2018/10/26 09:28 7/11 Chaos Matrix

MIDIbox - http://wiki.midibox.org/

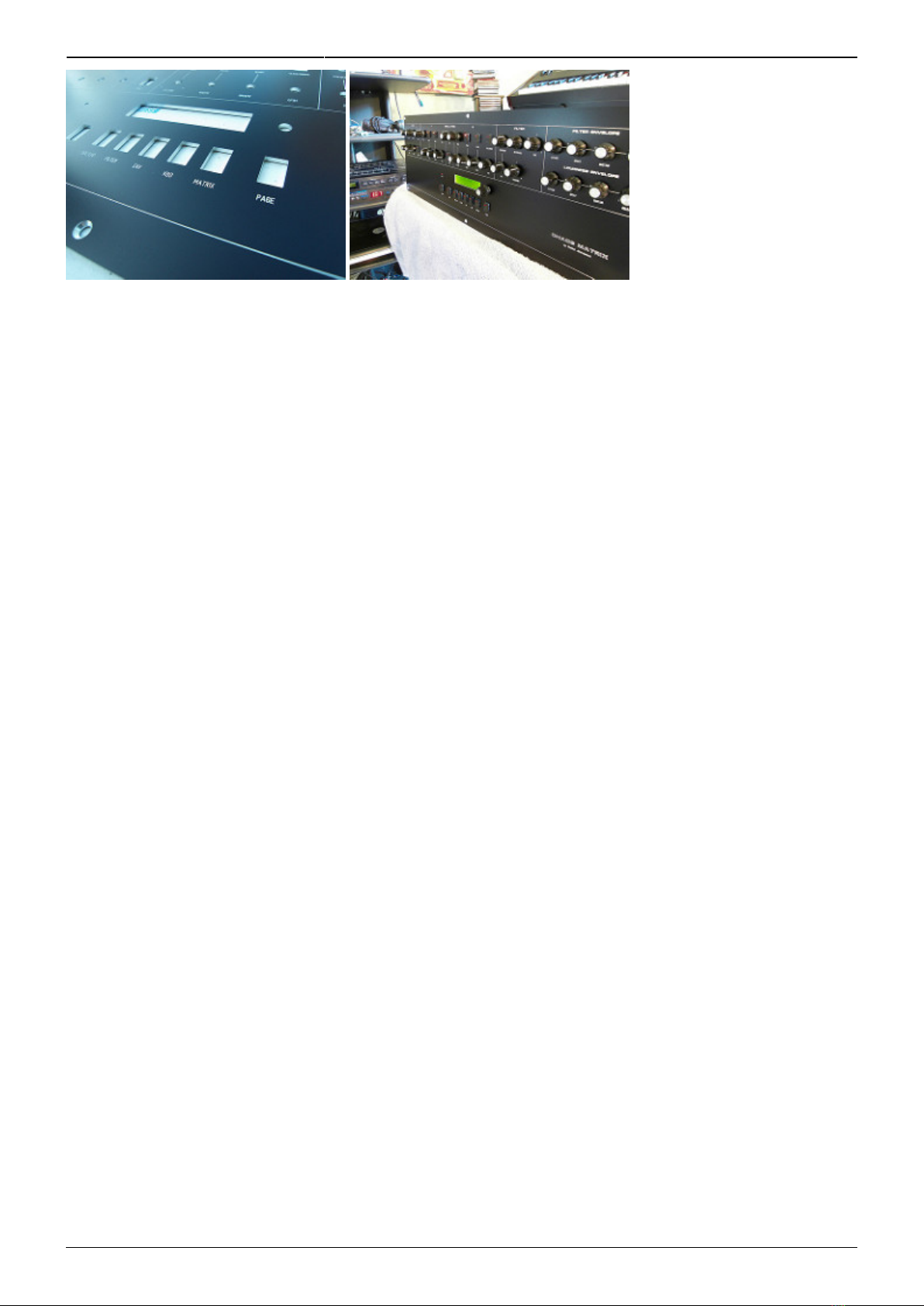

prototype originally used potentiometers but I found it difficult to dial in an exact frequency. I decided

to use detented encoders instead.

Pulse waveform can be enabled by toggling the pulse button and altering its shape with the “Width”

knob below it. Click the pulse button a 2nd time the button blinks and any adjustments to the “Width”

knob instead adjusts the pulse width modulation depth to LFO 2.

DCO2 Click/Noise button is a 3 state button allowing you to enable the noise wave without the need of

an additional button. When noise is enabled, the LED blinks.

The Sync button toggles the 4 oscillator sync modes.

Filter Section

The filter to envelope modulation modulates the cutoff frequency to envelope 1 by default when

editing preset patches. The Matrix 1000 firmware has a bug where envelope 1 sustain isn't handled

over its individual sysex parameter message. The work-around simply sends a complete packet of

parameters for the entire voice when sustain is adjusted.

Some of the parameters sent as system exclusive messages causes the Matrix 1000 to hang. If you're

playing notes and change some of the parameters, the notes will hold for a brief moment. Most of the

hanging is overcome by simply controlling the interval of messages being transmitted over MIDI for

each parameter. Most behave fine and the message can be sent at normal speed, but for others, the

transmit interval was reduced in order to compensate for the hanging.

The effect is ideal for slow pot movements, but for quick changes, a lot of the values in between the

1st and last movement are dropped. Despite this, the solution is better than having the Matrix 1000

hang.

Envelope Section

Instead of naming the envelopes “Envelope 1”, “Envelope 2” etc… I simply named them as they are

on the Oberheim OBX synthesizer. The filter envelope adjusts envelope 1 or 3 depending on which

patch is being edited.

Panel Construction

Some of the panel electronics, including the LCD module have to be mounted on the underside of the

panel. I used stripboards from FutureLec to mount the buttons together and applied Wilba's method of

attaching countersink machine screws with JB-Weld epoxy. The epoxy has to be applied in two steps

to ensure a good weld.

Step one: Simply dab a bit of the epoxy on the flat head of a machine screw and place the head down

on the aluminum panel (be sure to clean the panel surface thoroughly). Use a pair of clamps to

provide pressure between the screw and the panel. Wait at least 24 hours to allow the epoxy to cure.

Step two: Apply an additional amount of epoxy on the underside of the head of the counter-sunk