charger is disconnected from the power supply.

•After normal usage, a minimum of 1 hour of

charging time is required to fully recharge battery

pack.

•The battery pack and the charger will become

slightly warm to the touch while charging. This is

normal and does not indicate a problem.

•Do not place the charger and battery pack in an

area of extreme heat or cold. They will work best

at normal room temperature.

NOTICE: The charger and battery pack should be

placed in a location where the temperature is

more than 32°F but less than 100°F.

•When batteries become fully charged, unplug the

charger from power supply and remove the

battery pack.

CHARGING A HOT BATTERY PACK

When using the tool continuously, the batteries in

the battery pack will become hot. You should let a

hot battery pack cool down for approximately 30

minutes before attempting to recharge. When the

battery pack becomes discharged and is hot, this will

cause the green LED to come on instead of the red

LED. After 30 minutes, reinsert the battery pack in

the charger. If the green LED continues to remain on,

return battery pack to your nearest Mokeneye

Authorized Service Center for checking or replacing.

NOTICE: This situation only occurs when continuous

use of the tool causes the batteries to become hot. It

does not occur under normal circumstances. Refer to

"CHARGING A COOL BATTERY PACK" for normal

recharging of batteries. If the charger does not

charge your battery pack under normal

circumstances, return both the battery pack and

charger to your nearest Mokeneye Authorized

Service Center for electrical check.

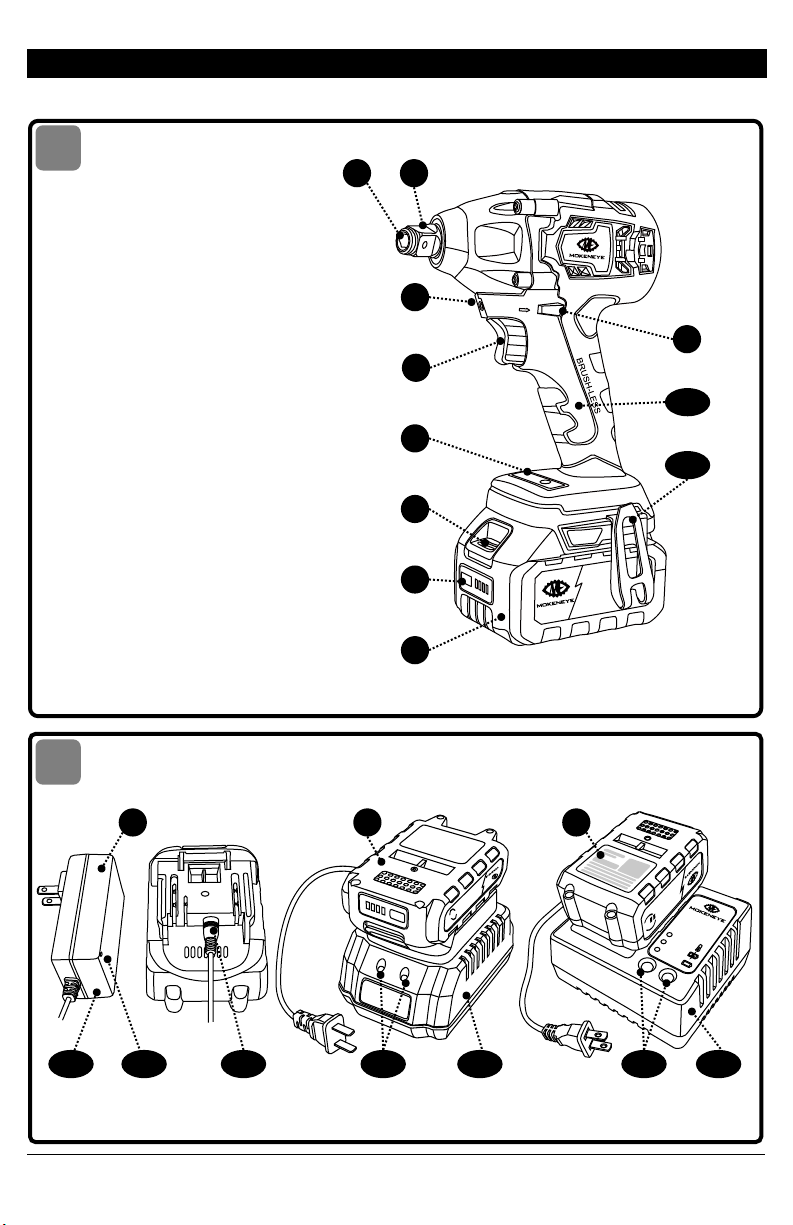

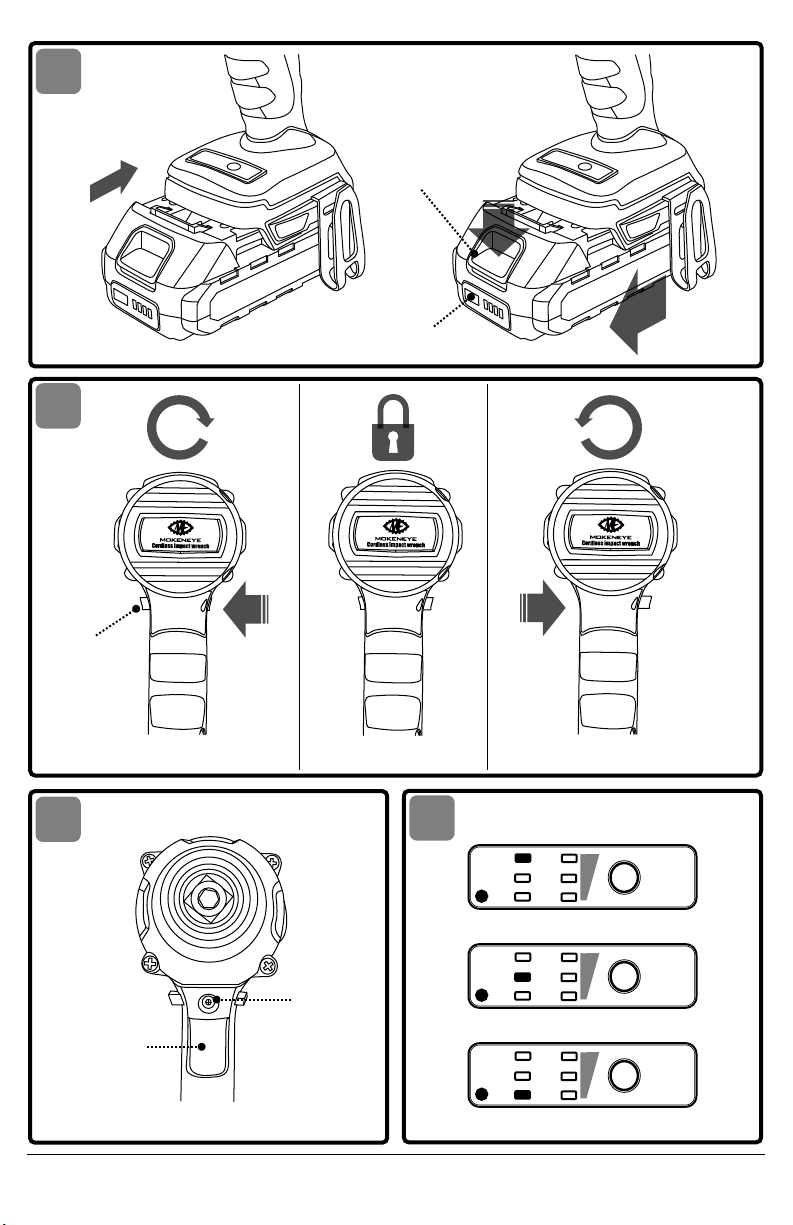

TO ATTACH/DETACH BATTERY PACK

See Fig. 3

Lock the variable-speed trigger switch "OFF" on the

tool by placing the direction-of-rotation

(forward/center-lock/reverse) selector in the center

position before attaching or detaching the battery

pack.

To attach the battery pack:

Align the raised rib on the battery pack with the

grooves in the tool, and then slide the battery pack

onto the tool.

To detach the battery pack:

Depress the battery-release button, located on the

front of the battery pack, to release the battery pack.

Pull the battery pack out and remove it from the tool.

NOTICE: When placing the battery pack onto the

tool, be sure that the raised rib on the battery pack

aligns with the groove inside the tool and that the

latches snap into place properly. Improper

attachment of the battery pack can cause damage

to internal components.

Battery tools are always in

operating condition. Therefore, the

direction-of-rotation (forward/center-lock/reverse)

selector should always be locked in the center

position when the tool is not in use or carrying it at

your side.

DIRECTION-OF-ROTATION SELECTOR

See Fig. 4

After tool use, lock the direction-

of-rotation selector in the "OFF"

position (center-lock) to help prevent accidental

starts and possible injury.

Your tool is equipped with a direction-of-rotation

selector located above the trigger switch. This

selector is designed for changing the direction of

rotation of the bit and for locking the trigger in the

"OFF" (center-lock) position.

1.Position the direction-of-rotation selector to the

far left of the tool for forward rotation.

2.Position the direction-of-rotation selector to the

far right of the tool for reverse rotation.

3.Setting the switch in "OFF" (center-lock) position

helps to reduce the possibility of accidental

starting when not in use.

NOTICE: To prevent gear damage, always allow the

IMPACT DRIVER WRENCH to come to a complete

stop before changing the direction of rotation.

NOTICE: The IMPACT DRIVER WRENCH will not run

unless the direction-of-rotation selector is engaged

fully to the left or right.

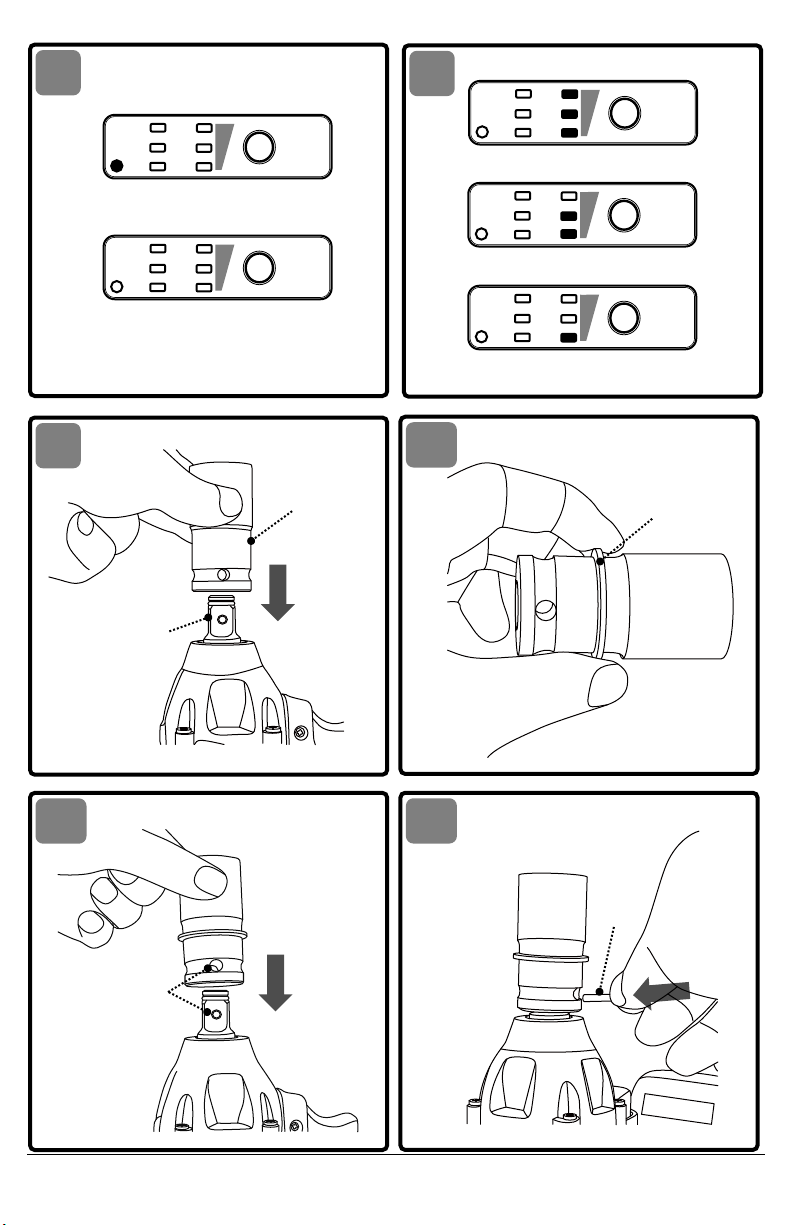

VARIABLE-SPEED TRIGGER SWITCH

See Fig. 5

Your tool is equipped with a variable-speed trigger

switch. The tool can be turned "ON" or "OFF" by

depressing or releasing the trigger.

The variable-speed trigger switch delivers high- er

speed with increased trigger pressure and lower

speed with decreased trigger pressure.

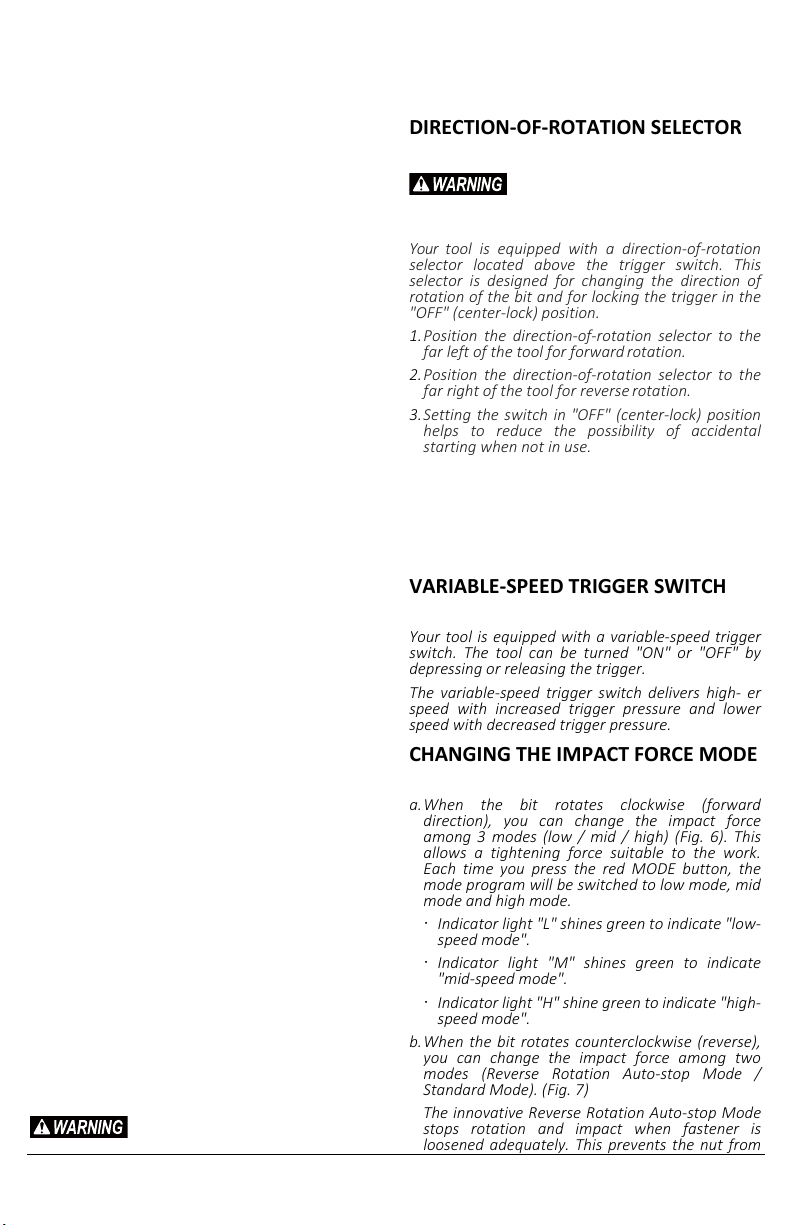

CHANGING THE IMPACT FORCE MODE

See Fig. 6,7

a.When the bit rotates clockwise (forward

direction), you can change the impact force

among 3 modes (low / mid / high) (Fig. 6). This

allows a tightening force suitable to the work.

Each time you press the red MODE button, the

mode program will be switched to low mode, mid

mode and high mode.

·Indicator light "L" shines green to indicate "low-

speed mode".

·Indicator light "M" shines green to indicate

"mid-speed mode".

·Indicator light "H" shine green to indicate "high-

speed mode".

b.When the bit rotates counterclockwise (reverse),

you can change the impact force among two

modes (Reverse Rotation Auto-stop Mode /

Standard Mode). (Fig. 7)

The innovative Reverse Rotation Auto-stop Mode

stops rotation and impact when fastener is

loosened adequately. This prevents the nut from