Equipter RB4000 User manual

RB4000 SERVICE MANUAL

i

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of New Heights, LLC.

The information in this manual is provided to promote the safe use of, and assist the operator in achieving

the best performance from Equipter products described herein, for their intended applications.

DISCLAIMER

Copyright 2019 by New Heights, LLC

Covered by Patent Number 6817677

ii

(1) Air Filter

(1) Spark Plug

(1) Engine Oil

(1) Long Neck Funnel for Engine Oil

(1) Hydraulic Oil Filter

(1) Grease Tube

(1) 12mm Wrench

(1) Pair of Gloves

EQUIPTER SERVICE KIT PART LIST

Recommended Service Schedule .................................................................................................................................... 1

Replacement Parts................................................................................................................................................................. 1

Maintenance Precautions.................................................................................................................................................... 1

Replace Air Filter.................................................................................................................................................................... 2

Replace Spark Plug............................................................................................................................................................... 2

Replace Engine Oil. ............................................................................................................................................................... 3

Replace Hydraulic Oil Filter................................................................................................................................................ 3

Inspect Trailer Brakes........................................................................................................................................................... 3

Inspect Parking Brake. ......................................................................................................................................................... 4

Inspect Breakaway System................................................................................................................................................. 4

Inspect Hydraulic Hoses...................................................................................................................................................... 4

Tires. ............................................................................................................................................................................................ 4

Lubricate Fittings............................................................................................................................................................... 5-6

Slide Rails............................................................................................................................................................................ 5

Wheel Lock Pin.................................................................................................................................................................. 5

Wheel Lock Handle.......................................................................................................................................................... 6

Front Axle Hub................................................................................................................................................................... 6

Axle Engagement System.............................................................................................................................................. 6

Index A: Service Providers...................................................................................................................................................7

Index B: Service Checklist.................................................................................................................................................. 8

Index C: Service Schedule...........................................................................................................................................9-10

TABLE OF CONTENTS

For more than 15 years, our team has manufactured Equipter products using top-quality processes

and components. To protect your investment and ensure a long service life, it’s essential to perform

regular maintenance.

If you encounter wear beyond what’s outlined in this manual, see Index A to have your RB4000

serviced at a qualified shop.

See Index A of this booklet or contact your local service provider to purchase a service kit for your

RB4000.

1

Recommended Service Schedule

We recommend doing the first preventative maintenance at about 30 service hours. Following this service,

select maintenance tasks should be performed monthly, every six months, and so forth. Please refer

to Index B: Service Checklist for a comprehensive list of preventative maintenance tasks and when to

complete them.

Replacement Parts

Use only manufacturer-recommended replacement parts. Other parts may be substandard in fit and

quality.

For additional replacement parts, contact the service provider (Index A).

Maintenance Precautions

Always take proper safety precautions while servicing this equipment. For complete RB4000 safety

and operation guidelines, refer to the Operator’s Manual. If you do not have a manual, contact the

manufacturer’s recommended service provider.

Always perform maintenance when the vehicle is level.

Never do any maintenance or adjustments while the equipment is operating. Turn off the engine when

performing maintenance to prevent accidental movement.

Never perform maintenance on this machine unless the dump box is completely in the transport position

(fully retracted and lowered). To perform maintenance under the dump box, the box can be tilted in the

dump position. It must be secured with the support arm in place. Never perform maintenance with the

dump box in the lifted position.

Make sure all operating and residual pressures are relieved before working on a hydraulic system.

Shut engine off and operate all the controls to relieve any pressure.

Replace all safety shields and guards when finished performing maintenance. Do not operate the

equipment with protective equipment removed.

2

1. Unscrew the wing knob.

2. Remove the air filter cover.

3. Remove the wing nut.

4. Lift the old air filter away and replace

with the new filter.

5. Replace the wing nut.

6. Replace the air filter cover.

7. Replace the wing knob.

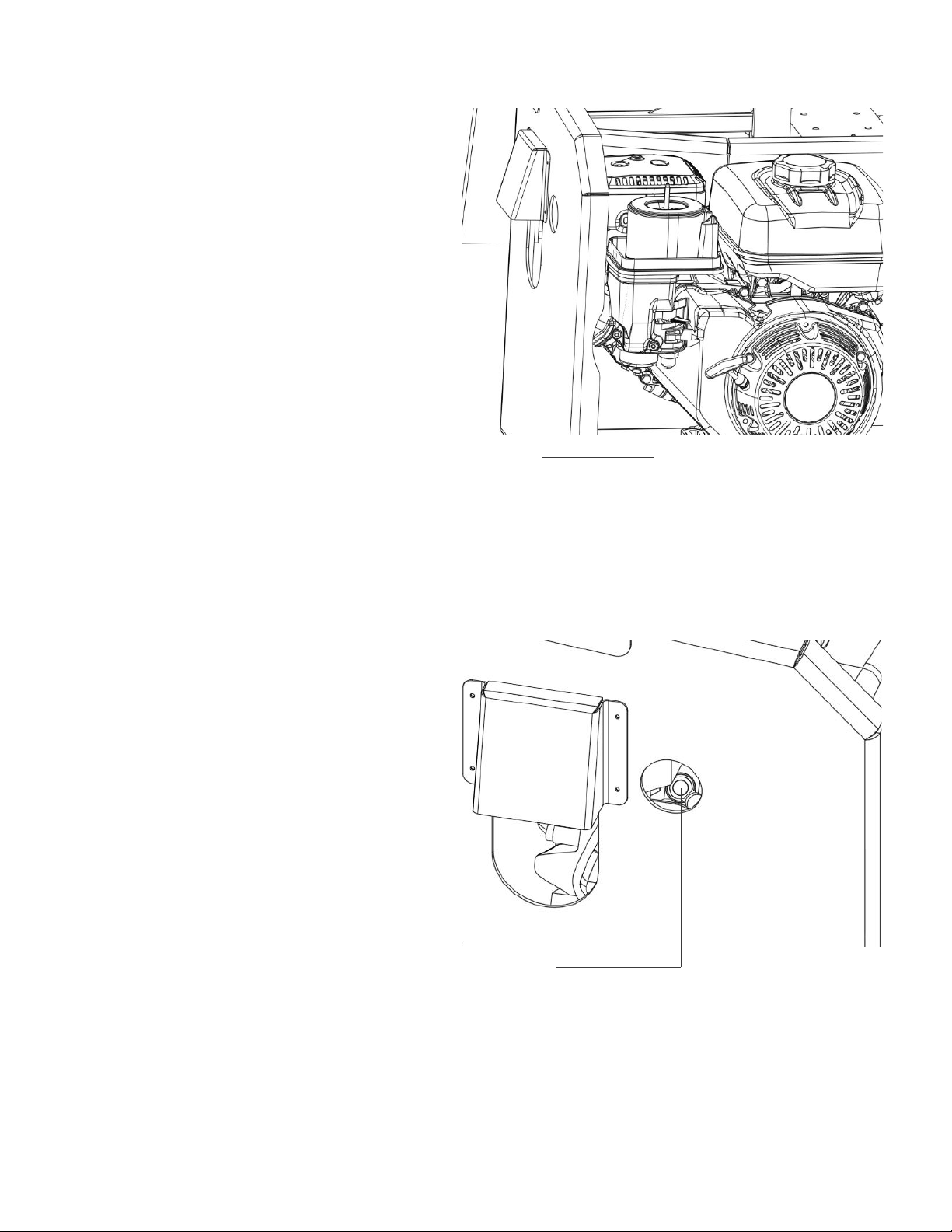

REPLACE AIR FILTER

NOTE: The spark plug is easier to

change with the air filter cover and base

removed. The wrench can be found in

the canister or holder that contains the

RB4000 Operator’s Manual.

1. Pull off the spark plug cap.

2. Use the wrench to unscrew the spark

plug.

3. Install the spark plug carefully, by hand,

to avoid cross-threading.

4. Tighten with the spark plug wrench to

compress the sealing washer until it sets.

5. Tighten the new spark plug ½ turn after

the spark plug seats.

6. Push the cap back on.

7. Replace the air filter cover and base.

REPLACE SPARK PLUG

Spark Plug

Air Filter

NOTE: Drain oil while the engine is

still warm to ensure rapid, complete

draining.

1. Undo the drain bolt using the 12mm

wrench provided in this service kit.

2. Drain oil through the hole into an

appropriate container.

3. Replace the bolt.

4. Remove the fill cap.

5. Insert the provided funnel through the

fill hole.

6. Add new oil using 1 US quart of low-30

synthertic oil.

7. Replace the fill cap.

REPLACE ENGINE OIL

1. Unscrew the used hydraulic filter.

2. Twist on the new filter.

3. As you twist, you will feel the seal hit the filter mount housing. When this happens, turn it another

¾ turn.

Always dispose of used oil filters in compliance with your local regulations.

REPLACE HYDRAULIC OIL FILTER

• Visually inspect all brake pads for wear.

• If brakes aren’t working properly, confirm the fuse is working and check the brake fluid level.

INSPECT TRAILER BRAKES

3

Always dispose of used oil in compliance with your local regulations.

Check / Replace Oil

Drain Oil Check / Replace Oil

4

• Visually inspect the parking brake

handle for wear.

• If it’s loose, turn the handle clockwise

until it’s tight.

INSPECT PARKING BRAKE

• Pull out the breakaway pin and listen for the actuator to make a humming noise from behind the

engine area.

• If you don’t hear the humming noise, check the inline fuse in the battery box. If needed, replace with

a 30-amp fuse (not included in this 6-month service kit).

INSPECT BREAKAWAY SYSTEM

• Visually inspect to ensure there’s no dry rot, wear, or damage that exposes the wires beneath.

• Damaged hoses should be replaced immediately by a qualified service shop.

CHECK HYDRAULIC HOSES

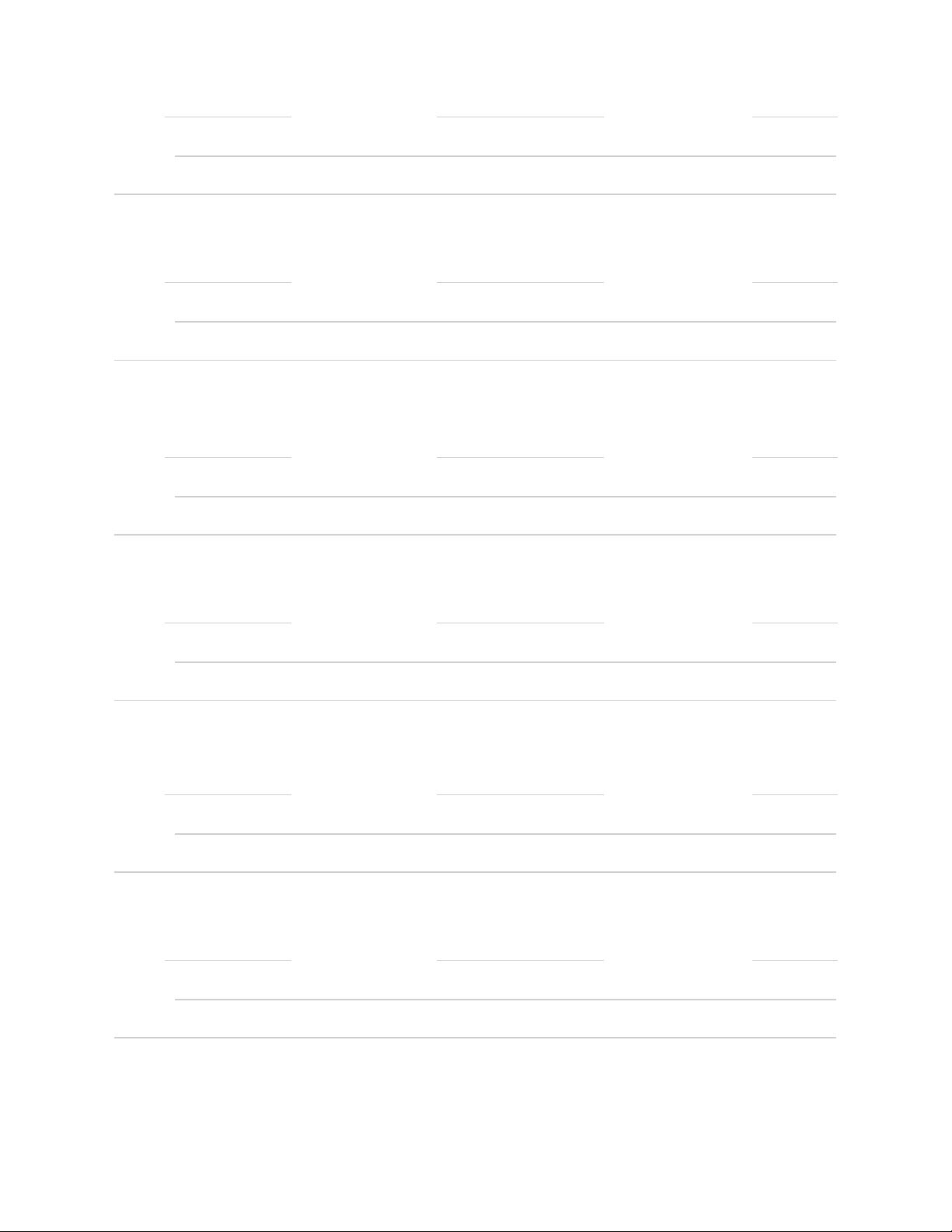

TIRES

• Front tires: visually inspect, check

pressure, and, if needed, tighten lug nuts.

• Rear tires: visually inspect and check

pressure. You must also make sure rear

tire lug nuts are tightened to 140 ft-lbs,

in the order outlined in the illustration.

Wheel bolt tightening sequence

Brake Handle

5

NOTE: Never work under the raised dump

box without using the safety arm to prevent

the box from falling down.

All four stabilizers and rollback must be

fully extended when greasing fittings on the

RB4000.

Greasing guidelines vary slightly on pre-

2014 RB4000 units. For older units, contact

the manufacturer’s recommended service

provider (Index A) for guidance on grease

locations.

Use provided grease tube to apply lubricant

to the following areas on all units:

LUBRICATE FITTINGS

Slide Rails

NOTE: Use provided gloves to apply the

grease to slide rails directly.

1. With the rollback fully extended, grease

the 3” x 5” tubes.

2. Grease the inside of the 4” x 6” tubes.

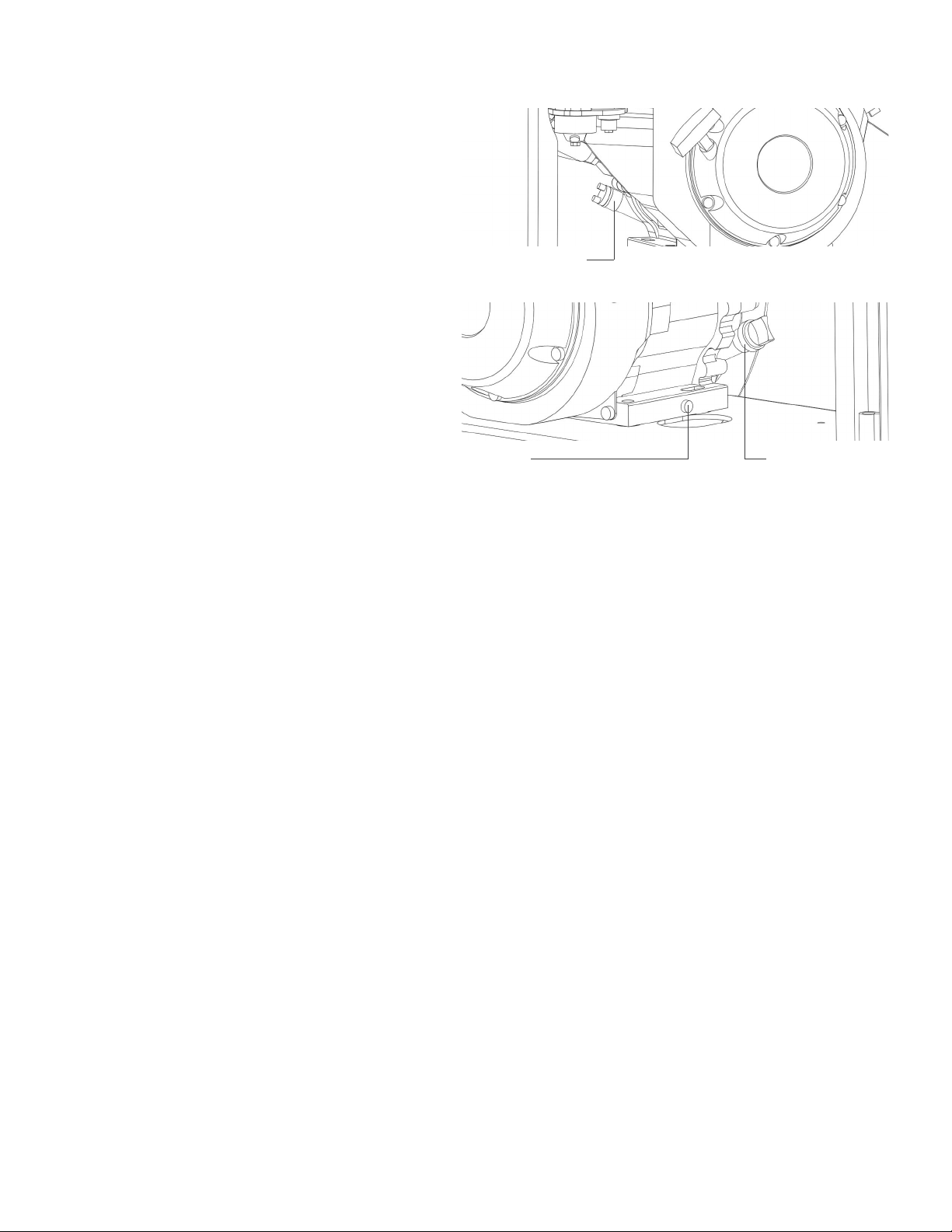

Wheel Lock Pin

NOTE: This step is applicable

for units manufactured on or

before October 2019. Units after

October 2019 are equipped with a

greaseless bushing.

1. Reach under the wheel lock

guard.

2. Insert grease into the zerk.

3. Pull the wheel lock handle and

grease the pin.

Step 1

Step 2

Safety Arm

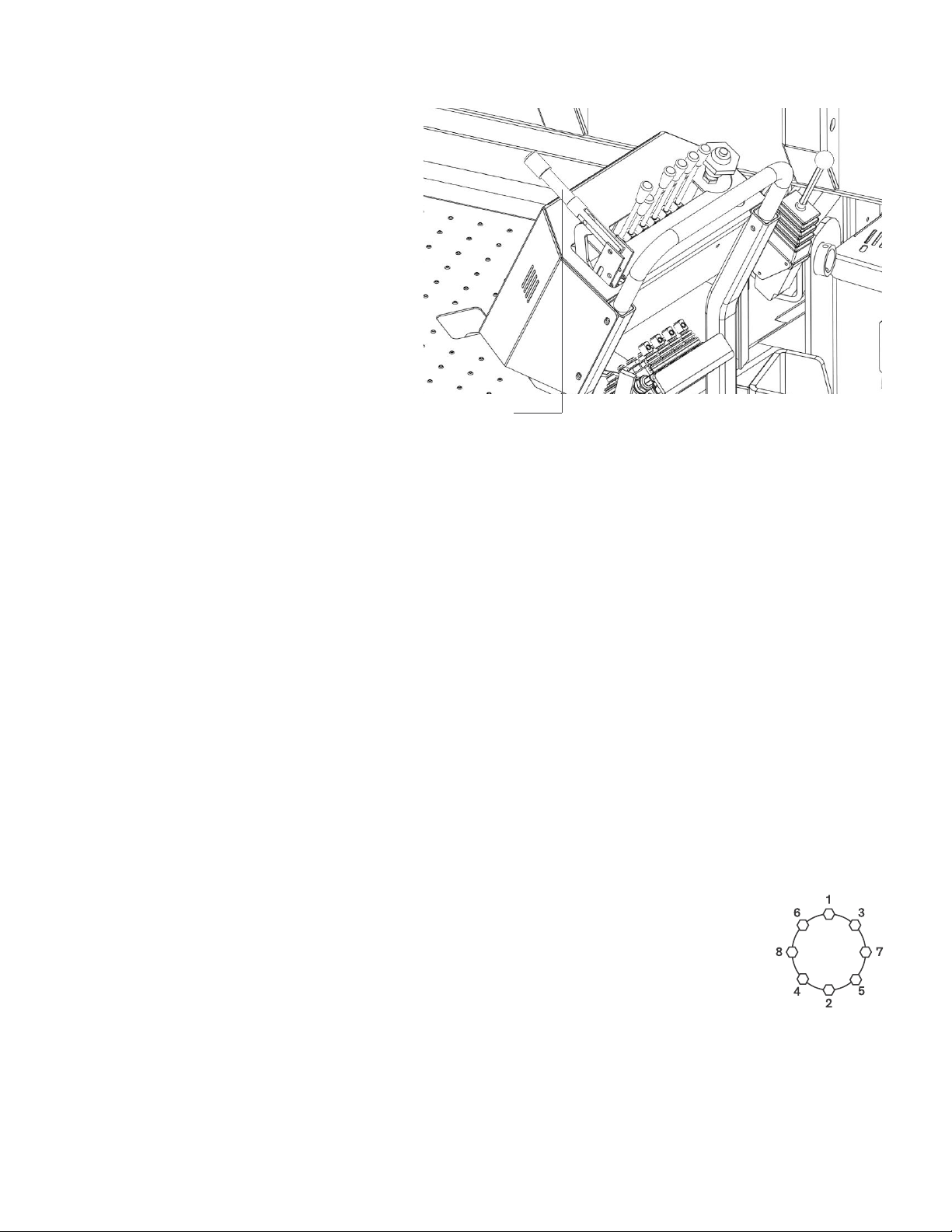

Axle Engagement System

NOTE: The fitting in the drive system should

be lubricated every 40 hours to ensure

proper operation. To access the grease

fitting:

1. Engage the parking brake.

2. Lower the stabilizers.

3. Release the safety latch and raise the front

steering wheels completely.

4. Tilt the dump box to gain access to the top

of the drive axle. Place prop under the dump

box for additional safety while lubricating the

axle engagement system.

5. Insert grease into the zerk.

NOTE: If the grease fitting is rotated away and cannot be accessed, the drive system can be

operated to spin the drive shaft. Use the drive control lever to “bump” the system until the grease

fitting is accessible.

For additional replacement parts or service assistance, contact the maufacturer’s recommended service

provider.

Front Axle Hub

1. Use a flat screwdriver to remove the

rubber grease cap.

2. Insert grease into the zerk until the zerk

is full.

3. Spin the tire to ensure the wheel turns

freely.

4. Replace the rubber grease cap.

5. Repeat on the opposite front wheel.

6

Grease Zerk

Wheel Lock Handle

1. Disengage the wheel lock pin.

2. Grease the wheel lock pin.

3. Replace the wheel lock pin.

Wheel Lock Pin

7

INDEX A: SERVICE PROVIDERS

Manufacturer’s Recommended Service Provider

Equipter, LLC

49 Eagle Drive

Suite 102

Leola, PA 17540

(717) 661-3591

support@equipter.com

Your Local Service Providers

8

INDEX C: RB4000 SERVICE SCHEDULE

Date:

Date:

Date:

Date:

Date:

Date:

Notes:

Notes:

Notes:

Notes:

Notes:

Notes:

Service Type:

Service Type:

Service Type:

Service Type:

Service Type:

Service Type:

Engine Hours:

Engine Hours:

Engine Hours:

Engine Hours:

Engine Hours:

Engine Hours:

9

INDEX C: RB4000 SERVICE SCHEDULE

Date:

Date:

Date:

Date:

Date:

Date:

Notes:

Notes:

Notes:

Notes:

Notes:

Notes:

Service Type:

Service Type:

Service Type:

Service Type:

Service Type:

Service Type:

Engine Hours:

Engine Hours:

Engine Hours:

Engine Hours:

Engine Hours:

Engine Hours:

10

©2019 New Heights, LLC. All rights reserved. No part of this manual may be reproduced, in any form, without prior, express, written

authorization of New Heights, LLC.

Other manuals for RB4000

2

Table of contents