Michigan Instruments ME60 User manual

EXCAVADORA

PREFACE

This operation manual systematically covers the correct operation and use, the methods for

overhaul and maintenance of this machine, and detailed notices.

Before operate this machine, make sure carefully read and fully understand this manual.

This manual should be attached with the machine for timely reference in case of any problem. Also,

review this manual in periodical manner.

Please refer to the operation manual of engine in terms of the engine.

In case of damage or loss of this manual, please contact our company or the designated dealer of

our company for subscription.

Make sure hand this manual over to the new owner in case of transfer of this machine.

The illustrations in this manual are just for obvious and clear instructions to the problems, instead of

implicating all contents of the text.

Our company reserved all rights for machine modifications. Please understand that the contents of

this manual may differ from the specifications of your machine due to machine improvements.

Please contact our company or the service dealer periodically to obtain latest data.

This is the first issued version. We will appreciate corrections and editing suggestions from experts

or readers may point out and correct our editing errors.

All rights reserved, unauthorized duplication and publish are a violation of applicable laws.

SPECIAL STATEMENT OF EXCAVATOR FUEL SYSTEM

OPERATION AND MAINTENANCE

Please read this manual carefully in order to maximize the benefits.

Fuel quality is an important factor for excellent performance quality, extension of service life and

efficient emission.

Diesel supplies the energy that is required by the diesel engine and supplies the cooling and

lubrication for the precision components in fuel system. Most of the diesel in the market can meet

the requirement of diesel engine. It must, however, meet the performance

requirements such as viscosity, cetane number, sulfur content, cloud point, water and sediment

content. Among them, viscosity, cetane number and cloud point in general will not change in case

that suitable diesel is well chosen. However, water and sediment will exceed the prescribed content

requirements (below 0.05 volume percentage) because of transport, storage and improper

maintenance, which increases the wear of fuel system of diesel engine and results in the engine

failure such as the difficulty in starting, decrease in power and black smoke.

Therefore, the users and operators need to do the following:

Select the diesel that meets the requirements. Do not use the low-grade diesel;

Take the appropriate measure during the transportation, storage and filling of diesel to reduce

the mixture of water and impurities;

Do the maintenance such as drainage, filter changing strictly in accordance with the

maintenance cycle stipulated by the provisions in 'operation maintenance manual'. If necessary,

please shorten drainage and the replacement cycle appropriately according to the working

environment.

ME60

OPERATION AND MAINTENANCE MANUAL

Our company reserves the right to continually improve our products in order to make the best

products as possible for the market. These improvements may be ready for implementation.

However, for the products sold, we do not change the material. Please contact the distributors

regularly for the latest material of the models that you are going to buy.

These materials may include accessories and optional parts with which your models may not be

attached. If you need these accessories, please contact the distribution agency of our company.

The illustrations in this manual are just for obvious and clear instructions to related parts of the

machine and may be different from the actual parts.

CONTENTS

Chapter I Introduction ................................................................................................................... 1

Literature Information................................ ................................ ................................ ................................ ..... 1-1

Manual Structure................................ ................................ ................................ ................................ .............. 1-1

Certied Engine Maintenance................................ ................................ ................................ ......................... 1-2

Design Performance of Machine................................ ................................ ................................ ..................... 1-2

Use of the Turbocharged Engine................................ ................................ ................................ ...................... 1-2

Product Information................................ ................................ ................................ ................................ ......... 1-3

Instruction of the Product Model................................ ................................ ................................ ............. 1-3

Machine Nameplate................................ ................................ ................................ ................................ .1-3

Memo:................................ ................................ ................................ ................................ ...................... 1-4

Chapter Safety............................................................................................................................ 2

Learn about Safety Information................................ ................................ ................................ ........................ 2-1

Comprehend Signal Terms................................ ................................ ................................ ................................ 2-1

Safety Mark and Label................................ ................................ ................................ ................................ ...... 2-2

Abide by Safety Instruction................................ ................................ ................................ ............................ 2-13

Compressed Air and Compressed Water................................ ................................ ................................ ......... 2-13

Preparation for Emergency................................ ................................ ................................ ............................. 2-14

Wear Protective Clothing................................ ................................ ................................ ................................ 2-14

Noise Prevention................................ ................................ ................................ ................................ ............. 2-15

Check Machine................................ ................................ ................................ ................................ ............... 2-15

General Advance Cautions for Cabin................................ ................................ ................................ ............. 2-16

Safety Device................................ ................................ ................................ ................................ .................. 2-16

Keep Machine Clean................................ ................................ ................................ ................................ ....... 2-17

Use Handrail and Ladder................................ ................................ ................................ ................................ 2-17

Regulate the Operator's Seat................................ ................................ ................................ ........................... 2-18

Fasten Seat Belt................................ ................................ ................................ ................................ .............. 2-18

Ensure Favorable Sight................................ ................................ ................................ ................................ ... 2-19

Move and Operate Machine Safely................................ ................................ ................................ ................ 2-19

Operation is Only Performed on the Operator's Seat................................ ................................ ...................... 2-20

Engine Starting with Jump Start Cable................................ ................................ ................................ ........... 2-20

The Passenger Shall Leave Machine................................ ................................ ................................ .............. 2-21

Signal Shall be Specied When Multiple Machines Operate Simultaneously................................ ............... 2-21

Conrm Travel Direction of the Driven Machine ................................ ................................ .......................... 2-21

Drive Machine Safely ................................ ................................ ................................ ................................ ..... 2-22

Avoid Being Injured Due to Roll -over Accident of Machine................................ ................................ ......... 2-23

Avoid Being Injured Due to Reverse and Swing Accident................................ ................................ ............. 2-24

Avoid Roll -over................................ ................................ ................................ ................................ .............. 2-25

Avoid Wire ................................ ................................ ................................ ................................ ...................... 2-26

Lifting Objects ................................ ................................ ................................ ................................ ................ 2-26

Preventthe Ejected Scrap................................ ................................ ................................ ............................... 2-27

Park the Machine Safely................................ ................................ ................................ ................................ .2-27

Handle Liquid Safely - Avoid Fire ................................ ................................ ................................ .................. 2-28

Safe Transportation................................ ................................ ................................ ................................ ......... 2-29

Implement Safety Maintenance................................ ................................ ................................ ...................... 2-30

No Operation Tag................................ ................................ ................................ ................................ ............ 2-31

Support Machine Correctly................................ ................................ ................................ ............................. 2-31

Keep Distance with Rotating Component................................ ................................ ................................ ....... 2-32

Prevent Part Being Ejected................................ ................................ ................................ ............................. 2-32

Store Machine Accessories Safely................................ ................................ ................................ .................. 2-32

Tools Shall be Used Properly................................ ................................ ................................ .......................... 2-33

Avoid Burn................................ ................................ ................................ ................................ ...................... 2-33

Hot InjectedFluid................................ ................................ ................................ ................................ .. 2-33

Hot L iquid andSurface................................ ................................ ................................ .......................... 2-33

Replace the Rubber Hose Regularly ................................ ................................ ................................ ............... 2-34

Avoid High Pressure Liquid ................................ ................................ ................................ ........................... 2-34

Prevent Fire................................ ................................ ................................ ................................ ..................... 2-35

Check Oil Leakage ................................ ................................ ................................ ................................ 2-35

Check Short Circuit ................................ ................................ ................................ ............................... 2-35

Remove Inammable Material................................ ................................ ................................ .............. 2-35

Check the Key Switch ................................ ................................ ................................ ........................... 2-35

Leave Machine When Fire Happens................................ ................................ ................................ ............... 2-36

Be Aware of the Discharged Fume................................ ................................ ................................ ................. 2-36

Advance Cautions for Welding and Polishing................................ ................................ ................................ 2-37

Avoid Heating Near Pressured Liquid Pipe................................ ................................ ................................ .... 2-37

Prevent the Pipe Containing Inammable Fluid Being Heated................................ ................................ ...... 2-38

The Paint Shall be Removed before Welding or Heating................................ ................................ ............... 2-38

Prevent Battery Explosion................................ ................................ ................................ .............................. 2-39

Maintain the Air-conditioning System Safely................................ ................................ ................................ .2-39

Handle Chemicals Safely................................ ................................ ................................ ................................ 2-40

Dispose Refuse Correctly ................................ ................................ ................................ ............................... 2-40

Prevention for Danger of Asbestos Dust................................ ................................ ................................ ......... 2-41

Before the Machine is Returned to the User................................ ................................ ................................ ... 2-41

Chapter III Product Information .................................................................................................. 3

ProductFeatures ................................ ................................ ................................ ................................ ............... 3-1

Main Uses andScope ofApplication................................ ................................ ................................ ................ 3-2

MachineProle ................................ ................................ ................................ ................................ ................ 3-3

Specications................................ ................................ ................................ ................................ .................... 3-4

Working Range................................ ................................ ................................ ................................ ................ 3-6

PerformanceParameters................................ ................................ ................................ ................................ .. 3-8

Chapter Product Operation ...................................................................................................... 4

Before Engine Started...................................................................................................................................... 4-1

Check Around the Machine................................ ..................................................................................... 4-1

Seat Adjustment and Check of Seat Belt................................................................................................ .4-1

Start of the Engine........................................................................................................................................... 4-2

Starting theEngine ................................................................................................................................ ..4-2

Normal Start............................................................................................................................................. 4-4

Low-temperatureStart................................ ............................................................................................. 4-4

Engine Start with Jump Start Cable......................................................................................................... 4-4

After Engine Start............................................................................................................................................ 4-6

Excavator Operation........................................................................................................................................ 4-7

Direction.................................................................................................................................................. 4-7

Operator Controls............................................................................................................................................ 4-7

Trial Run of New Machine ................................ ............................................................................................ 4-12

Engine Operation...........................................................................................................................................4-12

Driving Machine............................................................................................................................................ 4-13

Parking Machine............................................................................................................................................ 4-15

Long-term Storage......................................................................................................................................... 4-15

Operate Machine............................................................................................................................................ 4-16

Use of the Air-conditioner................................ ............................................................................................. 4-27

Air-conditioner Control Panel................................ ............................................................................... 4-27

Description of Key Functions................................ ................................................................................ 4-27

Operating Procedures and Precautions for Air Conditioner ..................................................................4-28

Main Failure Causes of the Air-Conditioner and Measures...................................................................4-28

Use of the Radio ............................................................................................................................................4-33

Radio Control Panel...............................................................................................................................4-33

Radio Tuning.........................................................................................................................................4-33

Automatic Protection Function..............................................................................................................4-33

Chapter VProduct Maintenance.................................................................................................. 5

Maintenance Guide...........................................................................................................................................5-1

Hour Meter Reading.........................................................................................................................................5-1

Authenticated Worn Parts ..............................................................................................................5-1

Authenticated Lubrication Oil .......................................................................................................5-1

Windshield Cleaning Liquid.............................................................................................................................5-1

Clean Engine Oil & Lubrication Oil

.................................................................................................................5-1

Check the Discharged Oil and Used Filter Element .........................................................................................5-1

Fuel Outer Element...........................................................................................................................................5-1

Welding Instruction...........................................................................................................................................5-1

Prevent Anything Falling into the Machine......................................................................................................5-2

Dusty Working Place ........................................................................................................................................5-2

Avoid Using Different Lubrication Oil Simultaneously...................................................................................5-2

Lock Inspection Cover......................................................................................................................................5-2

Hydraulic System-Air Discharge......................................................................................................................5-2

Installation of Hydraulic Hose..........................................................................................................................5-2

CheckAfter Inspection and Maintenance.........................................................................................................5-3

Select the Fuel and Lubrication Oil Matching the Ambient Temperature ........................................................5-3

Technical Specification of Tightening Torque..................................................................................................5-4

Technical Specification of Oil ..........................................................................................................................5-6

Technical Maintenance Outline ........................................................................................................................5-7

Routine Maintenance...............................................................................................................................5-7

Every 50 Hours........................................................................................................................................5-7

Every 250 Hours......................................................................................................................................5-7

Every 500 Hours......................................................................................................................................5-7

Every 1,000 Hours...................................................................................................................................5-8

Every 2,000 Hours...................................................................................................................................5-8

Every 4,000 Hours...................................................................................................................................5-8

Every 12,000 Hours.................................................................................................................................5-8

................................

................................

Technical Maintenance Operation................................ ................................ ................................ .................. 5-10

Boom andA rm L inkage - L ubrication................................ ................................ ................................ ... 5-10

Bucket Linkage - Check/Adjustment................................ ................................ ................................ ..... 5-12

Bucket Linkage - Lubrication................................ ................................ ................................ ................ 5-13

Bucket Tooth - Check/Replacement................................ ................................ ................................ ...... 5-13

Side Cutter - R eplacement................................ ................................ ................................ ..................... 5-14

Track - Regulation................................ ................................ ................................ ................................ .5-15

Final Drive Oil Level - Check ................................ ................................ ................................ ............... 5-17

Swing Gear - Lubrication ................................ ................................ ................................ ...................... 5-18

Tenseness, Crack, Wearing andTearing of Engine Fan Belt - Check ................................ .................... 5-18

Oil-Water Separator- Check................................ ................................ ................................ .................. 5-19

Fuse Link - Replacement................................ ................................ ................................ ....................... 5-20

Storage Battery- Check ................................ ................................ ................................ ......................... 5-22

Terminal Post of Storage Battery- Cleaning................................ ................................ ......................... 5-22

Swing Driving Oil L evel - Check................................ ................................ ................................ .......... 5-23

Cooling System L ongL ife Coolant- R eplacement................................ ................................ ............... 5-24

Condenser- Cleaning................................ ................................ ................................ ............................. 5-26

Cooling SystemHose - Check................................ ................................ ................................ ............... 5-27

EngineAir Filter OuterE lementC leaning/R eplacement.................................. ............................... ...... 5-28

Engine Oil L evel - C heck ................................ ................................ ................................ ...................... 5-31

Hydraulic Oil of the Hydraulic System- Replacement................................ ................................ .......... 5-31

Safety Components- Regular Replacement................................ ................................ .......................... 5-31

Use of Hoses within Time Limit - Check (European ISO 8331 and EN982 CEN Standard) ................ 5-31

Check Around theMachine................................ ................................ ................................ ................... 5-31

Wearing Parts................................ ................................ ................................ ................................ .................. 5-10

Main Parts................................ ................................ ................................ ................................ ....................... 5-10

Memo:................................ ................................ ................................ ................................ ............................. 5-32

Chapter Option Parts ................................................................................................................ 6

Hydraulic B reaker................................ ................................ ................................ ................................ ............ 6-1

Wrong Use Method................................ ................................ ................................ ................................ .......... 6-1

Position of Filling LubricatingGrease intoHydraulic Breaker................................ ................................ ....... 6-1

Appendix Operating Manual for Electronic Monitoring Meter

Proposal on Operation & Maintenance Manual Amendment

Chapter ⅠIntroduction

Introduction

1-1

Literature Information

The Operation & Maintenance Manual shall be

placed in the file folder or the document bag at

the back of seat in the cab.

The contents about improvement and

development may not be included in this Manual.

The pictures in the Manual or some structure in

the Figure or accessories may be different from

those of your machine.

Please read and comprehend the contents of this

Manual thoroughly and keep it with the machine.

When you have problems about the machine or

this Manual, please consult domestic

agent for the latest data.

Once you have problems, opinions or find some

error about the contents of this Manual, please

contact our company via the "Proposal on

Operation & Maintenance Manual Amendment"

at the end of the Manual. (Note: The copied can

be used.)

Manual Structure

This Manual consists of seven chapters:

Introduction, Safety, Product Information,

Product Operation, Product Maintenance, Option

parts, andAppendix.

The information contained in the chapter

"Safety" includes: The basic safety

prevention measures; position and contents

of warning label on the machine.

The information contained in the chapter

"Product Information" includes: Some

related data description of product.

The information contained in the chapter

"Product Operation" includes: Information of

instrument, switches, operating mechanism

of machine, operating mechanism of work

equipments, transportation and towing.

The information contained in the chapter

"Product Maintenance" includes: The

maintenance period for various parts of

machine. The maintenance items listed in the

maintenance period table shall be performed

within the stipulated maintenance period.

The items without stipulated period are listed

in column of "Maintenance on demand".

The information contained in the chapter

"Option Parts" includes:

Some relevant information of option parts as

well as related instruction.

The information contained in the chapter

"Appendix" includes:

Related profile and operation instruction of

MCSS electronic control system.

Introduction

1-2

Design Performance of Machine

If the increased accessory or the weight after change

exceeds the design performance of machine, it'll have

adverse impact on the machine performance,

including machine stability and system guaranteed

performance such as braking, turning and roll-over

protection architecture. For detailed data.

Certified Engine Maintenance

The proper maintenance and repair is significant for

normal operation of engine and machine. As the user

of heavy-duty non-road diesel engine, the

maintenance stipulated by the Manual shall be

performed.

The staff without approval can't do

the following work: repair, maintenance, sale,

rent or sell any disassembled and changed device

related with emission or system engine or

machine.

Some system of machine and engine such as

exhaust system, fuel system, electric system, inlet

system and cooling system is related with

emission, and the system can't be modified

without approval.

Introduction

1-3

Use of the Turbocharged Engine

Turbocharger is a device by use of exhaust of engine

to drive the turbine working. As the turbine often in

the state of high-speed and high temperature, the

temperature of turbine side is generally above 600℃.

Therefore, in order to ensure the normal operation,

proper use and daily maintain is very important. The

major methods for daily maintenance are as following:

1) At the beginning of engine started, do not step on

the accelerator pedal immediately but let the

engine run idle for about 3mins, to increase oil

temperature and its flowing property, in order to

make the turbocharger get adequate lubrication,

and then to increase engine speed. This is

particularly important in the winter.

2) After running in high-speed for long time, do not

stop the engine immediately. The reason was that

after the engine starts to work, one part of engine

oil is going to lubricate and cool for rotor bearing

of turbocharger. If the high-speed running engine

suddenly shuts down, it will cause the oil

pressure rapidly drop to zero and interrupt the

lubrication. Thus the heat inside the turbocharger

can not be taken away, but to be transferred to the

bearing housing, which would made the shaft

"bite" its sleeve and damage the bearing and

shaft at the time that the rotor is still rolling by

inertia. In addition, when the engine abrupt

stopped, with the high temperature of the exhaust

manifold, the heat will be absorbed onto the

housing of turbocharger, and turn the engine oil

remained in the inside of turbocharger into

carbon. And it will block the oil inlet port as the

carbon increasing, and lead to the sleeve lack oil,

rapid the abrasion between shaft and its sleeve.

Therefore, before the engine stopped, let the

engine run idle for about 3mins, to slow down

the speed of turbocharger rotor, and make the

internal heat fully discharged in order to

decreased the temperature.

3) Pay much attention to engine oil selection. As the

effects of the turbocharger, the quality and the

volume of the air which entering into the

combustion chamber are greatly improved, and

have a higher compression ratio, so that the

structure of the engine can be more compact and

reasonable, thus to improve its work efficiency.

Therefore, the turbocharged engine has features

of high temperature, high speed, big power, big

torque, and low-emission. And the components

of turbocharged engine can be withstand higher

temperature and greater impact, extrusion and

other harsh conditions. Consequently, the engine

oil for which wear resistance, high temperature,

high film strength and high stability should be

used.

4) Engine oil and oil filter must be kept clean to

prevent debris from entering, because the fit

clearance between the turbocharger shaft and its

sleeve are very small, if the oil lubricating ability

is lower, which will damage the turbocharger

prematurely.

5) The air filter should be cleaned on schedule, in

order to prevent impurities, such as dust, from

entering the high-speed compressor, and resulting

in instability of rotational speed or increasing the

abrasion between the sleeve and seals.

6) Check the tightness of seal ring of the

turbocharger frequently. If the tightness of seal

ring is lower, the exhaust will enter into the

lubrication system through the clearance, pollute

the oil and increase the crankcase pressure. In

addition, when the engine work with low speed,

the engine oil also discharge from exhaust

manifold through seal ring or enter into the

Introduction

1-4

combustion chamber burning, resulting in

excessive oil consumption or the phenomenon of

"burning engine oil" .

7) Check the turbocharger frequently for abnormal

sound or abnormal vibration, as well as the oil

pipe and fittings for leaks.

8) With high precision of rotor bearing, it is very

strict with the maintenance and installation of the

turbocharger. So come to the designated repair

station for the professional service when the

turbocharger is failure or damage.

Refer to it when the machine installs the

turbocharged engine.

Note

Introduction

1-5

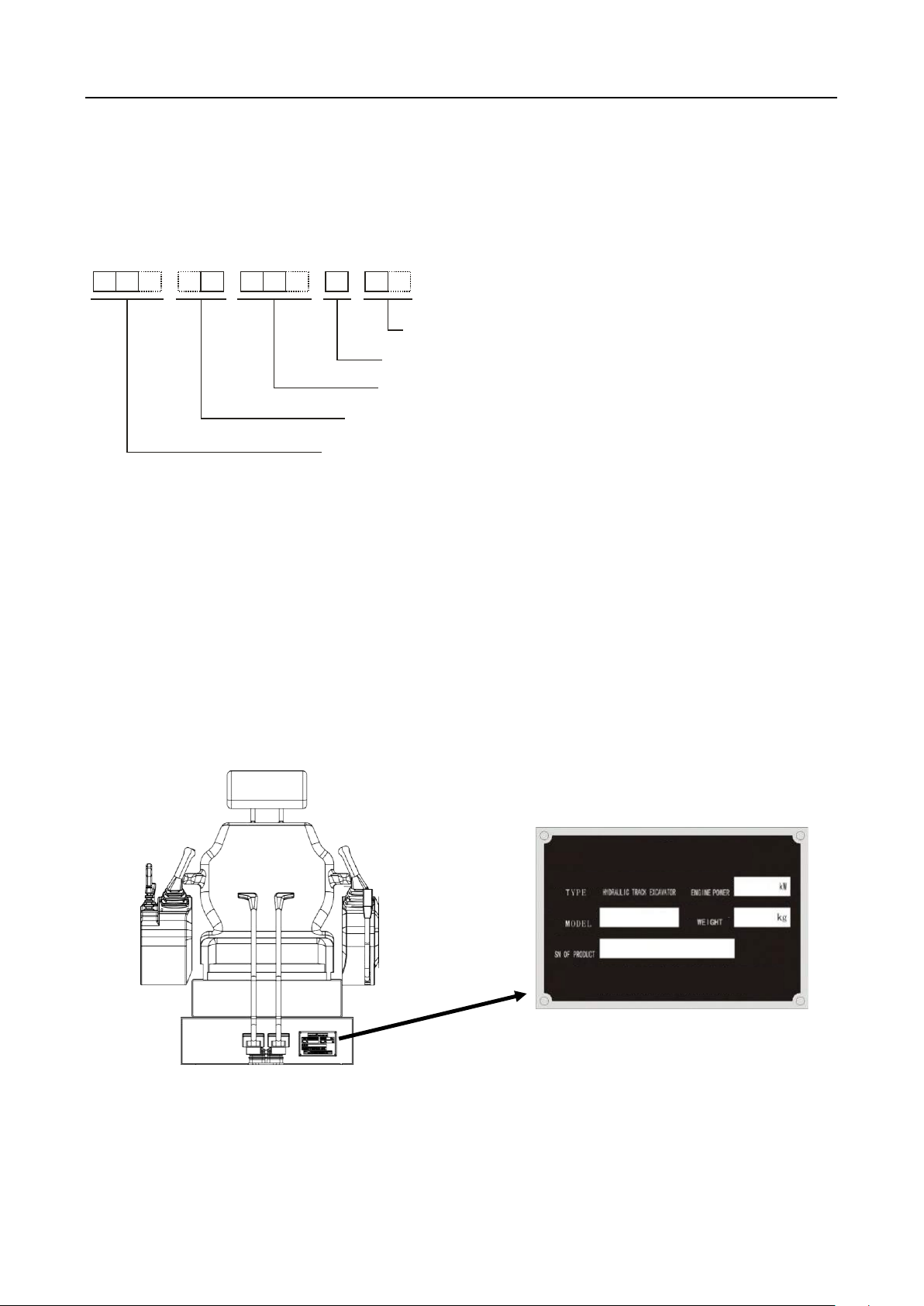

Product Information

Instruction of the product model

Product model consists machine body

(accessories) product code, principal parameters,

characteristic code and improved code.

Machine nameplate

The machine nameplate is situated at the bottom right

of driver's seat.

characteristic code

principal parameters

code

product code (machine body, accessories)

improved code (updat ed code)

Introduction

1-6

Your Machine Information Table

To make you know the basic information of our

products conveniently and promptly, you can fill

relevant information in the table below after you

purchased our products, in order to refer and affirm.

If you have any question, please call our

customer service hot line number.

Machine model

Product identification number(PIN)

Engine serial number

Agent name

Address

Maintenance staff

Tel/Fax

Service hot line number 400-100-6666

Note

Chapter ⅡSafety

Please read and comprehend the cautions stated by the safety labels

in this Manual and on the machine, when the machine is operated or

repaired, these cautions must be abode by.

Safety

2-1

Learn about Safety Information

This is the sign to note safety.

When you see this sign, you shall be aware

of the danger of staff injury.

Please abide by the proposed cautions and

safe operation method.

Comprehend Signal Terms

On the safety label of machine, the terms

indicating the extent or degree of injury such as

DANGER, WARNING or CAUTION will be

used with the sign of noting safety together.

"DANGER" indicates the condition of direct

danger. If this condition happens, death or

severe injury will be caused.

"WARNING" indicates the condition of

hidden danger. If this condition happens,

casualty will be caused.

"DANGER" or "WARNING" safety label is

set near specific hazard position. Refer to

"Caution" safety label for general safety

measures.

"CAUTION" indicates the condition of

potential hazard. If this condition happens,

minor or moderate injury will be caused.

"CAUTION" also has the meaning of noting

safety information in this Manual.

In order to separate machine protection from staff

safety, this Manual adopts the term

"IMPORTANT", if some dangerous state occurs,

machine will be damaged.

"Note" indicates adding some explanation to

certain part in relevant information.

Safety

2-2

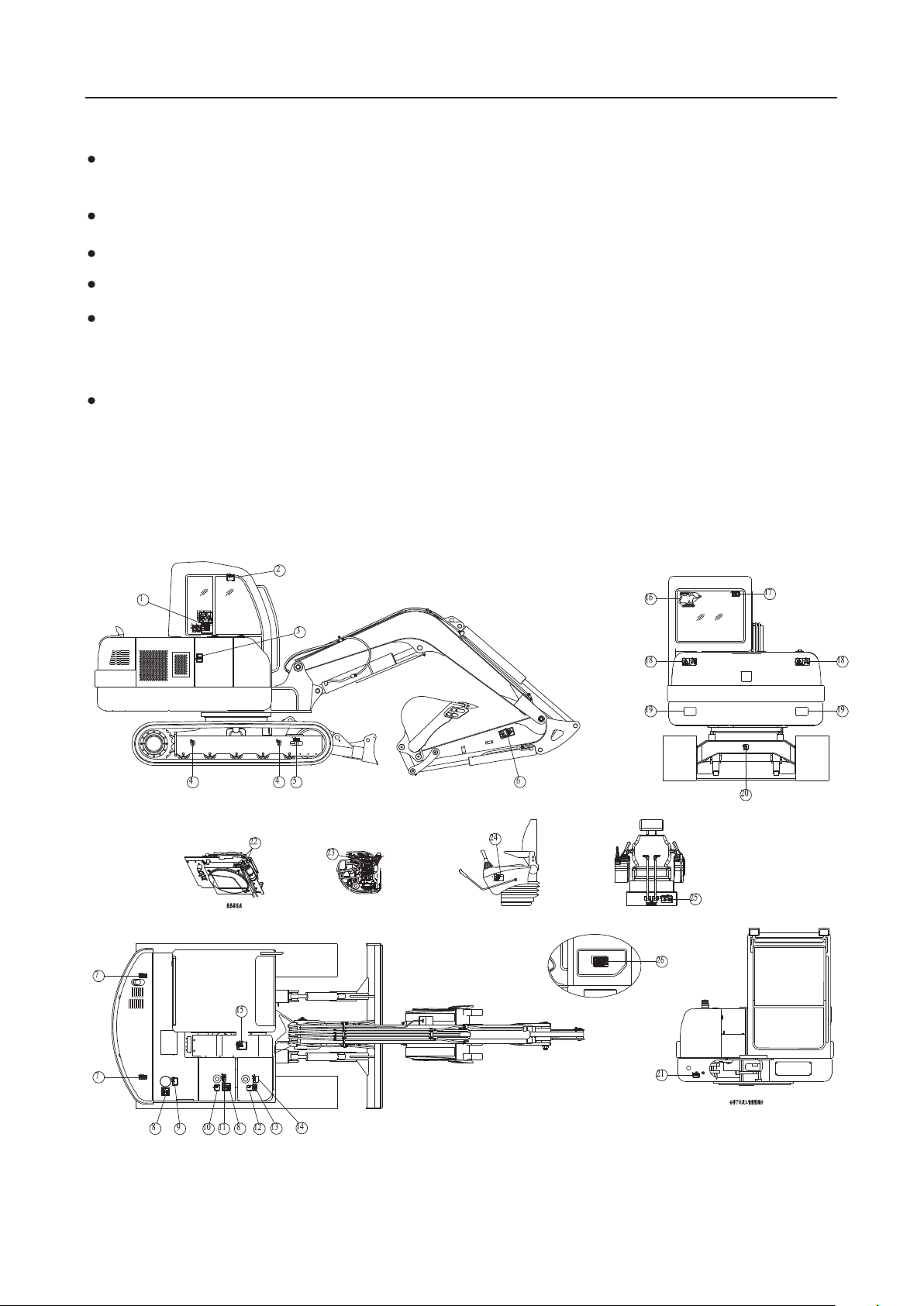

Safety Mark and Label

There are several special safety marks on the machine. This chapter will indicates their positions and describe

the accident hazard. Please be familiar with these safety marks.

Ensure you can distinguish all safety marks.

If the text of safety mark isn't clear, please clean or replace the mark.

If the safety mark is damaged, lost or the illustration isn't clear, the mark must be replaced.

Please clean the safety mark with wiping cloth, water and soap. The solvent, petrol or strong chemical agent

is forbidden for cleaning of safety mark. The adhesion of mark will be invalid due to solvent, petrol or strong

chemical agent, thereby falling.

If the replaced component has safety mark, ensure the new one also has safety mark.

液�油油位

�工(上海)挖掘机制造有限公司

Safety

2-3

○

1Stick on the right window of cabin

Precautions for safe operation

Be aware of electric shock and reference book

Warning for broken or movable window

○

2 Warning for use of front widow

WARNING

Be careful when opening or closing the

front window of the cab. Lock it with

the lock pin to avoid injury; and make

sure that the lock handle is in the

“LOCK” position in order to prevent

the machine from suddenly starting

when the lock handle is accidentally

operated.

Table of contents