3

ENGLISH

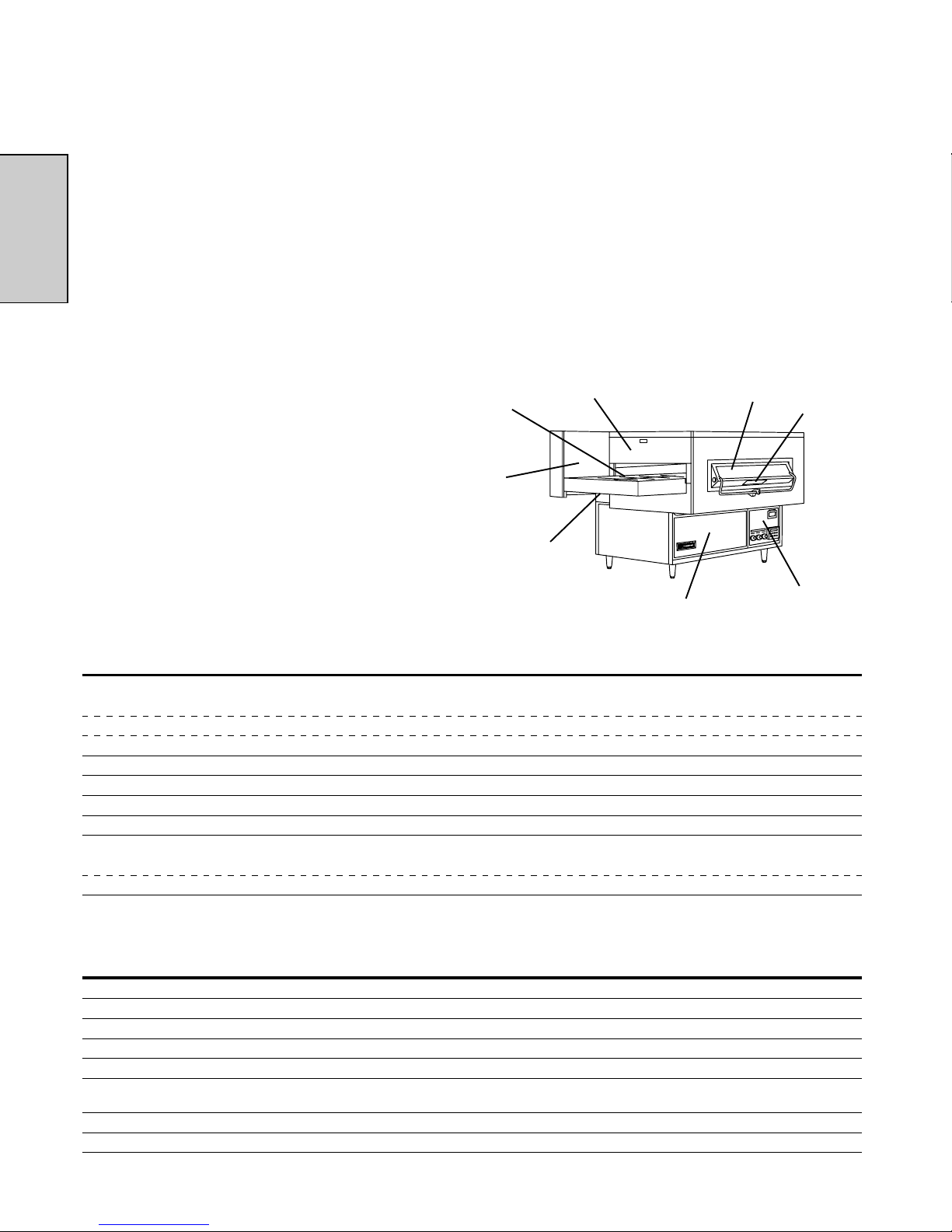

SECTION 1 - DESCRIPTION ................................................... 4

I. OVEN USES ............................................................. 4

II. OVEN COMPONENTS ............................................. 4

A. Crumb Pans ..................................................... 4

B. Conveyor Drive Motor ....................................... 4

C. Conveyor ........................................................... 4

D. End P ugs ......................................................... 4

E. Seria P ate ....................................................... 4

F. Window ............................................................. 4

G. Machinery Compartment Access Pane .......... 4

H. Contro Compartment Access Pane .............. 4

I. Contro Pane .................................................... 4

J. Eyebrows .......................................................... 4

K. Conveyor End Stop ........................................... 4

L. Gas Burner or Heating E ements .................... 4

M. B owers............................................................. 4

N. Air Fingers ........................................................ 4

III. OVEN SPECIFICATIONS ......................................... 4

A. Dimensions ...................................................... 4

B. Genera Specifications ..................................... 4

C. E ectrica Specifications ................................... 5

D. Gas Orifice and Pressure Specifications........ 5

SECTION 2 - INSTALLATION .................................................. 5

I. INSTALLATION KIT .................................................. 6

II. VENTILATION SYSTEM ........................................... 7

A. Requirements .................................................. 7

B. Recommendations .......................................... 7

C. Other Venti ation Concerns .............................. 7

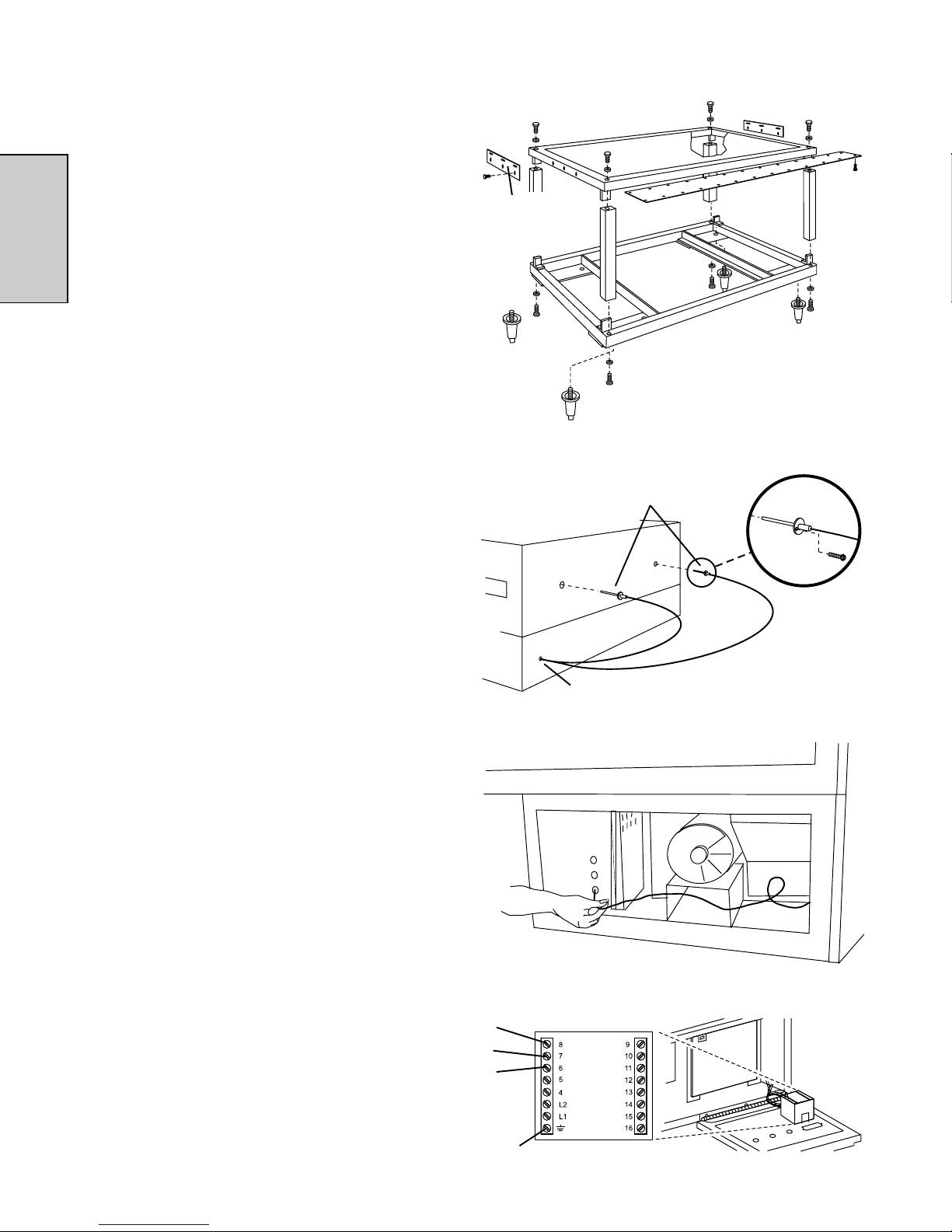

III. ASSEMBLY ............................................................... 8

A. Caster Remova ............................................... 8

B. Stacking ............................................................ 8

C. Stands ............................................................... 8

D. F ue Vent(s) ...................................................... 8

IV. THERMOCOUPLE INSTALLATION ......................... 8

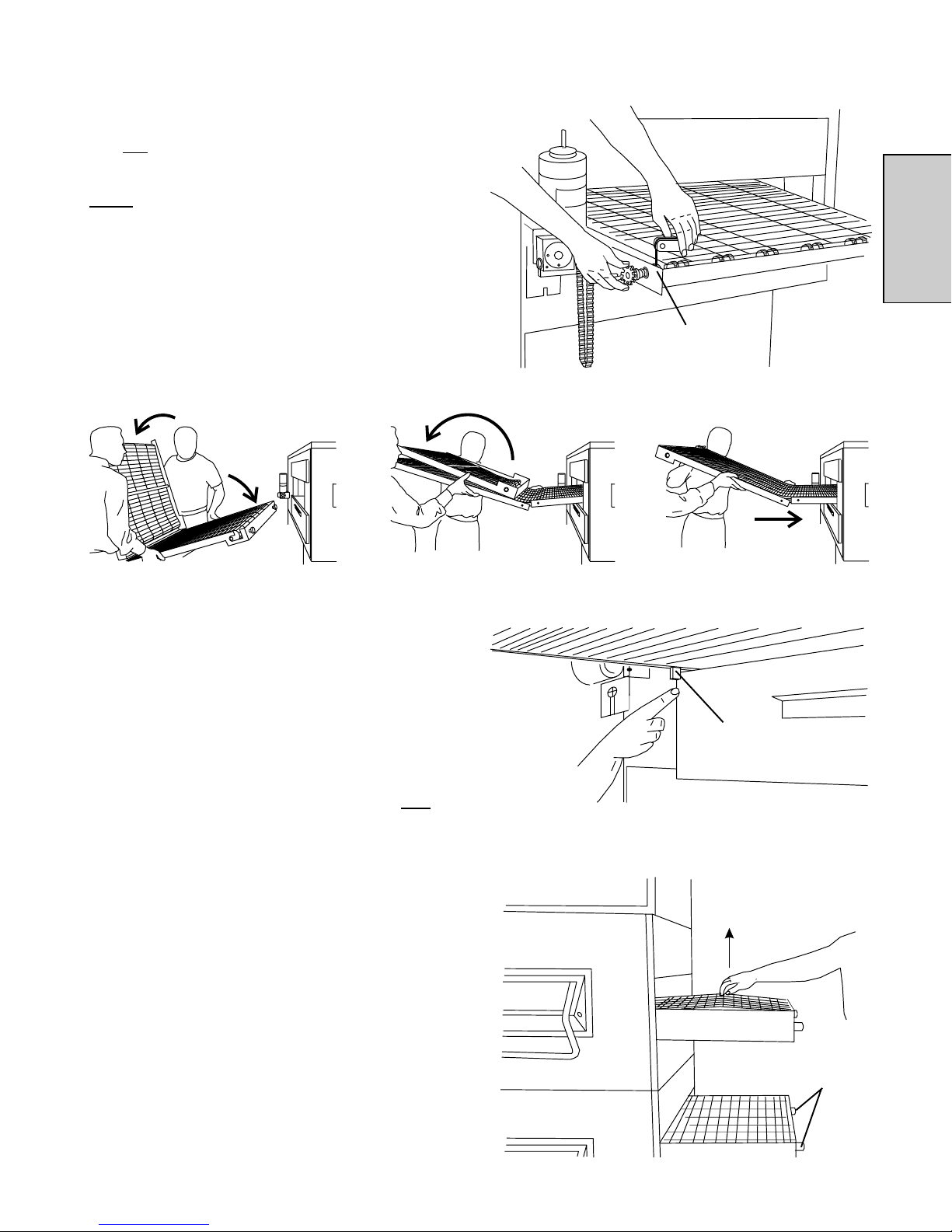

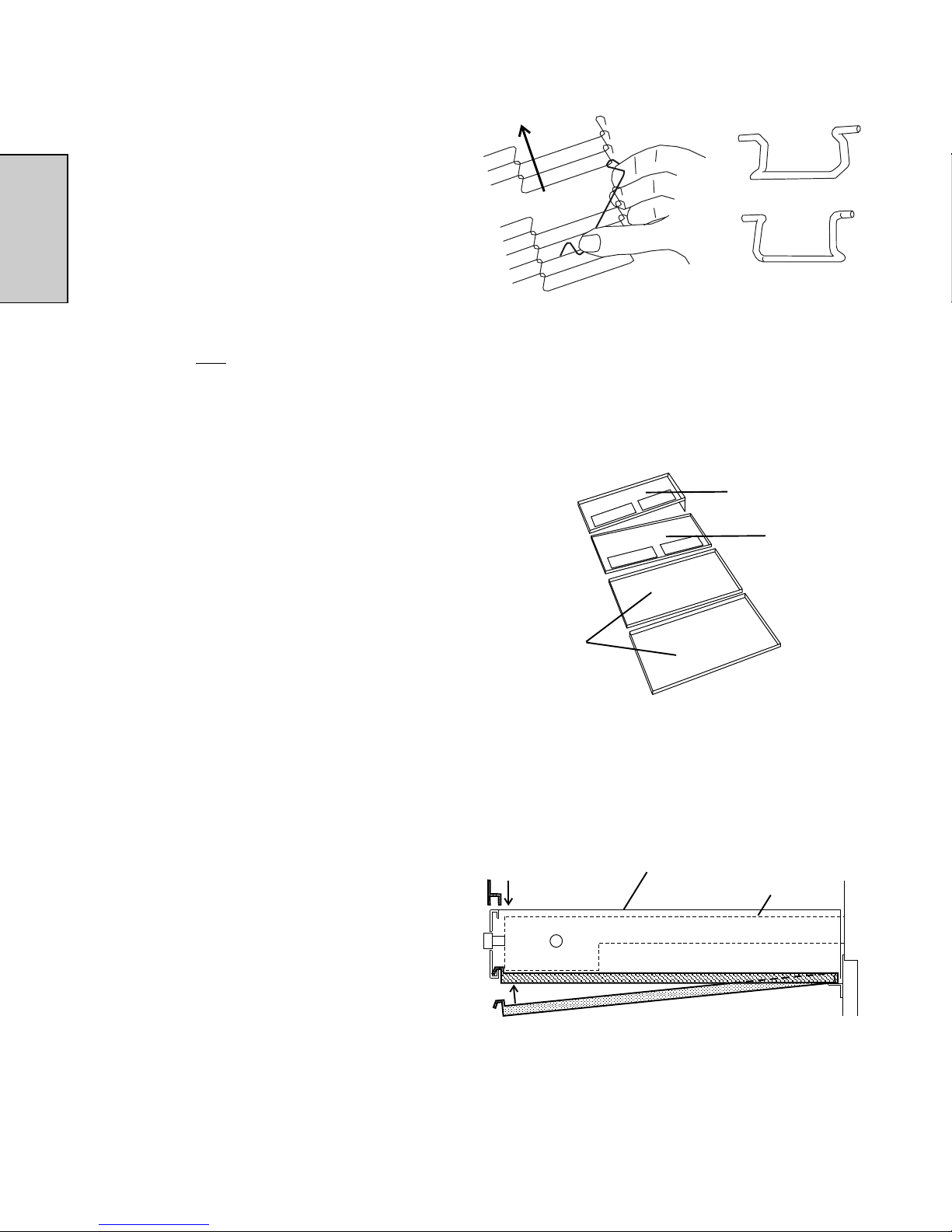

V. CONVEYOR INSTALLATION ................................... 9

VI. FINAL ASSEMBLY ................................................... 10

TABLE OF CONTENTS

VII. ELECTRICAL SUPPLY ........................................... 11

A. Additiona Information - Gas Ovens ................ 11

B. Additiona Information - E ectric Ovens .......... 11

C. Connection ...................................................... 11

VIII. GAS SUPPLY .......................................................... 11

A. Gas Uti ity Rough-in Recommendations ....... 12

B. Connection ...................................................... 12

C. Preparation for Use with Various Gases ....... 13

D. Rep acing the Gas Orifices ............................. 13

E. Checking the Gas Supp y (In et) Pressure .... 14

F. Adjusting the Orifice (Manifo d) Pressure

and Heat Input ................................................. 14

SECTION 3 - OPERATION ..................................................... 15

I. LOCATION AND DESCRIPTION OF CONTROLS . 15

A. "BLOWER" ( ) Switch ................................... 15

B. "HEAT" ( ) Switch ......................................... 15

C. "CONVEYOR" ( ) Switch ............................. 15

D. "RESET" ( ) Switch ....................................... 15

E. Conveyor Speed Contro er ............................. 15

F. Digita Temperature Contro er ....................... 15

G. Machinery Cpt. Access Pane Safety Switch .. 15

II. NORMAL OPERATION, STEP-BY-STEP ................ 16

A. Dai y Startup Procedures ................................ 16

B. Dai y Shutdown Procedures ........................... 16

III. QUICK REFERENCE: DIGITAL TEMP CONTROL . 17

IV. QUICK REFERENCE: TROUBLESHOOTING ....... 18

SECTION 4 - MAINTENANCE ................................................. 19

I. MAINTENANCE - DAILY .......................................... 19

II. MAINTENANCE - MONTHLY .................................. 20

III. MAINTENANCE - EVERY 3 MONTHS .................... 21

IV. MAINTENANCE - EVERY 6 MONTHS .................... 22

V. KEY SPARE PARTS KIT ......................................... 22

SECTION 5 - ELECTRICAL WIRING DIAGRAMS ................... 23

I. WIRING DIAGRAM, PS360-U/-L ELECTRIC OVEN,

380-400V, 50Hz, 1Ph .............................................. 23

II. WIRING DIAGRAM, PS360-U/-L OR PS360WB-U/-L

GAS OVEN, 220-230V, 50Hz, 1 Ph......................... 24

page page