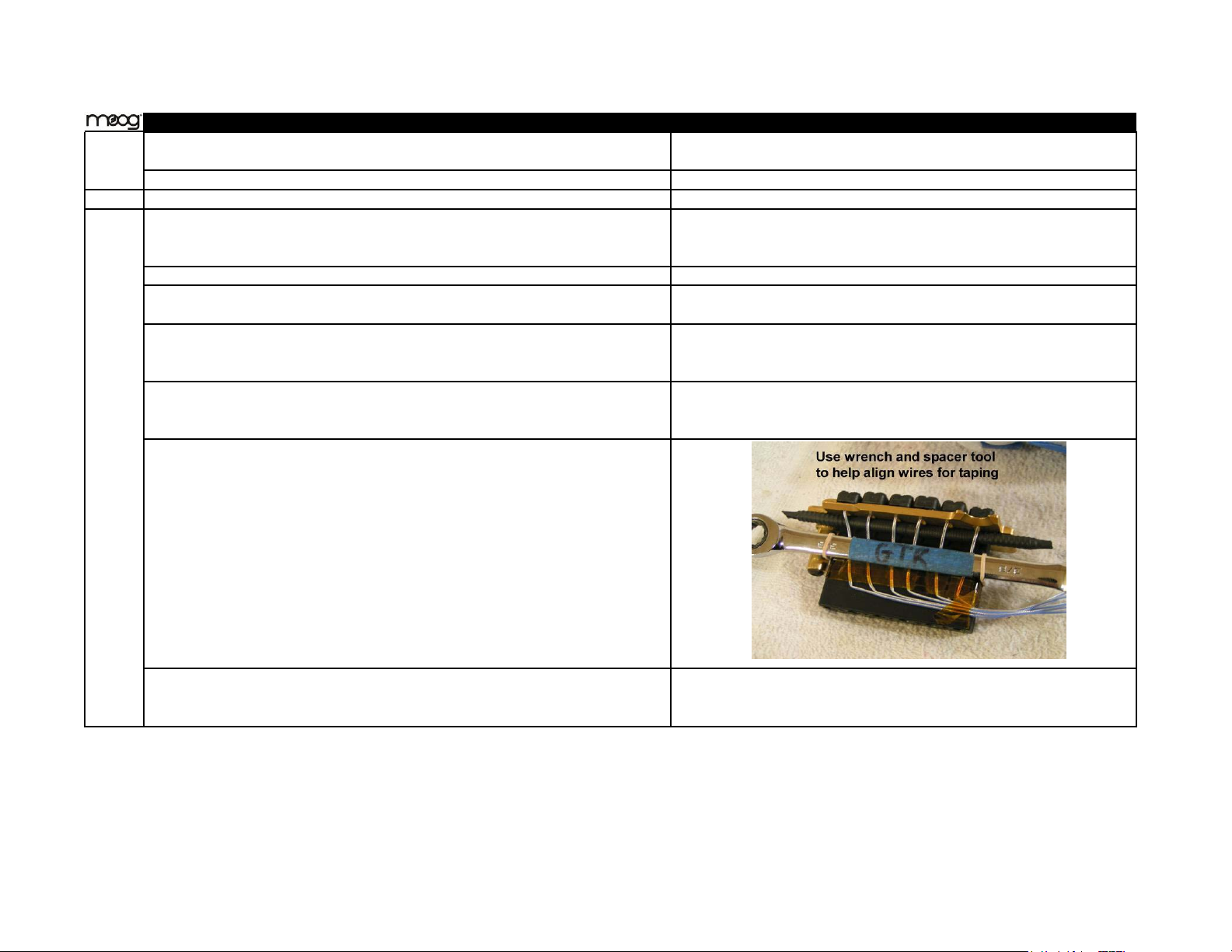

Once a height or position has been adjusted, tighten the string almost fully before tightening the center-saddle

locking screw. This will allow the saddle to slip into its “natural” position. (You don’t want it doing that later during

a performance.) Lastly, re-tighten the center-saddle locking screw. Do not tighten this screw beyond the point

where it is clearly pressing down firmly on the saddle or you may bend or break the saddle body.

As a rule, to raise or lower the overall string action it is better and much easier to raise the entire bridge platform

rather than each individual saddle. (Remember to first check the neck for the right bias as this greatly affects action

height.) In general, a saddle’s height adjustment set screws should not be over-extended, i.e., the saddle body

should sit fairly low to the bridge platform.

This advice applies to all installations of GraphTech Ghost saddles, not just the ones on the Moog Guitar.

Pickups:

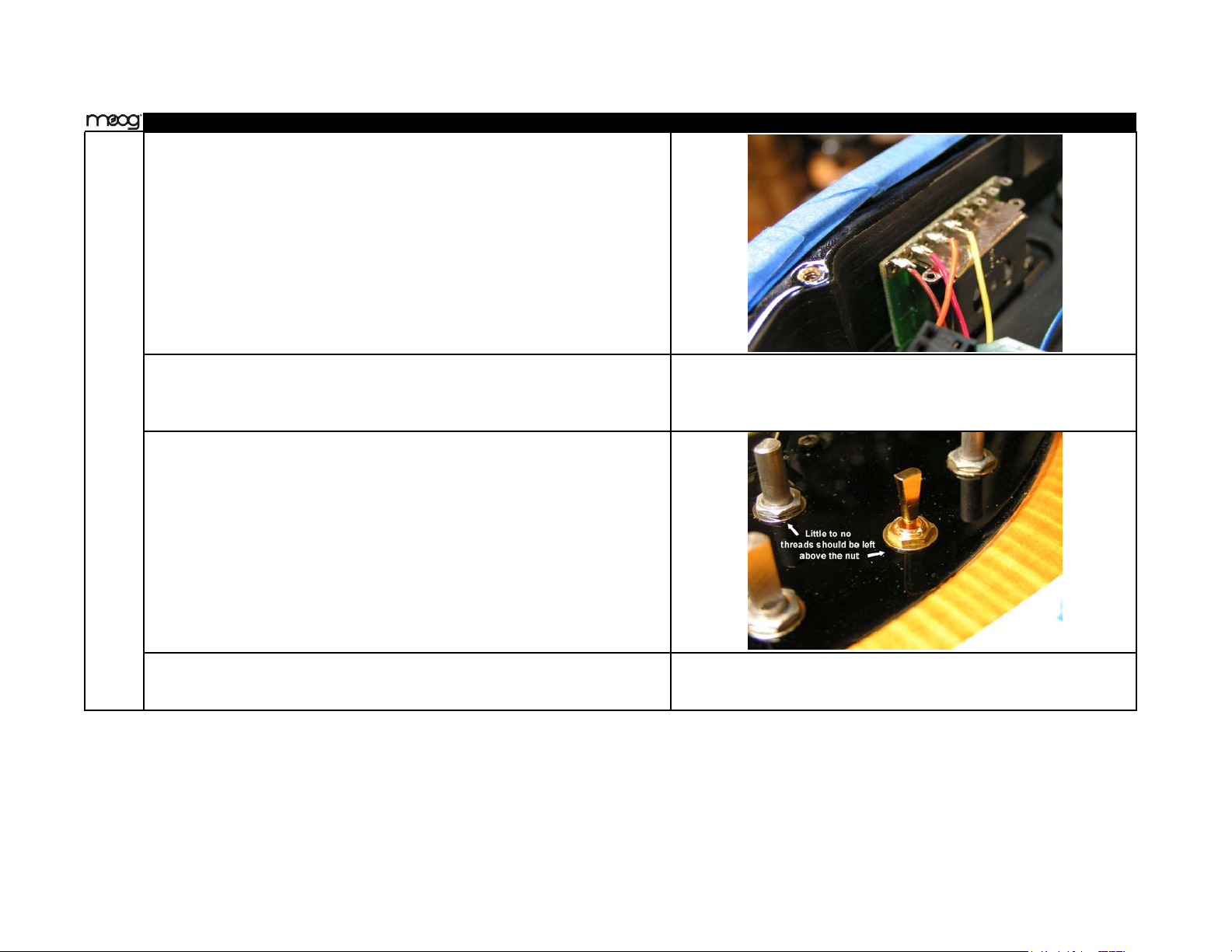

If the pickup height has been tampered with it may be necessary to readjust the pickups.

Use care when adjusting the pickup height. The pickup screws are nylon; if you forcefully turn the screws too far

the screw threads will fail - don‘t go there! The screws are easy to turn with light force as long as they are within

the intended pickup adjustment range.

End to end pickup angle and height: The strength of control exercised by the pickups upon the strings varies

significantly with pickup height. The pickups should be adjusted so that the high-E ends are as close as possible

(without buzzing) to the high-E string when it is fretted at the top fret. The low-E string should be about 0.15”

above the pickup on the low-E side at the neck pickup. The bridge pickup can be a tiny bit closer to the string at

the low E.

In general, lowering the pickups will reduce control quality and strength.

Side to side adjustment: Looking down between the strings and pickup from the normal playing position, the

horizontal of the pickup should be parallel to the strings, i.e., there should be a constant distance between any one

string and the pickup surface as the string passes across the pickup.