

Within 5°

■

Product name

GN-PT5M3 A / B

GN-CSK141B

GN-BP5MA

GN-BP161B

Screw / Nut

M5×0.5

M14×1

M5×0.5

M16×1

Tightning torque

1N・m

10N・m

1N・m

12N・m

Tightning torque for case screws and nuts

・Use in the environment in where cuttings and dust don't prevent

switch movement.

・Choose protective cover option in case cutting may damage the

rubber boot.

・An extra cover is recommended to avoid direct hit by high-pressure

coolant or heavy cuttings. Periodically remove chips and dust.

Apply force to the movable parts only in the direction of

measurement. Do not apply force in the other direction.

■Operating environment

■Contacting part material

・Even though hardened stainless steel is used as the material of

the contacting part or stopper surface, they are oxidized and may

gather rust under certain conditions.

■Rubber for protective structure(boot, seal, O-ring)

・Rubbers for some products are intended for water-soluble cutting

oil (Alkaline). For oily, chlorine-base, coolants and other

chemicals, consult METROL for assistance.

・The rubber material for High-accuracy MT-Touch Switch is for

both oily and water-soluble coolants.

・Rubber might be hardened when the ambient temperature is low.

When the contact is depressed for a long period of time, it might

take longer time for the contact to return the original position.

■Installation

・Ensure that the threaded part of the switch is not bent during

installation.

・When using fixing screws, do not tighten the screws with

excessive force. That may distort the switch shape or restrict the

movement of the plunger. If the fixing screws are damaged, the

switch can be stuck and difficult to be detached.

・When the switch with a protective cover is

installed horizontally, an extra cover is

needed separately to prevent coolant or

cuttings from entering inside and getting

piled up on the switch.

・Do not subject cable or core wire cable to excessive pulling or

twisting of 30N or more. The bending raduis should be at least R7.

(except for heat resistance cable)

・Do not swing the switch by grabbing the wires or its attaching

portion when installing (especially when the wire is perpendicular

to the switch).

・When installing it with several cables, hold the switch to avoid the

cables from being pulled by weight.

GM-10-2ES-K001

Metal

cutting

■How to use

・Objects shall be aligned straight ahead for the metal bearing

plunger type. (The angle must be within ±3 degrees when high

precision is required such as when using a high precision switch,

or when judging existence detection or ON/OFF.)

・For slide, deflection angle, or offset contacts, select bearing or ball

contact or lever type.

・When the plunger is pushed straight by the detected object, do

not allow the object to abruptly slide away, as it will cause the

plunger to snap back. Note that this may cause failure of the

bearing and built-in switching part.

・Please also note that forcing the plunger in by your fingers and

letting go (snapping it back out) may also cause failure of the

internal contact point.

・Because offset distance (misalignment with axis of the plunger)

should be shorter than 5mm, the maximum diameter for detecting

surface is 10mm for the plunger type with plain bearing.

(Feed speed: 50 mm/min, push-in amount: 1 mm)

・In case the detected surface is angled or ragged, note that the

switch may fail to operate properly or cause malfunction.

・If the contacting part is worn away depending on conditions, the

signal point becomes different. When designing the detected

objects, give consideration to its angle, chamfer and roughness

so that the contacting part holds up longer. (Mainly for sliding

touch type)

・Normally-close (NC) type structure might cause chattering

depending on the roughness of workpiece surface and

environment used (i.e. vibration and contacting speed). In such

case, please select Normally-open (NO) type switch.

・Use it with the operating speed of 50 to 200 mm/m when

precision is required.

For the switches without stopper

・Do not excessively press the plunger to the stroke end. It may

cause malfunction due to impact.

If the switch does not feature a stopper surface, stop it before it

reaches the end of the stroke.

・If there is possibility to press the plunger to the stroke end, install

a separate stopper to prevent malfunction.

Within stroke

Stopper

Work

piece

Within stroke

Stopper

surface

Work

piece

■Electrical

・Use under the specified contact rating.

・I/F units with a built-in contact point protection circuit are effective for

adverse condition environments where overcurrent may flow. Such

environments may involve, regardless of the presence of contact

points, inductive loads with coils (such inductive loads mainly mean

relay coils, motors, solenoids, many of which require a current of 30mA

or more when driven and generate counter-electromotive force when

switched OFF).

・Since operating errors may occur due to induction when high-voltage

lines or power lines are wired within the same conduit or duct as

switch wires, wire them in separate ducts.

・When using the switch with LED, keep the current below 10mA.

・Chattering may occur when opening and closing the circuit with

dry contacts regardless of whether the switch has a snap action

mechanism. Take the first signal as a judgment signal.

Connecting to a load

・Do not attempt to drive an inductive load directly with these

switches. Direct driving can damage the switching parts and

semiconductors of the internal circuitry. In case of driving an

inductive load, connect a surge absorber in parallel with the load,

and connect an external load such as a relay or transistor allowing an

adequate flow of current for load driving.

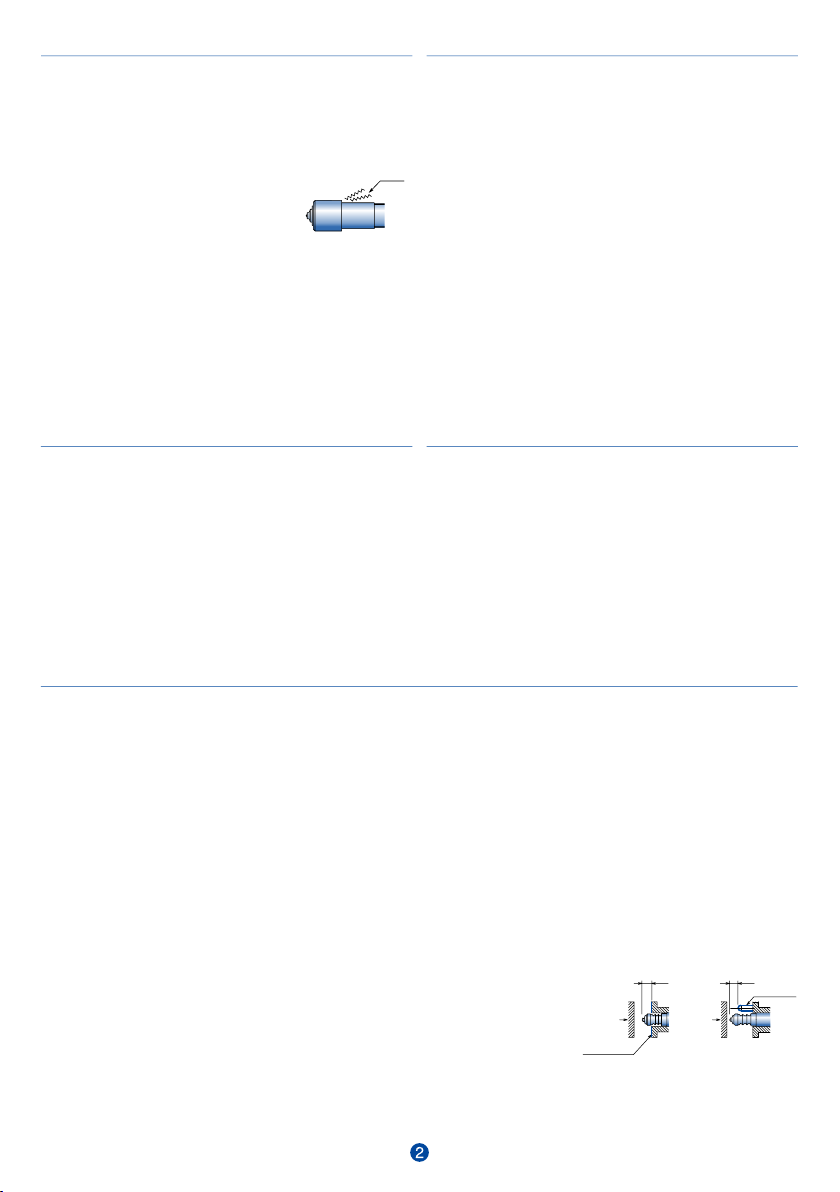

・Connect the switch in the manner shown in the diagram below.

・Limit the LED forward current to about 10mA by inserting a resistor.

・Resistance value = (power supply voltage - LED forward voltage) ÷

current = (24-2) ÷ 0.01 = 2KΩThe LED forward voltage is about 2V.

・The resistor may be installed on the DC 24V or 0V side.

・The LED glows when the circuit is closed. Switch operation is

normal.

・In case of using a sequencer, a resistor is not required if the outflow

current of the sequencer is about 7mA.

・Operation might not be properly confirmed using a digital test

(multi-meter)

Confirming operation by using resistance

・Set the tester to a resistance range of x 10, and connect the minus

lead of the tester to the switch output (brown), and connect the plus

lead of the tester to the switch 0V (blue).

・The deflection of the tester needle indicates around 0W when the

switch plunger is pushed in and roughly infinity (•) when switch tip is

returned.

Confirming operation by using voltage

・Set the tester to a voltage range of 50V and measure the voltage

between the switch output (white) and 0V (blue).

・For NPN output type, when the tip of the switch is pressed, the

indicator of the tester changes from 24V down close to 0V.

・For PNP output type, when the tip of the switch is pressed, the

indicator of the tester changes from 0V up close to 24V.

■Confirmation of switch operation

Current

24 V

power supply

■Wiring Precautions

・Do not pull or twist the cable with excessive force.

(Max.30N (3kgf)). The bending radius of the cable

should be R7 or larger.(except for heat resistance

cable)

・If you want to extend the cord on site, please make

the distance as short as possible as it will otherwise be susceptible to

the increase in the residual voltage and waveform distortion and

induction due to the influence of the line resistance and line-to-line

capacity. In addition, please use the cab tire cord with the

cross-sectional area of 0.2 mm²or more.

・As the wiring of the high-voltage line or power line with the switch will

cause malfunction by induction if it is done in the same pipe or duct,

please make sure that different routes are used.

・Cabtyre cables are used as robot cables without any safety

compromise since the working voltage and current are low, though

cabtyre cables are not applicable to UL, CSA, EN or other safety

standards.

・If waterproofing is required, please mold the terminal so that there will

be no exposed portion.

・Use wire braid or protective tube when using under harsh environment

such as where there are scattering of cutting chips.

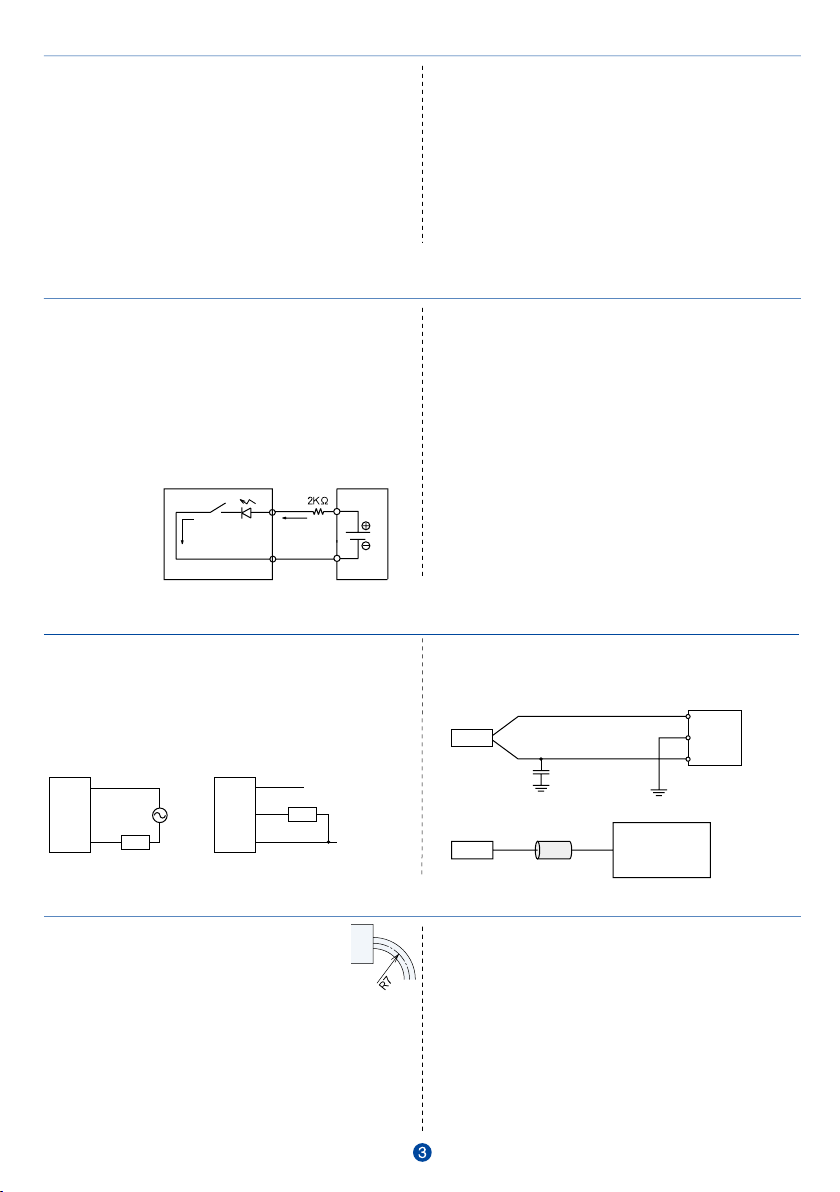

■Precautions for Switch Connection

NG

Always make sure to turn off the power before installing or

removing switches.

This is to prevent damage to the device caused by improper wiring

or short-circuits of output lines.

Application of an excessive voltage or application of an alternating

current power supply (AC 24 V or higher) to sensors using a direct

current power supply has the risk of damaging the switch.

GND

Either ground the switch with a switching power supply in close

proximity to the switch or ground through a capacitor (approx.

0.1~0.47 μF)for the purpose of lowering the impedance of the frame

in order to increase the resistance to entrance of induction noise by

servo drivers or similar devices.

Alternatively, attach a ferrite core to the switch cable.

(0.1〜0.47μF)

FG

0V

+V

Switch Switch

Switch

Switch

Brown

Black

Blue

Brown

Blue Load

Load

Voltage of +24 V

or higher (

×

)

Ferrite core

Level conversion

,etc.

・Use in the environment in where cuttings and dust don't prevent

switch movement.

・Choose protective cover option in case cutting may damage the

rubber boot.

・An extra cover is recommended to avoid direct hit by high-pressure

coolant or heavy cuttings. Periodically remove chips and dust.

Apply force to the movable parts only in the direction of

measurement. Do not apply force in the other direction.

■Operating environment

■Contacting part material

・Even though hardened stainless steel is used as the material of

the contacting part or stopper surface, they are oxidized and may

gather rust under certain conditions.

■Rubber for protective structure(boot, seal, O-ring)

・Rubbers for some products are intended for water-soluble cutting

oil (Alkaline). For oily, chlorine-base, coolants and other

chemicals, consult METROL for assistance.

・The rubber material for High-accuracy MT-Touch Switch is for

both oily and water-soluble coolants.

・Rubber might be hardened when the ambient temperature is low.

When the contact is depressed for a long period of time, it might

take longer time for the contact to return the original position.

■Installation

・Ensure that the threaded part of the switch is not bent during

installation.

・When using fixing screws, do not tighten the screws with

excessive force. That may distort the switch shape or restrict the

movement of the plunger. If the fixing screws are damaged, the

switch can be stuck and difficult to be detached.

・When the switch with a protective cover is

installed horizontally, an extra cover is

needed separately to prevent coolant or

cuttings from entering inside and getting

piled up on the switch.

・Do not subject cable or core wire cable to excessive pulling or

twisting of 30N or more. The bending raduis should be at least R7.

(except for heat resistance cable)

・Do not swing the switch by grabbing the wires or its attaching

portion when installing (especially when the wire is perpendicular

to the switch).

・When installing it with several cables, hold the switch to avoid the

cables from being pulled by weight.

GM-10-2ES-K001

Metal

cutting

■How to use

・Objects shall be aligned straight ahead for the metal bearing

plunger type. (The angle must be within ±3 degrees when high

precision is required such as when using a high precision switch,

or when judging existence detection or ON/OFF.)

・For slide, deflection angle, or offset contacts, select bearing or ball

contact or lever type.

・When the plunger is pushed straight by the detected object, do

not allow the object to abruptly slide away, as it will cause the

plunger to snap back. Note that this may cause failure of the

bearing and built-in switching part.

・Please also note that forcing the plunger in by your fingers and

letting go (snapping it back out) may also cause failure of the

internal contact point.

・Because offset distance (misalignment with axis of the plunger)

should be shorter than 5mm, the maximum diameter for detecting

surface is 10mm for the plunger type with plain bearing.

(Feed speed: 50 mm/min, push-in amount: 1 mm)

・In case the detected surface is angled or ragged, note that the

switch may fail to operate properly or cause malfunction.

・If the contacting part is worn away depending on conditions, the

signal point becomes different. When designing the detected

objects, give consideration to its angle, chamfer and roughness

so that the contacting part holds up longer. (Mainly for sliding

touch type)

・Normally-close (NC) type structure might cause chattering

depending on the roughness of workpiece surface and

environment used (i.e. vibration and contacting speed). In such

case, please select Normally-open (NO) type switch.

・Use it with the operating speed of 50 to 200 mm/m when

precision is required.

For the switches without stopper

・Do not excessively press the plunger to the stroke end. It may

cause malfunction due to impact.

If the switch does not feature a stopper surface, stop it before it

reaches the end of the stroke.

・If there is possibility to press the plunger to the stroke end, install

a separate stopper to prevent malfunction.

Within stroke

Stopper

Work

piece

Within stroke

Stopper

surface

Work

piece

■Electrical

・Use under the specified contact rating.

・I/F units with a built-in contact point protection circuit are effective for

adverse condition environments where overcurrent may flow. Such

environments may involve, regardless of the presence of contact

points, inductive loads with coils (such inductive loads mainly mean

relay coils, motors, solenoids, many of which require a current of 30mA

or more when driven and generate counter-electromotive force when

switched OFF).

・Since operating errors may occur due to induction when high-voltage

lines or power lines are wired within the same conduit or duct as

switch wires, wire them in separate ducts.

・When using the switch with LED, keep the current below 10mA.

・Chattering may occur when opening and closing the circuit with

dry contacts regardless of whether the switch has a snap action

mechanism. Take the first signal as a judgment signal.

Connecting to a load

・Do not attempt to drive an inductive load directly with these

switches. Direct driving can damage the switching parts and

semiconductors of the internal circuitry. In case of driving an

inductive load, connect a surge absorber in parallel with the load,

and connect an external load such as a relay or transistor allowing an

adequate flow of current for load driving.

・Connect the switch in the manner shown in the diagram below.

・Limit the LED forward current to about 10mA by inserting a resistor.

・Resistance value = (power supply voltage - LED forward voltage) ÷

current = (24-2) ÷ 0.01 = 2KΩThe LED forward voltage is about 2V.

・The resistor may be installed on the DC 24V or 0V side.

・The LED glows when the circuit is closed. Switch operation is

normal.

・In case of using a sequencer, a resistor is not required if the outflow

current of the sequencer is about 7mA.

・Operation might not be properly confirmed using a digital test

(multi-meter)

Confirming operation by using resistance

・Set the tester to a resistance range of x 10, and connect the minus

lead of the tester to the switch output (brown), and connect the plus

lead of the tester to the switch 0V (blue).

・The deflection of the tester needle indicates around 0W when the

switch plunger is pushed in and roughly infinity (•) when switch tip is

returned.

Confirming operation by using voltage

・Set the tester to a voltage range of 50V and measure the voltage

between the switch output (white) and 0V (blue).

・For NPN output type, when the tip of the switch is pressed, the

indicator of the tester changes from 24V down close to 0V.

・For PNP output type, when the tip of the switch is pressed, the

indicator of the tester changes from 0V up close to 24V.

■Confirmation of switch operation

Current

24 V

power supply

■Wiring Precautions

・Do not pull or twist the cable with excessive force.

(Max.30N (3kgf)). The bending radius of the cable

should be R7 or larger.(except for heat resistance

cable)

・If you want to extend the cord on site, please make

the distance as short as possible as it will otherwise be susceptible to

the increase in the residual voltage and waveform distortion and

induction due to the influence of the line resistance and line-to-line

capacity. In addition, please use the cab tire cord with the

cross-sectional area of 0.2 mm²or more.

・As the wiring of the high-voltage line or power line with the switch will

cause malfunction by induction if it is done in the same pipe or duct,

please make sure that different routes are used.

・Cabtyre cables are used as robot cables without any safety

compromise since the working voltage and current are low, though

cabtyre cables are not applicable to UL, CSA, EN or other safety

standards.

・If waterproofing is required, please mold the terminal so that there will

be no exposed portion.

・Use wire braid or protective tube when using under harsh environment

such as where there are scattering of cutting chips.

■Precautions for Switch Connection

NG

Always make sure to turn off the power before installing or

removing switches.

This is to prevent damage to the device caused by improper wiring

or short-circuits of output lines.

Application of an excessive voltage or application of an alternating

current power supply (AC 24 V or higher) to sensors using a direct

current power supply has the risk of damaging the switch.

GND

Either ground the switch with a switching power supply in close

proximity to the switch or ground through a capacitor (approx.

0.1~0.47 μF)for the purpose of lowering the impedance of the frame

in order to increase the resistance to entrance of induction noise by

servo drivers or similar devices.

Alternatively, attach a ferrite core to the switch cable.

(0.1〜0.47μF)

FG

0V

+V

Switch Switch

Switch

Switch

Brown

Black

Blue

Brown

Blue Load

Load

Voltage of +24 V

or higher (

×

)

Ferrite core

Level conversion

,etc.

GM-10-2EH-K001

Terms of Warranty

Before using, we would like to request that our customers have an understanding of warranty policy,

functions and specifications of applicable products as indicated in our catalogs, instruction manuals and

web site to ensure that they are used properly under specified conditions.

1) Applicable Products

The warranty defined below is applicable to products manufactured and sold by METROL (to be referred to as the

"applicable products").

2) Warranty Period

The warranty for applicable products is valid for one year

and three months from the original delivery date to the

location designated by the customer.

*Durability, life time and repeatability are described based

on our test conditions. Please note that the performance is

not guaranteed under your usage environment.

3) Range of Coverage

a. A replacement product will be provided on an exchange

basis or the malfunctioned product will be repaired free of

charge within the warranty period. If the product is or

becomes defective and that at the sole discretion of

METROL, the defects due to faulty materials or workman-

ship.

However, applicable products will not covered by the

warranty in the case of the following malfunctions even

within the warranty period.

( I ) Malfunctions occurred due to use of a product in a

manner that deviates from standards, specifications,

environments, usage procedures or usage precautions

described in the catalog, instruction manual or

specifications.

( II ) Malfunctions having occurred for reasons other than

those attributable to the delivered product.

( III ) Malfunctions having occurred due to disassembly,

modifications or repairs made by someone else other

than the Metrol representative.

(IV) Malfunctions or damage that results from external

causes outside our control which shall include

accident fire disaster, other natural disaster or other

force majeure.

b. The range of coverage is limited to warranty of the

applicable product only, and any other secondary loss or

damage resulting from the malfunction of an applicable

product is not covered by the warranty.

c. Please be aware that we don't offer installation,

de-installation on-site confirmation and repairs.

4)Applications

Applicable products are designed and manufactured as

general-purpose products used in ordinary industrial

environments.

In the case of incorporating an applicable product in an

apparatus, machine or system, please confirm the suitability of

the application along with any related standards, regulations

and restrictions.

With respect to the applications indicated below in particular,

customers are requested to conduct necessary tests on an

actual product in advance regarding usage conditions and

other details.

a. Applications for which usage conditions or environment are

outside those presumed by the manufacturer or applications

unable to be confirmed as being appropriate by the

manufacturer when using applicable products.

b. Applications likely to have an effect on human life or property

(such as nuclear power equipment, transportation machinery

or medical devices), applications used in public utilities (such

as electricity, gas or water lines), or applications applying

correspondingly thereto.

c. Applications in harsh environments (special environments

requiring heat resistance, vacuum and the like)

5) Attention

・The contents of this catalog, including specific models and,

specifications, and any other contents, are subject to change

without notice at METROL’s sole discretion.

・Durability, life time and repeatability are described based on

our test conditions. Please note that the performance is not

guaranteed under your usage environment.

・Second characteristic number of the protective structure (IP)

represents the waterproofness against water. This

waterproofness may not apply to the coolant.

Help desk

www.metrol.co.jp/en

+81-42-528-1442

+81-50-5558-7366

We accept inquiry regarding sensor selection, exclusive

specification, and technical matter through website, Fax,

and Tel listed below.

E-mail

METROL CO., LTD.

1-100 Takamatsu-cho Tachikawa, Tokyo 190-0011 JAPAN

Tel: +81 50 5558 7366 / Fax: +81 42 528 1442

Website: www.metrol.co.jp/en

TOKYO JAPAN

The specifications and descriptions are subjected to change without notice due to improvements in products.

4

This manual suits for next models

8