MiJET WASHSTATION User manual

For technical questions:

Phone: 585-637-3760

Email: technical@mijet.com or visit www.mijet.com

For sales questions contact:

Jeff Gagnon

VP of Sales

MiJET Division of Custom Service Solutions, Inc.

Phone: 585-472-6294

Fax: 207-345-3171

Email: je[email protected]m

MiJET™

www.mijet.com

U SE R G U I D E

Product of:

EASY TO GET STARTED

Ready to use with one existing air line.

All-in-one workstation powered by air

U S E R G U I D E

M I J E T

WA S HS TAT I O N

Date:

Page 2

MiJET User Guide

Description

MiJET®is designed to clean parts and capture residue with one easy touch,

keeping the work area and surrounding air clean.

The air nozzle is used to blow residue down into the inlet tube, while simul-

taneously creating suction. This will pull chips and lubricant into the contain-

er below.

The captured residue can be recycled ... saving money on expensive lubri-

cants and help to reclaim more chips instead of covering the floor.

Needed

A MiJET unit comes with a 1/4” FNPT

fitting for connecting to an existing shop

air line. A high–flow quick-connect

adaptor can be attached for ease of

use, however, to ensure a sufficient air

supply we recommend connecting into

the main air supply without any re-

strictions, such as a quick connect.

It is also recommended to utilize a 3/8”

diameter air hose from the main line to

supply the MiJET. A smaller diameter,

coiled air line, or a line that is too long

might not provide an optimum air sup-

ply.

Safety Instructions

Please read user guide carefully before

installing.

Disconnect the air supply if the unit is

taken apart for recycling of coolant,

retrieval of parts, or any other mainte-

nance.

Page 19

U S E R G U I D E

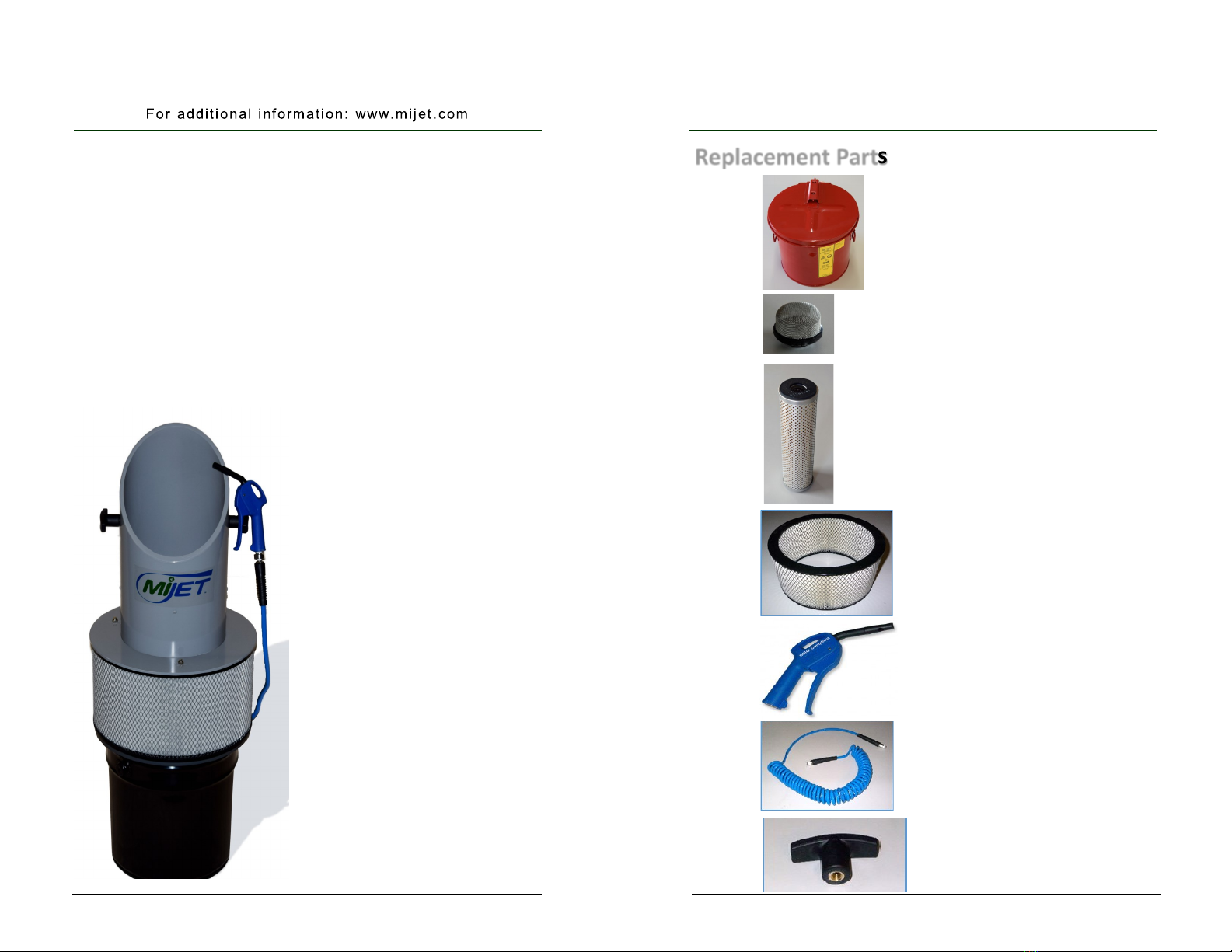

Replacement Parts

13-032 T-Handle Knob

Nylon with Aluminum insert

13-029

Spiral air hose with swivel end

ng

13 . x 1/4" MNPT, 5/16" ID

13-028

Air Nozzle by Prevost, OSHA Compliant

8.0" x 4.25" x 1.0"

15-100

Solvent Dip Container, 3.5 gallon with fusi-

ble link for re damping, 15” x 12.0”

13-006

Custom MiJET Filter, for 12” models only

6” H x 19.25” dia.

Fluid Filter Replacement for Washstaons only.

9.63“ H x 2.63” dia.

15-118

15-119 Basket strainer

Page 18

Oponal Accessories

13-035 Low-Noise Air Nozzle by Silvent

15-104

Non-metallic basket liner

For use inside SS basket to keep so parts

from geng damaged.

*Need to order both the body and the plug for correct connecon

Low-Noise Air Nozzle with Rubber

Tip by Silvent

OSHA compliant

13-071

15-107

Stainless Steel Parts Basket—

Fine Mesh, for 12” dia. MiJET angled top

workstaon and wash staon

13.5” x 7.25” x 9.75”

13-057*

13-058*

High-Flow Quick Disconnect - Body

High-Flow Quick Disconnect - Plug

Page 3

U S E R G U I D E

MiJET Diagram .………………….……........ Page 4

Air Supply Requirements …....…….……........ Page 6

Instructions ..………………………….……. Page 7

Using the Faucet …………..………….……. Page 9

Removing MiJET from Table ………….…..... Page 10

Maintenance ………………….…….……... Page 12

Installing the Air Deflector ………….……... Page 16

Troubleshooting …………………….……... Page 17

Optional Accessories ………….……………Page 18

Replacement Parts ….………………………Page 19

Table of Contents

**NOT FOR USE WITH HIGHLY

FLAMMABLE LIQUIDS**

Inlet

Page 4

MiJET Diagram

Loc-Line

Faucet

Dip Container

Air nozzle with

trigger handle

On/Off Ball

Valve

Flow Valve

Retainer hook

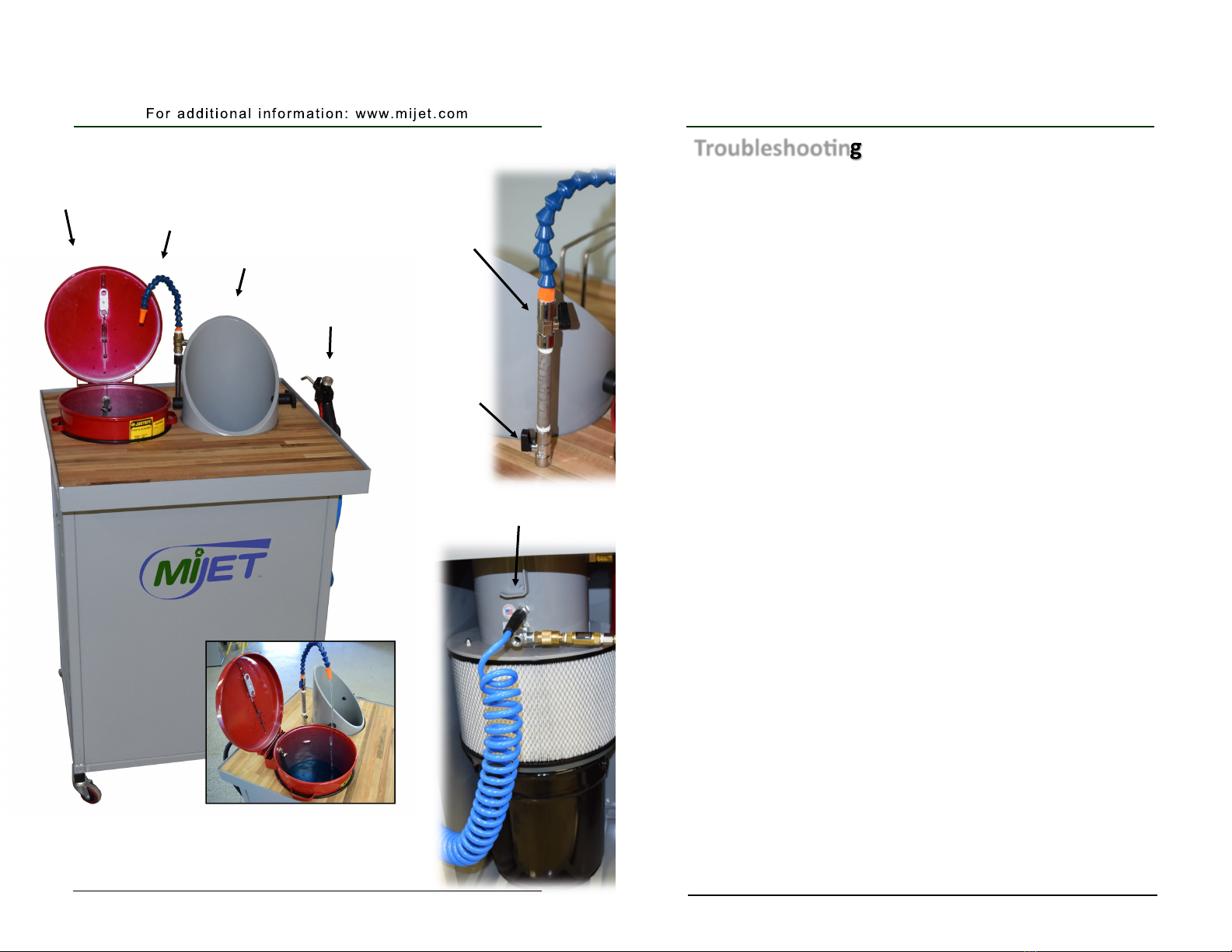

Troubleshoong

Q: The part is blown off and the air nozzle is not in use, but the

motor runs for an extended amount of time.

A: There are Viton O-rings that need to stay lubricated, try adding air

tool oil, refer to the maintenance steps on page 6.

B: Check for air leaks at air nozzle hose connections and air nozzle it-

self. Replace leaking components if needed. Contact us for replace-

ment air gun.

Q: The air motor sounds like it runs slower than when the unit

was brand new.

A: Try adding air tool oil, refer to the maintenance steps on page 6.

Q: The suction is reduced from when the unit was brand new.

A: Try adding air tool oil, refer to the maintenance steps on page 6.

B: Check filter and if oil-soaked or dirty, it is time to replace the filter.

Contact us for replacement filter.

Q: The blow off pressure has decreased while using the air noz-

zle.

A: Ensure all fittings and connections are correct, if so, try connecting the

MiJET to the air supply line without use of any quick-disconnect fitting.

B: Try connecting an airline from the main air supply to the MiJET with a

large enough diameter (3/8”) air hose to supply enough CFM to the

unit.

C: Try removing the blue air nozzle and replace with the operators’

usual air nozzle often creates familiarity with usual process of blow-

ing off parts.

Page 17

U S E R G U I D E

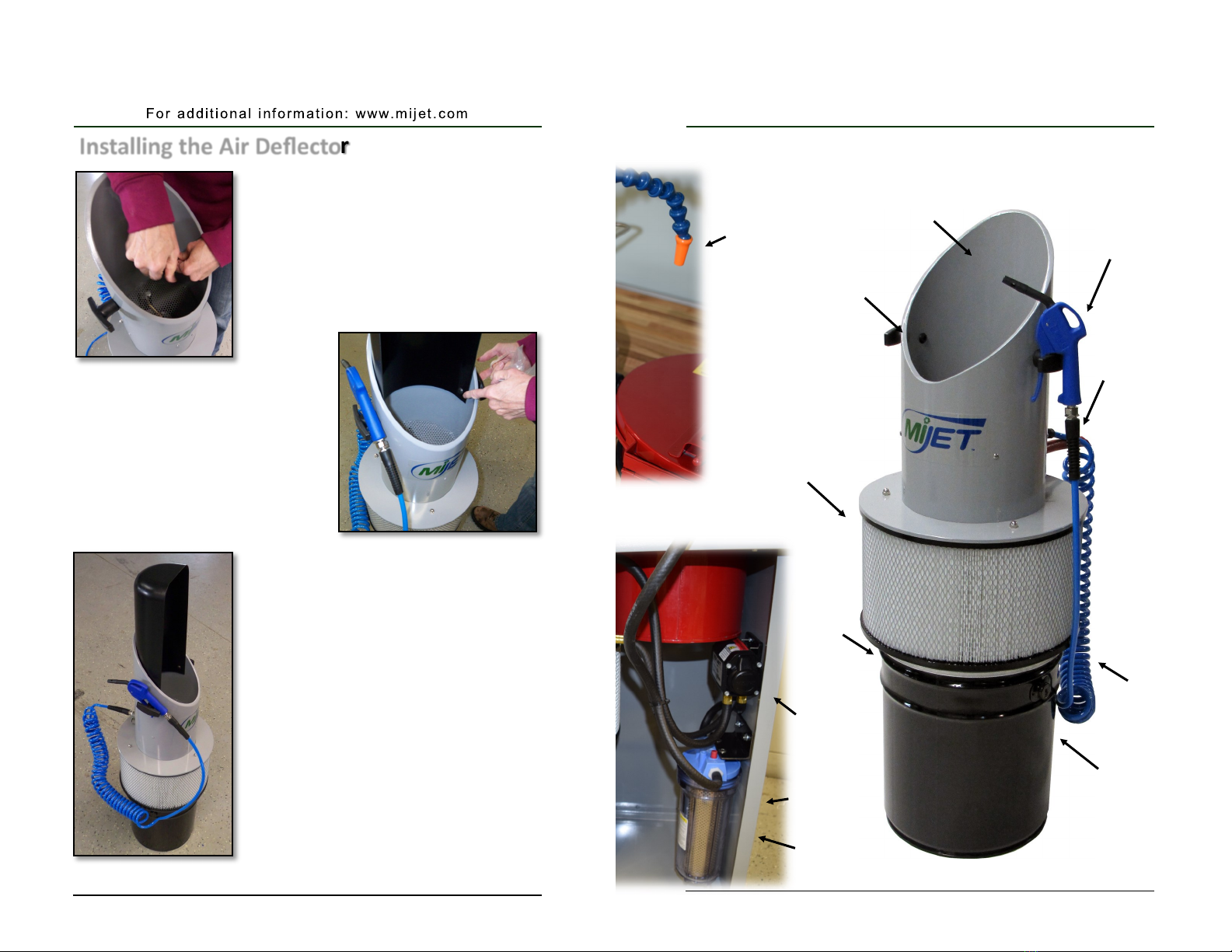

Page 16

Installing the Air Deector

1. Using a 7/32 Allen key, unscrew

the black screws from each handle,

as seen in Figure 20.

2. Take each screw and handle off of

the unit.

3. Place the air deflector into the

MiJET. Try to line-up the hole

on the air deflector (Figure 21)

with the hole on the MiJET.

4. Insert the screw through the air de-

flector and then through the MiJET.

5. Tighten both screws with the 7/32

Allen key. Hold the black plastic

handle while tightening to ensure

the correct handle orientation of the

T-Handle.

6. Repeat the same procedure for the

second screw on the opposite side.

The final product should look like

the MiJET picture in Figure 22.

Figure 20

Figure 21

Figure 22

Page 5

U S E R G U I D E

Air nozzle with

trigger handle

Air hose

Air inlet—

connect

directly to

air supply

or use high-

flow quick

connect

Carrying

handles

Container

Air filter

Clamping

tabs (not

shown)

Inlet pipe

MiJET Diagram

Changeable

nozzle

Fluid pump

Fluid filter

Fluid filter

housing

Table of contents