Mid-tech ARC 6000 User manual

ARC 6000 CONSOLE

USER GUIDE

PN: 98-05012

QUICK START REFERENCE

The following items should be checked before starting each days operation. The

BOLD TYPE designates the switch positions required to view the information

mentioned. (For detailed information, or if this is the initial setup for the machine, see

Chapter 2.)

1. Application Rate - APPLICATION RATE/OPERATE

2. Clear accumulators

A. Area Accumulators - There are two area accumulators that can be reset

individually. Select the desired area accumulator and hold down the INC/DEC

switch until the display reads zero.

1) FIELD AREA/DEC

2) TOTAL AREA/DEC

B. Volume Accumulator - TOTAL APPLIED/OPERATE/DEC

3. Load Volume

A. Full Load Volume - If you are starting with a new load, set the "Full Load

Value" by selecting PRODUCT VOL./OPERATE and holding the INC/DEC

switch up for at least three seconds.

B. Partial Load Volume - Select "Full Load Value" as described in 4.A above.

Then hold down on the INC/DEC switch until the display reads the actual

volume loaded into the tank.

QUICK SET UPREFERENCE

1. Perform the items found in the Quick Start Reference above plus the items below.

2. Select U.S./Metric Units - SPEED/OPERATE - Use INC/DEC switch to select.

A. INC to select Metrish

B. DEC to select U.S. and Metric

3. % Rate Change - % RATE/SET-UP

4. GSO Speed - SPEED/SET-UP

5. Test Speed - TEST SPEED/SET-UP or OPERATE

6. Field Area Alarm - FIELD AREA/SET-UP

7. Console Calibration Numbers

A. Distance Cal. # - DISTANCE/SET-UP

B. Flow meter Cal. # - TOTAL APPLIED/SET-UP

C. Boom Widths - IMPL. WIDTH/SET-UP - All booms OFF. Check each

individual boom section as it is displayed. All unused boom sections should be

set to zero.

8. Setting Hold/Close Response

A. Implement Status Off - TOTAL APPLIED/OPERATE - Hold INC/DEC

switch up. Will cycle between Hold and Close.

B. All Booms Off - IMPL. WIDTH/OPERATE - Hold INC/DEC switch up. Will

cycle between Hold and Close.

I98-05012

R3

ARC-6000

TABLE OF CONTENTS

TABLE OF CONTENTS I

LIST OF ILLUSTRATIONS III

REVISION LOG III

HOW TO USE THIS MANUAL IV

CHAPTER 1 SWITCHES AND CONTROLS 1-1

CONSOLE SWITCHES AND INDICATORS 1-1

DISPLAY SELECTOR SWITCH 1-2

DISPLAY SELECTOR FUNCTIONS - OPERATE MODE 1-2

DISPLAY SELECTOR FUNCTIONS - SETUP MODE 1-3

STATUS SWITCH 1-4

GROUND SPEED OVERRIDE SWITCH 1-5

CHAPTER 2 CALIBRATION 2-1

ENGLISH, METRIC, OR METRISH UNITS 2-1

SETTING APPLICATION RATES 2-2

SETTING THE % RATE CHANGE 2-3

SETTING BOOM WIDTHS 2-3

DISTANCE CALIBRATION - GROUND SPEED SENSOR 2-4

FLOW METER CALIBRATION 2-7

SETTING THE HOLD/CLOSE RESPONSE 2-10

SETTING THE TEST SPEED VALUE 2-11

SETTING THE GROUND SPEED OVERRIDE (GSO) VALUE 2-12

SETTING THE FIELD AREA ALARM 2-13

PRODUCT VOLUME (FULL LOAD VALUE) 2-13

CHAPTER 3 OPERATION 3-1

NORMAL START-UP AND OPERATION 3-1

CHANGING ACTIVE BOOM SECTIONS 3-2

CHANGING APPLICATION RATE 3-2

PRIMING THE MAIN PUMP AND BOOM 3-4

GROUND SPEED OVERRIDE 3-4

CHAPTER 4 MAINTENANCE 4-1

FLUSHING AND CLEANING 4-1

CONTROL CONSOLE 4-1

GROUND SPEED SENSOR 4-2

FLOW SENSOR 4-2

FLOW CONTROL VALVE 4-3

WIRING HARNESS 4-3

CHAPTER 5 TROUBLE SHOOTING - ERROR MESSAGES 5-1

CHAPTER 6 EMERGENCY OPERATION 6-1

GROUND SPEED SENSOR FAILURE 6-1

FLOW CONTROL VALVE FAILURE 6-2

FLOWMETER FAILURE 6-4

APPENDIX A - SYSTEM DIAGRAMS A-1

APPENDIX B - SYSTEM OVERVIEW B-1

HOW THE ARC CONTROLS APPLICATION RATE B-2

ARC SYSTEM COMPONENTS B-2

APPENDIX C - GLOSSARY/TABLES C-1

GLOSSARY C-2

USEFUL FORMULAS C-6

ENGLISH/METRIC CONVERSION C-6

MISCELLANEOUS NOTES C-8

CALIBRATION NUMBERS C-8

MID-TECH, Auto-Range, & TASC are all registered trademarks of Midwest Technologies, Inc.

II

ARC-6000

98-05012

R3

This page left blank intentionally

III 98-05012

R3

ARC-6000

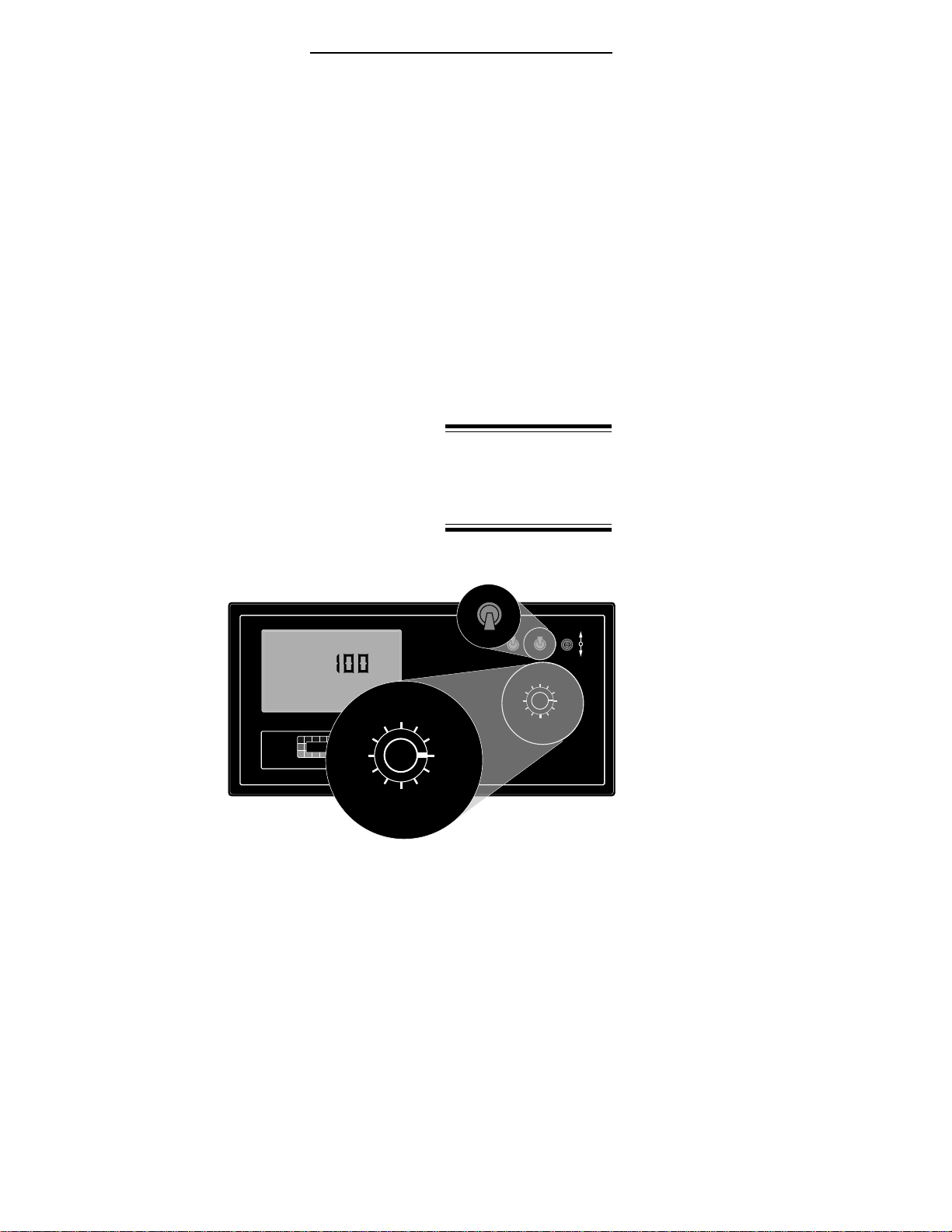

FIG. 1-1. ARC CONSOLE - SWITCHES AND INDICATORS 1-1

FIG. 1-2. DISPLAY SELECTOR FUNCTIONS - OPERATE MODE 1-2

FIG. 1-3. DISPLAY SELECTOR FUNCTIONS - SET-UPMODE 1-3

FIG. 3-1. BOOM SECTION SWITCHES 3-2

FIG. 3-2. CHANGING APP. RATE “O NTHE GO”. 3-3

FIG. A 1. ARC FLOW CONTROL - WIRING DIAGRAM A-2

FIG. A 2. ARC FLOW CONTROL - PLUMBING DIAGRAM A-3

FIG. A 3. SERVICE FORM A-4

FIG. B-1 ARC SYSTEM DATA FLOW B-2

FIG. B-2. ARC 6000 CONSOLE B-3

FIG. B-4. FLOW METER B-4

FIG. B-3. GROUND SPEED RADAR B-4

FIG. B-5. FLOW CONTROL VALVE B-4

FIG. B-6. BOOM CONTROL SWITCHBOX B-5

Revision Reason SW Ver.

97108 New Manual 1.31

98250 New Format 1.31

2 Updated Graphics 1.31

& Format

3 Updated Graphics 1.31

& Format

Revision Log

List of Illustrations

IV

ARC-6000

98-05012

R3

This page left blank intentionally

V98-05012

R3

ARC-6000

Mid-TMid-Tech

HOW TO USE THIS MANUAL

This manual is designed to provide you with

the basic information needed to set up and

operate the MID-TECH®Automatic Rate Control (ARC)

spraying system. Actual procedures may vary somewhat,

depending on the configuration of your system.

When you see "Mitch", he is pointing out special information

that you should be aware of, regarding safety, preventing

console damage, an easier way to perform an operation, etc..

Below is a listing of the chapters in this manual, along with a

brief description of the information found in each chapter.

Chapter 1 - Switches and Controls - Lists each control switch,

on the face of the console, and gives a brief description of its

use.

Chapter 2 - Calibration and Setup - Takes you, step by step,

through the calibration of each sensor providing input to the

console, and the entering of other information the console

needs to perform the functions you require.

Chapter 3 - Operation - Briefly describes how to initiate the

spraying operation.

Chapter 4 - Trouble shooting - Lists possible causes and

remedies for the error codes that appear on the ARC display

if the console detects a problem.

Chapter 5 - Maintenance - Describes the basic maintenance

needed to keep your system operating at peak performance.

Chapter 6 - Emergency Operations - Suggests ways to operate,

under reduced accuracy, in the event of a major fault.

Appendix A - Sample system wiring and plumbing diagrams.

Appendix B - System Overview - Describes the major compo-

nents of the ARC system and their individual functions in

application control.

Appendix C - Glossary/Tables

Back Cover - Quick Start/Quick Set Up Guides

VI

ARC-6000

98-05012

R3

This page left blank intentionally

1-1 98-05012

R3

ARC-6000

This chapter shows the location of each switch

and indicator found on the ARC control console

and discusses its function in both the Operate

and Setup modes. (Further information can be found

on pages shown in parenthesis.)

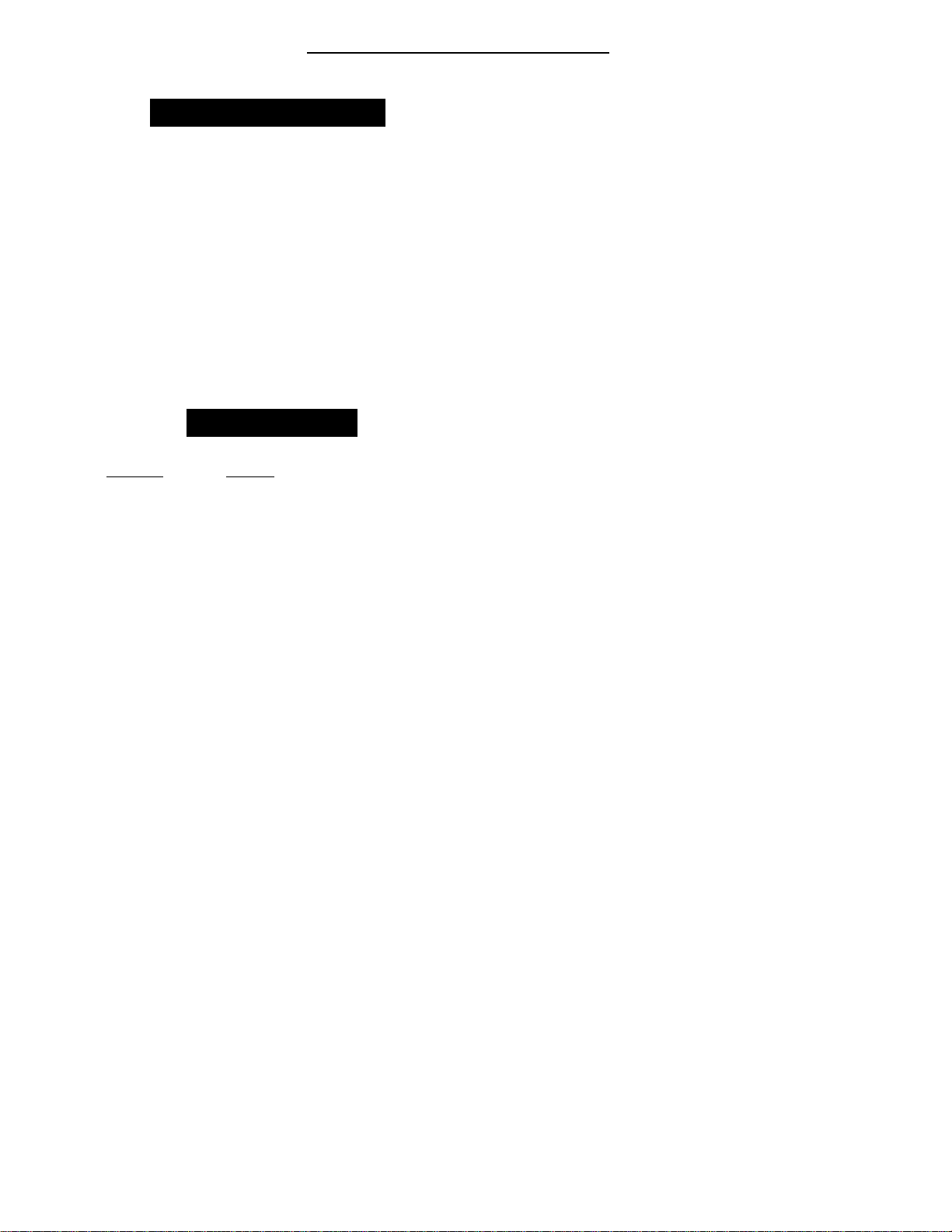

Console Switches and Indicators

POWER SWITCH

The Power switch (See #1 in Fig. 1-1) controls

the power to the console. Always turn the

Power switch “OFF”when not in use. This

protects against accidental operation of the control

system and unnecessary current drain on the vehicle

battery.

Don’t

worry about

the console

losing the

set-up

information

with the

power

turned off.

The ARC

Control

Console has

a nonvola-

tile memory

that doesn’t require constant power to hold it’s

information.

MODE SELECTOR SWITCH

The Mode Selector switch (See #2 in Fig. 1-1) is used

to switch between the OPERATE and SETUP modes

of the Control Console. When applying product, this

switch must be in the “OPERATE”position. The

“SET-UP”position is used for entering information

into the console. In the SETUP Mode an “Err”

message appears if a position is selected which can not

be programmed.

%Rate

DISPLAY SELECTOR

Speed

Field Area Impl.Width

Distance

Test

Speed

Prime

Total Applied

Application Rate

OFF SET- UP DEC.

ON OPERATE INC.

Scan

Total Area

Product Vol.

ARC-6000

Automatic

Rate Controller

MID-TECH

¨

MIDWEST TECHNOLOGIES, INC.

123456789

BOOMS

.

-Ac

Flow

RATE

Gal./

3

12

4

5

Chapter 1 Switches and Controls

Fig. 1-1. ARC Console -

Switches and Indicators

1-2

ARC-6000

98-05012

R3

OFF SET- UP DEC.

ON OPERATE INC.

ARC-6000

Automatic

Rate Controller

MID-TECH

MIDWEST TECHNOLOGIES, INC.

123456789

%Rate

DISPLAY SELECTOR

Speed

Field Area Impl.Width

Distance

Test

Speed

Prime

Total Applied

Application Rate

Scan

Total Area

Product Vol.

BOOMS

.

-Ac

Flow

RATE

Gal./

123456789

%Rate

DISPLAY SELECTOR

Speed

Field Area Impl.Width

Distance

Test

Speed

Prime

Total Applied

Application Rate

Scan

Total Area

Product Vol.

BOOMS

¨

%Rate

DISPLAY SELECTOR

Speed

Field Area Impl.Width

Distance

Test

Speed

Prime

Total Applied

Application Rate

Scan

Total Area

Product Vol.

OFF SET- UP

ON OPERATE

SET- UP

OPERATE

INC / DEC SWITCH

The Increase/Decrease (INC/DEC) switch (See #3 in

Fig. 1-1) is used, in both the OPERATE and SETUP

modes, to change the values appearing in the display.

Boom Section “ON/OFF” Indicators

The boom section On/Off indicators (See #5 in Fig. 1-

1.) indicate which boom sections are selected by the

operator. When a boom is been selected, its indicator

lamp is lit. Boom section number 1 is usually the one

to the left of the sprayer. There are a maximum of nine

boom sections available.

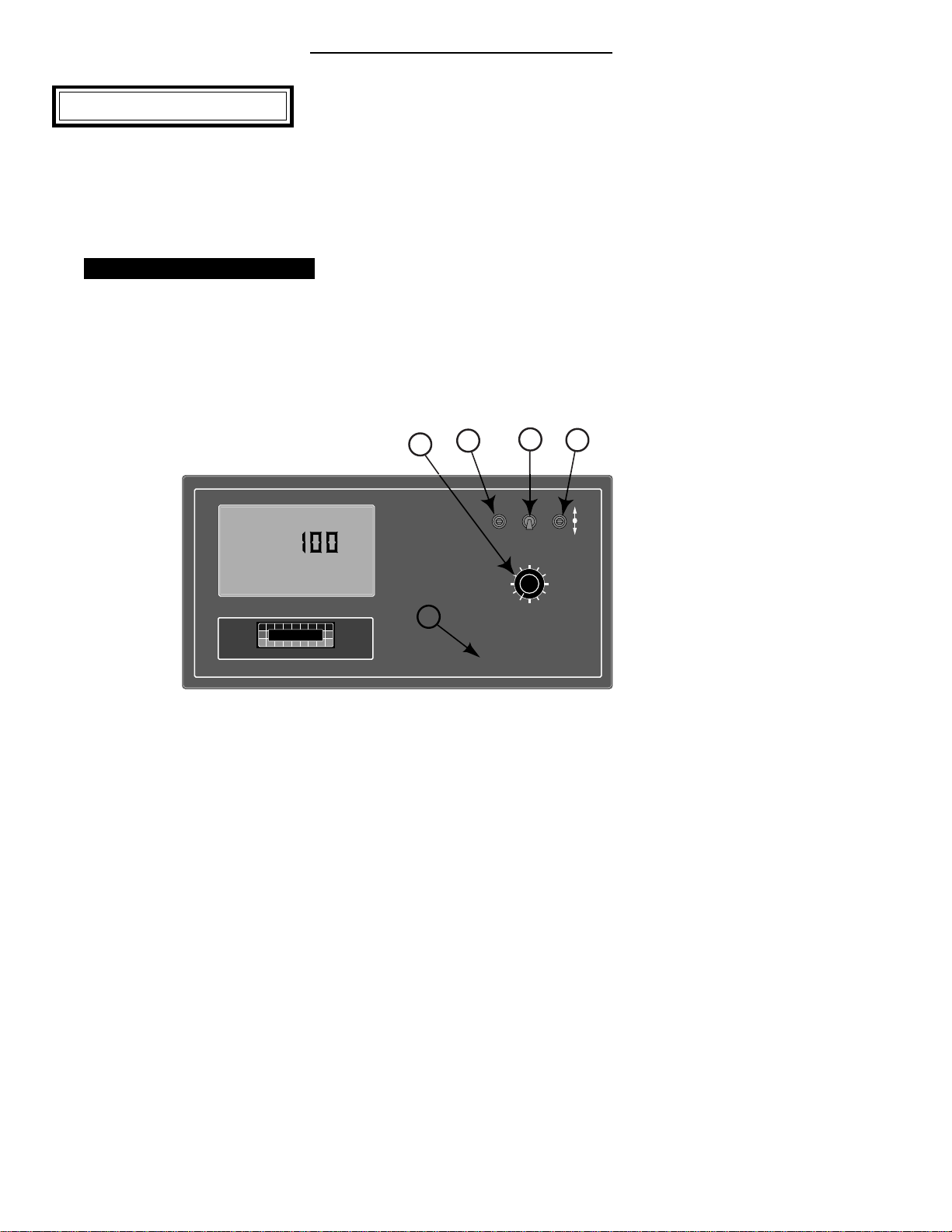

Display Selector Switch

The Display Selector (See #4, Fig. 1-1) is used to

choose which of the various console functions is to be

displayed on the screen and available for adjustment

by the operator.

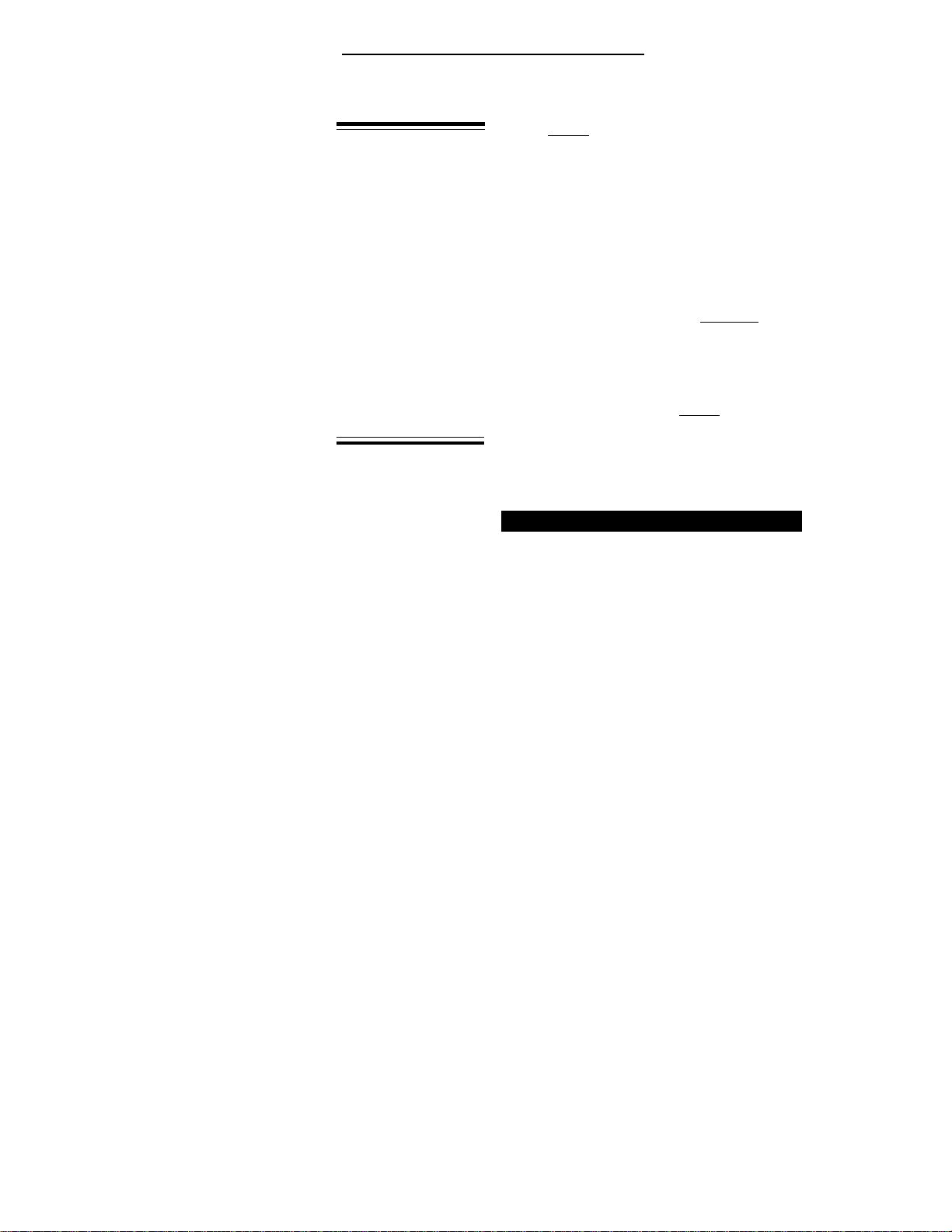

Display Selector Functions - Operate Mode

Speed: The current

vehicle speed.

Field Area:

Accumulated Area.

(Pg. 3-1)*

Total Area:

Accumulated Area.

(Pg. 3-1)*

Product Vol:

Amount of product

aboard the sprayer.

(Pg. 2-14)**

% Rate: The percent by which the programmed

application rate, at which the product is being

applied, is changed with each activation of the INC/

DEC switch. (Pg. 2-3)***

Fig. 1-2. Display Selector

Functions - Operate Mode

1-3 98-05012

R3

ARC-6000

Application Rate: The desired application rate. (Pg.

2-2)** Once application has started, and metered

discharge is established, the actual measured

application rate is displayed here. (Also used to set

the control valve to manual control.) (Pg. 6-4)

Total Applied: The total volume of product applied,

as measured by the flow meter.*

Impl. Width: The active boom width, (Total width of

all boom sections turned “ON”).

Distance: The accumulated distance.

Prime: This position is used to lock the control valve

open during product pump priming. (Pg. 3-4)

Test Speed: The speed the console uses for stationary

tests of the sprayer. (Pg. 2-12)**

Scan: The display scans SPEED, FIELD AREA,

PRODUCT VOLUME, APPLICATION RATE,

and TOTAL APPLIED, holding at each position

for approximately two seconds before automati-

cally cycling to the next.

Display Selector Functions - Setup Mode

Speed: Ground

Speed Override

(GSO) Value.

(Pg. 2-13)**

Field Area: Select

area alarm. The

display flashes

and the console

beeps each time

a selected

increment is

reached. The

display reacts for about three seconds and then

stops until the next increment is reached. (Set to

zero to disable.) (Pg. 2-14)**

Total Area: Err, No function in the SETUP mode.

* Totals can be reset in this

mode.

** Values are programmable

in this mode.

*** Values changeable by a %

increase or decrease.

OFF SET- UP DEC.

ON OPERATE INC.

ARC-6000

Automatic

Rate Controller

MID-TECH

MIDWEST TECHNOLOGIES, INC.

123456789

%Rate

DISPLAY SELECTOR

Speed

Field Area Impl.Width

Distance

Test

Speed

Prime

Total Applied

Application Rate

Scan

Total Area

Product Vol.

BOOMS

.

-Ac

Flow

RATE

Gal./

12345678

%Rate

DISPLAY SELECTOR

Speed

Field Area Impl.Width

Distance

Test

Speed

Prime

Total Applied

Application Rate

Scan

Total Area

Product Vol.

BOOMS

¨

%Rate

DISPLAY SELECTOR

Speed

Field Area Impl.Width

Distance

Test

Speed

Prime

Total Applied

Application Rate

Scan

Total Area

Product Vol.

OFF SET- UP

ON OPERATE

SET- UP

OPERATE

Fig. 1-3. Display Selector

Functions - Set-Up Mode

1-4

ARC-6000

98-05012

R3

Product Volume: Use the INC/DEC switch to set the

full load value of the vehicle. (Pg. 2-14)**

% Rate: The percent by which the programmed

application rate can be changed with each activa-

tion of the INC/DEC switch when application is

underway. (Pg. 2-3)**

Application Rate: ERR, No function in SETUP

mode.

Total Applied: This is the flow meter calibration

number. (Pg. 2-8)**

Width: Individual boom section widths. The display

cycles through the individual boom sections in

order, unless a particular boom switch is activated

and the boom master switch is ON. (Pg. 2-3)**

Distance: Distance Calibration Number. (Pg. 2-4)**

Prime: Reads Pump L STnrd - Cannot be changed.

Test Speed: The current Test Speed (Pg. 2-12).**

Status Switch

An external “Implement Status”input can be

used to override the ARC control. The input

must present a positive voltage (+12.0 VDC)

on the green (or white) wire of the Boom Interface

Cable. As long as this condition is present, the

Control Console operates normally. If the voltage is

interrupted, the Control Console automatically stops

applying. At the same time, the Control Console will

either "HOLD" or "CLOSE" the Control Valve,

depending on the response selected by the operator.

(See Page 2-11).

This feature allows the operator to control the

operation of the control valve through the normal

operation of the vehicle. The Status input can be

used to sense the "ON"/"OFF" condition of the main

vehicle pump switch, a separate Master Switch, or, an

external switch monitoring an implement "UP"/

"DOWN" condition.

* Totals can be reset in this

mode.

** Values are programmable

in this mode.

*** Values changeable by a %

increase or decrease.

1-5 98-05012

R3

ARC-6000

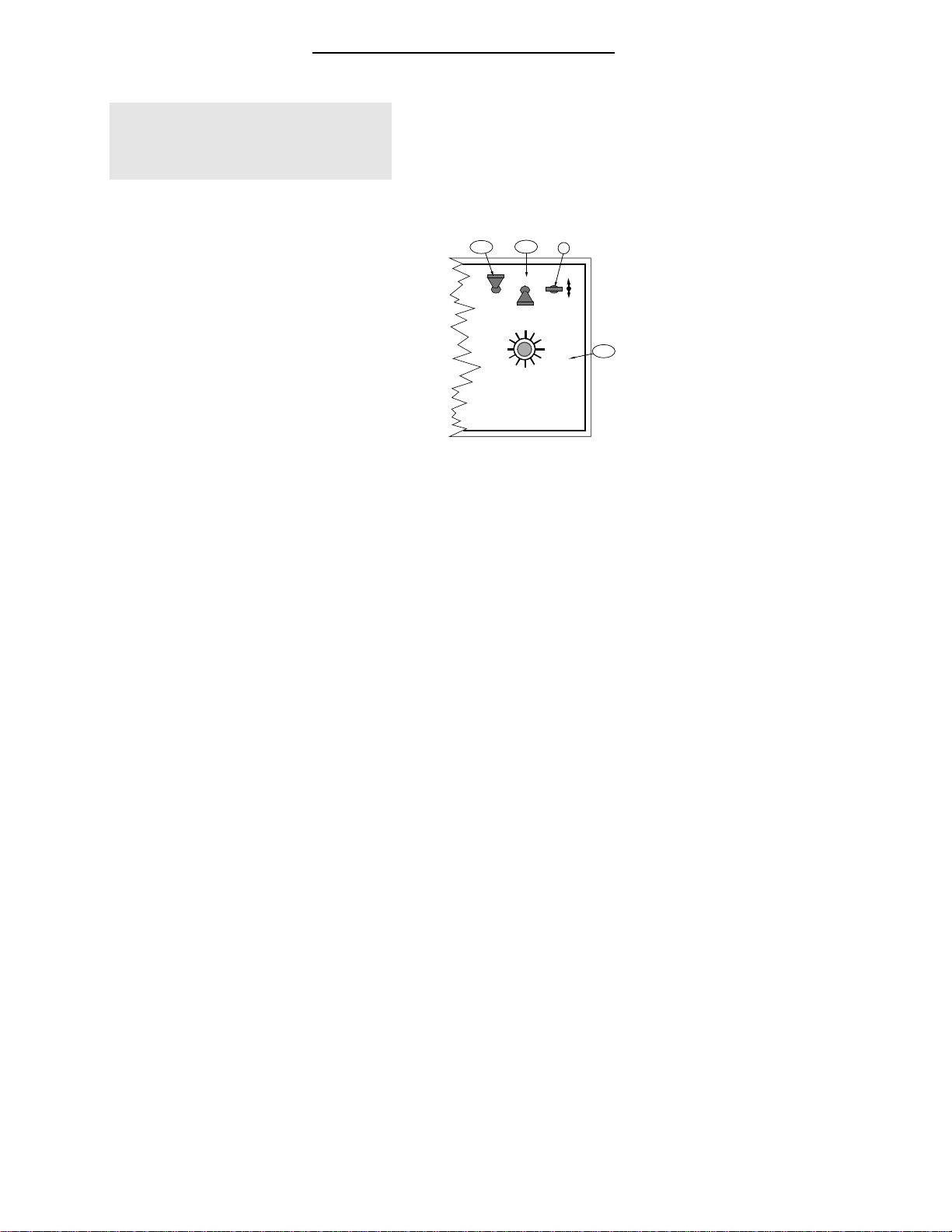

Ground Speed Override Switch

If your ARC system includes an optional MID-

TECH®Boom Control Switch Box, the Ground

Speed Override (GSO) switch is already installed.

An optional, externally mounted, GSO switch can be

used to temporarily operate the sprayer using a pre-

selected, "GSO”, minimum speed rather than the

actual vehicle ground speed. The override feature is

used to reach the application rate quickly when

starting the vehicle from a complete stop or to

maintain an adequate spray pattern when the vehicle

is moving at very low ground speeds. It can also be

used to allow the operator to flush or empty the tank

from the cab, with the vehicle stopped.

The Control Console operates normally as long as the

GSO switch condition is open (OFF). Whenever the

switch is closed (ON) and the actual ground speed is

less than the "GSO Speed", the Control Console

automatically uses the "GSO Speed" value to control

application rate. As soon as the switch reverts to its

normally open (OFF) condition, or the actual ground

speed increases above the preset "GSO Speed", the

Control Console will adjust the application rate based

on the actual ground speed.

CAUTION: Controlling application rates based on a

"GSO Speed" is not as accurate as using the actual

ground speed. When Ground Speed Override is being

used and the true ground speed is less than the

"Ground Speed Override”speed, the console sounds

an alarm and the display flashes a "Too Slow"

message to warn the operator of possible mis-

application.

Mid-Tech

Fig. B-6, in Appendix B,

shows a “Boom Control

Switch Box” which incorpo-

rates the Implement Status

Switch and the GSO function

into one switch. The “OFF”

position provides a Status

Switch “OFF” condition,

“AUTO” furnishes Status

Switch ON, and “GSO”

activates the GSO function.

Other methods of controlling

these functions are also

available. This switchbox also

includes an individual ON/

OFF switch for each boom

section.

1-6

ARC-6000

98-05012

R3

This page left blank intentionally

2-1 98-05012

R3

ARC-6000

Chapter2Calibration

NOTE: PLEASE READ THROUGH THE FOLLOW-

ING SECTIONS COMPLETELY BEFORE YOU

BEGIN CALIBRATION!

The Control Console must be calibrated and pro-

grammed with certain information before it can be

used. First, the specific details of your applicator

(i.e. Application Rates, Boom Widths, Test Speed, etc.)

are entered. Next, the flowmeter and ground speed

sensors are both calibrated. The calibration and set up

procedures are not difficult, however, they must be

followed precisely in order to get the maximum possible

accuracy out of the system.

English,Metric,orMetrishUnits

The Control Console is capable of displaying

three different units of measure, US, Metric

and Metrish. Metrish is the same as Metric, except

area is measured in Acres.

UNITS FOR EACH DISPLAY SELECTOR SWITCH POSITION

Mid-Tech

POSITION US METRIC METRISH

Speed Miles/Hour (mph) Kilometers/Hour (kph) Kilometers/Hour (kph)

Field Area Acres (acre) Hectares (ha) Acres (acre)

Total Area Acres (acre) Hectares (ha) Acres (acre)

Product Vol. US Gallons (gal.) Liters (l) Liters (l)

Appl. RateUS Gallons/acre (gpa) Liters/Hectare (l/ha) Liters/Acre (l/acre)

Total Applied US Gallons (gal.) Liters (l) Liters (l)

Impl. Width Inches - Feet (in., ft.) Meters (m) Meters (m)

Distance Feet - Miles (ft.-miles)* Meters - Kilometers (m-km)* Meters - Kilometers (m-km)*

Test Speed Miles/Hour (mph) Kilometers/Hour (kph) Kilometers/Hour (kph)

* No units displayed after roll over of feet to miles or meters to kilometers

2-2

ARC-6000

98-05012

R3

Setting the APPLICA-

TION RATE to 0.0 will

turn off the flow

control function.

DISPLAY SELECTOR

Speed

Field Area Impl. Width

Distance

Test

Speed

Prime

Total Applied

Application Rate

OFF SET- UP DEC.

ON OPERATE INC.

Scan

Product Vol.

Total Area

BOOMS

123456789

% Rate

B

A-1 A-2

A-3

DISPLAY SELECTOR

Speed

Field Area Impl. Width

Distance

Test

Speed

Prime

Total Applied

Application Rate

OFF SET- UP DEC.

ON OPERATE INC.

Scan

Product Vol.

Total Area

BOOMS

123456789

% Rate

B

A-1 A-2

A-3

CHANGING UNITS

A. Set the console switches to the following positions:

1. Power “ON”

2. Mode Selector “OPERATE”

3. Display Selector “SPEED”

The display shows the current speed units.

B. Using the INC/DEC Switch, select the measuring

system desired (See following chart). The INC/DEC

Switch must be held for approximately 5 sec. before

the change occurs.

Units INC./DEC. Switch

English to Metric “DOWN”

Metric to English “DOWN”

English to Metrish “UP”

Metrish to English “DOWN”

NOTE: Metric to Metrish is not available. Change to

English first and then to Metrish.

SettingApplicationRates

The ARC 6000 system is designed to maintain a

constant, pre-selected application rate. In order for

the Control Console to do this, the operator must

enter the desired application rate. To set the desired

applicationrate:

A. Set the console switches to the following positions:

1. Power “ON”

2. Mode Selector “OPERATE”

(Application Rate is set in the Operate Mode!!!)

3. Display Selector “APPLICATION RATE”

The display shows the current application rate.

B. Using the INC/DEC switch, set the desired rate.

2-3 98-05012

R3

ARC-6000

MASTER

ON

OFF

MI

B

F

DISPLAY SELECTOR

Speed

Field Area Impl. Width

Distance

Test

Speed

Prime

Total Applied

Application Rate

OFF SET- UP DEC.

ON

OPERATE INC.

Scan

Product Vol.

Total Area

BOOMS

123456789

% Rate

B

A-1 A-2

A-3

DISPLAY SELECTOR

Speed

Field Area Impl. Width

Distance

Test

Speed

Prime

Total Applied

Application Rate

OFF SET- UP DEC.

ON OPERATE INC.

Scan

Product Vol.

Total Area

BOOMS

123456789

% Rate

C, D, E

A-1 A-2

A-3

F

Setting the % Rate Change

This feature allows the operator to change the

application rate “ON THE GO”with a simple

actuation of the INC/DEC switch. The amount of

change each switch actuation makes is proportional to the

value programmed into this position, (e.g. 20 =20% change

in the target rate). For example, with the liquid application

rate set to 10.0 gallons per acre, a single actuation of the

INC switch causes the system to control flow at the rate of

12.0 gallons per acre (10.0 + 20% = 12.0). To set the

desired % Rate Change value:

A. Set the console switches to the following positions:

1. Power “ON”

2. Mode Selector “SETUP

3. Display Selector “% RATE”

The display shows the current % change value.

B. Using the INC/DEC switch, set this number to the

desired % change value.

SettingBoomWidths

TheMIDWESTTECHNOLOGIESControlConsole

is designed to automatically compensate for

changes in the swath width, caused by turning

boom sections on or off. To accurately respond to

changes in swath width, the console must know the size

of each boom section. To set the desired boom section

widths:

A. Set the Console to the following positions;

1. Power “ON”

2. Mode Selector “SET- UP”

3. Display Selector “IMPL.WIDTH”

B. All Boom Switches (or Master Switch) “OFF”

The display cycles through each boom position (1

through 9) and displays its current width in inches.

2-4

ARC-6000

98-05012

R3

RECORD THESE CALIBRATION NUMBERS ON LAST PAGE OF MANUAL.

C. As each boom position appears on the display, use

the INC/DEC Switch to set the display to the number

of inches covered by that boom. Repeat for each

section.

D. Set all unused boom sections to a width of zero “ 0”

inches. This insures that accidentally turning a boom

switch “ON”doesn’t affect the control console.

E. Finally, let the boom width display cycle through the

boom sections until it shows “Boom C”. When the

“ C” width is displayed, set it to the normal operating

width of the entire sprayer, in inches, using the INC/

DEC switch.

F. The boom width is now set. Turn all booms “ON”and

return to the OPERATE Mode, the new total boom

width will be displayed in feet. If this does not agree

with your total applicator width, check the individual

boom widths, ( steps A, B and C).

DistanceCalibration-GroundSpeedSensor

GENERAL CONSIDERATIONS AND INITIAL CALIBRATION

NUMBERS

The Control Console must be calibrated to the

ground speed sensor installed to ensure accurate

application rates. The procedure involves physi-

cally measuring an accurate distance along a road or field,

driving the vehicle through that distance, mathematically

comparing the distance computed by the control console

to the actual measured distance, and making any neces-

sary adjustments to the distance calibration number.

Follow the recommended procedure below to ensure

accuracy of operation.Follow the recommended proce-

dure below to ensure accuracy of operation.

The distance calibration should be checked periodically to

maintain its accuracy. A calibration test is especially

important if the sensor mounting has become loose or has

been repositioned (Radar Sensor), or if the tires have been

changed (Wheel and Speedometer Sensor).

Boom widths are

entered in inches in the

US system. For

example; for a liquid

boom with 7 nozzles on

30" spacings, enter 210

for that boom. There is

no need to convert to

feet, the control

console does that

automatically when it is

switched back to the

Operate Mode. (In

metricand metrish,all

widths are entered in

meters.)

2-5 98-05012

R3

ARC-6000

Use the following initial calibration numbers.

MID-TECH®COMPACTRADAR-780

Dj RADAR - 1000

WHEEL SENSOR - 3500

SPEEDOMETERSENSOR-3500

To view and adjust the speed calibration number:

A. Set the Control Console switches to the following

settings:

1. Power “ON”

2. Mode Selector “SETUP”

3. Display Selector “DISTANCE”

The display shows the distance calibration value.

B. Use the INC/DEC switch to select the initial distance

calibration number suggested. You can now perform

the distance calibration procedure.

DISTANCE CALIBRATION PROCEDURE

The following procedure is recommended by MIDWEST

TECHNOLOGIES for establishing an accurate distance

calibration. NOTE: All boom switches should remain

“OFF”during the entire procedure.

A. Fill the vehicle 1/2 full of material (unless it is a pull

type unit with the speed sensor mounted on the tow

vehicle), to approximate actual load conditions. This

minimizes the effect on the radar mounting angle or

actual working diameter of the tires as the load

empties.

B. Measure a known distance of 400 ft. or more in a field

or roadway (preferably in terrain similar to that being

treated). Select an easy place in which to maneuver

the vehicle. A longer distance, allows a more accurate

test to be performed.

C. Record the current Distance Cal. #.

1. Turn the Display Selector to the “DISTANCE”

position.

DISPLAY SELECTOR

Speed

Field Area Impl. Width

Distance

Test

Speed

Prime

Total Applied

Application Rate

OFF SET- UP DEC.

ON

OPERATE INC.

Scan

Product Vol.

Total Area

BOOMS

123456789

% Rate

B

A-1 A-2

A-3

2-6

ARC-6000

98-05012

R3

RECORD THIS CALIBRATION NUMBER ON LAST PAGE OF MANUAL.

2. Set Mode Select switch to the “SET- UP”mode.

The console displays the current Distance

Calibration Number. Record this number for future

reference. As an example, assume this number is

1000.

D. Drive the vehicle to the starting point of the mea-

sured distance and stop.

E. Zero out the Distance Accumulator

1. Return the Mode Select switch to the “OPERATE”

position.

2. Reset the distance to zero using the DEC. switch.

F. Drive the vehicle to the other end of the measured

distance at a speed of between five and ten miles per

hour. Distance measurements will accumulate on the

display.

G. Stop the vehicle at the measured distance end marker.

Compare the indicated distance to the actual Mea-

sured distance, to determine how much correction is

necessary. For example: if the indicated distance is

396 Ft. after driving over a 400 foot range, the error in

the distance calibration is 1.0%.

H. Calculate the new Distance Calibration Number using

the following formula:

Example: (400 / 396) x 1000 = 1010, the New DC#

NOTE: The same calibrations are used, regardless of

the type of distance sensor .

J. Enter the corrected Cal. #.

1. Select "SETUP" mode.

2. Use the "INC/DEC" switch to enter the new

calibration number (See page 2-5).

3. Switch back to the "OPERATE" mode. The

distance accumulator should now agree with the

measured distance that you traveled. If it doesn't ,

recheck your calculations.

DISPLAY SELECTOR

Speed

Field Area Impl. Width

Distance

Test

Speed

Prime

Total Applied

Application Rate

OFF SET- UP DEC.

ON

OPERATE INC.

Scan

Product Vol.

Total Area

BOOMS

123456789

% Rate

E-1

C-2

C-1

E-2

DISPLAY SELECTOR

Speed

Field Area Impl. Width

Distance

Test

Speed

Prime

Total Applied

Application Rate

OFF SET- UP DEC.

ON

OPERATE INC.

Scan

Product Vol.

Total Area

BOOMS

123456789

% Rate

J-1 J-3 J-2

(Measureddistance/Indicateddistance)xOldDC#=NewDC#

Table of contents