1. GENERAL INFORMATION

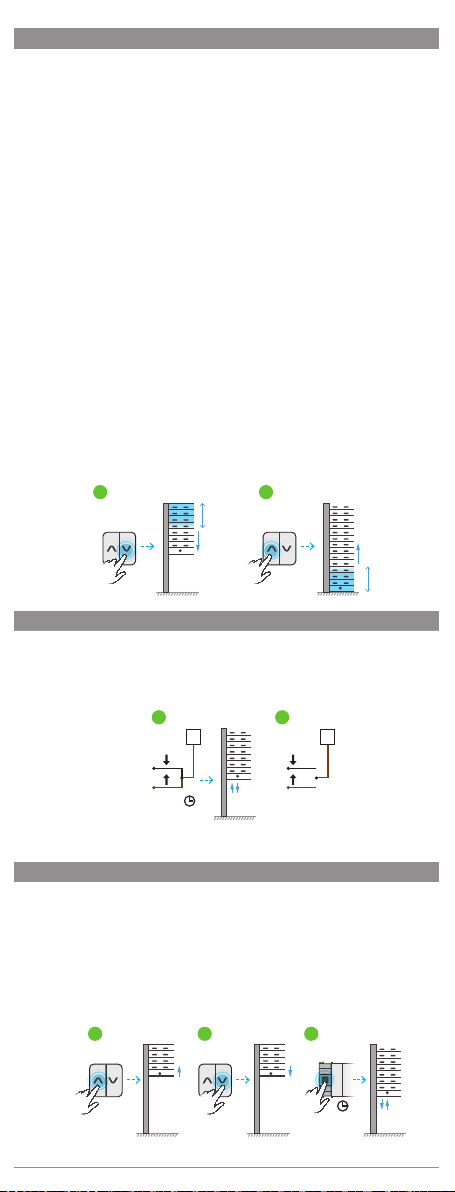

Tubular motor MOBILUS EP is equipped with the function of automatic configuration of the

end positions. It can be controlled by means of any wall switch - however, it is recommended to

use a support switch (using the switch without supporting it requires holding down the button

when lowering or lifting the armor).

The MOBILUS EP tubular motor is used in roller blinds drives.

The MOBILUS EP tubular motor has a protective function against current overload. This pheno-

menon may occur, e.g. when the blind is frozen or the armor is blocked in the roller shutter box

(requires the use of rigid hangers). The result of these events is the sudden stop of the motor

and the rapid increase in the current. Long-term overload may be dangerous for the motor, and

the solution used effectively protects against damage.

The current overload protection function in the MOBILUS EP motors is not identical to the OB-

STACLE DETECTION function possessed by the MOBILUS ERS SENSO motors.

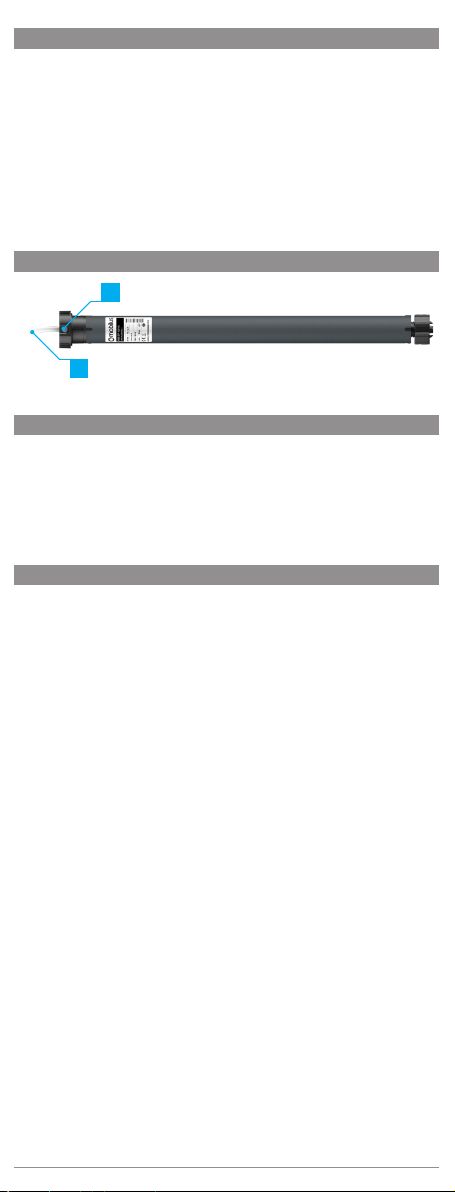

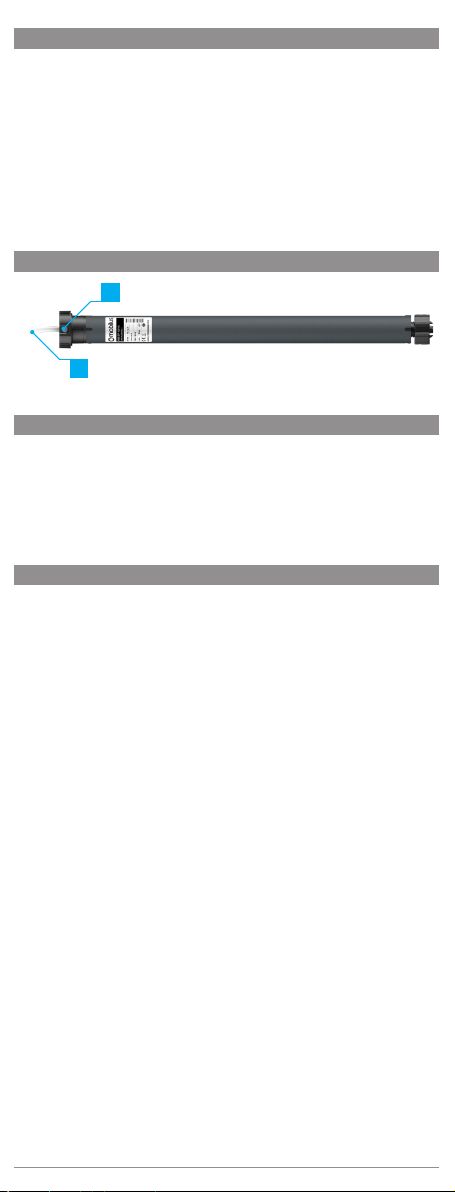

2. DESCRIPTION OF THE PRODUCT

2

1

1- Power cord. 2 - Settings button.

3. TECHNICAL PARAMETERS

Supply voltage: 230 V~ 50 Hz.

Limit switchers: Electronic

Protection rating: IP44

Insulation class: F

Continuous working time / break

time: 4 min / 90 min

Working temperature:

-20°C to +55°C

Nominal Power:

M35 EP 10/14 - 120 W

M35 EP 6/28 - 155 W

M35 EP 13/14 - 155 W

M45 EP 10/17 - 155 W

M45 EP 15/17- 175 W

M45 EP 25/17- 225 W

Torque:

M35 EP 10/14 - 10 Nm

M35 EP 6/28 - 6 Nm

M35 EP 13/14 - 13 Nm

M45 EP 10/17 - 10 Nm

M45 EP 15/17 - 15 Nm

M45 EP 25/17 - 25 Nm

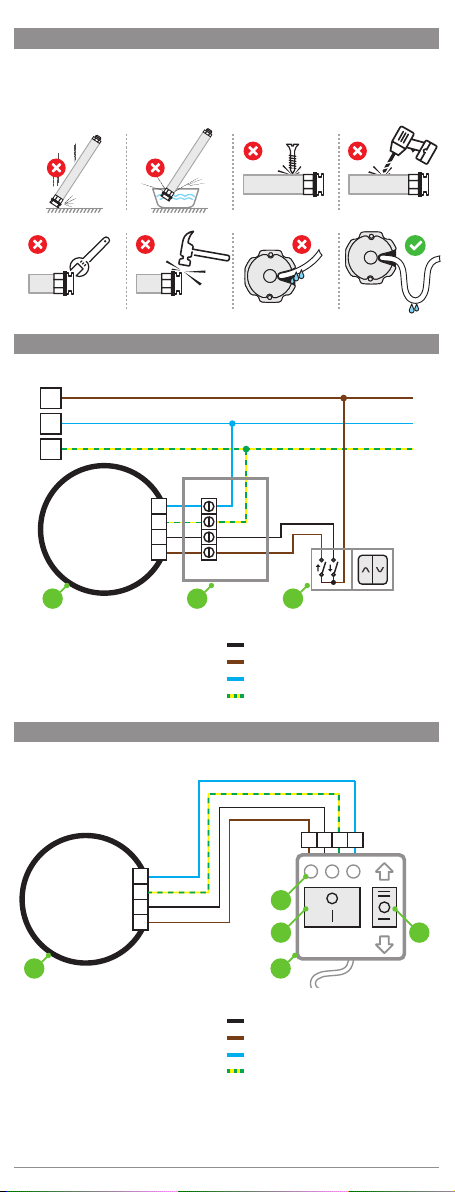

4. IMPORTANT INFORMATION

The proper functioning of MOBILUS EP Motor depends on manufacturing the roller and its correct

installation. The shutter armor should move smoothly, without any obstacles along the slides. Pay

careful attention to:

• using slat hangers,

• using buffers in the endslat or stoppers in the slides,

• ensuring the lower point of the support – window sill, floor level or in the case of their absence in

the bottom part of the slides,

• the vertical fitting of the slides,

• smooth work of the shaft bearing,

•

deflection of the shaft (of the roll tube) caused by exceeding the width or weight of the shutter

armor,

• the high quality of shutter armor, especially of profile’s work in locks – armor’s beam cannot rub

against the box or its elements, e.g., thermal insulation (polystyrene) in the top-mounted roller

blinds.

Using of the MM 35 motors requires fulfilling the additional conditions. This is a consequence of using

the 40 mm octagonal roll tubes in which between roller-tube and the motor’s housing there is a small

space. There are some instructions that should be followed:

• Pipe’s seam cannot rub against motor’s housing,

• We recommend using pipes with the outer seam,

•

Motor’s position in the octagonal roll tube should enable the hanger’s installation in the largest

space between pipe and motor’s housing,

• The most safest is the hanger with the low catch.

We suggest using a switch without support (bistable).

The motor should be suitable for the blind’s weight.

The MOBILUS EP motor should only be powered from the power grid meeting the appropriate stan-

dards. It is forbidden to connect the MOBILUS EP motor to all types of generators / power generators.

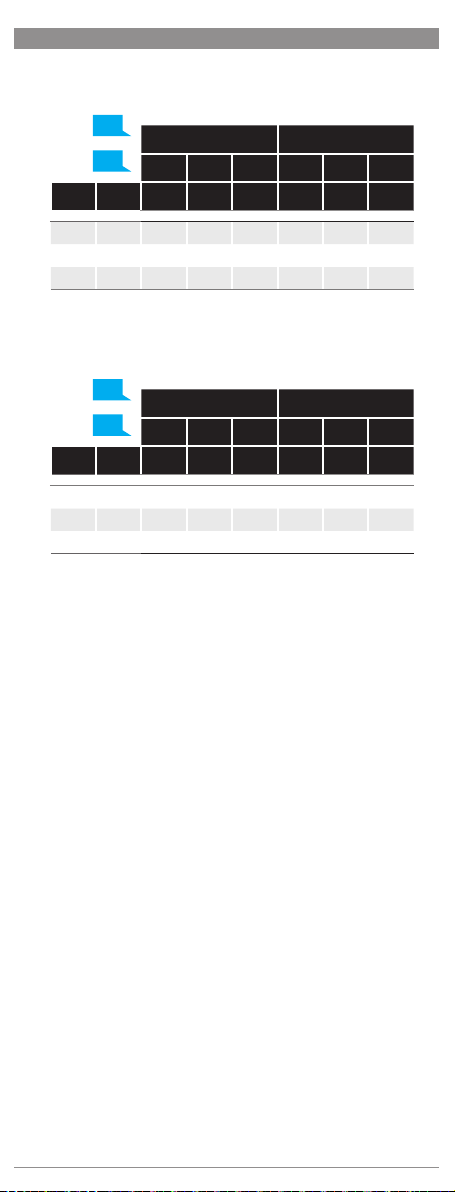

The MOBILUS EP motor enables setting the end limit switches in the AUTOMATIC MODE – using the

buffers is required. In this case, following issues have to be taken into consideration:

• The most profitable is using of the inside buffers installed in the lower endslat,

• In case of using the outer buffers that are installed in the lower endslat, they should be located on

the right side of the shutter armor. The point-intake designed for screwing should be located in the

distance not larger than 100 mm from the shutter armor’s edge.

2